Documente Academic

Documente Profesional

Documente Cultură

Presentation Cumene

Încărcat de

Bis ChemDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Presentation Cumene

Încărcat de

Bis ChemDrepturi de autor:

Formate disponibile

PRESENTATION ON CUMENE PLANT

15

TH

FEB 2012

PRESENTED BY

HARIDASAN V A

No. 1

CAPACITY AND TECHNOLOGY

Plant capacity : 290,000 MT of Cumene per year

On stream factor : 8,000 Hours

Hourly production rate : 36.25 MT/hr of Cumene

Technology : BADGER Licensing LLC

Catalysts : EXXON MOBIL

No. 2

2

RAW MATERIALS

Raw materials required for the production of 290,000 MT per year of Cumene:

Benzene -- 190,904 MT per year

Propylene 102,728 MT per year

Hourly rate:

Benzene -- 12.841 MT/hr

Propylene 23.863 MT/hr

No. 3

CUMENE PRODUCT SPECIFICATION

Component Unit Specification

Cumene purity wt % 99.93

Ethyl Benzene wt ppm 100

N Propylbenzene wt ppm 300

Total Butylbenzene wt ppm 70

Benzene wt ppm 10

Toluene wt ppm 5

Total Cymene wt ppm 30

Di is Propylbenzene wt ppm 5

No. 4

USES

Cumene is mainly used for the manufacturing of Phenol and Acetone.

Cumene is oxidized with air to get Cumene Hydro Peroxide (CHP). This CHP is cleaved to

get Phenol and Acetone.

Cumene is also used in small quantities for the manufacturing of Pesticides.

No. 5

PROCESS CHEMISTRY

Benzene is Alkylated with Propylene in the Alkylation reactor to produce Iso Propyl

Benzene or Cumene.

Zeolite catalyst from EXXON MOBIL is used as the catalyst for the Alkylation

reaction.

Reaction takes place in liquid phase.

Benzene and Propylene are fed to the reactor with a molar ratio of 2:1

Excess Benzene is recycled to the reactor through Benzene column.

Di Iso Propyl Benzene(DIPB) and Tri Iso Propyl Benzene(TIPB) are also formed

as side reaction products in the reactor. These are collectively called PIPB.

DIPB is formed by the reaction of Propylene with Cumene and TIPB is formed by

the reaction of Propylene with DIPB.

Both DIPB and TIPB are converted to Cumene in the Transalkylator reactor by

reaction with Benzene.

5

No. 6

PROCESS CHEMISTRY

ALKYLATION REACTION

6

SECONDARY ALKYLATION REACTION

BENZENE

CH 3 -CH-CH 3

CUMENE

+

CH 3 -CH-CH 3

DIPB

CH

3 -CH-CH

3

CH

2

=CH-CH

3

CH 3 -CH-CH 3

CUMENE PROPYLENE

CH

2

=CH-CH

3

PROPYLENE

+

No. 7

PROCESS CHEMISTRY

SECONDARY ALKYLATION REACTION

7

+

CH 3 -CH-CH 3

TIPB

CH

3 -CH-CH

3

CH

2

=CH-CH

3

CH 3 -CH-CH 3

DIPB PROPYLENE

CH 3

-CH-CH 3

CH

3

-CH-CH

3

No. 8

PROCESS CHEMISTRY

8

TRANSALKYLATION REACTIONS

CH 3 -CH-CH 3

BENZENE

+

CUMENE

CH 3 -CH-CH 3

DIPB

CH

3 -CH-CH

3

2

CH 3 -CH-CH 3

CUMENE

BENZENE

+

CH 3 -CH-CH 3

TIPB

CH 3 -CH-CH 3

CH 3 -CH-CH 3

DIPB

CH 3 -CH-CH 3

+

CH 3 -CH-CH 3

No. 9

BENZENE

PROPYLENE

RESIDUE

NON AROMATIC

PURGE

AROMATIC PURGE

CUMENE

COLUMN

C-51031

BENZENE

COLUMN

C-51021

PIPB

COLUMN

C-51041

ALKYLATION

REACTOR

V-51001

TRANSALKYLATION

REACTOR

V-51002

CLAY TREATERS

V-51051 A/B

NON AROMATIC

VENT AROMATIC

VENT

NON AROMATIC

PURGE

Water

V-51022

V-51021

V-51031

V-51041

Bypass

CUMENE

PROPYLENE

TREATERS

V-51053 A/B

SECONDARY BENZENE

TREATERS

V-51052 A/B

12841 kg/h

121 kg/h

88 kg/h

35 kg/h

5 kg/h

36250 kg/h

15 kg/h

95 kg/h

110 kg/h

No. 10

PROCESS DESCRIPTION

Major equipments in Cumene plant are:

Alkylation Reactor

Benzene column

Cumene column

PIPB column

Transalkylation Reactor

Propylene Treaters

Clay Treaters

Secondary Benzene Treaters

Active Carbon bed

10

No. 11

ALKYLATION REACTOR

Alkylation reactor consists of 4 beds; each one filled with Zeolite catalyst(EM-5100) supplied

by Exxon Mobil.

Recycle Benzene from Secondary Benzene Treater is fed to the first (top) bed of the Reactor.

Propylene and Alkylation Effluent Recycle are fed to all the four beds of the reactor.

In the Alkylator, Benzene reacts with Propylene to produce Cumene. Some DIPB and TIPB

are also produced as side reaction products;

Reaction between Propylene and Benzene is exothermic. Part of the reactor effluent is cooled

and recycled to the reactor as quench flow to all the four beds to control the catalyst bed

temperature.

Alkylator effluent is then sent to Benzene column for separating and recycling unreacted

Benzene.

11

No. 12

BENZENE COLUMN

The primary function of the Benzene Column, is to recover all of the unreacted benzene

contained in the Alkylation Reactor effluent and Transalkylation Reactor. Benzene is

collected as a side draw from Benzene column and recycled to Alkylator and Transalkylator.

The column removes the non aromatic components that are contained in the fresh Benzene

feed to the plant by purging from Benzene column reflux pump discharge and Benzene

recycle pump discharge. These purges are incinerated in the light incinerator

Benzene column also serves as a Benzene dryer by removing the moisture present in the

fresh benzene. Water present in the Benzene feed will get separated and collected in the

reflux drum boot and from there it is drained to effluent water treatment system.

No. 13

BENZENE COLUMN (CONTD..)

Benzene and Toluene levels in the bottom stream from the Benzene column are to be

maintained at very low levels as any Benzene or Toluene present in the bottom stream of

Benzene column will appear in the product Cumene.

Propane and other inerts present in the feed are vented to flare from Benzene column under

pressure control.

Benzene column bottom stream mainly contains Cumene, DIPB, PIPB, heavies etc which is

fed to Cumene column for recovering pure Cumene.

No. 14

CUMENE COLUMN

Cumene Column separates butyl benzene, cymenes, DIPB, TIPB and heavier components

to the levels required to produce specification grade cumene product.

The cumene product is recovered mainly as a sidedraw from tray # 50 and partly as a small

distillate stream from reflux pump discharge. Product is directed to one of the two rundown

tanks after cooling and from there transferred to Cumene main storage tank.

There is one off spec storage tank to receive product when the plant is under start up or

whenever plant is not stable. This off spec material can be fed to Benzene column for

reprocessing.

DIPB, TIPB, Cymenes and heavier compounds are removed in the bottom stream from the

column. Bottom from Cumene column is directed to PIPB column.

No. 15

PIPB COLUMN

The PIPB Column operates under vacuum condition, recovers di-isopropylbenzene (DIPB)

and tri-isopropyl benzene (TIPB), collectively referred to as polyisopropylbenzene (PIPB), as

a side stream.

The PIPB recycle from PIPB column side draw is fed to the Transalkylation Reactor, where

both DIPB and TIPB are converted to cumene.

Light components (mainly cumene, butylbenzene,and cymene) are separated as a distillate

purge stream and send to incinerator.

Heavy components (mainly dicyclic aromatics such as diphenyl propane) leave the column

from the bottom and send to incinerator.

No. 16

TRANSALKYLATION REACTOR

The Transalkylation Reactor serves to convert the PIPB back to cumene to increase

the overall cumene production. Transalkylation reactor is filled with Exxon Mobil

Zeolite catalyst.

Part of the recycled benzene stream from the Benzene Column is combined with the

recycled PIPB in a 1:1 ratio to feed to the Reactor.

The Transalkylation Reactor converts about 50% of the feed DIPB back to cumene

and the resultant effluent is fed to the Benzene Column for product recovery.

No. 17

:

PROPYLENE TREATERS

Propylene treaters are used to remove Sulfur compounds, Arsine and Phosphine from Propylene

feed before admitting it to Alkylation Reactor because these are poison to the Alkylation catalyst.

It uses BASF R3-12 as catalyst. This is a mixture of CuO, ZnO and Al2O3.

Treaters are used in series with lead and lag positions.

Each Treater catalyst has a total life of 2 years with first year in lead position and second year in

lag position.

Total Sulfur at the outlet of Propylene Treater should be 0.015 ppm.

17

No. 18

CLAY TREATERS

Clay Treaters are used to remove Basic Nitrogen compounds from fresh Benzene feed.

It uses Englehard F-25 Activated clay as catalyst.

Each Treater catalyst has a total life of 6 months with 3 months in lead position and next 3 months

in lag position.

Basic Nitrogen at the outlet of Clay Treaters should be less than 0.03 ppm.

18

No. 19

SECONDARY BENZENE TREATORS

Secondary Benzene Treators are used to remove polar Nitrogen compounds from the

Recycle Benzene stream which are poisonous to the Zeolite catalyst.

Each treator is filled with the a single bed of type 13X Molecular sieve adsorbent.

Expected life of the catalyst is 3 months in the lead position and 3 months in the lag position

based on a polar nitrogen concentration in the fresh benzene at 0.5 ppmw

Total Nitrogen at the outlet of Secondary benzene Treater shall be 0.03 ppm.

No. 20

ACTIVE CARBON BED

Active carbon bed is used to remove Hydrocarbon from PIPB column vacuum pump

discharge vent before releasing to atmosphere.

Life of the Carbon bed is 6 months.

No. 21

IMPORTANT PARAMETERS

No. 22

ALKYLATION REACTOR

It is important to keep the reactor pressure sufficiently high to keep all the components in

liquid state. Low pressure will lead to flashing of Propylene which will result in Propylene

oligomerization and deactivation of the catalyst. Reactor pressure is maintained by

controlling the reactor effluent flow to Benzene column.

Reactor inlet temp is important to get full conversion of Propylene. Higher temp will lead to

more generation of N Propylbenzene and heavies. Low temp will lead to reduced activity of

catalyst. Inlet temp need to be increased as the catalyst ages. Temperature is maintained

by controlling the reactor effluent recycle stream.

Temp rise across each bed shall be kept low to prevent catalyst deactivation and to reduce

side reactions. This is achieved by controlling the Alkylator effluent recycle flow

Benzene to Propylene mole ratio shall be maintained to get Cumene quality and to reduce

side reactions. This is achieved by controlling the Recycle Benzene flow to the reactor.

No. 23

BENZENE COLUMN

Benzene column pressure is maintained low to allow flashing of Benzene from reactor

effluents. Pressure is maintained by controlling vent to flare and by Nitrogen make up to the

column.

Tray #3 temp is maintained to get proper separation of Benzene from other constituents.

Low temp will lead to slippage of Benzene and Toluene to Cumene column. High temp will

increase the Cumene content in recycle Benzene to Alkylator and Transalkylator which will

lead to more heavies generation. Temp is maintained by controlling HP steam flow to the

reboiler and by adjusting top reflux and side draw reflux flow .

Purge flow from Benzene column overhead and side draw to incinerator are to be

maintained to maintain non aromatic concentration in recycle benzene.

No. 24

CUMENE COLUMN

Cumene column tray #7 temp is maintained to get proper separation between Cumene and

heavier components. Higher temp will lead to presence of DIPB and Cymene in Cumene

product. Low temp will lead to Cumene slippage to PIPB column. Temperature is

maintained by controlling HP steam flow to reboiler and by controlling reflux flow.

Column pressure is maintained by venting to flare header and by making up with Nitrogen.

Maintaining column pressure is important to keep the temperature profile steady.

A small purge flow from Cumene column overhead is maintained to prevent accumulation of

lighter ends at the top section of the column.

No. 25

PIPB COLUMN

PIPB column is operated under vacuum to reduce the boiling temperature of DIPB and

TIPB.

Column bottom temp is maintained to get proper separation between PIPB and heavy

aromatics by controlling HP steam to the reboiler. Low temp will lead to loss of PIPB to

incinerator from column bottom. High temp will lead to presence of heavier impurities in

PIPB recycle stream. Column top reflux and side draw reflux are also to be maintained to

get proper separation.

PIPB recycle flow to Transalkylator has to be maintained to prevent accumulation of PIPB in

the system.

No. 26

TRANSALKYLATOR

Transalkylator reactor pressure has to be maintained by controlling the reactor effluent flow

to the Benzene column. Controlling the pressure is important to keep all the constituents in

liquid medium.

Benzene to PIPB ratio shall be maintained to get maximum yield from PIPB. Recycle

Benzene flow shall be adjusted to get this ratio.

DIPB conversion shall be maintained by adjusting reactor inlet temp. Higher conversion will

lead to more byproducts and low conversion will lead to accumulation of PIPB in the system

and will come out through Cumene product.

No. 27

TROUBLE SHOOTING

No. 28

HIGH BENZENE IN CUMENE PRODUCT

CAUSE

Low Benzene column bottom temperature.

CORRECTIVE ACTION

Increase steam flow to reboiler and maintain temp.

CAUSE

Tube leak on Cumene product/Recycle Benzene exchanger

CORRECTIVE ACTION

Confirm the leak by sampling and rectify the leak.

No. 29

HIGH TOLUENE IN CUMENE PRODUCT

CAUSE

Low Benzene column bottom temperature.

CORRECTIVE ACTION

Increase steam flow to reboiler and maintain temp

CAUSE

High toluene in the Benzene feed (more than 300ppm)

CORRECTIVE ACTION

Take corrective action to improve the feed quality

No. 30

HIGH ETHYL BENZENE IN CUMENE PRODUCT

CAUSE

High Ethylene in propylene feed

CORRECTIVE ACTION

Take corrective action to improve the feed quality

CAUSE

Ethyl Benzene is produced in Transalkylator because of high temp

CORRECTIVE ACTION

Reduce temp in Transalkylator.

No. 31

HIGH NPB IN CUMENE PRODUCT

CAUSE

High temp in Alkylator and Transalkylator

CORRECTIVE ACTION

Reduce reactor temperature

CAUSE

High Cyclo Propane in the Propylene feed.

CORRECTIVE ACTION

Take corrective action to improve the feed quality.

No. 32

HIGH NPB IN CUMENE PRODUCT (CONTD)

CAUSE

Low B/P ratio in Alkylator feed

CORRECTIVE ACTION

Increase recycle Benzene flow to Alkylator

CAUSE

Low Benzene to PIPB ratio

CORRECTIVE ACTION

Increase recycle Benzene flow to Transalkylator

No. 33

HIGH BUTYL BENZENE IN CUMENE PRODUCT

CAUSE

High Butylene in propylene feed

CORRECTIVE ACTION

Take corrective action to improve the feed quality

CAUSE

Cumene column is not operated properly.

CORRECTIVE ACTION

Reduce Cumene column bottom temp and increase reflux flow.

No. 34

HIGH CYMENE IN CUMENE PRODUCT

CAUSE

Cymene is produced by reaction of Propylene with Toluene. Toluene enters the section

through fresh benzene feed.

CORRECTIVE ACTION

Take corrective action to improve the feed quality

CAUSE

Cumene column is not operated properly.

CORRECTIVE ACTION

Reduce Cumene column bottom temp and increase reflux flow.

No. 35

HIGH CYMENE IN CUMENE PRODUCT (CONTD..)

CAUSE

Cymene is not purged out from the plant.

CORRECTIVE ACTION

Increase aromatic purge from PIPB overhead.

No. 36

HIGH NON AROMATICS IN THE CUMENE PRODUCT

CAUSE

High non aromatics in the Benzene feed

CORRECTIVE ACTION

Take corrective action to improve the feed quality. Increase non aromatics purge from

Benzene column overhead and side draw.

CAUSE

Alkylation reactor catalyst is getting aged.

CORRECTIVE ACTION

Increase reactor inlet temp. Increase non aromatics purge.

No. 37

HIGH DIPB IN CUMENE PRODUCT

CAUSE

Cumene column is not operated properly

CORRECTIVE ACTION

Reduce temp and increase reflux to Cumene column.

CAUSE

Conversion in Transalkylator is not sufficient and DIPB is accumulating in the system

CORRECTIVE ACTION

Increase transalkylator inlet temp to get 50% DIPB conversion.

No. 38

38

S-ar putea să vă placă și

- Presentation CumeneDocument39 paginiPresentation Cumeneممدوح الرويليÎncă nu există evaluări

- Cumene Methods 2520of ProductionDocument4 paginiCumene Methods 2520of ProductionYunardi YusufÎncă nu există evaluări

- Recent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004De la EverandRecent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004Încă nu există evaluări

- Phenol PlantDocument33 paginiPhenol PlantrakeshÎncă nu există evaluări

- Manufacture of Phenol From CumeneDocument8 paginiManufacture of Phenol From CumeneFabi OneÎncă nu există evaluări

- Acetylene, the Principles of Its Generation and Use A Practical Handbook on the Production, Purification, and Subsequent Treatment of Acetylene for the Development of Light, Heat, and PowerDe la EverandAcetylene, the Principles of Its Generation and Use A Practical Handbook on the Production, Purification, and Subsequent Treatment of Acetylene for the Development of Light, Heat, and PowerÎncă nu există evaluări

- Cumene A PDFDocument4 paginiCumene A PDFdanena88Încă nu există evaluări

- CumeneDocument5 paginiCumeneNasmiyeth Rodriguez VittaÎncă nu există evaluări

- Cumene Production Process DescriptionDocument1 paginăCumene Production Process DescriptionAudrey Patrick KallaÎncă nu există evaluări

- Cumene ProductionDocument26 paginiCumene ProductionAMOGH JHANWARÎncă nu există evaluări

- Side ReactionsDocument22 paginiSide ReactionsAna Mariel VenturaÎncă nu există evaluări

- Cumene Production PlantDocument6 paginiCumene Production PlantMertcan AslanÎncă nu există evaluări

- CumeneDocument21 paginiCumeneDiv SavaliyaÎncă nu există evaluări

- Toluene Toluene Toluene Hydrogen Chromium PlatinumDocument6 paginiToluene Toluene Toluene Hydrogen Chromium PlatinumBerry101Încă nu există evaluări

- Viewcontent11 PDFDocument54 paginiViewcontent11 PDFEr Mayur PatilÎncă nu există evaluări

- Hydrogenation of Fatty Acid Methyl Esters To FattyDocument9 paginiHydrogenation of Fatty Acid Methyl Esters To FattyYulius Harmawan Setya PratamaÎncă nu există evaluări

- Chapter I - Introduction To CumeneDocument4 paginiChapter I - Introduction To CumeneQilah Kamarudin100% (1)

- Reactor ModelDocument12 paginiReactor ModelTanuja ThanuÎncă nu există evaluări

- PropeneDocument2 paginiPropenemow007100% (1)

- EnnnDocument9 paginiEnnnSajid AliÎncă nu există evaluări

- For Hysys UsersDocument5 paginiFor Hysys UsersZohaib RanaÎncă nu există evaluări

- Production of Isopropyl BenzeneDocument15 paginiProduction of Isopropyl BenzeneMehdi SirajÎncă nu există evaluări

- First Review Report On Production of Phenol: Done by GuideDocument27 paginiFirst Review Report On Production of Phenol: Done by GuideRuban RkÎncă nu există evaluări

- Design of EthylbenzeneDocument5 paginiDesign of Ethylbenzenesahar vahdatifarÎncă nu există evaluări

- N-Butane To Maleic AnhydrideDocument6 paginiN-Butane To Maleic AnhydrideNomeacuerdo Yo MismoÎncă nu există evaluări

- MEK in School SecondDocument13 paginiMEK in School Secondifiok100% (1)

- Cumene212 PDFDocument10 paginiCumene212 PDFtiaradyepiÎncă nu există evaluări

- Cumene Production Robert SchmidtDocument14 paginiCumene Production Robert SchmidtVatsalÎncă nu există evaluări

- Progress in Synthesis of Ethylene Glycol Through C1 ChemicalDocument10 paginiProgress in Synthesis of Ethylene Glycol Through C1 ChemicalFelipe A. Peña RincónÎncă nu există evaluări

- It1.Introduction & History:-: 1.1 Introduction To Cumene:-StructureDocument12 paginiIt1.Introduction & History:-: 1.1 Introduction To Cumene:-StructureJaymin GoswamiÎncă nu există evaluări

- Styrene From Ethane and BenzeneDocument6 paginiStyrene From Ethane and BenzeneAmy Puah100% (2)

- Physical Properties of Cumene Property ValueDocument4 paginiPhysical Properties of Cumene Property ValueC.Çağrı Yekeler50% (2)

- Art:10 1134/S0965544111010038Document10 paginiArt:10 1134/S0965544111010038CátiaLuzÎncă nu există evaluări

- Simulation and Optimization of Cumene Plant Using ASPENPlusDocument2 paginiSimulation and Optimization of Cumene Plant Using ASPENPlusTheødřøš ÄbÎncă nu există evaluări

- Designandcontrolofthecumeneprocess PDFDocument24 paginiDesignandcontrolofthecumeneprocess PDFTobias De Somer100% (1)

- 2 4Document11 pagini2 4Berry1010% (1)

- Production of N Octane From Ethylene and I ButaneDocument2 paginiProduction of N Octane From Ethylene and I ButaneRamyaÎncă nu există evaluări

- Ethylbenzene ProductionDocument30 paginiEthylbenzene ProductionUum LukmanÎncă nu există evaluări

- Production of PhenolDocument120 paginiProduction of PhenolAlyxÎncă nu există evaluări

- 1 Start Download - View PDF 2 Glass-Lined Reactors: Enter Your Search HereDocument11 pagini1 Start Download - View PDF 2 Glass-Lined Reactors: Enter Your Search HerewrdlifeÎncă nu există evaluări

- Energy Balance 2-Ethyl HexanolDocument12 paginiEnergy Balance 2-Ethyl HexanolDeep PatelÎncă nu există evaluări

- Cumene Process, Prod - CBIDocument2 paginiCumene Process, Prod - CBIChris LindseyÎncă nu există evaluări

- Report BTPDocument47 paginiReport BTPvpsrpuchÎncă nu există evaluări

- Butene-1: Trans-2-Butene, Isobutylene, and ButadieneDocument1 paginăButene-1: Trans-2-Butene, Isobutylene, and ButadieneYESIKBMARTIN100% (1)

- Kinetics of Catalytic Dehydrogenation of Ethylbenzene To StyreneDocument5 paginiKinetics of Catalytic Dehydrogenation of Ethylbenzene To Styreneibrahim3318Încă nu există evaluări

- Types of Phenol Manufacturing ProcessDocument4 paginiTypes of Phenol Manufacturing ProcessIsma AzraÎncă nu există evaluări

- Ethyl Benzene Plant DesignDocument45 paginiEthyl Benzene Plant DesignfaridzawiÎncă nu există evaluări

- Propane Dehydrogenation in Modified Membrane Porous ReactorDocument7 paginiPropane Dehydrogenation in Modified Membrane Porous ReactorNoezran AzwarÎncă nu există evaluări

- 0203 2 TocDocument7 pagini0203 2 Tocعمر الاسمريÎncă nu există evaluări

- Manfacture OF: Cyclo HexaneDocument91 paginiManfacture OF: Cyclo HexaneNikhil Kumar Chennuri100% (4)

- Acrolein Project Final PDFDocument104 paginiAcrolein Project Final PDFPankaj RanaÎncă nu există evaluări

- Production of Aniline by Reduction of Nitrobenzene: Group#2Document26 paginiProduction of Aniline by Reduction of Nitrobenzene: Group#2Arsal MaqboolÎncă nu există evaluări

- Chemical Modification of Natural Rubber Under Supercritical CarbonDocument8 paginiChemical Modification of Natural Rubber Under Supercritical CarbonKristina HuffmanÎncă nu există evaluări

- Energy Saving of A Methyl Methacrylate Separation Process PDFDocument11 paginiEnergy Saving of A Methyl Methacrylate Separation Process PDFClaudia CelestinoÎncă nu există evaluări

- Production of Maleic AnhydrideDocument8 paginiProduction of Maleic AnhydrideZafran AliÎncă nu există evaluări

- Tong Quan Benzene - pt1Document213 paginiTong Quan Benzene - pt1Văn Đại - BKHNÎncă nu există evaluări

- EthylbenzeneDocument4 paginiEthylbenzeneMouaath Al-Kalbani75% (4)

- Mesoscale Spherical and Planar Organizations of GoDocument12 paginiMesoscale Spherical and Planar Organizations of GoBis ChemÎncă nu există evaluări

- A General Statistical Mechanical Approach For Modelingredox Thermodynamics - The Reaction and Reorganizationfree Energies PDFDocument9 paginiA General Statistical Mechanical Approach For Modelingredox Thermodynamics - The Reaction and Reorganizationfree Energies PDFBis ChemÎncă nu există evaluări

- IrrepDocument14 paginiIrrepsibasishbanerjeeÎncă nu există evaluări

- Great Orthogonality TheoremDocument6 paginiGreat Orthogonality TheoremBis ChemÎncă nu există evaluări

- A General Statistical Mechanical Approach For Modelingredox Thermodynamics - The Reaction and Reorganizationfree Energies PDFDocument9 paginiA General Statistical Mechanical Approach For Modelingredox Thermodynamics - The Reaction and Reorganizationfree Energies PDFBis ChemÎncă nu există evaluări

- FEBS J 2008 Crystallography For Non CrystallographerspdfDocument22 paginiFEBS J 2008 Crystallography For Non CrystallographerspdfAntonio LopezÎncă nu există evaluări

- Character Tables: Christopher C. CumminsDocument101 paginiCharacter Tables: Christopher C. CumminsMohammad RameezÎncă nu există evaluări

- SymmetryDocument12 paginiSymmetryBis ChemÎncă nu există evaluări

- Huang LectureDocument1 paginăHuang LectureBis ChemÎncă nu există evaluări

- Laboratory Manual Physical Chemistry M. Sc. I YearDocument44 paginiLaboratory Manual Physical Chemistry M. Sc. I YearrajamatheÎncă nu există evaluări

- Solvation ModelsDocument66 paginiSolvation ModelsBis ChemÎncă nu există evaluări

- OrcaDocument827 paginiOrcaAlina Andreea100% (1)

- Computer-Aided Drug Design (CADD) : Rational Drug Design Structure-Based Drug Design Intelligent Drug DesignDocument21 paginiComputer-Aided Drug Design (CADD) : Rational Drug Design Structure-Based Drug Design Intelligent Drug DesignPranav NakhateÎncă nu există evaluări

- Bioinfo PDFDocument7 paginiBioinfo PDFSubash KumarÎncă nu există evaluări

- GCEMDocument42 paginiGCEMBis ChemÎncă nu există evaluări

- Introduction To Density Functional TheoryDocument44 paginiIntroduction To Density Functional TheoryredaelwanÎncă nu există evaluări

- ch1 PDFDocument2 paginich1 PDFBis ChemÎncă nu există evaluări

- Bioinfo PDFDocument7 paginiBioinfo PDFSubash KumarÎncă nu există evaluări

- Mo (CN) 8Document17 paginiMo (CN) 8Bis ChemÎncă nu există evaluări

- Advanced Engineering Mathematics PDFDocument1.057 paginiAdvanced Engineering Mathematics PDFBis ChemÎncă nu există evaluări

- OrcaManual 2 9Document532 paginiOrcaManual 2 9Sergio L. E. PrezaÎncă nu există evaluări

- Anderson72more Is DifferentDocument5 paginiAnderson72more Is DifferentcormacÎncă nu există evaluări

- 2012 05 Neese ComputationalChemistryDocument129 pagini2012 05 Neese ComputationalChemistryBis ChemÎncă nu există evaluări

- Modern Electrochemistry 1 IonicsDocument825 paginiModern Electrochemistry 1 Ionicsdspilios70% (10)

- Researchers in An Entropy Wonderland: A Review of The Entropy ConceptDocument29 paginiResearchers in An Entropy Wonderland: A Review of The Entropy ConceptBis ChemÎncă nu există evaluări

- 2012 05 Neese ComputationalChemistryDocument129 pagini2012 05 Neese ComputationalChemistryBis ChemÎncă nu există evaluări

- Lshort PDFDocument171 paginiLshort PDFJoe MullerÎncă nu există evaluări

- Laidler CHEMICAL KINETICS PDFDocument272 paginiLaidler CHEMICAL KINETICS PDFRajeev Chand Nishad71% (35)

- Http://Chem Ps Uci Edu/ kieron/Dft/BookDocument104 paginiHttp://Chem Ps Uci Edu/ kieron/Dft/BookjmartiarÎncă nu există evaluări

- CHARMMDocument189 paginiCHARMMBis ChemÎncă nu există evaluări

- MAXOFIN TechnologyDocument2 paginiMAXOFIN TechnologyHưng LucaÎncă nu există evaluări

- Double Bond EquivalentDocument4 paginiDouble Bond EquivalentJubin KumarÎncă nu există evaluări

- Grupa Azoti Propane PresentationDocument13 paginiGrupa Azoti Propane PresentationHosienÎncă nu există evaluări

- D 2163 PDFDocument5 paginiD 2163 PDFseterisparigus100% (1)

- Energy 32 (2007) 335-343Document9 paginiEnergy 32 (2007) 335-343JhofranHidalgoÎncă nu există evaluări

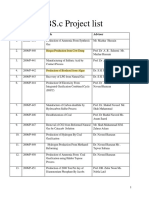

- BSC Project List (Last 10 Years)Document16 paginiBSC Project List (Last 10 Years)ahmadÎncă nu există evaluări

- Propane To Acrylic AcidDocument231 paginiPropane To Acrylic AcidCluisantony Jayco DizeÎncă nu există evaluări

- APIC2015 - Acrylonitrile Market PDFDocument23 paginiAPIC2015 - Acrylonitrile Market PDFsergey sergeevÎncă nu există evaluări

- Production of Acrylic Acid Form Propylene: University Institute of Engineering Department of Chemical EngineeringDocument41 paginiProduction of Acrylic Acid Form Propylene: University Institute of Engineering Department of Chemical EngineeringGaurav Spencer67% (3)

- Project On Propylene OxideDocument38 paginiProject On Propylene Oxidemikelycan75% (4)

- UOP Oleflex ProcessDocument13 paginiUOP Oleflex ProcessAashish Gaurav100% (1)

- Ammoxidation Catalysis (Review Cat Tod)Document13 paginiAmmoxidation Catalysis (Review Cat Tod)Roger David Melendez GuevaraÎncă nu există evaluări

- FCC Petrochemicals Production at Minimum CapexDocument5 paginiFCC Petrochemicals Production at Minimum CapexAsifÎncă nu există evaluări

- Msa s47k ManualDocument53 paginiMsa s47k ManualSlim ToumiÎncă nu există evaluări

- ESE Tecniche Cumene 130314Document4 paginiESE Tecniche Cumene 130314John DalkiaÎncă nu există evaluări

- Cumene: Process Features Process BenefitsDocument2 paginiCumene: Process Features Process BenefitsahmedÎncă nu există evaluări

- Oxidative Dehydrogenation of Propane To Propylene With Carbon Dioxide ReviewDocument17 paginiOxidative Dehydrogenation of Propane To Propylene With Carbon Dioxide ReviewKumaresan LoganathanÎncă nu există evaluări

- CUMENEDocument24 paginiCUMENEhiteshÎncă nu există evaluări

- Simulation and Optimization of An Ethylene PlantDocument114 paginiSimulation and Optimization of An Ethylene PlantEvelyne Jahja100% (1)

- Fluid Catalytic CrackingDocument16 paginiFluid Catalytic Crackingbubalazi100% (1)

- Hemical Ndustries Ewsletter: CEH Marketing Research Report AbstractDocument13 paginiHemical Ndustries Ewsletter: CEH Marketing Research Report AbstractRicardo Javier PlasenciaÎncă nu există evaluări

- FYDP Final Report G13 PDFDocument30 paginiFYDP Final Report G13 PDFJeanette Hong May Hurn0% (1)

- Petrochen - 4-10Document8 paginiPetrochen - 4-10pppppp5Încă nu există evaluări

- Model For ProductDocument6 paginiModel For ProductJay MaradiyaÎncă nu există evaluări

- (Aziz Belmiloudi (Editor) ) Heat Transfer - Theoret (B-Ok - CC)Document666 pagini(Aziz Belmiloudi (Editor) ) Heat Transfer - Theoret (B-Ok - CC)AshenafiÎncă nu există evaluări

- Desilication Seminar ReportDocument37 paginiDesilication Seminar ReportMahendra GuptaÎncă nu există evaluări

- Methanol To Ole Fins (MTO) : From Fundamentals To CommercializationDocument17 paginiMethanol To Ole Fins (MTO) : From Fundamentals To Commercializationsrijangupta1996Încă nu există evaluări

- Couldcoalbetheanswertoglobalplasticsshortages-Platts May 2015 PDFDocument61 paginiCouldcoalbetheanswertoglobalplasticsshortages-Platts May 2015 PDFfakhruddin valikaÎncă nu există evaluări

- Project 4 Acrylic AcidDocument16 paginiProject 4 Acrylic AcidN193746100% (3)

- Anexo 9 Puraspec 7151Document7 paginiAnexo 9 Puraspec 7151Edgar Hector GarciaÎncă nu există evaluări