Documente Academic

Documente Profesional

Documente Cultură

Tata Motors

Încărcat de

SandeepRaj0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări20 paginippt

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentppt

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări20 paginiTata Motors

Încărcat de

SandeepRajppt

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 20

Presentation on summer industrial training

FROM: SUBMITTED TO:

PRAVEEN KUMAR ASSISTANT PROFESOR

ME-B VIJAY KUMAR SINGH

CONTENT

1. Tata motors

2. Jamshedpur plant

3. Engine factory layout

4. Assembly line

5. Machining shop

6. Some information about cam & crank shaft, cylinder

head & block

7. Study of bearing

8. Recommendation

9. Workplace safety

10. Conclusion

Tata motors

JAMSHEDPUR (JHARKHAND): Heavy & Medium

Commercial Vehicle Unit

PUNE (MAHARASHTRA) : Passanger Car Commercial

Vehicle Unit

LUCKNOW (UTTAR PRADESH): Light Commercial Vehicle

Unit

PANTNAGAR (UTTARAKHAND): Light Commercial Vehicle

Unit

DHARWAD (KARNATAKA): light Commercial Vehicle Unit

RANJANGAON (MAHARASHTRA): Fiat and Tata cars and

Fiat power trains.

SANAND (GUJARAT): Tata Nano

Tata motors, Jamshedpur

Jamshedpur unit is 1

st

plant of the company

Major divisons are:

Truck Factory

Engine Factory

Cab & Cowl Factories

Forge and Foundry Factories

FRAME Factory

TML DRIVELINE

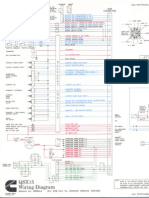

Engine factory layout

Assembely line

Machining shop

1. Cam shaft

2. Crank shaft

3. Cylinder head

4. Cylinder block

Cam shaft

Bearing eccentric cam lobes gear drive

In cam shaft machining line there are 15 work

station

Crank shaft

main bearing diameters.

Key way for

vibration damper

This is the timing

gear which

drives the

camshaft

These are the 6 crankpins for each of the

pistons. The crank pin and main bearing dia

parallelism should be within 10 microns.

Cylinder head

These two holes accommodate the

valves the bigger one is for the

inlet valve and the smaller one is

for the exhaust valve.

Fuel injector tip projects

from here.

Dowel hole

Dowel hole

This is the underside of the head.

For airtight sealing with the block, 3

parameters have to be checked -

Flatness not exceeding 0.05mm

Localized waviness

Surface finish

Cylinder block

The entire side face of

the cylinder bore is filled

with cooling water on

both sides.

This lower part of the

block is the crankcase

where the crankshaft

rotates. The cylinder

block and crankcase

are cast as an integral

unit.

Air compressor fits

here.

These two holes are drilled after

casting in the foundry. They are used

as reference for drilling the

machining reference on the sump

side.

These are the machining references

for subsequent machining of the

cylinder block.

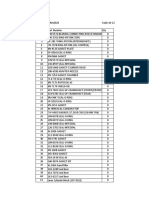

Bearing

Data analysis of its consumption in machine

shop

Study of bearing

Recommendation

Types of bearing

Rolling contact bearing:

Ball bearing

Roller bearing:

Needle roller bearing

Taper rolling bearing

Thrust bearing

Sliding contact bearing

Ball bearing

Able to handle both

radial and axial load

High speed

Low noise

Maintenance less

Roller bearing

Can hold heavy radial

loads

Types :

Needle bearing

Taper rolling bearing

Use:

Conveyer belt

Pump, compressor

Lubrication of bearing

Maintains a stable viscosity over a broad range

of temperatures

Good film strength that can support loads

Stable structure that provides for long service

life

Non-corrosive and compatible with adjacent

components

Provides a barrier against contaminant and

moisture

Recommendation

Lubricant Failure

Misalignment of bearings

Contamination

Corrosion

Excessive load

Reverse Loading

Tight Fits

Workplace safety

Safety class

Safety kit

Conclusion

Study of different division and processes

Assembly of engine

Analysis of bearing consumption and study

Visited different divisons like TML driveline

and truck factory

Get the opportunity to see the assembly of

tata prima truck

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Diagrama qsx15 PDFDocument7 paginiDiagrama qsx15 PDFJavier Agudelo F94% (18)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- MotorDocument4 paginiMotorAlexandru Manea0% (1)

- KTM 390 Tech Self Study Module PDFDocument26 paginiKTM 390 Tech Self Study Module PDFNikhil Jayanth83% (6)

- Series 300 3179, 4239, 6359, 4276, and 6414 Diesel Engines: Component Technical ManualDocument547 paginiSeries 300 3179, 4239, 6359, 4276, and 6414 Diesel Engines: Component Technical ManualPeter Rivera100% (3)

- Operation Stages HDI SIEMENSDocument9 paginiOperation Stages HDI SIEMENSSergio SambuelliÎncă nu există evaluări

- Microsoft Word - MA - QPDocument16 paginiMicrosoft Word - MA - QPSandeepRajÎncă nu există evaluări

- Ankit Final RMP ReportDocument3 paginiAnkit Final RMP ReportSandeepRajÎncă nu există evaluări

- Frigate Flyer Dribble ConveyorDocument1 paginăFrigate Flyer Dribble ConveyorSandeepRajÎncă nu există evaluări

- Online Application - NSPCL 2015 PDFDocument2 paginiOnline Application - NSPCL 2015 PDFSandeepRajÎncă nu există evaluări

- Experiment No.2Document6 paginiExperiment No.2SandeepRajÎncă nu există evaluări

- Blis-I Semester (Paper B-103 - Library Classification (Practical) ) DuDocument3 paginiBlis-I Semester (Paper B-103 - Library Classification (Practical) ) DuSandeepRaj100% (1)

- B 384 K 94 ApplicationformDocument1 paginăB 384 K 94 ApplicationformSandeepRajÎncă nu există evaluări

- Curriculum Vitae: Ankit SharmaDocument2 paginiCurriculum Vitae: Ankit SharmaSandeepRajÎncă nu există evaluări

- CHBT 3 FDocument4 paginiCHBT 3 FSandeepRajÎncă nu există evaluări

- (Firstname) (Middle/Initial) (Lastname)Document3 pagini(Firstname) (Middle/Initial) (Lastname)SandeepRajÎncă nu există evaluări

- BARC Syllabus 2015 For (CSE, ECE, EEE, Civil, Mechanical Engineering) - Recruitment, Result, Application Form, Admit CardDocument4 paginiBARC Syllabus 2015 For (CSE, ECE, EEE, Civil, Mechanical Engineering) - Recruitment, Result, Application Form, Admit CardSandeepRajÎncă nu există evaluări

- Shaurya Aggarwal: Contact No: 9568138576Document2 paginiShaurya Aggarwal: Contact No: 9568138576SandeepRajÎncă nu există evaluări

- Job Interview Questions & Answers - Mechanical EngineeringDocument8 paginiJob Interview Questions & Answers - Mechanical EngineeringSandeepRajÎncă nu există evaluări

- Three Major Categories of Sheet Metal ProcessesDocument2 paginiThree Major Categories of Sheet Metal ProcessesSandeepRajÎncă nu există evaluări

- Industrial TrainingDocument8 paginiIndustrial TrainingSandeepRajÎncă nu există evaluări

- Presentation On Heavy Engineering Corporation LimitedDocument20 paginiPresentation On Heavy Engineering Corporation LimitedSandeepRajÎncă nu există evaluări

- Mun2019 09 11Document1 paginăMun2019 09 11argentum19619692Încă nu există evaluări

- 2uztrd PDFDocument33 pagini2uztrd PDFbob loblawÎncă nu există evaluări

- M Di 0018Document3 paginiM Di 0018Miguel ruizÎncă nu există evaluări

- QQQQQQQQQQQQQQQQQQQQDocument8 paginiQQQQQQQQQQQQQQQQQQQQreal_paladineÎncă nu există evaluări

- Combustion & Combustion Chamber Design: Lecture-8Document122 paginiCombustion & Combustion Chamber Design: Lecture-8Tesfa TemesgenÎncă nu există evaluări

- FiatDocument4 paginiFiatdaniwesaÎncă nu există evaluări

- Manual de Servicio Deutz PDFDocument82 paginiManual de Servicio Deutz PDFDaniel Castillo Peña100% (1)

- How Fuel PumpDocument3 paginiHow Fuel PumpCarlos Carvajal AlvarezÎncă nu există evaluări

- SKODA OCTAVIA Turbo Removal How ToDocument16 paginiSKODA OCTAVIA Turbo Removal How Tovizitiub2934Încă nu există evaluări

- Honda IDSI SM - 5 PDFDocument14 paginiHonda IDSI SM - 5 PDFauto projectÎncă nu există evaluări

- Calculation Tool Engine CompressorxlsDocument64 paginiCalculation Tool Engine Compressorxlsfauzy2504Încă nu există evaluări

- List of Auto PartsDocument16 paginiList of Auto PartsVicky MotwaniÎncă nu există evaluări

- Land Rover TD5Document77 paginiLand Rover TD5Giovani Bottega100% (1)

- Experiment No: 2 Fuel Pump & InjectorsDocument4 paginiExperiment No: 2 Fuel Pump & InjectorsAjay JachakÎncă nu există evaluări

- Emergency Diesel Generator Engine Cooling SystemsDocument11 paginiEmergency Diesel Generator Engine Cooling SystemsEng1 ApollohxÎncă nu există evaluări

- Product Equivalents OIL PDFDocument5 paginiProduct Equivalents OIL PDFLucasÎncă nu există evaluări

- Yamaha FZ6-SS (SSC) 2004 Service ManualDocument432 paginiYamaha FZ6-SS (SSC) 2004 Service ManualBivol LeonidÎncă nu există evaluări

- Especificaciones PERKINS 1104CDocument5 paginiEspecificaciones PERKINS 1104CJesús Manuel Paz GonzálezÎncă nu există evaluări

- 07 1963 CH-Engine Tune-UpDocument3 pagini07 1963 CH-Engine Tune-UpJose LaproviteraÎncă nu există evaluări

- Repair ListDocument7 paginiRepair Listangga andi ardiansyahÎncă nu există evaluări

- 773E (Bda) Tier Ii 775E (Bec) Tier I Emissions Off-Highway TrucksDocument37 pagini773E (Bda) Tier Ii 775E (Bec) Tier I Emissions Off-Highway TrucksWilliams ArayaÎncă nu există evaluări

- Mazda Engine BP B6 Workshop Manual PDFDocument100 paginiMazda Engine BP B6 Workshop Manual PDFGabriel CalderonÎncă nu există evaluări

- PowerKit Datasheet 6M16G250-5Document4 paginiPowerKit Datasheet 6M16G250-5Sia NasserÎncă nu există evaluări

- Engine: Gasket DisassemblyDocument130 paginiEngine: Gasket DisassemblyChristian MartinezÎncă nu există evaluări

- Catbu1501 BeruDocument822 paginiCatbu1501 BeruceljkoÎncă nu există evaluări