Documente Academic

Documente Profesional

Documente Cultură

MS3-ASME Gas Turbine Technologies Presentation

Încărcat de

Augustine Owo UkpongDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MS3-ASME Gas Turbine Technologies Presentation

Încărcat de

Augustine Owo UkpongDrepturi de autor:

Formate disponibile

Gas Turbine Technologies

Gas Turbine Technologies

for Electric Generation

for Electric Generation

by

Rob Shepard, P.E.

www.Neel-Schaffer.com

rob.shepardneel-schaffer.com

2

Gas Turbine !asics

Gas Turbines

Types

How They Work

Applications

Components of Plant

Flow Paths

Operation

3

Gas Turbine "pplications

imple Cycle

Combine! Cycle

Co"eneration

#

Types of Gas Turbine Plants

imple Cycle

Operate When $eman! is Hi"h % Peak $eman!

Operate for hort & 'ariable Times

$esi"ne! for (uick tart)*p

+ot !esi"ne! to be ,fficient but -eliable

+ot Cost ,ffecti.e to /uil! for ,fficiency

Combine! Cycle

Operate for Peak an! ,conomic $ispatch

$esi"ne! for (uick tart)*p

$esi"ne! to ,fficient0 Cost),ffecti.e Operation

Typically Has Ability to Operate in C 1o!e

2

The ener"y containe! in a flowin" i!eal "as

is the sum of enthalpy an! kinetic ener"y3

Pressuri4e! "as can store or release

ener"y3 As it e5pan!s the pressure is

con.erte! to kinetic ener"y3

Principles of

#peration

Open Cycle

Also referre! to as simple cycle6

$in% to picture

7

!rayton &ycle ' Gas Turbine &ycle

8

Thermodynamic (undamentals

Pressure -atio 9

CT Components

:

&ombustion or Gas Turbine

;

Principles of #peration

Compressor

As air flows into the compressor0 ener"y is transferre! from its

rotatin" bla!es to the air3 Pressure an! temperature of the air

increase3

1ost compressors operate in the ran"e of 82< to :2< efficiency3

Combustor

The purpose of the combustor is to increase the ener"y store! in

the compressor e5haust by raisin" its temperature3

Turbine

The turbine acts like the compressor in re.erse with respect to

ener"y transformation3

1ost turbines operate in the ran"e of :=< to ;=< efficiency3

>=

Principles of #peration

#)erall Energy Transformations *Thermal Efficiency+

*seful Work ? ,ner"y release! in turbine minus ener"y absorbe! by

compressor3

The compressor re@uires typically appro5imately 2=< of the ener"y release! by

the turbine3

O.erall Thermal ,fficiency ?

*seful Work&Fuel Chemical ,ner"y A>==

Typical o.erall thermal efficiencies of a combustion turbine are 2=< ) #=<3

>>

Gas Turbine "pplications

imple Cycle

CO1P-,O- T*-/B+,

CO1/*TO-

G,+,-ATO-

B+C,T AB- ,DHA*T GA

$in% to picture

>2

Simple &ycle Power Plant

,estinghouse -./0- ' 12. 3,

>3

&ombined &ycle Power Plant

>#

Combine! Cycle Plant $esi"n

GT P-O >33= $rew Wo4niak

>2>2 >=)>3)2==# 23E28E3> file?CEFTflow>3F1GFBC,F3P = 8=3"tp

+et Power ;2;2; kW

CH' Heat -ate 88=2 /T*&kWh

pHpsiaI0 THFI0 1HkpphI0 team PropertiesE Thermoflow ) T(*BJ

#38>8 m

Fo""er

>D G, 72:>/ 2 D GT

338:> kW

>232# p

;= T

3= <-H

;## m

#328 ft ele.3

>233; p

7: T

;#:38 m

+atural "as >:32: m

;7 T 88 T

CH' 37;78> k/T*&h

>#;32 p

7:# T

>#332 p

2=82 T

;7833 m

>23;3 p

>=3# T

>;3#37 1

833:2 <+2

>3323 <O2

33233 <CO2KO2

:3#;8 <H2O

=3::;# <Ar

>=3> T

>;3#37 1

>=3> :;8 27; 27: 23: 23# #:> #>; 327 27:

27: T

>;3#37 1

3=:>3 kW

=3>2;7 1

FW

>37;# p

>2= T

2223> 1

>2= T

+atural "as

= 1

>22 T

2;237 1

>22 T

>83>; p

22= T

2

;

3

2

:

1

>83>; p

22= T

2;372 1

CP/

2

;

3

7

2

1

2

;

2

3

7

1

2=337 p

383 T

2;237 1

BP,2

2=337 p

3:3 T

37382 1

BP/

>;;38 p

#7= T

37382 1

BP>

>;23: p

2== T

37382 1

BP2

;2#32 p

#82 T

22>3> 1

HP,2

;>=32 p

223 T

22>3> 1

HP,3

;>=32 p

233 T

2#:37 1

HP/>

:8;3: p

;2# T

2#:37 1

HP3

:2= p

;2= T

2#:37 1

:

8

;

3

:

p

;

2

#

T

73:; 1

>:3 p 382 T 8= 1 '#

27337 1

>

;

2

3

:

p

2

;

8

T

':

73:; 1

>2

Gas Turbine &omponents

&ompressor ' &ombustor - Turbine

>7

Gas Turbine &omponents 4 Systems *cont5d+

Combustion ystem

ilo0 Cannular0 Annular

Water0 team0 $C+

Turbine

1ultiple haft0 in"le

haft

+umber of ta"es

1aterial an!

1anufacturin"

Processes

,5haust ystem

imple Cycle tack

Transition to H-G

Generator

Open)Air coole!

T,WAC

Hy!ro"en Coole!

tartin" ystems

$iesel

1otor

tatic

Paper Towel thru

compressor

>8

&ombustion Turbine (uels

Con.entional Fuels

+atural Gas

Ci@ui! Fuel Oil

+oncon.entional Fuels

Cru!e Oil

-efinery Gas

Propane

ynthetic Fuels

Chemical Process

Physical Process

>:

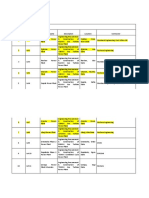

GE &ombustion Turbine &omparisons

>;

A!.ance! Hea.y)$uty *nits

A!.ance! Aero!eri.ati.e *nits

Gas Turbine Types

2=

Gas Turbine 3a6or Sections

"ir 7nlet

&ompressor

&ombustion System

Turbine

E8haust

Support Systems

2>

Gas Turbine !arrier 7nlet (ilter Systems

22

Gas Turbine Pulse 7nlet (ilter System

23

7nlet Guide 9anes

2#

7nlet Guide 9anes

22

Gas Turbine &ompressor Rotor "ssembly

27

:! Gas Turbine

28

Gas Turbine &ut "way Side 9iew

2:

Gas Turbine &ombustor "rrangement

2;

(rame - GT

3=

GE $3;-.. "eroderi)ati)e Gas Turbine

Compressor

Compressor

Turbine

ection

Power

Turbine

ection

3>

(T2 Gas Turbine

32

(T2 Gas Turbine ' Gas Generator *&ompressor+

33

(T2 Gas Turbine ' Gas Generator *&ompressor+

3#

(T2 Gas Turbine ' (ree Turbine

32

(T2 Gas Turbine ' (ree Turbine Gas Path

37

(T2 Gas Generator Performance

38

(T2 (ree Turbine Performance

3:

"eroderi)ati)e 9ersus <ea)y 0uty &ombustion

Turbines

Aero!eri.ati.es

Hi"her Pressure -atios an! Firin" Temperatures -esult

in Hi"her Power Output per Poun! of Air Flow

maller Chillin"&Coolin" ystems -e@uire!

Compressor Bnlet Temperature Has a Greater Bmpact on

Output an! Heat -ate

/enefits of Chillin"&Coolin" ystems are 1ore

Pronounce!

3;

Typical Simple &ycle &T Plant &omponents

Prime 1o.er LCombustion Turbine6

Fuel upply 9 Preparation

,missions Control ,@uipment

Generator

,lectrical witch"ear

Generator tep *p Transformer

tartin" ystem LCombustion Turbines6

Au5iliary Coolin"

Fire Protection

Cubrication ystem

#=

Typical Pea%ing Plant &omponents

Cube Oil ystem G* Generator

Fire Protection tartin" ,n"ine witch"ear & 1CC

#>

&ombining the !rayton and Ran%ine &ycles

Gas Turbine ,5haust use! as the heat source for the team

Turbine cycle

*tili4es the maMor efficiency loss from the /rayton cycle

A!.anta"esE

-elati.ely short cycle to !esi"n0 construct 9 commission

Hi"her o.erall efficiency

Goo! cyclin" capabilities

Fast startin" an! loa!in"

Cower installe! costs

+o issues with ash !isposal or coal stora"e

$isa!.anta"es

Hi"h fuel costs

*ncertain lon" term fuel source

Output !epen!ent on ambient temperature

#2

Picture courtesy of Nooter/Eriksen Picture courtesy of Nooter/Eriksen

<ow does a &ombined &ycle Plant ,or%=

#3

&ombined &ycle <eat !alance

##

&ombined &ycles Today

Plant ,fficiency N 2:)7= percent

/i""est losses are mechanical input to the compressor an! heat in the

e5haust

team Turbine output

Typically 2=< of the "as turbine output

1ore with !uct)firin"

+et Plant Output L*sin" Frame si4e "as turbines6

up to 82= 1W for 3 on > confi"uration

*p to 22= 1W for 2 on > confi"uration

Construction time about 2# months

,n"ineerin" time :=k to >3=k labor hours

,n"ineerin" !uration about >2 months

Capital Cost LO;==)O>>==&kW6

Two L26 .ersus Three L36 Pressure $esi"ns

Car"er capacity units utili4e the a!!itional !rums to "ain efficiency at

the e5pense of hi"her capital costs

#2

&ombined &ycle Efficiency

imple cycle efficiency Lma5 N ##<A6

Combine! cycle efficiency Lma5 N2:)7=<A6

Correlatin" ,fficiency to Heat -ate L/ritish *nits6

? 3#>2&LHeat -ate6 ))P 3#>2& ? Heat -ateA

imple cycle % 3#>2&3## ? 80828 /tu&JwhA

Combine! cycle % 3#>2&32: ? 20::# /tu&JwhA

Correlatin" ,fficiency to Heat -ate LB *nits6

? 37==&LHeat -ate6 ))P 37==& ? Heat -ateA

imple cycle % 37==&3## ? :0>:2 JQ&JwhA

Combine! cycle % 37==&32: ? 702=8 JQ&JwhA

Practical 'alues

HH' basis0 net output basis

imple cycle 8FA Lnew an! clean6 >=0:7= /tu&Jwh L>>0#28 JQ&Jwh6

Combine! cycle 25> 8FA Lnew an! clean6 702>: /tu&Jwh L7027= JQ&Jwh6

AGross CH' basis

#7

Gas Turbine Generator Performance

Factors that Bnfluence Performance

Fuel Type0 Composition0 an! Heatin" 'alue

Coa! L/ase0 Peak0 or Part6

Compressor Bnlet Temperature

Atmospheric Pressure

Bnlet Pressure $rop

'aries si"nificantly with types of air cleanin"&coolin"

,5haust Pressure $rop

Affecte! by a!!ition of H-G0 C-0 CO catalysts

team or Water BnMection -ate

*se! for either power au"mentation or +O

5

control

-elati.e Humi!ity

#8

"ltitude &orrection

#:

<umidity &orrection

#;

&ogeneration Plant

A Co"eneration Plant

Power "eneration facility that also pro.i!es

thermal ener"y Lsteam6 to a thermal host3

Typical thermal hosts

paper mills0

chemical plants0

refineries0 etcR

potentially any user that uses lar"e @uantities of

steam on a continuous basis3

Goo! applications for combine! cycle plants

-e@uire both steam an! electrical power

2=

3a6or &ombined &ycle Plant E>uipment

Combustion Turbine LCT&CTG6

team Generator L/oiler&H-G6

team Turbine LT&TG6

Heat -eMection ,@uipment

Air (uality Control ystem LA(C6 ,@uipment

,lectrical ,@uipment

2>

<eat Reco)ery Steam Generator *<RSG+

22

Steam Turbine

GE D11

23

ame Function as

!iscusse! earlier in

ession ;

*sually utili4es a

coolin" tower to

reMect heat to the

atmosphere

-arely uses once

throu"h coolin"

Lretrofit applications

or ocean6

<eat Re6ection E>uipment - &ondenser

2#

(uestionsS

Rob Shepard

Neel-Schaffer, 7nc.

www.Neel-Schaffer.com

rob.shepardneel-schaffer.com

S-ar putea să vă placă și

- Nipp ProjectsDocument22 paginiNipp ProjectsAugustine Owo Ukpong100% (1)

- MK6e Control System ChecksDocument4 paginiMK6e Control System ChecksAugustine Owo Ukpong100% (1)

- Generation and Revenue Projections First 6 Months With 1 GTDocument2 paginiGeneration and Revenue Projections First 6 Months With 1 GTAugustine Owo UkpongÎncă nu există evaluări

- Steady Power Supply - Will Privatisation Do The Magic - Vanguard NewsDocument27 paginiSteady Power Supply - Will Privatisation Do The Magic - Vanguard NewsAugustine Owo UkpongÎncă nu există evaluări

- Thermal PeakingDocument26 paginiThermal PeakingbananosnetÎncă nu există evaluări

- Swagelok Fitting ManualDocument120 paginiSwagelok Fitting ManualSmit ShahÎncă nu există evaluări

- Coal Fired Power PlantDocument56 paginiCoal Fired Power PlantAugustine Owo Ukpong100% (1)

- GTs Rate of Gas ConsumptionDocument2 paginiGTs Rate of Gas ConsumptionAugustine Owo UkpongÎncă nu există evaluări

- Swagelok Tubing SpecificationsDocument8 paginiSwagelok Tubing SpecificationsAugustine Owo UkpongÎncă nu există evaluări

- Oakton Con 6 Conductivity Meter ManualDocument56 paginiOakton Con 6 Conductivity Meter ManualAugustine Owo UkpongÎncă nu există evaluări

- Energy Saving TipsDocument128 paginiEnergy Saving TipsAugustine Owo Ukpong100% (1)

- M-424 Basics of Vibration AnalysisDocument22 paginiM-424 Basics of Vibration AnalysisAugustine Owo UkpongÎncă nu există evaluări

- Engg & Piping Design Guide (FRP Pipe)Document36 paginiEngg & Piping Design Guide (FRP Pipe)karuna346Încă nu există evaluări

- Transformer MaintenanceDocument22 paginiTransformer MaintenanceAugustine Owo UkpongÎncă nu există evaluări

- Causes of Vibration For Steam TurbineDocument21 paginiCauses of Vibration For Steam TurbineAugustine Owo Ukpong100% (6)

- Oil Conditioning SystemDocument5 paginiOil Conditioning SystemAugustine Owo UkpongÎncă nu există evaluări

- Tranformer Bushing RepairDocument1 paginăTranformer Bushing RepairAugustine Owo Ukpong100% (1)

- Transformer Installation ManualDocument38 paginiTransformer Installation ManualbhsujanÎncă nu există evaluări

- Tranformer MaintenanceDocument87 paginiTranformer MaintenanceAugustine Owo UkpongÎncă nu există evaluări

- Turbine FundamentalsDocument75 paginiTurbine FundamentalsingeniraÎncă nu există evaluări

- Powerplant Theory DesignDocument9 paginiPowerplant Theory DesignAugustine Owo UkpongÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- vn48 1009MeasuringAirflow PDFDocument2 paginivn48 1009MeasuringAirflow PDFحسان السوفانيÎncă nu există evaluări

- Ame101 LecturenotesDocument5 paginiAme101 Lecturenotesagrocel_bhvÎncă nu există evaluări

- Production Ii PDFDocument235 paginiProduction Ii PDFADARSH KUMARÎncă nu există evaluări

- Dodecatemoria - FirmicusDocument3 paginiDodecatemoria - FirmicusMihaela Dicu100% (1)

- 05d52977f57be2 - Contents - DK Tripathi - Novel Drug Delivery SystemsDocument8 pagini05d52977f57be2 - Contents - DK Tripathi - Novel Drug Delivery SystemsHely Patel0% (1)

- Sist en 50180 1 2016Document13 paginiSist en 50180 1 2016charles panÎncă nu există evaluări

- General Properties of MaterialsDocument24 paginiGeneral Properties of Materials1900651Încă nu există evaluări

- ACCURIS 3 Page UV TransilluminatorDocument3 paginiACCURIS 3 Page UV TransilluminatorSigit SadewoÎncă nu există evaluări

- Jgeot.21.00089 OffprintDocument11 paginiJgeot.21.00089 OffprintBrian SheilÎncă nu există evaluări

- 20200414014739976f2ee727 1Document12 pagini20200414014739976f2ee727 1Ram RathiyaÎncă nu există evaluări

- Ir Func GroupDocument52 paginiIr Func GroupEry NourikaÎncă nu există evaluări

- Chemical BondingDocument7 paginiChemical BondingSanaa SamkoÎncă nu există evaluări

- FP-Lect10 - Water PropertiesDocument34 paginiFP-Lect10 - Water PropertiesMohamed SadekÎncă nu există evaluări

- Textile TechnologyDocument5 paginiTextile TechnologyKaye NicolasÎncă nu există evaluări

- Sci9 Q2 Summative-4Document6 paginiSci9 Q2 Summative-4Lanie BuenavistaÎncă nu există evaluări

- ONSemi-Developing A 25-kW SiC-Based Fast DC Charger Solution OverviewDocument8 paginiONSemi-Developing A 25-kW SiC-Based Fast DC Charger Solution Overview133514Încă nu există evaluări

- Biological Process Removes Sulfur From Three Refinery StreamsDocument16 paginiBiological Process Removes Sulfur From Three Refinery StreamsLindsey BondÎncă nu există evaluări

- Astronomy Chapter 1 NotesDocument4 paginiAstronomy Chapter 1 NoteskrmooshÎncă nu există evaluări

- Msds Sodium BicarbonateDocument4 paginiMsds Sodium BicarbonateDeny Aditya PratamaÎncă nu există evaluări

- 04 Breakdown in SolidsDocument44 pagini04 Breakdown in SolidsYii Su Hieng100% (2)

- Thermochemistry NotesDocument5 paginiThermochemistry NotesNephtali Pinos-anÎncă nu există evaluări

- NATTOKINASEDocument57 paginiNATTOKINASEpranavb23Încă nu există evaluări

- Nano ComputingDocument12 paginiNano Computingsdtechman100% (1)

- PetrographyDocument13 paginiPetrographyMI ChoudharyÎncă nu există evaluări

- FeynArts PsDocument52 paginiFeynArts PsAndres VasquezÎncă nu există evaluări

- Microemulsion System As A Steel Corrosion InhibitorDocument5 paginiMicroemulsion System As A Steel Corrosion InhibitorINRO IngeníeriaÎncă nu există evaluări

- Agglomeration PracticeDocument57 paginiAgglomeration Practiceabdulloh_99Încă nu există evaluări

- EPA 608 Certification Test QuestionsDocument96 paginiEPA 608 Certification Test Questionslanzea91% (65)

- Q2M3Document22 paginiQ2M3Sophia Jhayne AquinoÎncă nu există evaluări

- Correlations To Predict Frictional Pressure Loss of Hydraulic-Fracturing Slurry in Coiled TubingDocument15 paginiCorrelations To Predict Frictional Pressure Loss of Hydraulic-Fracturing Slurry in Coiled TubingErdal AYDINÎncă nu există evaluări