Documente Academic

Documente Profesional

Documente Cultură

LimeKiln Modeling

Încărcat de

arv_dev0 evaluări0% au considerat acest document util (0 voturi)

256 vizualizări40 paginiThe document discusses modeling lime kilns used in pulp and paper mills. It provides an overview of the modeling process, which involves building a computer model of the real-size kiln and using computational fluid dynamics and other mathematical models to simulate processes within the kiln. The modeling can be used to optimize burner design, evaluate different fuel types, minimize emissions, and improve kiln performance and operations. Inputs to the kiln model include detailed measurements of the kiln and operating conditions as well as models of chemical and physical processes within the kiln. Model outputs provide detailed visualization and profiles of conditions throughout the kiln.

Descriere originală:

Titlu original

LimeKiln Modeling.ppt

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document discusses modeling lime kilns used in pulp and paper mills. It provides an overview of the modeling process, which involves building a computer model of the real-size kiln and using computational fluid dynamics and other mathematical models to simulate processes within the kiln. The modeling can be used to optimize burner design, evaluate different fuel types, minimize emissions, and improve kiln performance and operations. Inputs to the kiln model include detailed measurements of the kiln and operating conditions as well as models of chemical and physical processes within the kiln. Model outputs provide detailed visualization and profiles of conditions throughout the kiln.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

256 vizualizări40 paginiLimeKiln Modeling

Încărcat de

arv_devThe document discusses modeling lime kilns used in pulp and paper mills. It provides an overview of the modeling process, which involves building a computer model of the real-size kiln and using computational fluid dynamics and other mathematical models to simulate processes within the kiln. The modeling can be used to optimize burner design, evaluate different fuel types, minimize emissions, and improve kiln performance and operations. Inputs to the kiln model include detailed measurements of the kiln and operating conditions as well as models of chemical and physical processes within the kiln. Model outputs provide detailed visualization and profiles of conditions throughout the kiln.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 40

Modeling Lime Kilns in

Pulp and Paper Mills

Process Simulations Ltd.

#206, 2386 East Mall, Vancouver, BC, Canada

www.psl.bc.ca

August 23, 2006

Lime Kiln Issues

Kiln efficiency

Lower fuel costs

Burner characteristics

Refractory life

Dams and rings

Stable operation

Primary Air

Secondary Air

Gas/Oil

Firehood

Burner

Motor

Chains

Limestone CaCO

3

Lime CaO

DRYING

ZONE

CALCINING

ZONE

BURNING

ZONE

COOLING

ZONE

Principle of Conservation

Mass

Momentum

Energy

.

IN = OUT

IN

OUT

OUT

Computational Modeling

Build a real size kiln model

Use computer to solve

equations

Simulate processes in kiln

Mathematical Models for Kiln

Fully three-dimensional Reynolds-

averaged transport equations of mass,

momentum energy, and chemical species

Block-structure body-fitted coordinates

with domain segmentation

Two-equation k-e turbulence model

Ray tracing model for 3D radiation heat

transfer

Gas combustion model

Lagrangian solid fuel combustion models

Refractory and Calcination Models

Multi-layer refractory heat transfer model

Heat transfer and lime calcination

CaCO

3

= CaO + CO

2

Heat absorbed 1.679 MJ/kg CaCO

3

@1089K

Modeling Output:

Gas Velocity

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60

Vmag

[m/s]

Case 6

Modeling Output:

Gas Temperature

400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500 2600 2700 2800 2900 3000

Tgas

[F]

Case 6

Modeling Output:

Gas Species Concentrations

* Other species include CO, H

2

O, NOx, etc.

Modeling Output:

Flame Shape

0

-5

Modeling Output:

Refractory Temperature

Modeling Output:

Shell Temperature

Average Shell Temperature

0

50

100

150

200

250

300

350

400

0 30 60 90

Axial Distance (m)

T(C)

Model

Shell Scan

Modeling Output:

Kiln Axial Profiles

Distance fromKiln Hood [m]

T

e

m

p

e

r

a

t

u

r

e

o

f

G

a

s

a

n

d

L

i

m

e

[

K

]

V

o

l

u

m

e

F

r

a

c

t

i

o

n

o

f

O

2

,

C

O

2

,

H

2

O

i

n

F

l

u

s

G

a

s

[

v

o

l

%

]

E

m

i

s

s

i

o

n

o

f

N

O

i

n

F

l

u

e

G

a

s

[

p

p

m

v

]

M

a

s

s

F

r

a

c

t

i

o

n

o

f

L

i

m

e

C

o

m

p

o

n

e

n

t

s

[

w

t

%

]

0 20 40 60 80 100

5

0

0

1

0

0

0

1

5

0

0

2

0

0

0

0

5

10

15

20

25

30

35

40

0

1

0

0

2

0

0

3

0

0

4

0

0

5

0

0

0

10

20

30

40

50

60

70

80

90

100

F

e

e

d

E

n

d

F

i

r

e

E

n

d

Tgas

CaCO

3

CaO

Tck

NO

CO

2

O

2

H

2

O

Predicted Axial Profile Data

Modeling Output:

Gas Flow Animation

Modeling Output:

Solid Fuel Flow Animation

Value and Benefit of Kiln Modeling

Optimize burner design

Optimize kiln performance

Evaluate alternative fuels

Minimize Emissions

Identify and eliminate thermal hot spots

that lead to reduced brick lining lifetime

Identify and fix problems with kiln

performance

Improve waste gas incineration

Advantages of Kiln Modeling

Model provides comprehensive information

throughout kiln at relatively low cost

Can evaluate what if scenarios to

improve operation

Supplements operator knowledge of lime

kiln operations

Assists mill managers in making decisions

regarding kiln retrofits/replacements

Assists in optimizing burner and kiln

designs

Modeling Application:

Burning Different Fuels

Heavy Oil

Petroleum Coke

Natural Gas

Modeling Application:

Oil/Gas Burner Design

Modeling Application:

Coal Burner Design & NOx Emission

R1

R2

R3

Swirl Air

20 vanes

groove width = 17.7 mm

slot width =18.8 mm;

20 degrees

R0

R4

R5

R6

Coal

Transport Air

Axial Air

24 holes

18 mm Dia

R1

axial air

24 slots

0.0245 (1") wide

0.0130 (0.51") deep

21 degrees inward

R2

R4

R3

R5

R0

Swirl air

No swirl

Transport air

Swirl Air

20 vanes

groove width = 17.7 mm

slot width =18.8 mm;

20 degrees

Modeling Application:

Direct & Indirect Coal Combustion

Axial Air

Coal Air

Axial Air

Coal Air

Swirl Air

Swirl Air

Coal Air

Coal Air

Modeling Application:

Burner with Different Primary Air

Oil Flame

@ Primary Air

Ratio of 22%

Oil Flame

@ Primary Air

Ratio of 60%

Modeling Application:

Burning NCG in Kilns

Case 2: NCG incineration with less HVLC

Case 3: NCG incineration with more HVLC

Case 4: No NCG incineration with less natural gas

Gas temperature on a vertical cross section

400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800

Case 1: No NCG incineration with more natural gas

T [K]

Kiln Modeling Inputs: Overview

Site Survey and

Measurements

Mass and Energy Balance

Calculation

Kiln Geometry

Refractory Lining

Burner Design

Lime Feed Properties

Air Supplies

DCS Data Analysis

Kiln Modeling Inputs:

Site Survey and Measurements

Measured

streams:

- air in

- fuel in

- flue gas out

- mud in

- product out

Measured

parameters:

- flow rate

- temperature

- composition

Kiln Modeling Inputs:

Example of Mass Balance

Mass In = Mass Out

Kiln Modeling Inputs:

Example of Energy Balance

Energy In = Energy Out

Kiln Modeling Inputs:

Kiln Geometry - Fire End

10' 6" Dia.

Barrel Tilt = 1.7899 = 3/8" per 12"

o

Burner

4' 2 3/4"

24"

24"

9"

5' 6"

2' 9"

17 3/4"

kiln c

L

Z

X

Barrel Start

(non rotated)

Kiln Modeling Inputs:

Kiln Geometry - Front View

Hood

dimension, kiln

diameter and

length, tilt

angle, kiln

rotation

Location and

size of any

openings

Location and

tilt angle of

burner

15"

5' 3"

6' 7"

7' 3"

6 1/2"

4 1/2"

2 3/4"

2' 4 3/4"

15"

24" 12"

dia=?

24"

24"

2' 7/8"

15

o

20" Dia.

Y

X

Kiln Modeling Inputs:

Kiln Burner Design

Kiln Modeling Inputs:

Refractory Lining and Property

9"

70%Alumina

9"

Magnel RSV

9"

70%Alumina

2-1/2"

Greenlite HS

6"

Clipper DP

3-1/2"

Mix Refratherm

Greenlite

3"

Greenlite HS

6"

Castable

6"

Castable

0

'

0

m

2

'

0

.

6

0

9

6

m

9

.

5

'

2

.

8

9

5

6

m

1

9

.

5

'

5

.

9

4

3

6

m

3

9

.

5

'

1

2

.

0

3

9

8

8

4

.

5

'

2

5

.

7

5

5

6

m

1

3

4

.

5

'

4

0

.

9

9

5

6

m

2

1

6

'

6

5

.

8

3

6

8

m

2

2

1

'

6

7

.

3

6

0

8

m

2

2

6

.

5

'

6

9

.

0

3

7

2

m

Burner

3'

0.9144m

6"

0.1524m

18"

0.4572m

39"

0.9906m

1

0

2

"

2

.

5

9

0

8

m

1

0

'

3

.

0

4

8

m

6

'

7

"

2

.

0

0

6

6

m

9

7

"

2

.

4

6

3

8

m

1

0

2

"

2

.

5

9

0

8

m

1

0

8

"

2

.

7

4

3

2

m

54'

16.4592m

Chain

System

1

0

1

"

2

.

5

6

5

4

m

0 1

2

2

3

3

4

4

4

0

a T a T a T a T a T a

j

j

j

thermal conductivity, W/mk

T temperature, K

Material

4

a

3

a

2

a

1

a

0

a

Greenlite -2.554e-7 7.878e-4 5.248e-2

Refratherm 150 -3.571e-7 8.021e-4 0.1576

Magnel RSV 2.394e-12 -1.332e-8 2.771e-5 -0.02586 12.54

Kruzite - 70 5.908e-7 -0.0013 2.301

Clipper DP -3.571e-7 8.021e-4 0.1576

Kiln Modeling Inputs:

Kiln Lime Mud

Kiln Modeling Inputs:

Kiln DCS Data Display

Kiln Modeling Inputs:

Kiln Operational Data Analyzer

Kiln Modeling Inputs:

Selected Data Windows - 1

Kiln Modeling Inputs:

Selected Data Windows - 2

Kiln Modeling Inputs:

Computed Secondary Air Area

Kiln Modeling Inputs:

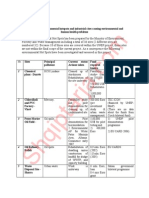

Averaged Mill DCS Data

Parameter Case 1

9/25/2003 8:30 to

10/2/2003 14:30

AIR

Primary Air Flow (kg/s) 1.28

Excess O2 (%) 1.34%

FEED

Dry Feed rate (kg/s) 6.14

Dust Losses (% dry feed) 10.8%

PRODUCT

CaO Production Rate (kg/s) 2.99

CaCO3 Remaining (% of Product) 1.86%

FUEL OIL

Fuel flow-crude tall oil (kg/s) 0.444

MISCELLANEOUS

Feed end draft (Pa) -535.1

Firing end draft (Pa) -124.1

Lime feed solids content 80%

Inerts (% of Product) 4%

AVERAGE DCS DATA

Time period for data average

SUPPLIED OR ESTIMATED DATA

Kiln Modeling Inputs:

Operation Conditions - Lime & Fuel

Production rate 274.42 tpd 3.1761 kg/s

Total feed rate 663.12 tpd 7.6750 kg/s

Solids content 80% 80%

CaCO3 462.23 tpd 5.3498 kg/s

Dust 57.29 tpd 0.6631 kg/s

Inerts 10.98 tpd 0.1270 kg/s

Moisture 132.62 tpd 1.54 kg/s

663.12 tpd 7.6750 kg/s

Oil flow rate 0.4440 kg/s

Oil composition 100.00%

Carbon 78.30% 0.3477 kg/s

Hydrogen 9.88% 0.0439 kg/s

Oxygen 11.57% 0.0514 kg/s

Nitrogen 0.00% 0.0000 kg/s

Sulphur 0.14% 0.0006 kg/s

Ash 0.11% 0.0005 kg/s

High heat value 44.7040 MJ/kg

Density 935.0 kg/m3

Oil temperature 230

o

F

383 K

Stoichiometric air ratio for oil combustion 12.0178 kgAir/kgOil

Stoichiometric air for oil combustion 5.3359 kg/s

Atomizing steam flow rate lb/hr 0.08 kg/s

Mixture flow rate 0.5240

Mass fraction of oil in mixture 0.8473

Total heat input 19.8 MW

LIME

FUEL

Kiln Modeling Inputs:

Operation Conditions - Air Supply

Excess air ratio 8.51%

Stochiometric air flow rate*(1+excess air ratio) 5.7900 kg/s

PRIMARY AIR

Primary air flow rate 1.2800 kg/s

Primary air temperature 298.15 K

Primary air density 1.1835 kg/m^3

Primary Axial Air 25.0% 0.3200 kg/s

Primary Spin Air 75.0% 0.9600 kg/s

SECONDARY AIR

Secondary air temperature 298.15 K

Secondary air density 1.1835 kg/m^3

Left side flow area 0.2027 m*m

Right side flow area 0.2027 m*m

Left side open area ratio 5.00%

Right side open area ratio 5.00%

Left side flow velocity 13.0334 m/s

Right side flow velocity 13.0334 m/s

Left side flow rate 0.1563 kg/s

Right side flow rate 0.1563 kg/s

BURNER/HOOD GAP AIR

Burner/Hood gap air temperature 298.15 K

Burner/Hood gap air density 1.1835 kg/m^3

Burner/Hood gap area 0.0488 m*m

Burner/Hood gap open area ratio 80.00%

Burner/Hood gap velocity 13.0334 m/s

Burner/Hood flow rate 0.6018 kg/s

DISCHARGE GRATE AIR

Discharge grate air temperature 450 K

Discharge grate air density 0.7841 kg/m^3

Discharge grate area 0.5226 m*m

Discharge grate open area ratio 54.80%

Discharge grate velocity 16.0120 m/s

Discharge grate flow rate 3.5956 kg/s

Total air flow rate 5.7901 kg/s

Total air flow rate - stochiometric air flow rate 0.0001 kg/s

Air

Kiln Modeling Inputs:

Flue Gas Calculation

species

Molecular

Weight

Volume % Mass %

H2O 2.0098 kg/s 18 31.3% 19.7%

CO2 3.6287 kg/s 44 23.1% 35.6%

O2 0.1044 kg/s 32 0.92% 1.02%

N2 4.4583 kg/s 28 44.6% 43.7%

SO2 0.0012 kg/s 64 0.005% 0.012%

Total 10.2024 kg/s 100.0% 100.0%

species

Molecular

Weight

Volume % Mass %

CO2 3.6287 kg/s 44 33.7% 44.3%

O2 0.1044 kg/s 32 1.33% 1.27%

N2 4.4583 kg/s 28 65.0% 54.4%

SO2 0.0012 kg/s 64 0.0% 0.015%

Total 8.1926 kg/s 100.0% 100.0%

mass flow

True Flue Gas Calculation (dry based)

mass flow

True Flue Gas Calculation (wet based)

Gas Constant 287.15

Ambient Pressure 101325 Pa

Ambient Temperature 298.15 K

Loss Coefficient 0.9

Firing End Draft -124.1 Pa

kg/s to tpd (metric) 86.4

28 16 44

1 CO + 0.5*O2 = CO2

16 64 44 36

2 CH

4

+ 2*O

2

= CO

2

+ 2*H

2

O

2 16 18

3 H

2

+ 0.5*O

2

= H

2

O

12 32 44

4 C + O2 = CO2

100 44 56

5 CaCO

3

= CO

2

+ CaO

14 16 30

6 N + 0.5*O2 = NO

32 32 64

7 S + O2 = SO2

Species Reactions (with molecular weights)

S-ar putea să vă placă și

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDe la EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasÎncă nu există evaluări

- Heat BalanceDocument18 paginiHeat BalanceVinish Shankar100% (1)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationDe la EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosÎncă nu există evaluări

- Kiln Heat and Mass Balance September 2010Document20 paginiKiln Heat and Mass Balance September 2010samuel libsework50% (2)

- Flame and Combustion Forcement Kilns KPK PDFDocument62 paginiFlame and Combustion Forcement Kilns KPK PDFPradeep KumarÎncă nu există evaluări

- Rotary Kilns: Transport Phenomena and Transport ProcessesDe la EverandRotary Kilns: Transport Phenomena and Transport ProcessesEvaluare: 4.5 din 5 stele4.5/5 (4)

- Formulas KilnDocument53 paginiFormulas KilnNael93% (14)

- Combustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsDe la EverandCombustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsEvaluare: 3 din 5 stele3/5 (1)

- Kiln Preheater Fan CoatingDocument6 paginiKiln Preheater Fan CoatingVijay Bhan100% (1)

- Theory and Calculation of Heat Transfer in FurnacesDe la EverandTheory and Calculation of Heat Transfer in FurnacesEvaluare: 3 din 5 stele3/5 (4)

- Heat BalanceDocument3 paginiHeat Balanceayaskant751001Încă nu există evaluări

- Thermos Design of Rotary Kiln For Reduction of Radiantion LossesDocument20 paginiThermos Design of Rotary Kiln For Reduction of Radiantion LossesMadhav Krishna MÎncă nu există evaluări

- Pyro ProcessingDocument29 paginiPyro ProcessingMKPashaPasha100% (2)

- Calculations in Furnace Technology: Division of Materials Science and TechnologyDe la EverandCalculations in Furnace Technology: Division of Materials Science and TechnologyEvaluare: 3 din 5 stele3/5 (2)

- Improving Energy Efficiency in Cement Plants PDFDocument45 paginiImproving Energy Efficiency in Cement Plants PDFNguyen ThanhÎncă nu există evaluări

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDe la EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshÎncă nu există evaluări

- Heat Balance of Kilns and Coolers and Related Topics PDFDocument62 paginiHeat Balance of Kilns and Coolers and Related Topics PDFAli HüthütÎncă nu există evaluări

- Useful Equations For Kiln & CoolerDocument7 paginiUseful Equations For Kiln & CoolerAbul Qasim100% (2)

- Turbulence and Molecular Processes in CombustionDe la EverandTurbulence and Molecular Processes in CombustionT. TakenoÎncă nu există evaluări

- Critical Review of Planetary Coolers TechnologyDocument10 paginiCritical Review of Planetary Coolers TechnologyLucio PereiraÎncă nu există evaluări

- Engineering Calculations in Radiative Heat Transfer: International Series on Materials Science and TechnologyDe la EverandEngineering Calculations in Radiative Heat Transfer: International Series on Materials Science and TechnologyEvaluare: 5 din 5 stele5/5 (1)

- V2 Materials Technology 2Document2 paginiV2 Materials Technology 2RRHHÎncă nu există evaluări

- Combustion Engineering Issues for Solid Fuel SystemsDe la EverandCombustion Engineering Issues for Solid Fuel SystemsÎncă nu există evaluări

- What Kiln Operator Should Do in Emergency SituationDocument12 paginiWhat Kiln Operator Should Do in Emergency SituationLe HoangÎncă nu există evaluări

- Kilns Khaled PDFDocument16 paginiKilns Khaled PDFbulentbulut100% (1)

- A Better Kiln CoatingDocument2 paginiA Better Kiln Coatingamir100% (4)

- Kiln Audit H&M Balance Calculation 2012Document24 paginiKiln Audit H&M Balance Calculation 2012Anonymous 3ESYcrKP100% (7)

- GGBFS Opeartion ManualDocument41 paginiGGBFS Opeartion ManualPushpendra Kumar KushwahaÎncă nu există evaluări

- Duoflex BurnerDocument6 paginiDuoflex Burnersinghite100% (1)

- 05 CombustionDocument15 pagini05 CombustionMKPashaPasha100% (1)

- Coal Combustion in A Rotary Kiln: Application Briefs From FluentDocument2 paginiCoal Combustion in A Rotary Kiln: Application Briefs From Fluentjimmy_burgos_11Încă nu există evaluări

- Process Optimization-Pyrosection Hand BookDocument195 paginiProcess Optimization-Pyrosection Hand Bookramsumiran vishwakarma100% (1)

- False Air - Measuerment OverviewDocument11 paginiFalse Air - Measuerment OverviewVijay BhanÎncă nu există evaluări

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDocument26 paginiClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedÎncă nu există evaluări

- Kiln Thermal LoadDocument33 paginiKiln Thermal Loadeng_mhassan1100% (1)

- Fuel and Combustion CalculationsDocument6 paginiFuel and Combustion Calculationsvvijaybhan100% (2)

- 04.04 Kiln Operations Guide Lines - ENGDocument23 pagini04.04 Kiln Operations Guide Lines - ENGbrenbra50% (2)

- Clinker Vs Kiln Feed FactorDocument3 paginiClinker Vs Kiln Feed FactorSSAC PVT.LTD.Încă nu există evaluări

- Grinding Media Pattern & Charge CalcDocument1 paginăGrinding Media Pattern & Charge CalcJayaram SudhakarÎncă nu există evaluări

- R A R F U: % Passing Size, M Feed Coarse FinesDocument3 paginiR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütÎncă nu există evaluări

- Flow MeasurementsDocument19 paginiFlow MeasurementsHazem DiabÎncă nu există evaluări

- Rotary Kiln-1910 PDFDocument96 paginiRotary Kiln-1910 PDFSunday Paul100% (1)

- Flame MomentumDocument1 paginăFlame Momentumayaskant751001Încă nu există evaluări

- Odudimu Certification ScenerioDocument50 paginiOdudimu Certification Scenerioabosede2012Încă nu există evaluări

- Kiln Audit Training DetailsDocument20 paginiKiln Audit Training DetailsTamer Fathy100% (5)

- Vertical Roller Mill Steps To Adjust When Temp VariesDocument2 paginiVertical Roller Mill Steps To Adjust When Temp VariesVijay BhanÎncă nu există evaluări

- Project:: 2800TPD Burning System CalculationDocument7 paginiProject:: 2800TPD Burning System CalculationOUSSAMA LAKHILIÎncă nu există evaluări

- Free Lime - Reasons Impacts and Corrective Actions R1Document17 paginiFree Lime - Reasons Impacts and Corrective Actions R1Gulam Dastgir100% (2)

- Kiln Feed Mix CalculationsDocument2 paginiKiln Feed Mix CalculationsElwathig Bakhiet100% (3)

- Fls Kiln Systems ProcessDocument99 paginiFls Kiln Systems ProcessKeshav Nanda100% (1)

- Fine Coal Conveying Velocity in Kiln Firing SystemDocument2 paginiFine Coal Conveying Velocity in Kiln Firing SystemVijay BhanÎncă nu există evaluări

- Tromp Curve Calculations and ResultsDocument3 paginiTromp Curve Calculations and Resultsrecai100% (3)

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocument12 paginiEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julÎncă nu există evaluări

- Plant EfficiencyDocument51 paginiPlant EfficiencyknsaravanaÎncă nu există evaluări

- Kiln Cooler Heat Mass BalanceDocument99 paginiKiln Cooler Heat Mass Balancesaji kumar100% (5)

- GulfSea DE Compressor Oil Series 100Document2 paginiGulfSea DE Compressor Oil Series 100Md.Obydur RahmanÎncă nu există evaluări

- JMS - Partial Insulation For Hot Piping - Rev1Document7 paginiJMS - Partial Insulation For Hot Piping - Rev1Raaj ChandranÎncă nu există evaluări

- RetroJet System ManualDocument11 paginiRetroJet System ManualetritÎncă nu există evaluări

- Difference Between Biodegradable and Non Biodegradable WasteDocument3 paginiDifference Between Biodegradable and Non Biodegradable WasteArjun ParmarÎncă nu există evaluări

- UFC 3-250-06 Repair of Rigid Pavements Using Epoxy Resin Grouts, Mortars and Concretes (01!16!2004)Document18 paginiUFC 3-250-06 Repair of Rigid Pavements Using Epoxy Resin Grouts, Mortars and Concretes (01!16!2004)Bob VinesÎncă nu există evaluări

- Thermodynam TasksDocument1 paginăThermodynam TasksEhtıram SeyıdovÎncă nu există evaluări

- SG 6.6-155 - Estimated Foundation Design T122.5-51ADocument4 paginiSG 6.6-155 - Estimated Foundation Design T122.5-51AJIMYJONÎncă nu există evaluări

- Chapter 2 MahoganyDocument2 paginiChapter 2 MahoganyRichelle DandoÎncă nu există evaluări

- Structural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersDocument3 paginiStructural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersBoby CuliusÎncă nu există evaluări

- Lab Report - Part A: Kanvasree Vuyyuru (C2084903)Document8 paginiLab Report - Part A: Kanvasree Vuyyuru (C2084903)suryaÎncă nu există evaluări

- Lubrication Solutions For Industrial ApplicationsDocument44 paginiLubrication Solutions For Industrial ApplicationsFocuÎncă nu există evaluări

- Water RemovalDocument12 paginiWater Removalvemanreddy29Încă nu există evaluări

- Chapter 8pt2Document23 paginiChapter 8pt2Stephen Rey CaldeaÎncă nu există evaluări

- Wood Adhesives: Vital For Producing Most Wood ProductsDocument9 paginiWood Adhesives: Vital For Producing Most Wood ProductsBogdan BukaraÎncă nu există evaluări

- Banglore Metro Rail Corporation-Bogie SystemDocument52 paginiBanglore Metro Rail Corporation-Bogie SystemAshutosh Kumar100% (1)

- Materials - Characterization - of - High-Temperature - Epoxy S-15Document35 paginiMaterials - Characterization - of - High-Temperature - Epoxy S-15rizkboss8312Încă nu există evaluări

- Kubota Super Udt: Safety Data SheetDocument14 paginiKubota Super Udt: Safety Data SheetMichaelÎncă nu există evaluări

- Contact Mechanics and Friction: Fig. A3.1 Friction Caused (A)Document12 paginiContact Mechanics and Friction: Fig. A3.1 Friction Caused (A)Nrl SyafiniÎncă nu există evaluări

- Underwater WeldingDocument27 paginiUnderwater WeldingAbhishek Jain87% (15)

- Hot Spotet, Lista Me 31 Pikat Më Të Rrezikshme Mjedisore Në VendDocument5 paginiHot Spotet, Lista Me 31 Pikat Më Të Rrezikshme Mjedisore Në VendTelevizioni A1 ReportÎncă nu există evaluări

- Module1 PDFDocument42 paginiModule1 PDFmohanÎncă nu există evaluări

- Inks FoodDocument42 paginiInks FoodJavier Martinez CañalÎncă nu există evaluări

- Shabrina Nur Adini Xi KaDocument7 paginiShabrina Nur Adini Xi KaDedi NuralamsyahÎncă nu există evaluări

- RA Sep-Dec 2020 EditedDocument104 paginiRA Sep-Dec 2020 EditedMymoon MoghulÎncă nu există evaluări

- Garlock Metallic Gasket CatalogDocument48 paginiGarlock Metallic Gasket CatalogcoyuncoÎncă nu există evaluări

- Flange Bolting Torque Values API 6ADocument1 paginăFlange Bolting Torque Values API 6Aparthameister100% (1)

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 paginiLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- CE3070 Geotechnical Engineering: Clay MineralogyDocument22 paginiCE3070 Geotechnical Engineering: Clay MineralogyCharan DeepÎncă nu există evaluări

- Pipe and Equipment Install Manual (Pyrogel)Document4 paginiPipe and Equipment Install Manual (Pyrogel)EdinsonÎncă nu există evaluări

- BW Cleaner+401 en 2022 GL 151 PreviewDocument2 paginiBW Cleaner+401 en 2022 GL 151 PreviewDeivid MiquelinoÎncă nu există evaluări