Documente Academic

Documente Profesional

Documente Cultură

Plastic Analysis

Încărcat de

Chan Keng ChunDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plastic Analysis

Încărcat de

Chan Keng ChunDrepturi de autor:

Formate disponibile

Concepts of Plastic Analysis

LECTURE 8

Concepts of Plastic Analysis

Plastic design utilizes the ductility of steel.

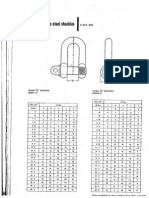

Steel grades for plastic design

grade Thickness

less than

or equal

to

Design

strength,

py,

N/mm2

Minimum

yield

stress, Ys

Minimum

ultimate

strength, Us

Minimum

elongation on

gauge length of

5.65S

0

43 16 275 275 410 20-22%

40 265 265 410

63 255 255 410

100 245 245 410

50 16 355 355 490 20-22%

40 345 345 490

63 335 335 490

100 325 325 490

55 16 450 450 550 19%

40 430 430 550

63 415 430 550

100 400 415 550

In BS5950 , The design strength py should be

taken as 1.0Ys but not greater than Us /1.2

=0.833..U

S

where Ys and Us are respectively

the minimum yield strength ReH and the

minimum tensile strength Rm

Requirements of steel for plastic

design

Stress strain diagram has a plateau at the yield

stress extending for at least 6 times the yield

strain

Ratio of the specified minimum ultimate

tensile strength to specified minimum yield

strength is not less than 1.2

The elongation on a gauge length of 5.65S

0

is

not less than 15% where S

0

is the original cross

sectional area of the gauge length

Structure must be robust to achieve a mechanism of

collapse without instability

Local instability: limits given in table 11

For rolled section b/T 9

For built up welded section: b/T 8

For webs generally :d/t

Lateral instability

Frame instability

Basis of plastic design

Structures are assumed to collapse by the

formation of sufficient plastic hinges to create

a collapse mechanism

Fundamental problems of plastic design

Prediction of the correct collapse mechanism

Determination of load factor at collapse

Determination of BMD at collapse

Fundamental requirements for

different methods of solving problems

Equilibrium condition: the bending moments must

represent a state of equilibrium between internal

forces in the structure and applied loads

Mechanism condition: At collapse, the bending

moment must be equal to the full plastic moment of

resistance of the cross section at a sufficient number of

sections of the structure for the associated plastic

hinges to constitute a mechanism involving the whole

structure or some part of it

Yield condition: At every cross section of the structure,

the bending moment must be less than or equal to, the

full plastic moment of resistance.

Advantage of plastic theory

It is not necessary to consider continuity

This makes plastic analysis considerably easier

than the elastic analysis of any given structure

Plastic theory

In many structures, there a number of

alternative collapse mechanisms

The correct mechanism is not immediately

obvious

It is necessary to approach correct solution in

a series of steps

The following theorems help in arriving at an

acceptable solution

No proofs are given as proofs are complicated

Method 1:Upper Bound Theorem

Also called Kinematic theorem or Minimum Principle

In the analysis of a structure, an arbitrary choice of

collapse mechanism will lead to an estimate of the

collapse load which is greater than or equal to the

correct one

If the correct collapse mechanism is not known and a

guess is made, then the solution will give an upper

bound on collapse load factor

c

and is potentially

unsafe.

Methods based on assumed collapse mechanism

generally satisfy only the equilibrium and mechanism

condition

Method 2: Lower bound theorem

Or Static theorem or maximum Principle

An arbitrary equilibrium condition which also

satisfies the yield condition will lead to an

estimate of the collapse load which is less

than or equal to the correct one

Satisfying the equilibrium and yield condition

without necessarily obtaining a mechanism is

essentially safe procedure

Uniqueness theorem

The value of the collapse load which satisfies

the three conditions of equilibrium,

mechanism and yield is unique.

Applications

Fixed beam subject to two concentrated load

Continuous beams

Portal frames

Fixed beam subject to two concentrated load

The beam shown in figure is fixed at both ends. It is subject to

loads 20kN and 30 kN. If the full plastic moment capacity Mp

is 78.0kNm, then determine the load factor against collapse.

Answer:

Method 1: Steps:

(1) Consider all possible collapse mechanisms

4 m 4 m 2 m

20kN 30 kN

4 m 4 m 2 m

20kN 30 kN

20kN 30 kN

20kN 30 kN

20kN 30 kN

Equilibrium between bending moments and applied loads is satisfied by

using the virtual work method

20 30

78

78

78

4 m 6 m

First collapse mechanism

The method considers a virtual displacement of

the mechanism that is under investigation

assuming that all internal strain is concentrated in

the plastic hinges

The members between the plastic hinges are

assumed to be perfectly rigid and make no

contribution to the internal work

For compatibility 4 = 6

By principle of virtual work, work done by

external load = work done internally

20x 4 + 30 x 4 =78(2+2)

20x 6 + 30 x 4 =78(3+2)

=390/240=1.625

Second collapse mechanism 20kN 30 kN

78

78

78

For compatibility 4 = 6

By principle of virtual work, work done by external load = work done internally

30x 4 + 20 x 4 =78(2+2)

30x 6 + 20 x 4 =78(3+2)

=390/260=1.5

All possible collapse mechanisms have been considered. Using minimum principle, we can

confidently choose the mechanism with the lowest load factor.

Therefore =1.5

6 m

4 m

Method 2

Method 2 combines free and reactant bending

moment diagram to obtain solution that

satisfies the equilibrium and yield condition.

Continuous beams

One of the advantages of plastic theory is that

there are no compatibility conditions in the

analysis

As plastic hinges form, they destroy the

continuity of the deflection profile and an

important consequence of this in continuous

beams is that the collapse of any span is

independent of the adjacent spans

Continuous beams

Consider a uniform beam of several equal spans.

Let w be the unfactored load acting on it.

It is required to find the load factor at collapse.

There are only 2 collapse cases to consider namely

midspan and endspan.

Internal span

Each of the internal span has exactly the same collapse

mechanism.

L/2 L/2

Mp

Mp Mp

Udl

Factored load =w

For the interior span using the work

equation method (free and reactant

bending moments is equally simple)

wL x L/4 = Mp(+2+)

Mp = wL

2

/16

=16Mp/ wL

2

The left side of work equation

represents the virtual work done by

the udl. Here a virtual mechanism is

considered in which the members

remain perfectly straight between

plastic hinges. The distributed load

can therefore be considered to be

concentrated at the centroids of the

straight lengths of the members.

Derivation of external work term

L/4

L/4

wL/2 wL/2

L/4

L/4

L/4

External span

The collapse condition in the end span is not so

obvious because it is not clear where the internal

plastic hinge is located.

The kinematic theorem implies that all possible

locations of the hinge must be considered.

Choose one which gives the lowest load factor (or

the highest value of Mp in a design calculation).

This can be conveniently done by choosing an

arbitrary hinge position defined by variable x, and

using the method of calculus.

The rotations and are related by considering the

vertical deflection at the hinge position

x = (L-x)

The work equation can be written down as

x L-x

Mp

Mp Mp

Udl

Factored load =w

wL .X/2=Mp(2+)=Mp(2+x/(L-x))

I.e . Mp=wL.x(L-x)/(2(2L-x)

The critical value of x is that which maximises Mp

i.e dMp/dx=0

Solving, x=L(22)

This gives a unique root within the span 0 to L

x=L(2-2)=0.586L

Backsubstituting

Mp = wL

2

/11.66 or =11.66Mp/wl2

The end bay condition occurs frequently in practical

design

Note that if a beam is designed to be fully

continuous over several spans, the end bays require

a considerably stronger section than the internal

bays (Mp = wL

2

/11.66 compared to =16Mp/ wL

2

)

The fabrication of connections that are adequate to

ensure full continuity is expensive and a fully

continuous uniform bean may well not be the

optimum practical solution

Plastic analysis of portal frames

The collapse mechanism in portal frames is

not obvious

Necessary to consider several possibilities

Two types of portal frames

Rectangular portal frames

Pitched portal frames

RECTAGULAR PORTAL FRAMES

The rectangular frame shown in figure has a

uniform full plastic moment of 20knm. The loads

shown are unfactored. Find the load factor

against collapse. Use the work equation method

10Kn

5 M

5KN

3.75M

3.75M

A

B

C

D

E

RECTAGULAR PORTAL FRAMES

The only possible locations for plastic hinges

are at A,B,C, D and E where there is a change

of slope in the bending moment diagram

It is impossible for plastic hinges to form

between these points which are termed as

CRITICAL SECTIONS

Thus THERE ARE ONLY 3 VALID MECHANISMS

shown below:

Different collapse mechanisms

10

5

Sway mechanism

10

5

Beam mechanism

2

10

5

Combined mechanism

2

2

For a small, rigid-link movement of the mechanism, the beam

moves bodily sideways and there is no downward movement

of the 10kN load

Work equation is 5 x 5=20(+++)

=80/25=3.2

In plastic collapse mechanism, the bending moment at a

plastic hinge is always related to the direction of rotation of

that hinge with the result that plastic hinges always do

positive virtual work.

10

5

Sway mechanism

For a small movement of the mechanism, the stanchion remain

vertical and there is no movement of the 5 kN load. The work

equation is therefore 10x 3.75 = 20(+2+)

Therefore =80/37.5=2.13

10

5

Beam mechanism

2

Combined mechanism: this a combination of 1 and 2. It is essential to

carry out this combination in such a way that the hinge at B is eliminated

and replaced by a rigid joint. If this were not the case , it would be

impossible to relate all movements in the virtual mechanism to a single

variable

5x 5 + 10x3.75=20(+2+2+)

=120/62.5=1.92

10

5

Combined mechanism

2

2

All possible mechanisms have been

considered. It follows from the minimum

principle that the combined mechanism with

the lowest load factor is the correct collapse

mechanism.

The load factor against collapse is 1.92

References

Plastic design to BS 5950, Davies, J.M. and

B.A.Brown, Blackwell Science, Steel

Construction Institute, 1996.

S-ar putea să vă placă și

- Plastic Analysis PresnetationDocument123 paginiPlastic Analysis PresnetationMisganaw YeshiwasÎncă nu există evaluări

- Plastic AnalysisDocument51 paginiPlastic AnalysisHafeel Ahamed Ashraf AliÎncă nu există evaluări

- Platic AnalysisDocument29 paginiPlatic AnalysisSiddhanth S NairÎncă nu există evaluări

- Plastic Analysis Principles for Steel StructuresDocument31 paginiPlastic Analysis Principles for Steel StructuresVarun ShastryÎncă nu există evaluări

- Plastic AnalysisDocument90 paginiPlastic AnalysisBishanjit Singh Grewal100% (4)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDe la EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresEvaluare: 4 din 5 stele4/5 (1)

- Plastic Behaviour of Beams and FramesDocument26 paginiPlastic Behaviour of Beams and FramesTom WilkinsonÎncă nu există evaluări

- Governing equations for Timoshenko beam theoryDocument6 paginiGoverning equations for Timoshenko beam theoryLakshmi NarayananÎncă nu există evaluări

- Yield Line Theory: Prepared byDocument22 paginiYield Line Theory: Prepared byKartikMandaniÎncă nu există evaluări

- Study of Plastic Hinge Formation in Steel BeamsDocument22 paginiStudy of Plastic Hinge Formation in Steel BeamsTejas PatilÎncă nu există evaluări

- PLASTIC ANALYSIS OF STRUCTURESDocument13 paginiPLASTIC ANALYSIS OF STRUCTURESAkshata Deshpande100% (1)

- Analytical Solutions in Elasto-Plastic Bending of Beams With PDFDocument12 paginiAnalytical Solutions in Elasto-Plastic Bending of Beams With PDFMariusz Milewski50% (2)

- Plastic AnalysisDocument31 paginiPlastic Analysisgaiagmr100% (1)

- 17 - Yield Line Theory For SlabsDocument9 pagini17 - Yield Line Theory For SlabsRavindra MR100% (1)

- Deflections in Thin PlatesDocument29 paginiDeflections in Thin PlatesPrashant KoteÎncă nu există evaluări

- Plate Bending Theory and Governing EquationsDocument52 paginiPlate Bending Theory and Governing EquationsLeonardoMadeira11Încă nu există evaluări

- Theory of Elasticity and Plasticity for Mechanical EngineeringDocument12 paginiTheory of Elasticity and Plasticity for Mechanical EngineeringVinayak UntwaleÎncă nu există evaluări

- Beams Deflection - Macaulay's MethodDocument4 paginiBeams Deflection - Macaulay's MethodYadanaÎncă nu există evaluări

- Beam Bending Lab Report AnalysisDocument23 paginiBeam Bending Lab Report AnalysisDennisse MarinoÎncă nu există evaluări

- Plastic Analysis NotesDocument26 paginiPlastic Analysis NotesTatiana Espinoza Eusebio100% (1)

- Structural Analysis II Syllabus 20101 2Document17 paginiStructural Analysis II Syllabus 20101 2Christian Nicolaus MbiseÎncă nu există evaluări

- Matrix Stiffness Method for Structural AnalysisDocument141 paginiMatrix Stiffness Method for Structural AnalysisTamara Knox100% (1)

- Module 5.1 Influence Lines For Statically Indeterminate StructureDocument3 paginiModule 5.1 Influence Lines For Statically Indeterminate StructureEleonor Pacomios-VirtudazoÎncă nu există evaluări

- Yield Line Examples 2Document40 paginiYield Line Examples 2Helen Negash100% (1)

- Plastic Analysis 3rd Year Structural EngineeringDocument117 paginiPlastic Analysis 3rd Year Structural EngineeringArjun RajÎncă nu există evaluări

- Chapter 1 - IntroductionDocument26 paginiChapter 1 - IntroductionEvo LanzÎncă nu există evaluări

- Beam ElasticDocument22 paginiBeam ElasticPankaj KarnaÎncă nu există evaluări

- Plastic Analysis 1011Document129 paginiPlastic Analysis 1011Omkar Bapat0% (1)

- Chapter 2 (Indeterminte Structures)Document7 paginiChapter 2 (Indeterminte Structures)Hilary WatsonÎncă nu există evaluări

- Analysis of Beams and Framed StructuresDocument16 paginiAnalysis of Beams and Framed StructuresSayed Urooj AbbasÎncă nu există evaluări

- Comparing Theoretical and Experimental Plastic Bending Moments of Steel Beams Under Different Support ArrangementsDocument12 paginiComparing Theoretical and Experimental Plastic Bending Moments of Steel Beams Under Different Support ArrangementsJohn Diete-Koki100% (1)

- Yield Line Analysis For Slabs Module12 Lesson30Document29 paginiYield Line Analysis For Slabs Module12 Lesson30Ajit Singh Rathore100% (2)

- Timoshenko Beam TheoryDocument8 paginiTimoshenko Beam Theoryksheikh777Încă nu există evaluări

- Plastic Analysis Notes PDFDocument14 paginiPlastic Analysis Notes PDFVineetha KrishnanÎncă nu există evaluări

- Moment Distribution Method ExplainedDocument37 paginiMoment Distribution Method ExplainedSuleiman Yusuf JibrilÎncă nu există evaluări

- T - Shear Force and Bending Moment Diagr-1Document95 paginiT - Shear Force and Bending Moment Diagr-1Freddie Burnham100% (2)

- Strain: Strength of MaterialsDocument5 paginiStrain: Strength of MaterialsDon MatiasÎncă nu există evaluări

- 4 Shear Force and Bending MomentDocument20 pagini4 Shear Force and Bending Momentmuhamadsaidi0% (1)

- Strain RosettesDocument14 paginiStrain Rosettesbasit_ehsan88% (8)

- Deflection of BeamsDocument5 paginiDeflection of BeamsMohammedAlasaadÎncă nu există evaluări

- Unit 4 Plastic Behaviour of Structural SteelDocument37 paginiUnit 4 Plastic Behaviour of Structural SteelMahesh KumarÎncă nu există evaluări

- Introduction To Beams: Part ADocument49 paginiIntroduction To Beams: Part AMorad AJÎncă nu există evaluări

- Virtual Work and Variational Principles ExplainedDocument9 paginiVirtual Work and Variational Principles ExplainedBill Erick CastilloÎncă nu există evaluări

- Timoshenko Beam TheoryDocument7 paginiTimoshenko Beam TheoryAmália EirezÎncă nu există evaluări

- Composite - Design ProjectDocument6 paginiComposite - Design ProjectSomen DasÎncă nu există evaluări

- Solid 65Document9 paginiSolid 65MarKusskadeÎncă nu există evaluări

- 08032012-Nice PPT Strain TransformationDocument124 pagini08032012-Nice PPT Strain Transformationمحمد عادل خٹکÎncă nu există evaluări

- 9A01709 Advanced Structural AnalysisDocument8 pagini9A01709 Advanced Structural AnalysisReddy Kiran KD0% (1)

- Conjugate Beam Method DeflectionsDocument18 paginiConjugate Beam Method DeflectionsRaghul TÎncă nu există evaluări

- Unit - Iv Plastic Analysis of StructuresDocument32 paginiUnit - Iv Plastic Analysis of StructuresOraib AljaafrehÎncă nu există evaluări

- Computers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliDocument17 paginiComputers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliSayna KellenyÎncă nu există evaluări

- Shear Stress in BeamsDocument29 paginiShear Stress in Beamspoom2007Încă nu există evaluări

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsDe la EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsÎncă nu există evaluări

- Elastic, Plastic and Yield Design of Reinforced StructuresDe la EverandElastic, Plastic and Yield Design of Reinforced StructuresÎncă nu există evaluări

- Engineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDe la EverandEngineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionÎncă nu există evaluări

- Stability of Discrete Non-conservative SystemsDe la EverandStability of Discrete Non-conservative SystemsEvaluare: 1 din 5 stele1/5 (1)

- Finite Element Simulation in Surface and Subsurface HydrologyDe la EverandFinite Element Simulation in Surface and Subsurface HydrologyÎncă nu există evaluări

- FBM KLCI up 8.64 points as DRB-HICOM to exit ProtonDocument33 paginiFBM KLCI up 8.64 points as DRB-HICOM to exit ProtonChan Keng ChunÎncă nu există evaluări

- Braced Beam DesignDocument32 paginiBraced Beam DesignChan Keng ChunÎncă nu există evaluări

- Lecture 2 Intro Continued - 2072Document46 paginiLecture 2 Intro Continued - 2072Chan Keng ChunÎncă nu există evaluări

- Column To Steel Plate CalculationDocument1 paginăColumn To Steel Plate CalculationChan Keng ChunÎncă nu există evaluări

- D3 - Buckling Analysis (Designer)Document18 paginiD3 - Buckling Analysis (Designer)Chan Keng ChunÎncă nu există evaluări

- Shabu Ten Dinner Buffet Voucher for 2 PeopleDocument1 paginăShabu Ten Dinner Buffet Voucher for 2 PeopleChan Keng ChunÎncă nu există evaluări

- D3 - Buckling Analysis (Designer)Document18 paginiD3 - Buckling Analysis (Designer)Chan Keng ChunÎncă nu există evaluări

- Comparing wind load standards Eurocode and BSV 97Document10 paginiComparing wind load standards Eurocode and BSV 97andre_vicenteÎncă nu există evaluări

- Tutorial 2 - Axially Loaded Members-TensionDocument27 paginiTutorial 2 - Axially Loaded Members-TensionChan Keng ChunÎncă nu există evaluări

- Tutorial 4 - Flexural Members - Bending and ShearDocument42 paginiTutorial 4 - Flexural Members - Bending and ShearChan Keng ChunÎncă nu există evaluări

- Higher Tensile Steel 'D' and 'Bow' Shackles To BS 3032Document2 paginiHigher Tensile Steel 'D' and 'Bow' Shackles To BS 3032Chan Keng ChunÎncă nu există evaluări

- Summary - Flexural Members - Lateral Torsional BucklingDocument5 paginiSummary - Flexural Members - Lateral Torsional BucklingChan Keng ChunÎncă nu există evaluări

- Lecture 1 Introduction - 2072Document48 paginiLecture 1 Introduction - 2072Chan Keng ChunÎncă nu există evaluări

- Design of Lifting and Tailing LugsNetsc001Document30 paginiDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Plastic AnalysisDocument37 paginiPlastic AnalysisChan Keng ChunÎncă nu există evaluări

- Stainless Steel Grade 316 Data Sheet (Aalco)Document3 paginiStainless Steel Grade 316 Data Sheet (Aalco)Chan Keng ChunÎncă nu există evaluări

- AISC Errata ListDocument8 paginiAISC Errata ListLuis Gonzales Salazar67% (3)

- CNPC No7 Chinese Steel Sections (2004)Document5 paginiCNPC No7 Chinese Steel Sections (2004)Chan Keng ChunÎncă nu există evaluări

- Kaolite Insulating CastablesDocument2 paginiKaolite Insulating CastablesChan Keng ChunÎncă nu există evaluări

- Strength of Fillet and Full Penetration Butt Weld To BS 639Document1 paginăStrength of Fillet and Full Penetration Butt Weld To BS 639Chan Keng ChunÎncă nu există evaluări

- 304 Vs 316 PDFDocument2 pagini304 Vs 316 PDFRiza KhanÎncă nu există evaluări

- LiftingLugStress Rev 1.5Document20 paginiLiftingLugStress Rev 1.5ilijarskÎncă nu există evaluări

- ASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedDocument68 paginiASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedAnthony Gravagne100% (5)

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDocument20 paginiTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- Astm A 216, Grade WCBDocument12 paginiAstm A 216, Grade WCBChan Keng ChunÎncă nu există evaluări

- CED 2 Final Presentation - Compile PDFDocument133 paginiCED 2 Final Presentation - Compile PDFChan Keng Chun100% (1)

- Construction Costs Across Asia PacificDocument0 paginiConstruction Costs Across Asia PacificSudhakar GanjikuntaÎncă nu există evaluări

- Fault Database - Flat TVDocument3 paginiFault Database - Flat TVZu AhmadÎncă nu există evaluări

- Accidentally Pulled A Remote Branch Into Different Local Branch - How To Undo The Pull?: GitDocument4 paginiAccidentally Pulled A Remote Branch Into Different Local Branch - How To Undo The Pull?: GitEdouard Francis Dufour DarbellayÎncă nu există evaluări

- Visit To Kadana Hydro Power Plant and Wanakbori Thermal Power Plant.Document5 paginiVisit To Kadana Hydro Power Plant and Wanakbori Thermal Power Plant.Kunal VaghasiyaÎncă nu există evaluări

- Bitsler DicebotDocument4 paginiBitsler DicebotShinsÎncă nu există evaluări

- StradaDocument4 paginiStradayzk14Încă nu există evaluări

- Arinc Industry Activities Cabin Systems Overview: Version 2018-01Document42 paginiArinc Industry Activities Cabin Systems Overview: Version 2018-01je_carD23Încă nu există evaluări

- Answer Key Workbook Academic Plan DynEd Pro Certification B1 1Document22 paginiAnswer Key Workbook Academic Plan DynEd Pro Certification B1 1Dendel Ciprado EbioÎncă nu există evaluări

- CSD Counter Drone Systems ReportDocument23 paginiCSD Counter Drone Systems ReportmrkuroiÎncă nu există evaluări

- Class XII Computer Science: HOTS (High Order Thinking Skill)Document14 paginiClass XII Computer Science: HOTS (High Order Thinking Skill)JanakiÎncă nu există evaluări

- Dome AbcsDocument1 paginăDome AbcsRiddhi BhutadaÎncă nu există evaluări

- Chapter 19 - Managing Personal CommunicationDocument37 paginiChapter 19 - Managing Personal CommunicationAmit Thapa100% (2)

- Strategic Human Resource Development I SlidesDocument26 paginiStrategic Human Resource Development I SlidesAbhiman Behera50% (2)

- A Day in The Life of A Proactive Maintenance TechnicianDocument6 paginiA Day in The Life of A Proactive Maintenance TechnicianAshraf Al KirkuklyÎncă nu există evaluări

- Finaldc 2Document10 paginiFinaldc 2Noel BactonÎncă nu există evaluări

- Chap4 Student VersionDocument39 paginiChap4 Student VersionAzrif MoskamÎncă nu există evaluări

- Model 2000 Flow ComputerDocument8 paginiModel 2000 Flow ComputerAdnan SalihbegovicÎncă nu există evaluări

- Urban Transit Systems and Technology Vuchic PDFDocument614 paginiUrban Transit Systems and Technology Vuchic PDFARAVIND PATIL100% (1)

- Wet Scrapper Equipment SpecificationDocument1 paginăWet Scrapper Equipment Specificationprashant mishraÎncă nu există evaluări

- Al Washali2016Document17 paginiAl Washali2016tomi wirawanÎncă nu există evaluări

- GENRE DocumentaryDocument10 paginiGENRE Documentaryemilyweal123Încă nu există evaluări

- AlarmsReference ME-B 1212 PDFDocument130 paginiAlarmsReference ME-B 1212 PDFNAGENDRA KUMAR DÎncă nu există evaluări

- Year 11 IPT ProjectworkDocument12 paginiYear 11 IPT Projectworkoiu7hjjs50% (2)

- F Pv28T: PR EN 2714-013A/B/C/DDocument2 paginiF Pv28T: PR EN 2714-013A/B/C/DFredÎncă nu există evaluări

- DELL XPS 11 VAZ90 LA-A161P Rev 1.0 (A00) 20130814Document49 paginiDELL XPS 11 VAZ90 LA-A161P Rev 1.0 (A00) 20130814Sonel SmithÎncă nu există evaluări

- Rajib Mall Lecture NotesDocument97 paginiRajib Mall Lecture NotesAnuj Nagpal100% (1)

- Tim'S Tinkerings: My Ikea Billy' Bookcase Hack For Under $500Document1 paginăTim'S Tinkerings: My Ikea Billy' Bookcase Hack For Under $500Jolgra PokerÎncă nu există evaluări

- Strategic Control ProcessDocument18 paginiStrategic Control ProcessMudassir IslamÎncă nu există evaluări

- AllProducts catalogGREENHECKDocument52 paginiAllProducts catalogGREENHECKGenes Macalintal GalleneroÎncă nu există evaluări

- Abb CatDocument9 paginiAbb CatMukesh Kumar MeenaÎncă nu există evaluări

- Badger Range Guard Wet Chemical Cylinder Assemblies: FeaturesDocument4 paginiBadger Range Guard Wet Chemical Cylinder Assemblies: FeaturesLee WenjianÎncă nu există evaluări