Documente Academic

Documente Profesional

Documente Cultură

Top 4 Hazards in Construction

Încărcat de

Ahmed Hassan SabryDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Top 4 Hazards in Construction

Încărcat de

Ahmed Hassan SabryDrepturi de autor:

Formate disponibile

The leading causes of fatalities in

construction:

90% of all construction fatalities are:

falls from elevations (e.g., floors, platforms,

roofs) - 33%;

struck by (e.g., falling objects, vehicles) - 22%;

caught in/between (e.g., cave-ins, unguarded

machinery, equipment) - 18%;

electrical shock (e.g., overhead power lines,

power tools and cords, outlets, temporary wiring)

- 17%.

The leading causes of fatalities in

construction:

Primary Causes of

Fall-Related Fatalities

Unprotected sides, edges and holes

Improperly constructed walking/working

surfaces

Improper use of access equipment

Failure to properly use PFAS

Slips and Trips (housekeeping)

Primary Causes of

Caught-in-Between Fatalities

Trench/Excavation Collapse

Rotating Equipment

Unguarded Parts

Equipment Rollovers

Equipment Maintenance

Primary Causes of

Struck-by Fatalities

Falling Objects

Rigging Failure

Loose or Shifting Materials

Equipment Tipover or Malfunction

Lack of Overhead Protection

Vehicle and Equipment Strikes

Backing Incidents

Workers on Foot

Flying Objects

Primary Causes of

Electrocution Fatalities

Contact with Overhead Powerlines

Contact with Live Circuits in Panels

Poorly Maintained Cords and Tools

Lightning Strikes

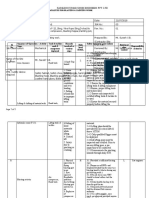

BRIEF DESCRIPTION OF ACCIDENT

A painter foreman

climbed over a bridge

railing to inspect work

being done, slipped,

and fell 150 feet

(45.72m) to his

death.

Fall From Elevation example

ACCIDENT PREVENTION RECOMMENDATIONS

Employers are to require employees to wear suitable

personal protective equipment (safety belts) in all

operations where employees are exposed to hazardous

conditions

Safety nets must be provided when workplaces are more

than 25 feet (7.62 m) above the ground or water surface, or

other surfaces where the use of ladders, scaffold, catch

platforms, temporary floors, safety lines, or safety belts is

not practical

Except where either permanent or temporary stairways or

suitable ramps or runaways are provided, suitable ladders

should be used to give safe access to all elevations

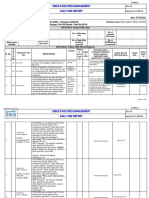

Hey Charlie, have

you seen my hardhat?

A carpenter apprentice was killed when he

was struck in the head by a nail that was

fired from a powder actuated tool.

The tool operator, while attempting to

anchor a plywood form in preparation for

pouring a concrete wall, fired the gun

causing the nail to pass through the

hollow wall. The nail traveled some

twenty-seven feet (8.22 m) before striking

the victim.

The tool operator had never received

training in the proper use of the tool, and

none of the employees in the area were

wearing personal protective equipment

BRIEF DESCRIPTION OF ACCIDENT

Struck By example

Institute a program for frequent and regular

inspections of the job site, materials, and

equipment by a competent person(s).

Regulations require employees exposed to the

potential hazards associated with flying nails to

use appropriate personal protective equipment.

Train employees using powder actuated tools in

the safe operation of the particular tool.

Train employees operating power actuated tools

to avoid firing into easily penetrated materials.

ACCIDENT PREVENTION RECOMMENDATIONS

An employee was driving a front-

end loader up a dirt ramp onto a

lowboy trailer.

The tractor tread began to slide off

the trailer.

As the tractor began to tip, the

operator, who was not wearing a

seat belt, jumped from the cab.

As he hit the ground, the tractor's

rollover protective structure fell on

top of him, crushing him.

BRIEF DESCRIPTION OF ACCIDENT

Caught In/Between example

The front-end loader was not equipped with seat

belts.

INSPECTION RESULTS

ACCIDENT PREVENTION RECOMMENDATIONS

Provide seat belts in material handling equipment.

Instruct employees to recognize and avoid unsafe

conditions associated with their work.

Permit only employees qualified by training or

experience to operate equipment and machinery.

An electrician was

removing metal fish

tape from a hole at

the base of a metal

light pole.

The fish tape became

energized,

electrocuting him.

BRIEF DESCRIPTION OF ACCIDENT

Electrocution example

Had requirements for de-energizing energy sources

been followed, the electrocution might have been

prevented.

INSPECTION RESULTS

ACCIDENT PREVENTION RECOMMENDATIONS

Ensure all circuits are de-energized before beginning

work.

Controls to be deactivated during the work on

energized or de-energized equipment or circuits must

be tagged.

Employees must be instructed to recognize and

avoid unsafe conditions associated with their work.

S-ar putea să vă placă și

- Excavation Safety Dos and DontsDocument4 paginiExcavation Safety Dos and DontsVidya SagarÎncă nu există evaluări

- Ladder SafetyDocument27 paginiLadder SafetySantanu Kumar Sahu100% (1)

- Safety Training: Hot WorksDocument66 paginiSafety Training: Hot WorksMuneeb Ur Rehman100% (1)

- Safety Plan HSDDocument110 paginiSafety Plan HSDvijayÎncă nu există evaluări

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 paginiCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazÎncă nu există evaluări

- 51 General Safety Precautions in ConstructionDocument4 pagini51 General Safety Precautions in ConstructionFazal Ahmed ShaikÎncă nu există evaluări

- JSA-Confined Space Activity - 05Document4 paginiJSA-Confined Space Activity - 05babjihanumanthuÎncă nu există evaluări

- JSA Formet New Blasting & PaintingDocument5 paginiJSA Formet New Blasting & Paintingsakthi venkatÎncă nu există evaluări

- Project OHS Plan ContentDocument1 paginăProject OHS Plan ContentARIF SHAIKHÎncă nu există evaluări

- Safe Working at Heights Part 1 - KG - 310519Document15 paginiSafe Working at Heights Part 1 - KG - 310519eugene stevensÎncă nu există evaluări

- Daily HSE ReportDocument5 paginiDaily HSE ReportSayeed MalikÎncă nu există evaluări

- Hse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationDocument61 paginiHse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationJinadÎncă nu există evaluări

- Jobsite Safety Checklist Long Ver 1Document5 paginiJobsite Safety Checklist Long Ver 1Usman ShahidÎncă nu există evaluări

- Expert Trainers Academy - Hse Interview Questions V1Document14 paginiExpert Trainers Academy - Hse Interview Questions V1greewin88Încă nu există evaluări

- HSE InductionDocument20 paginiHSE InductionShailendraÎncă nu există evaluări

- Constructionsafetymanagement 150817114845 Lva1 App6892Document67 paginiConstructionsafetymanagement 150817114845 Lva1 App6892Oliver DimailigÎncă nu există evaluări

- Safety Alert 304 - Unsafe MEWP's OperationDocument2 paginiSafety Alert 304 - Unsafe MEWP's OperationAbdulKatherÎncă nu există evaluări

- OSHA Fatal Fact 57Document2 paginiOSHA Fatal Fact 57jacc009Încă nu există evaluări

- Working at Height TrainingDocument47 paginiWorking at Height TrainingthinkpadÎncă nu există evaluări

- ObservationsDocument6 paginiObservationsjeffreyÎncă nu există evaluări

- Workplace Exposure To Vibration in Europe: An Expert ReviewDocument12 paginiWorkplace Exposure To Vibration in Europe: An Expert Reviewrajesh kumarÎncă nu există evaluări

- FATAL RISK ConstructioniDocument10 paginiFATAL RISK ConstructioniraghuvarmaÎncă nu există evaluări

- 3.gypsum CeilingDocument5 pagini3.gypsum Ceilingmohammed sohailÎncă nu există evaluări

- Permit To Work Shafts and Elevators: Compliance ChecklistDocument1 paginăPermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorÎncă nu există evaluări

- Division of Safety and HygieneDocument8 paginiDivision of Safety and HygienePrshant ThakurÎncă nu există evaluări

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 paginiAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferÎncă nu există evaluări

- HSE Alert 98 08 - Concrete Truck Access RoutesDocument1 paginăHSE Alert 98 08 - Concrete Truck Access Routesrodman823Încă nu există evaluări

- Basics of FireDocument2 paginiBasics of FireMr. XÎncă nu există evaluări

- Acf-Mra-063 - UaDocument1 paginăAcf-Mra-063 - UaFateh AliyaÎncă nu există evaluări

- Line of Fire Awareness (Safety Day)Document16 paginiLine of Fire Awareness (Safety Day)Muhammad SalmanÎncă nu există evaluări

- Hazard ObservationDocument8 paginiHazard ObservationMarya HasniÎncă nu există evaluări

- Safety Alert: Laying Out Drill Pipe Results in Broken Finger (Lti)Document1 paginăSafety Alert: Laying Out Drill Pipe Results in Broken Finger (Lti)vikrant911Încă nu există evaluări

- Part 3 ObservationsDocument7 paginiPart 3 ObservationsAmjadÎncă nu există evaluări

- HSE Alert - LTI Fall From Heights TBTDocument12 paginiHSE Alert - LTI Fall From Heights TBTrodman823Încă nu există evaluări

- CV - 11 10 2021Document4 paginiCV - 11 10 2021Fuzail AyazÎncă nu există evaluări

- Working at Height PDFDocument30 paginiWorking at Height PDFSibasis ParidaÎncă nu există evaluări

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 paginiSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerÎncă nu există evaluări

- Risk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1Document29 paginiRisk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1طارق رضوانÎncă nu există evaluări

- Ohs Legal - Ohsa Act 1994Document1 paginăOhs Legal - Ohsa Act 1994Nurul HidayahÎncă nu există evaluări

- Safety Quiz Answer KeyDocument5 paginiSafety Quiz Answer KeyKianna Shane HirabanÎncă nu există evaluări

- Toolbox Talk 9: Critical Risks - ExcavationsDocument2 paginiToolbox Talk 9: Critical Risks - ExcavationsPravin GowardunÎncă nu există evaluări

- Power Tool TrainingDocument20 paginiPower Tool TrainingToyota MatinaÎncă nu există evaluări

- Presentation On Safety For E1 E2 PDFDocument84 paginiPresentation On Safety For E1 E2 PDFdalalanup90Încă nu există evaluări

- Theme Based Safety Discussion (TBT) For Manual Grinding OperationDocument3 paginiTheme Based Safety Discussion (TBT) For Manual Grinding OperationMr. XÎncă nu există evaluări

- Hand and Power ToolsDocument57 paginiHand and Power ToolsMarvin TriaÎncă nu există evaluări

- Safety InterviewDocument35 paginiSafety InterviewMuhammad Ali Raza100% (1)

- Question and Answer Ig1Document8 paginiQuestion and Answer Ig1RahulÎncă nu există evaluări

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocument12 paginiWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentSheri DiĺlÎncă nu există evaluări

- Agenda National Safety Day CelebrationDocument3 paginiAgenda National Safety Day CelebrationDhilip AnÎncă nu există evaluări

- ARA - For Emergency Diesel GeneratorDocument4 paginiARA - For Emergency Diesel GeneratorShaikh AftabÎncă nu există evaluări

- Module 2Document29 paginiModule 2AlbertDatuÎncă nu există evaluări

- Hotworks and Welding SafetyDocument21 paginiHotworks and Welding SafetyprokjongÎncă nu există evaluări

- Safe Work Procedure For Hot WorksDocument1 paginăSafe Work Procedure For Hot WorksHtin Lin AungÎncă nu există evaluări

- ScaffoldingDocument16 paginiScaffoldingHSEÎncă nu există evaluări

- SAfety Qns AnswerDocument19 paginiSAfety Qns AnswerIrfan QadriÎncă nu există evaluări

- Safety ObservationDocument327 paginiSafety ObservationSafetyÎncă nu există evaluări

- Workingatheights 110623224858 Phpapp02Document21 paginiWorkingatheights 110623224858 Phpapp02naveeduddin2001Încă nu există evaluări

- Safety Orientation For Excavation WorkersDocument8 paginiSafety Orientation For Excavation WorkersHaroonAbdulRahimÎncă nu există evaluări

- Safety Precautions Durring Dismentling of StructresDocument83 paginiSafety Precautions Durring Dismentling of StructresshujaÎncă nu există evaluări

- Republic of The PhilippinesDocument7 paginiRepublic of The PhilippinesLaisah MindajaoÎncă nu există evaluări

- Gi-0006 030Document8 paginiGi-0006 030Ahmed Hassan SabryÎncă nu există evaluări

- 5 Star ImpelementationDocument37 pagini5 Star ImpelementationAhmed Hassan Sabry70% (10)

- Occupational Health, Safety & Environment Management System: Hse Biweekly ReportDocument3 paginiOccupational Health, Safety & Environment Management System: Hse Biweekly ReportAhmed Hassan SabryÎncă nu există evaluări

- HSE Monthly Report For XXXX2 ProjectDocument30 paginiHSE Monthly Report For XXXX2 ProjectAhmed Hassan Sabry80% (5)

- OSHA Machine SafeguardingDocument47 paginiOSHA Machine SafeguardingAhmed Hassan SabryÎncă nu există evaluări

- Risk Control: OSHA Office of Training and EducationDocument60 paginiRisk Control: OSHA Office of Training and EducationAhmed Hassan Sabry100% (1)

- HS ProgramDocument7 paginiHS ProgramAhmed Hassan SabryÎncă nu există evaluări

- Confined Space EntryDocument59 paginiConfined Space EntryAhmed Hassan SabryÎncă nu există evaluări

- Means of EgressDocument58 paginiMeans of EgressAhmed Hassan SabryÎncă nu există evaluări

- Hand & Pwoer ToolsDocument18 paginiHand & Pwoer ToolsAhmed Hassan SabryÎncă nu există evaluări

- Walking-Working SurfacesDocument39 paginiWalking-Working SurfacesAhmed Hassan Sabry100% (1)

- ISO9001-2008 ArabicDocument3 paginiISO9001-2008 Arabicrate00Încă nu există evaluări

- OSHA 511 Subpart N Materials HandlingDocument64 paginiOSHA 511 Subpart N Materials HandlingAhmed Hassan SabryÎncă nu există evaluări

- OSHA Subpart N Materials HandlingDocument74 paginiOSHA Subpart N Materials HandlingAhmed Hassan SabryÎncă nu există evaluări

- OSHA 511 Control of Hazardous EnergyDocument73 paginiOSHA 511 Control of Hazardous EnergyAhmed Hassan SabryÎncă nu există evaluări

- OSHA 511 Sub I PPEDocument33 paginiOSHA 511 Sub I PPEAhmed Hassan SabryÎncă nu există evaluări

- OSHA 511 Welding Sub QDocument59 paginiOSHA 511 Welding Sub QAhmed Hassan SabryÎncă nu există evaluări

- OSHA 511 Electrical Sub SDocument120 paginiOSHA 511 Electrical Sub SAhmed Hassan SabryÎncă nu există evaluări

- OSHA 511 Electrical Sub SDocument120 paginiOSHA 511 Electrical Sub SAhmed Hassan SabryÎncă nu există evaluări

- Roadwork SafetyDocument56 paginiRoadwork SafetyAhmed Hassan SabryÎncă nu există evaluări

- Infection Prevention and Control For Epidemic-And Pandemic-Prone Acute Respiratory DiseasesDocument44 paginiInfection Prevention and Control For Epidemic-And Pandemic-Prone Acute Respiratory DiseasesAmos AdlerÎncă nu există evaluări

- Data Sheet Flextool Tufftruk Eb500 Electric v4 0Document3 paginiData Sheet Flextool Tufftruk Eb500 Electric v4 0EVAÎncă nu există evaluări

- Build Build Build ProgramDocument2 paginiBuild Build Build Programlanz kristoff rachoÎncă nu există evaluări

- Master Ship Handing Over ProcedureDocument9 paginiMaster Ship Handing Over Procedurepushkar lamba100% (2)

- My CRUSHED ROCKS AND STONES FOR BASE COURSEDocument9 paginiMy CRUSHED ROCKS AND STONES FOR BASE COURSEJuanitha100% (1)

- Motor Vehicle Insurance Alteration - 11QA580109MPA-1Document6 paginiMotor Vehicle Insurance Alteration - 11QA580109MPA-1Ästra MosesÎncă nu există evaluări

- PHC Valeo Outsourcing Catalogue (130718)Document20 paginiPHC Valeo Outsourcing Catalogue (130718)ivanqh0% (1)

- Warranty Information & Maintenance Guide: W4/W6/W8/W10Document41 paginiWarranty Information & Maintenance Guide: W4/W6/W8/W10Harshal DhanawadeÎncă nu există evaluări

- 04 - Streamline English - DestinationsDocument46 pagini04 - Streamline English - DestinationsThoLe100% (1)

- Sniper: Owner'S ManualDocument84 paginiSniper: Owner'S ManualbillyÎncă nu există evaluări

- War Memoirs of Corporal Peter L. EmerDocument20 paginiWar Memoirs of Corporal Peter L. EmerjtrobinÎncă nu există evaluări

- RwallDocument51 paginiRwallandualemÎncă nu există evaluări

- Spare Parts Catalogue: Bajaj Auto LimitedDocument46 paginiSpare Parts Catalogue: Bajaj Auto LimitedGabriel ZamoraÎncă nu există evaluări

- State of Texas Driving Safety Course Uniform Certificate of CompletionDocument1 paginăState of Texas Driving Safety Course Uniform Certificate of CompletionTanay Patel100% (1)

- Chapter 1 5 and AppendicesDocument73 paginiChapter 1 5 and Appendicesjohn-john castañedaÎncă nu există evaluări

- Disability Rights in GhanaDocument26 paginiDisability Rights in GhanaFLEXCODEC TECHÎncă nu există evaluări

- Design Criteria For Highways and Railways - EditedDocument16 paginiDesign Criteria For Highways and Railways - EditedArianne Mae De Vera Gallon100% (1)

- Ogre RulebookDocument24 paginiOgre Rulebookkukuduxu100% (2)

- Lejr PDFDocument37 paginiLejr PDFMiguel Angel MartinÎncă nu există evaluări

- M161-120 - Falk Drive One High Torque Gear Drives - CatalogDocument24 paginiM161-120 - Falk Drive One High Torque Gear Drives - Catalogsuperhunter007Încă nu există evaluări

- 2 bản - 2 mặt - LỚP 7 - ĐỀ CƯƠNG GIỮA HK2 (PHẦN 2)Document7 pagini2 bản - 2 mặt - LỚP 7 - ĐỀ CƯƠNG GIỮA HK2 (PHẦN 2)Trà GiangÎncă nu există evaluări

- Thousand Islands Bridge: 75 Years of International GoodwillDocument16 paginiThousand Islands Bridge: 75 Years of International Goodwillwdt_rpominvilleÎncă nu există evaluări

- Bulk Carrier Design ProjectDocument23 paginiBulk Carrier Design ProjectAmeer KhalifullahÎncă nu există evaluări

- TransChicago Truck Group Project SummaryDocument17 paginiTransChicago Truck Group Project SummaryTodd FeurerÎncă nu există evaluări

- Problem Set 3Document4 paginiProblem Set 3tvdkuijl_668189273Încă nu există evaluări

- TBM Operation For Tunneling Work (Final) PDFDocument117 paginiTBM Operation For Tunneling Work (Final) PDFkiller_pro75% (8)

- Sugadev. G Mie, Chartered Engineer, 13 West Veli Street, 3Document5 paginiSugadev. G Mie, Chartered Engineer, 13 West Veli Street, 3Nithyanandhan TranzionÎncă nu există evaluări

- Density Based Traffic Light Controller Using Wireless Sensor Network and Arm ProcessorDocument4 paginiDensity Based Traffic Light Controller Using Wireless Sensor Network and Arm ProcessorqaaaziÎncă nu există evaluări

- Coc Certificate Model SDocument2 paginiCoc Certificate Model Sanastasia semushevaÎncă nu există evaluări

- Indian Biogas Association Biogas Market IndiaDocument36 paginiIndian Biogas Association Biogas Market Indiasj singh100% (1)