Documente Academic

Documente Profesional

Documente Cultură

Pad Eye Design Calculation

Încărcat de

Lưu XuânDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pad Eye Design Calculation

Încărcat de

Lưu XuânDrepturi de autor:

Formate disponibile

TOPSIDE

PADEYE DESIGN

CALCULATION

TOPSIDE

PTS 34.19.10.30 ( Appendix IX )

In lifting attachment design load the padeye shall be

designed for lateral load of a least 5% of this load.

Permissible stresses shall be as defined in AISC with

following additional requirements :

- Transfer of stresses through the thickness of the

plate shall not be allowed unless the material has

through thickness properties. In this instance through

thickness stresses shall be limited to 0.2 Fy.

TOPSIDE

= (MBL / Sling MBL)

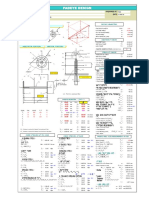

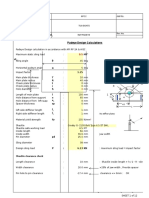

1.1 Design Calculation

Example1

TOPSIDE

O.75 X

Use min value 35 : 45

O.75 X

Use min value 25 : 26.25

=((radius of main plate-(pin hole/2))*(tm) +(radius cheekplate1-(pin

hole/2))*tce*2+(radius cheekplate2 -(pin hole/2))*tc2e*2)*2

=2*(2* radius of cheekplate(1)* tce)+2*(2* radius of cheek plate(2)*

tc2e)+(radius of main plate*2* (tm))-2* pin hole* (tm)

= Max static sling load *1000/ Area at tension failure

=Tension stress / Allowable tensile stress

=(tce/((tm) +2* tce+2* tc2e))* Max static sling load

= 0.7* (tc)

= F * 1000 / Aw

= shear stress / Allowable shear stress

= shear stress at weld / Allowable shear stress

= ([B]-((tm) +2* 0.75tm+2* tc2e))/2

= 0.1*[B]

= 0.2*[B]

TOPSIDE

TOPSIDE

S-ar putea să vă placă și

- PadEye Design CalculationDocument7 paginiPadEye Design Calculationhyoung65Încă nu există evaluări

- Lifting PadeyeDocument16 paginiLifting PadeyeLưu XuânÎncă nu există evaluări

- Padeye CalculationDocument6 paginiPadeye CalculationKarun DasÎncă nu există evaluări

- SWI PadeyeDocument11 paginiSWI PadeyeFian ArdiyanaÎncă nu există evaluări

- 8 Padeye - Spreadsheet Check1Document4 pagini8 Padeye - Spreadsheet Check1oluomo1Încă nu există evaluări

- 6a Padeye Aisc 360 2005Document6 pagini6a Padeye Aisc 360 2005mjlazoÎncă nu există evaluări

- Design of Pad Eye Using Check PlatesDocument3 paginiDesign of Pad Eye Using Check Plateshyoung65Încă nu există evaluări

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocument5 paginiCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaÎncă nu există evaluări

- Pad-Eye MainDocument8 paginiPad-Eye MainPradeep ChitluriÎncă nu există evaluări

- My Padeye CalcDocument10 paginiMy Padeye CalcReda Elawady100% (1)

- LiftingLug TrunnionDocument22 paginiLiftingLug Trunnionrichardchiam100% (2)

- 17 Padeye - Spreadsheet Rev ADocument12 pagini17 Padeye - Spreadsheet Rev Aoluomo1Încă nu există evaluări

- Report of Lifting Beam DesignDocument5 paginiReport of Lifting Beam Designnarutothunderjet216100% (1)

- Spreader Bar For LiftingDocument1 paginăSpreader Bar For LiftingTran ThoÎncă nu există evaluări

- Spreader BeamDocument7 paginiSpreader BeamAnonymous sfkedkymÎncă nu există evaluări

- Lifting Lug DesignDocument4 paginiLifting Lug DesignRohith V VÎncă nu există evaluări

- Lifting Lug AnalysisDocument3 paginiLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- RD339 (1MB File) Spreader BeamsDocument20 paginiRD339 (1MB File) Spreader BeamsnamasralÎncă nu există evaluări

- Padeye DesignDocument32 paginiPadeye DesignMuhammad Iqbal100% (1)

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 paginăSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaÎncă nu există evaluări

- 17 TonsDocument8 pagini17 Tonsabuzahrau100% (3)

- Spreader Beam BLOCK EDocument26 paginiSpreader Beam BLOCK ESteve MoonÎncă nu există evaluări

- Sample Section Modulas CalculationDocument18 paginiSample Section Modulas CalculationShamik ChowdhuryÎncă nu există evaluări

- Lifting Lug Design-MrDocument5 paginiLifting Lug Design-MrMiguelRagasÎncă nu există evaluări

- Sparta Spreader Bar CalculatorDocument1 paginăSparta Spreader Bar CalculatorNalini MathuraÎncă nu există evaluări

- PadEye Genset 300kvaDocument3 paginiPadEye Genset 300kvadandy imam fauziÎncă nu există evaluări

- Padeye Calculation For Lifting AnalysisDocument3 paginiPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- Calculation Lifting LugDocument4 paginiCalculation Lifting Lugelang purbayaÎncă nu există evaluări

- Lifting Lug DesignDocument27 paginiLifting Lug Designmramico100% (1)

- Padeye .5MT CHKDocument12 paginiPadeye .5MT CHKDhanraj VasanthÎncă nu există evaluări

- Design Calculation LiftingDocument19 paginiDesign Calculation LiftingAbu Al Sayyid100% (1)

- Padeye Calculation LatestDocument10 paginiPadeye Calculation LatestPavan RayÎncă nu există evaluări

- Padeye 7Document24 paginiPadeye 7Ramesh SelvarajÎncă nu există evaluări

- Lifting Lug Calculation-1Document1 paginăLifting Lug Calculation-1dtgpand100% (4)

- Pveng: Pressure Vessel Engineering LTDDocument5 paginiPveng: Pressure Vessel Engineering LTDBruno TrujilloÎncă nu există evaluări

- Section Properties: Design of Padeye As Per Aisc 360-2005Document6 paginiSection Properties: Design of Padeye As Per Aisc 360-2005Enrique BarajasÎncă nu există evaluări

- Calculation PadeyeDocument6 paginiCalculation PadeyeAddy Sumoharjo ST100% (1)

- 17 TonsDocument8 pagini17 TonsFernando Humberto100% (1)

- Padeye DolphinDocument38 paginiPadeye DolphinMuhammad FadelÎncă nu există evaluări

- Padeye Design CheekDocument3 paginiPadeye Design CheekBolarinwa89% (9)

- CALCULATIONS Pad Eye DesignDocument5 paginiCALCULATIONS Pad Eye DesignVijay Verma100% (1)

- DNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDocument2 paginiDNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDhanraj VasanthÎncă nu există evaluări

- Pad Eye New ReleaseDocument10 paginiPad Eye New ReleaseRaza AidanÎncă nu există evaluări

- Padeye Design Calculation: TopsideDocument7 paginiPadeye Design Calculation: TopsideBumi AzarakhÎncă nu există evaluări

- Asda Bridgewater - Cohesive Piling Platform - RevADocument9 paginiAsda Bridgewater - Cohesive Piling Platform - RevAAnonymous qEPNPwAÎncă nu există evaluări

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 paginiDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghÎncă nu există evaluări

- Variable Design Point Method.Document56 paginiVariable Design Point Method.jwochÎncă nu există evaluări

- Two Way Slab DesignDocument9 paginiTwo Way Slab DesignChan Kin Cheung100% (1)

- Design As Per APIDocument82 paginiDesign As Per APINeeraj BhallaÎncă nu există evaluări

- 6 X 8.1M ShadeDocument7 pagini6 X 8.1M ShadeehikmatÎncă nu există evaluări

- AC DesignDocument31 paginiAC DesignRauMuống100% (1)

- Storage Tank CalculationDocument10 paginiStorage Tank CalculationChaitanya Sai TÎncă nu există evaluări

- Pile Cap DesignDocument25 paginiPile Cap DesignGanesh Konar100% (5)

- End Block Design AidDocument6 paginiEnd Block Design AidAhsan KhanÎncă nu există evaluări

- 6 X 8 1M ShadeDocument11 pagini6 X 8 1M ShadeamachmouchiÎncă nu există evaluări

- One Way Slab DesignDocument16 paginiOne Way Slab DesignAssad Mohammed AliÎncă nu există evaluări

- 3 Spread FootingDocument17 pagini3 Spread Footingkhajaimad100% (2)

- Jutpani SS20Document23 paginiJutpani SS20Suman NakarmiÎncă nu există evaluări

- IMO SymbolDocument2 paginiIMO SymbolLưu Xuân100% (2)

- Japan Stockless AnchorDocument2 paginiJapan Stockless AnchorLưu XuânÎncă nu există evaluări

- IMO SymbolDocument2 paginiIMO SymbolLưu Xuân100% (2)

- Keel and Rudder DesignDocument18 paginiKeel and Rudder DesignLưu XuânÎncă nu există evaluări

- Flange Coupling - Reamer, Coupling BoltDocument2 paginiFlange Coupling - Reamer, Coupling BoltLưu XuânÎncă nu există evaluări

- Mariner Schilling Rudder: An Example of A "Mariner Schilling Rudder " Installed On Board A Full-Scale VesselDocument2 paginiMariner Schilling Rudder: An Example of A "Mariner Schilling Rudder " Installed On Board A Full-Scale VesselLưu XuânÎncă nu există evaluări

- DMCDocument42 paginiDMCLưu XuânÎncă nu există evaluări

- Sheave Quote / Order Form: Complete / Copy This Form and Email / Fax It in For A QuoteDocument1 paginăSheave Quote / Order Form: Complete / Copy This Form and Email / Fax It in For A QuoteLưu XuânÎncă nu există evaluări

- Tài Liệu Gối SKFDocument118 paginiTài Liệu Gối SKFLưu XuânÎncă nu există evaluări

- IMO SignsDocument8 paginiIMO SignsLưu Xuân100% (1)

- IMO Safety Signs On Dura Lumi-Glow™: 6" X 6" Fire Control SignsDocument1 paginăIMO Safety Signs On Dura Lumi-Glow™: 6" X 6" Fire Control SignsLưu XuânÎncă nu există evaluări

- Cargo CranesDocument2 paginiCargo CranesLưu XuânÎncă nu există evaluări

- Deck Machineries: Windlass & Winches Onboard Offshore and AshoreDocument30 paginiDeck Machineries: Windlass & Winches Onboard Offshore and AshoreAlexEcnom100% (3)