Documente Academic

Documente Profesional

Documente Cultură

PP PP 02 Mmreview

Încărcat de

mailstosjDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PP PP 02 Mmreview

Încărcat de

mailstosjDrepturi de autor:

Formate disponibile

Production Planning 2 - 1

Section 2:

Materials Management and

MM Master Data Review

Production Planning

Production Planning 2 - 2

Production Planning

Sections

1. Production Planning Overview

2. Materials Management & MM Master Data

Review

3. Demand Planning & Long-term Planning

4. Master Production Schedule

5. Material Requirements Planning

6. Capacity Requirements Planning

7. Production Reports

8. Whats Next

Production Planning 2 - 3

Learning Objectives

Upon completion of this section, you will be able to:

Define the key terms related to Materials

Management and MM Master Data

Describe how MM/MM Master Data fits into the

SAP system

List the key MM Master Data processes described

in the AeLS courses

Production Planning 2 - 4

Materials Management Review

MM is a part of

SAPs integrated

enterprise

resource

planning (ERP)

system

Production Planning 2 - 5

MM Functionality

MM supports all phases of materials management:

Materials planning and control

Purchasing

Goods receiving

Inventory management

Invoice verification (a FICO task)

The system is updated with information from on-line

transactions from purchasing, inventory management, and

invoice verification

Provides real-time reporting capabilities

Production Planning 2 - 6

MM Key Terms and

Definitions

Term Definition

Material A substance or object dealt with on a

commercial basis or used, consumed, or

generated during production.

Example: P725003 Cover, Fl. Box Lg. Capacity

Purchasing Group A code indicating a buyer or group of buyers

responsible for a material or material group.

Example: 102 Jim Simkins

Purchasing

Organization

An organizational level that negotiates

conditions of purchase with vendors for one

or more plants. It is legally responsible for

completing purchasing contracts.

Example: 3000 Hubbell Wiring Sys.

Production Planning 2 - 7

MM Key Terms and

Definitions (continued)

Term Definition

MRP

Materials requirements planning is

the process of planning materials

for current and future requirement.

Vendor

A business partner from whom

materials or services are procured.

Production Planning 2 - 8

MM Master Data Review

MM Master Data is a primary component of MM, along with

Inventory Management, Purchasing, and Warehouse Management

MM Master Data

WM

IM

PR

Production Planning 2 - 9

Production Planning

Master Data

Master

Data

Routing

Material

Master

Work Center

Capacity /

Resources

Bill

of

Material

Production Planning 2 - 10

Working with Master Data -

Overview

Master data is used in every transaction in the system

Master data contains information that is frequently needed and

in the same format

Information is read from the material master data and

defaulted in transactional data such as:

Bills of Material

Purchase orders

Routings

Master data changes do not change previously created

transactions

Master data generally resides in the system for a long time and

security access is restricted

Production Planning 2 - 11

Benefits of Master Data

All material data are stored in a single database, thereby

eliminating redundant data storage

Information is created once, minimizing data input

Real-time data is available for review at any time

Data is integrated with other SAP modules and processes:

Order Management

Inventory Management (IM)

Warehouse Management (WM)

Accounts Receivable (AR)

Accounts Payable (AP)

Goods Receipt and Movement

Production Scheduling

Production Planning 2 - 12

Material Master Record Views

Basic Data

Classification

Quality

Management

Warehouse

Management

Material

Master

Record

MRP

Accounting

Costing

Forecasting

Sales

Storage

Work

Scheduling

Purchasing

Production Planning 2 - 13

Material Types Review

Material type (for example, raw material or finished

good) determines which views are created

Hubbell has identified the following material types:

ZFIN Finished Goods

ZSEM Semi-Finished Goods

ZRAW Raw

ZPKG Packaging

ZSER Services

ZMRO Operating Supplies

ZCFG Configurable Materials

Production Planning 2 - 14

Selecting Material Views

Material type drives the

possible material views

List of possible views for

ZRAW

Use the vertical

scrollbar to see

additional

available views

Production Planning 2 - 15

Material Master Record Views

Views Fields Description

Basic data 1 Basic Unit of

Measure

Material unit of measure, i.e., EA, LB, BT

Purchasing Purchasing

Group

Responsible buyer or department

MRP1 MRP Type Key that determines how a material is planned

MRP2 Procurement

type

Defines how a material is procured, i.e. in-house

GR Processing

time

Number of days required from the receipt of

goods for inspection and placement into storage

Plnd delivery

time

Number of days to obtain an externally procured

material

Safety Stock Quantity required to satisfy unexpectedly high

demand and/or inconsistent supply

This is a list of

the views and

fields on a

material master

record relevant

to creating MRP

purchase

requisitions

Production Planning 2 - 16

Material Master Record Views

(continued)

Views Field Description

MRP3 Period indicator Specifies period in which the consumption

values and the forecast value are managed, i.e.,

monthly

Availability

check

Procedure that ensures enough components are

available for planned or production orders.

Indicates how or when availability is checked,

i.e., 01=Daily requirement

MRP4 Component

Scrap

Percentage of scrap that occurs during

production

Accounting 1 Standard price Standard price of material

Stor. location

stock

Stor. Loc. Where material is stored in the warehouse

Production Planning 2 - 17

MM/PP Key Master Data Terms

Term Definition

Bill of Material

(BOM)

Complete list of components making up a

product, including description, quantity, unit

of measure, document information records,

comments, and notes

Alternate BOM A modified BOM with a new effectivity date.

Allows you to make significant changes to the

BOM, while maintaining the original BOM

structure

Capacity

Defines the ability of a work center to perform

a task: Can be measured in time (as in hours)

or in units

Material Master

Data Record

Contains a complete set of data for all material

procured, sold, produced, and stored

Production Planning 2 - 18

MM/PP Key Master Data Terms

(continued)

Term Definition

Material Type

Grouping of materials with same basic

attributes, allowing these materials to be

uniformly managed

Routing

List of operations that must be performed in

sequence to manufacture a product

Work Center An organizational unit that defines where an

operation must be performed: Can be a

person, machine, or product line; includes

information about capacity planning

Production Planning 2 - 19

Learning Review

You should now be able to:

Define the key terms related to Materials

Management and MM/PP Master Data

Describe how MM/PP Master Data fits into

the SAP system

List the key MM Master Data processes

described in the AeLS courses

Production Planning 2 - 20

This completes the review of

the AeLS prerequisites:

Materials Management Overview

MM Master Data

Questions?

S-ar putea să vă placă și

- SAP Implementation Project: Business Blueprint Key Data Structure Material Management ModuleDocument12 paginiSAP Implementation Project: Business Blueprint Key Data Structure Material Management ModuleAasif Ahmed Jalaludeen80% (5)

- Google Cloud Platform for Data Engineering: From Beginner to Data Engineer using Google Cloud PlatformDe la EverandGoogle Cloud Platform for Data Engineering: From Beginner to Data Engineer using Google Cloud PlatformEvaluare: 5 din 5 stele5/5 (1)

- Archiving StrategyDocument14 paginiArchiving StrategyAmit Guglani100% (2)

- Materials Requirement PlanningDocument12 paginiMaterials Requirement PlanningJoju JohnyÎncă nu există evaluări

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyDe la EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyEvaluare: 4 din 5 stele4/5 (6)

- PP Training Presentation M&MDocument49 paginiPP Training Presentation M&MNikhil WaniÎncă nu există evaluări

- SAP Production Planning: A Workshop That Provides An Overview of The SAP R/3 Production Planning (PP) ModuleDocument177 paginiSAP Production Planning: A Workshop That Provides An Overview of The SAP R/3 Production Planning (PP) ModuleShaffiullahÎncă nu există evaluări

- Computer Aided Computer Aided Production Production Planning and Planning and Control Control (Lecture #11) (Lecture #11)Document43 paginiComputer Aided Computer Aided Production Production Planning and Planning and Control Control (Lecture #11) (Lecture #11)Sreedhar PugalendhiÎncă nu există evaluări

- What Is SAPDocument17 paginiWhat Is SAPSunil KumarÎncă nu există evaluări

- Sap Production Planning (Old)Document100 paginiSap Production Planning (Old)Nina PagkatipunanÎncă nu există evaluări

- INTERVIEWDocument8 paginiINTERVIEWSireesha ReddyÎncă nu există evaluări

- OM Critics On Journal Ind AssignDocument15 paginiOM Critics On Journal Ind AssignJeffrilim VkiatÎncă nu există evaluări

- Module-4: Material Requirement Planning (MRP)Document10 paginiModule-4: Material Requirement Planning (MRP)DhiyaneshÎncă nu există evaluări

- CH 5 MRPDocument20 paginiCH 5 MRPahsanzia62Încă nu există evaluări

- Make To Stock Planning StrategiesDocument4 paginiMake To Stock Planning StrategiesAJay DumpalaÎncă nu există evaluări

- PP MFG End UserDocument92 paginiPP MFG End Userprasadpandit123Încă nu există evaluări

- ERP Assignment 1Document10 paginiERP Assignment 1Ankit SinghÎncă nu există evaluări

- 0-Erp - Sap OverviewDocument99 pagini0-Erp - Sap OverviewSABARI NATHANÎncă nu există evaluări

- A Study On Manufacturing Resources Planning of Tamilnadu Cement Corportation Limited at AriyalurDocument25 paginiA Study On Manufacturing Resources Planning of Tamilnadu Cement Corportation Limited at Ariyalurk eswariÎncă nu există evaluări

- Materials Management - Aim, Functions and FlowDocument29 paginiMaterials Management - Aim, Functions and FlowvijiÎncă nu există evaluări

- Materials Management Instructor Guide MM300 - Intro To MM Chapter 1 - GeneralDocument5 paginiMaterials Management Instructor Guide MM300 - Intro To MM Chapter 1 - Generalnaresh08Încă nu există evaluări

- SAP MM Master DataDocument14 paginiSAP MM Master Datamimmopianese100% (2)

- Material Type ConfigurationDocument24 paginiMaterial Type ConfigurationShailendra TiwariÎncă nu există evaluări

- Material Requirement Plannin1Document4 paginiMaterial Requirement Plannin1Shikha ThapaÎncă nu există evaluări

- Production CycleDocument11 paginiProduction CycleClaire JOY PascuaÎncă nu există evaluări

- Cp-4 Erp A Manufacturing PerspectiveDocument32 paginiCp-4 Erp A Manufacturing PerspectiveMinu SahÎncă nu există evaluări

- 2011-1-Training Manual On Material ManagementDocument119 pagini2011-1-Training Manual On Material ManagementPrudhvikrishna GurramÎncă nu există evaluări

- Material Requirements PlanningDocument5 paginiMaterial Requirements PlanningNiño Rey LopezÎncă nu există evaluări

- MRP Assignment PraveenDocument9 paginiMRP Assignment PraveenPraveen MishraÎncă nu există evaluări

- Production CycleDocument37 paginiProduction Cycleara amelÎncă nu există evaluări

- Materials ManagementDocument35 paginiMaterials ManagementarÎncă nu există evaluări

- 7 1 MRP ProcessDocument27 pagini7 1 MRP ProcessAshokÎncă nu există evaluări

- List of Business Processes To Be Implemented: 1.1 Master DataDocument41 paginiList of Business Processes To Be Implemented: 1.1 Master DataSowjanya KÎncă nu există evaluări

- Learn SAP PP in 1 Day: ALL RIGHTS RESERVED. No Part of This Publication May Be Reproduced orDocument23 paginiLearn SAP PP in 1 Day: ALL RIGHTS RESERVED. No Part of This Publication May Be Reproduced orAmr ShararaÎncă nu există evaluări

- Benefits of MRP 001Document4 paginiBenefits of MRP 001lynnthuÎncă nu există evaluări

- Material Requirement PlanningDocument23 paginiMaterial Requirement Planningsangaleabhi100% (1)

- Mrp1 Mrp2 ErpDocument14 paginiMrp1 Mrp2 ErpAarti Ck100% (1)

- 310 CH 6Document24 pagini310 CH 6Ashok SharmaÎncă nu există evaluări

- Decoding MRP and MRP ViewsDocument15 paginiDecoding MRP and MRP ViewsBalanathan Virupasan100% (1)

- Computer Aided Production Planning and Control JomyDocument32 paginiComputer Aided Production Planning and Control JomyJo100% (2)

- Production: © SAP University AllianceDocument29 paginiProduction: © SAP University AlliancesameeÎncă nu există evaluări

- Unit III ErpDocument16 paginiUnit III ErpSûrèndhár ChîYān RàsígânÎncă nu există evaluări

- mrp2-3 FinalDocument33 paginimrp2-3 FinalMatthew Smith50% (2)

- Management Science/Unit-VI 1Document16 paginiManagement Science/Unit-VI 1GOVIND LAKKARAJUÎncă nu există evaluări

- PP NotesDocument33 paginiPP NotesRohail Tahir100% (1)

- Aggregate Resource PlanningDocument8 paginiAggregate Resource PlanningAbhishek ThakurÎncă nu există evaluări

- Sales and DistributionDocument32 paginiSales and Distributionraghunandan2293Încă nu există evaluări

- Everis Training: SAP PP Training Chapter 4 - Master Data in Production Planning December, 2007Document39 paginiEveris Training: SAP PP Training Chapter 4 - Master Data in Production Planning December, 2007GilbertoÎncă nu există evaluări

- Introduction To: MRP & ErpDocument42 paginiIntroduction To: MRP & ErpAnupama P Shankar100% (1)

- MM 1 003 Master DataDocument16 paginiMM 1 003 Master DataAnwar Bin Saleem MirzaÎncă nu există evaluări

- CPIM (Certified in Production and Inventory Management)Document9 paginiCPIM (Certified in Production and Inventory Management)TannelsÎncă nu există evaluări

- Technical Aspects in LIS With Special Focus On ProductionDocument108 paginiTechnical Aspects in LIS With Special Focus On Productiondinhlap237Încă nu există evaluări

- BME1 Operations MGT Chapter 7Document8 paginiBME1 Operations MGT Chapter 7Cristina maeÎncă nu există evaluări

- Production Planning Document - MainDocument3 paginiProduction Planning Document - MainSureshÎncă nu există evaluări

- PP Master Data SAPDocument31 paginiPP Master Data SAPDavid100% (2)

- Global Bike IncDocument39 paginiGlobal Bike IncSameet DoshiÎncă nu există evaluări

- Materials Requirement PlanningDocument5 paginiMaterials Requirement PlanningJohn Yaoto100% (1)

- Practical Guide To Production Planning & Control [Revised Edition]De la EverandPractical Guide To Production Planning & Control [Revised Edition]Evaluare: 1 din 5 stele1/5 (1)

- Dates Decimals in SAPDocument3 paginiDates Decimals in SAPmailstosjÎncă nu există evaluări

- Consulting Response For Training RequestDocument50 paginiConsulting Response For Training RequestmailstosjÎncă nu există evaluări

- 611 SAPMassChangeDocument9 pagini611 SAPMassChangemailstosjÎncă nu există evaluări

- How To Print From SAPDocument4 paginiHow To Print From SAPmailstosjÎncă nu există evaluări

- Implementation Strategies For SAP R3 in A Multinational OrganizationDocument369 paginiImplementation Strategies For SAP R3 in A Multinational OrganizationRositsa Ivanova100% (2)

- Fortune 500 ListDocument12 paginiFortune 500 ListmailstosjÎncă nu există evaluări

- Net StatDocument3 paginiNet StatchraimÎncă nu există evaluări

- CISSP Study PlanDocument6 paginiCISSP Study PlanDudeviswaÎncă nu există evaluări

- TURBOARD International Trade AnalyticsDocument11 paginiTURBOARD International Trade AnalyticsYasemin ŞahinÎncă nu există evaluări

- SEO Implementation ChecklistDocument7 paginiSEO Implementation ChecklistSatya RaoÎncă nu există evaluări

- 1 - SAPBI - Unload HierarchiesDocument28 pagini1 - SAPBI - Unload HierarchiesMark SteenhoekÎncă nu există evaluări

- UCCX Integration With Office 365 For AgeDocument12 paginiUCCX Integration With Office 365 For AgeRafael SalgadoÎncă nu există evaluări

- Aws Interview Questions - Oracle DBA Useful InformationDocument7 paginiAws Interview Questions - Oracle DBA Useful InformationcharlesgsamÎncă nu există evaluări

- EDI Specifications 850Document9 paginiEDI Specifications 850Ankita TripathiÎncă nu există evaluări

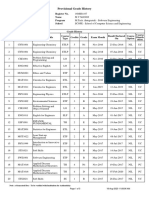

- Provisional Grade History: Register No. Name Program SchoolDocument5 paginiProvisional Grade History: Register No. Name Program SchoolMike RomeoÎncă nu există evaluări

- Slick Envi Nitf ModuleDocument1 paginăSlick Envi Nitf ModuleVijay KumarÎncă nu există evaluări

- Enkitec RealWorldExadataDocument38 paginiEnkitec RealWorldExadatatssr2001Încă nu există evaluări

- Ramada Limited Policy and Procedure Manual Section6 5Document2 paginiRamada Limited Policy and Procedure Manual Section6 5Usama JavedÎncă nu există evaluări

- Ankit's Resume 2023Document1 paginăAnkit's Resume 2023Harneesh Singh ChhabdaÎncă nu există evaluări

- BPOS Standard Deployment Guide February2010 PDFDocument100 paginiBPOS Standard Deployment Guide February2010 PDFRuben Dario Pinzón ErasoÎncă nu există evaluări

- Academic - Transcript20221017 46 rpxqj6Document8 paginiAcademic - Transcript20221017 46 rpxqj6SanLynnAungÎncă nu există evaluări

- 8 SDLC - ClassDocument15 pagini8 SDLC - Classsandra072353Încă nu există evaluări

- SOLMAN Solution Manager CEN and Alerting Configuration Guide For DummiesDocument5 paginiSOLMAN Solution Manager CEN and Alerting Configuration Guide For DummiesbardouniÎncă nu există evaluări

- Configuring Siebel Eai WorkflowsDocument20 paginiConfiguring Siebel Eai WorkflowsJoelRotichÎncă nu există evaluări

- Set Up OpenDMARC With Postfix On CentOSRHEL To Block Email SpoofingDocument11 paginiSet Up OpenDMARC With Postfix On CentOSRHEL To Block Email SpoofingMordor Chalice100% (1)

- CCNA 3 - ENSA Practice PT Skills Assessment (PTSA) AnswersDocument19 paginiCCNA 3 - ENSA Practice PT Skills Assessment (PTSA) Answersfabrizio fioriÎncă nu există evaluări

- 402 IT Sample PaperDocument10 pagini402 IT Sample Paperkrishparjapat2008Încă nu există evaluări

- Python Classes Objects Special Methods Inheritance, Polymorphism, EncapsulationDocument138 paginiPython Classes Objects Special Methods Inheritance, Polymorphism, EncapsulationMK JAYANTHI KANNANÎncă nu există evaluări

- Rekognition DGDocument449 paginiRekognition DGpark hyoÎncă nu există evaluări

- What Is An IT ProjectDocument3 paginiWhat Is An IT ProjectPsychopath HunterÎncă nu există evaluări

- Lecture 02 EEL4781Document9 paginiLecture 02 EEL4781Mary DunhamÎncă nu există evaluări

- Health Prediction Using Data MiningDocument3 paginiHealth Prediction Using Data MiningUsman YousafÎncă nu există evaluări

- Enabling ADOP Online PatchingDocument6 paginiEnabling ADOP Online PatchingKingÎncă nu există evaluări

- Ic102 AssignmentDocument1 paginăIc102 AssignmentJoesamay CaingalÎncă nu există evaluări

- Serv-U User's ManualDocument82 paginiServ-U User's ManualAnh Quốc LêÎncă nu există evaluări

- Informe Lab52 Q1 - 2023 - EN - 23-05-2023Document26 paginiInforme Lab52 Q1 - 2023 - EN - 23-05-2023sandrajony20Încă nu există evaluări

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)