Documente Academic

Documente Profesional

Documente Cultură

Improving Operational Efficiencies

Încărcat de

acantillanapDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Improving Operational Efficiencies

Încărcat de

acantillanapDrepturi de autor:

Formate disponibile

Improving Operational Efficiencies Through

Lean Manufacturing

May 2010

n

2

ADVICE IMPLEMENTATION

Operational

Assessment

Optimized

Facility

Design

Improvement

Implementatio

Detailed

Design

Support

Manufacturing Advisory Services

Definition of Lean

A management philosophy/ strategy that focuses on eliminating

wastes in manufacturing. Waste inflate costs, lead times and

inventory requirements. By eliminating waste, quality is improved,

and production time and cost are reduced

Lean principles come from the Japanese manufacturing industry.

For many, Lean is the set of "tools" that assist in the identification and

steady elimination of waste.

The original seven wastes are:

Transportation

Inventory (raw material ,WIP, and finished product)

Motion (people or equipment moving or walking more than is required)

Waiting (Down time)

Overproduction (production ahead of demand)

Over Processing (resulting from poor tool or product design creating activity)

Defects (the effort involved in inspecting for and fixing defects)

3

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

4

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

5

6

Material is the largest contributor to operational cost regardless of

market type

Any reduction/ elimination of wastage in material directly impacts

bottom line

9%

2%

3%

7%

3% 2% 2%

1%

2%

24%

Automotive

Large Tonnage

60%

PET

Preform

85%

Material

Primary Equipment

Energy

Labor

16%

6%

7%

1%

1%

Closure

molders

18%

5%

2%

Custom

molders

Building & Infrastructure

Maitenance

5%

69%

Waste In Raw Material

6% 64%

7

Material waste typically happens in the following areas:

Part weight

2004 2007 2009

Lightweighing Weight Annual Resin

Opportunity

Sub-total Savings

Assumptions

Savings (g)

2.8

Savings

$3,148,235

Preforms (3 machine plant)

PET Resin Cost

HDPE Resin Cost

850 Million/yr

$1.40 $/kg

$1.10 $/kg

14.5g 12.3g 11.7g

Waste In Raw Material

8

Material waste typically happens in the following areas:

Part weight

Unrecoverable scrap

Waste In Raw Material

%variationfromnominal

9

Material waste typically happens in the following areas:

Part weight

Unrecoverable scrap

Over packing

0.90%

0.70%

0.50%

0.30%

Weight variation due to process control

0.10%

current range

0 10 20 30 40 50 60 70

-0.10%

-0.30%

-0.50%

-0.70%

-0.90%

-1.10%

-1.30%

-1.50%

Resin consumption reduction: 312,000 kg/yr ($450,000/yr)

Based on plant with 69 SKU (preforms) and 13 IMM

Waste In Raw Material

improved range

quality spec

10

Material waste typically happens in the following areas:

Part weight

Unrecoverable scrap

Over packing

Spillage, Purge, Start up

Waste In Raw Material

11

Material waste typically happens in the following areas:

Part weight

Unrecoverable scrap

Over packing

Spillage, Purge, Start up

Excessive use of colorant

Waste In Raw Material

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

12

Common Goal Between Departments

Best-in-class molders enable collaboration among

maintenance, production, and financial groups

Maintenance, operation, and engineering have traditionally

been compensated on different goals

Best-in-Class molders address this challenge by establishing

goals that are aligned (i.e. OEE)

OEE = Availability x Performance x Quality

Connecting these metrics will ensure that functional groups

work collaboratively to achieve common goal

13

Overall Equipment/ Factory Efficiency

OEE/ OFE = Availability x Performance x Quality

OFE

OEE

=

=

Scheduled time = (Total available hours - Hours not scheduled due to lack of sales)

14

15

Asset Intensive Companies: Source: Aberdeen Group, Nov. 2009

Best-in-Class

(Top 20%)

Industry Average

(Middle 50%)

Laggards

(Bottom 30%)

OEE

Unscheduled Down Time

88%

2%

81%

11%

75%

18%

Injection Molding Companies:

PET (1) Closure (2)

Thinwall /

Medical (2)

Custom Automotive

OEE

Unscheduled downtime

>96%

< 3%

>90%

< 5%

>90%

< 5%

> 80%

< 8%

> 85%

< 8%

(1) Preforms only

Best-in-Class Metrics

16

Increasing Availability through predictive maintenance

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Shift from Reactive to Predictive Maintenance

17

Increasing Availability through predictive maintenance

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Shift from Reactive to Predictive Maintenance

MachineAvailability

18

Increasing Availability through predictive maintenance

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Predictive

100,0%

98,0%

96,0%

94,0%

Machine Availability

Preventive

Program

Program

92,0%

90,0%

88,0%

86,0%

84,0%

82,0%

80,0%

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5 5,0 5,5 6,0 6,5 7,0 7,5 8,0 8,5 9,0 9,5 10,0

Years of Production

Data curve generated from more than 200 Husky machine audits

Shift from Reactive to Predictive Maintenance

20.00

-

19

300,000.00

250,000.00

200,000.00

Spending 150,000.00

100,000.00

50,000.00

-

Breakdown of Maintenance Spend

35.00

30.00

25.00

20.00

15.00

10.00

5.00

-

Lost Production caps in Milions per year

2005 2006 2007 2008 2009 2005 2006 2007 2008 2009

Lost Prod'n/Year

Emergency Maintenance Parts

Revenues lost K$

New policy started 2007 to minimize

maintenance spend

Postponed PM visits

Affect on reducing maintenance resulted in

increased total spend and production loss

120.00

100.00

80.00

60.00

40.00

By Q3 of 2008 PM practices were renewed

2005 2006 2007 2008 2009

Revenue Loss

Predictive Maintenance - Case Study

20

Increasing Availability through Quick Mold Change (QMC)

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Reduce Scheduled Down Time by QMC

2.

4.

21

Increasing Availability through Quick Mold Change (QMC)

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Steps to reduce mold change time:

1. Separation of internal from external

times

Conversion of internal to external

3. Parallel operations

Automation (hardware)

Quick connects and disconnects

Hydraulic, Pneumatic, Magnetic clamping

Ejector Couplers

5. Elimination of adjustments

Reduce Scheduled Down Time by QMC

2.

3.

Other

22

Increasing Availability through Quick Mold Change (QMC)

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Steps to reduce mold change time:

1. Separation of internal from external

times

Conversion of internal to external

Parallel operations

Organization

Up to 60% immediate

reduction through

the first three steps

4. Automation (hardware)

Quick connects and disconnects

Hydraulic, Pneumatic, Magnetic clamping

Ejector Couplers

Tool positioning

10%

Press settings

6%

Water line

7%

Clamping

9%

Ejector

6%

5. Elimination of adjustments

4%

Organization

58%

Reduce Scheduled Down Time by QMC

2.

4.

23

Increasing Availability through Quick Mold Change (QMC)

OEE = Availability x Performance x Quality

Unscheduled and Scheduled Down time

Steps to reduce mold change time:

1. Separation of internal from external

times

Conversion of internal to external

3. Parallel operations

Automation (hardware)

Quick connects and disconnects

Hydraulic, Pneumatic, Magnetic clamping

Ejector Couplers

5. Elimination of adjustments

Reduce Scheduled Down Time by QMC

24

Increasing Performance and Quality through Asset

Performance Optimization Program

OEE = Availability x Performance x Quality

Improving Equipment Life Cycle Costs

25

Increasing Performance and Quality through Asset

Performance Optimization Program

OEE = Availability x Performance x Quality

Improving Equipment Life Cycle Costs

CostperPart

Life

26

Increasing Performance and Quality through Asset

Performance Optimization Program

OEE = Availability x Performance x Quality

Existing System

with Technology

Upgrades /Encore

New System

Today

Economical End of

Life

New End of Life

Upgraded system

Improving Equipment Life Cycle Costs

Key Strategies to Increase Return On

Assets (RoA) in Molding

1. Adopt a Risk based strategy to enable efficient decision making

Plant and operational assessment to Identify, Quantify, and Prioritize

risks that are inherent to the organization (i.e. unscheduled down time)

2. The key strategy that differentiates Best-in-Class is to implement APM

(Asset Performance Management) as the company moves from

reactive to predictive asset management

One of the main goals of the best-in-class molders is to maximize

OEE and minimize down time.

The only way to achieve this goal is by being predictive in managing

assets and proactive in controlling the process

This key strategy enables Best-in-Class molders to perform at a

maximum efficiency and minimum unscheduled down time.

Best-in-Class molders avoid asset failure before they actually happen

resulting in lower unscheduled down time

27

PercentageofParticipants

Key Strategies to Increase RoA in Molding

3. The successful execution of previous strategy requires molders to have

real time visibility into asset performance (also a differentiating factor)

Making effective asset decisions requires molders to equip their employees

with the right data at the right time in the right form

Best-in-Class differentiate themselves from industry average and laggards

by more effectively leveraging data and turning data into action

70%

Best-in-Class

60%

59%

50%

59%

52%

Industry average

Laggards

50%

45%

40%

30%

21%

20%

10%

0%

Failure data is used to perform root

cause analysis

Historical as well as real time data is

used as actionable intelligence

Source: Aberdeen Group, Nov. 2009

28

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

29

Labor Reduction without Automation

Case study: Workcells pared for labor sharing

Warehouse

3 1 1 1

1 1 1 1 1

30

Labor Reduction with Automation

Utilize the existing automation (i.e. robots)

Consider other financial metrics in addition to simple

payback when evaluating automation

Life cycle costing

31

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

32

%ofscheduledproduction

4 6 1

Over Production

Is Conformance Ratio one of your main KPIs?

Over production leads to excess inventory

High unscheduled down time leads to under production

which in turn leads to low service level

180%

160%

140%

120%

100%

80%

60%

40%

20%

0%

Over production due to

High scheduled down time

Under production due to high

Unscheduled down time

12 37 99 41 17 36 97 13 40 24 14 11 42 25 22 22 48 11 98 18 91

Machine number

33

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

34

Cost($)

35

Combined cost

Set Up Costs

Carrying Costs

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Annual Inventory Turns

Optimum Inventory turns

Cost($)

36

Combined cost

Set Up Costs

Carrying Costs

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Annual Inventory Turns

Optimum Inventory turns

Cost($)

37

Combined cost

Savings

1 2 3 4

Combined cost

Set Up Costs

Carrying Costs

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Annual Inventory Turns

Optimum Inventory turns

A

B

C

Mold Change Time and Inventory

UTILIZATION

Total production: 24

2 changes, I hour each

Total production: 27

Lot size reduced in half.

Lot size reduced in half.

5 Changes, I hour each

5 Changes, 24 min. each

Total production: 24

Production

Mold change

38

Servicelevel

Inventorylevel(x1000)

0

39

Category A

Category B

Service level and inventory @ 85% OEE

Category C

Top 10

Inventory Top 10

102.0%

100.0%

98.0%

96.0%

94.0%

92.0%

90.0%

88.0%

86.0%

700

600

500

400

300

200

100

84.0%

Category A

Category B

Category C

Top 10

Inventory Top 10

Base

93.5%

95.1%

96.0%

92.4%

512

50% lot size

97.0%

95.0%

95.9%

99.4%

466

25% lot size

97.5%

95.2%

96.1%

99.6%

352

200% lot size

92.0%

92.3%

91.8%

89.6%

591

Simulated the effects of different lot sizing policies on inventory and

service level

Lot size reduction improved service level and reduced inventories

Case study- lot size reduction simulation

Valueofinventory

40

Sensitivity to spare parts inventory

$2,100,000

$2,000,000

$1,900,000

$1,800,000

$1,700,000

$1,600,000

$1,500,000

$1,400,000

$1,300,000

$1,200,000

$1,100,000

Preventive Maintenance

Mean Time Between Failures (MTBF)

10% - reduction of parts not used

25% - reduction of parts not used

50% - reduction of parts not used

75% - reduction of parts not used

90% - reduction of parts not used

0% - reduction of parts not used

$1,000,000

$900,000

$800,000

$700,000

50% reduction in not used parts

Today

Reduction to 3 months for

parts used in 2009

$600,000

$500,756

$500,000

$400,000

$300,000

$200,000

$100,000

$0

Goal

2 1.9 1.8 1.7 1.6 1.5 1.4 1.3 1.2 1.1 1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0

Years of inventory (parts used in 2009)

Case Study Spare Parts

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

41

42

ASSEMBLY, PACKAGING,

MACHNE HALL

and PALLETIZING

Assembly

Assembly/

Packaging/

Conveyor

Palletizing

WAREHOUSE

Product Flow Before

43

ASSEMBLY, PACKAGING,

PALLETIZING

Assembly/

WIP

MACHNE HALL

Packaging

Palletizing

STAGING

Product Flow After

44

Suppliers

Forecast

PRODUCTION CONTROL

SYACC

Forecast

Customer

Demand: 127K

Daily/ Weekly orders

Injection:

part #: 8720, 90ml vial

Cavitation: 24 cavity

Cycle: 9.6 sec.

Parts/ hr.: 9,000

Daily demand: 127,000/ day

12 sec.

7 days

Scheduling

Daily/ Weekly orders

Units/day

Injection:

part #: 9962, 48 mm cap

Cavitation: 16 cavity

Cycle: 10 sec.

Parts/hr.: 6,000

Daily demand: 127,000/ day

10 sec.

7 days

14 days

Assembly:

Part #: B 90210

Cycle: 0.58 sec. / unit

Parts/hr.: 6,200

Daily demand: 127,000/ day

Sterilizing:

Outside supplier

Daily demand: 127,000/ day

8 days

Receiving/ Shipping:

Daily demand: 127,000/ day

Production Lead Time:

22 days

Processing Time:

22 sec. 0.58 sec.

22.6 sec.

Value Stream Map - Existing System

Lleno

Vaco

7 days

15 days

45

Forecast

PRODUCTION CONTROL

Forecast

Suppliers

Daily/ Weekly orders

SYACC

Full

Daily/ Weekly orders

Customer

Demand: 127K

Units/day

Scheduling

Empty

Injection:

part #: 8720, 90ml vial

Cavitation: 24 cavity

Cycle: 9.6 sec.

Parts/ hr.: 9,000

Daily demand: 127,000/ day

12 sec.

Production

Kan Ban

Withdrawal

Kan Ban

Injection:

part #: 9962, 48 mm cap

Cavitation: 16 cavity

Cycle: 10 sec.

Parts/hr.: 6,000

Daily demand: 127,000/ day

10 sec.

3 days

Assembly:

Part #: B 90210

Cycle: 0.58 sec. / unit

Parts/hr.: 6,200

Daily demand: 127,000/ day

Sterilizing:

Outside supplier

Daily demand: 127,000/ day

8 days

Receiving/ shipping:

Daily demand: 127,000/ day

Production Lead Time:

11 days

Processing Time:

22 sec. 0.58 sec.

22.6 sec.

Value Stream Map - Future System

CarryingCost

AverageInventory

46

1,600,000

Push

$2,000,000

$1,800,000

1,400,000

$1,600,000

1,200,000

$1,400,000

1,000,000

$1,200,000

800,000

600,000

Pull

$1,000,000

$800,000

$600,000

400,000

$400,000

200,000

$200,000

0

Push: 46 machines Pull: Summer + reduced mold change Pull: Level summer + reduced mold

$0

time (26 machines)

Average Inventory

change time (21 machines)

Inventory Carry Cost

Pull System reduced :

Batch size by an average of 56% on high volume products and 74% on low

volume products

Safety Stock from an average of 15 days to 3 days

Inventory by 68%

Push Vs. Pull Simulation Analysis

47

Shift from Push to Pull system requires standardization, process

stability and repeatability

Stabilize operation prior to lean conversion

Material Control

Methods

Level

Production

Reduce response times or changes in demand

Reduce upstream schedule variability

Pull

System

Material replenishment linked to customer withdrawals

Constraint management applied to

manage bottlenecks

Synchronized

Production

Synchronize operations with customer

requirements

Create disciplined process repeatability

Continuous

Flow

Standardize work

Increase process flexibility

Reduce WIP inventory, time loss and defects

Create repeatability between workstations

Stability

Bring processes under control

Provide an environment to eliminate waste

Show a quick business impact

Start here

Time

Shift from Push to Pull

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

48

Social Responsibilities with Profits

Reducing energy consumption of assets is an untapped

resource in both the quest for profits and social responsibilities

ENERGY

Lighting

HVAC

8%

Air compressors

6%

Others

1%

3%

Labour

Infrastructure

d cooling

12%

Machines

Energy

3%

2%

2%

Maintenance

2%

50%

Dryers

20%

Equipment

5%

Resin

86%

49

Two Approaches to Reduce Energy Cost

1. Reduce the cost per unit of energy ($/KWh) through

negotiation and risk mitigation

Numerous consulting firms provide Negotiation and risk

mitigation services

Alternative Energy generation

2. Reduce the amount of energy used (KW/lb):

Certain utility companies offer programs that provide molders

rebates towards the purchase and installation of qualified

equipment that improves their facilitys energy efficiency

These two approaches alone without an Energy Management

Program can not be sustainable

50

1-

5-

Total Energy Management Program

Estimate and verify site energy profile

2-

3-

4-

Understand your Base and Process loads

Understand when and how much energy is used

Identify, Quantify, and Prioritize opportunities

Phase 1:

Energy audit

& reduction

strategy

Eliminate waste and reduce consumption through

- Implementation of selected energy reduction projects

6 - Monitoring and Targeting

- Understand Where energy is used

7 - Data analysis and reporting energy KPIs

- (Energy dashboard) by department

Phase 2:

Sustainability

Through

M&T

8 - Conduct internal and external benchmarking

9 - Repeat the steps Continuous improvement

51

0

0

52

Estimated

Capital Cost

Estimated

Annual Savings

Payback Electricity

Reduction

Carbon

Reduction

Identified Opportunities ($) ($) (year) (KW) (ton)

Process Water System

Free cooling

Option 1

Option 2 (4)

$ 60,000

$ 128,000

$ 29,000

$ 26,000

2.1 years

4.9 years

322,222

288,889

72

64

Compressed Air

Air Leaks

Reduced PSI for IMMs

Install ES control solution

$ 2,500 (1)

$0

$ 8,500

$ 37,500

$ 8,376 (2)

$ 12,000

24 days

immediate

0.7 years

416,667

150,000

93

33

Cost avoidance of new Air comp.

$50,000

Lighting

Retrofit to T5s as per layout $ 98,560 $ 46,689 2.1 years 449,206 100

Power Conditioning

Power cure to condition power $ 55,300 $ 23,000 (3) 2.4 years 204,254 45

and improve power factor

Cycle times

Estimated 6% reduction plant wide

TOTAL ESTIMATED COSTS & SAVINGS

$ 24,000

$ 248,860

$ 25,000

$ 178,564

0.96 years

1.39 years

318,000

1,827,016 KW

71

407 ton

Percent reduction compared to current usage

Case Study

17.77%

Wastes in Injection Molding

Waste in:

1. Raw material

2. Overall Equipment/ Plant Efficiency

Machine Availability (Scheduled/ Unscheduled down time)

Machine Performance (Cycle and cavitation)

Rejects

3. Labor

4. Over production

Conformance ratio

5. Inventory

WIP, FG, and spare parts

6. Product flow/ Transportation

7. Production lead time

Value stream mapping

Push vs. Pull system

8. Energy

9. House keeping

53

54

Visual Kan Ban to eliminate excessive material handling

Implement 5S

Action Plan

Start with assessing your current operation

Plant and operational assessment to Identify,

Quantify, and Prioritize Waste reduction

opportunities that are inherent to the organization

Huskys Manufacturing Advisory Services team

can assist you in developing and implementing a

Lean Manufacturing program tailored to your

operation

55

Contacts

Santiago Archila,

sarchila@husky.ca

905-951-5000, Ext. 3810

Sean Golzarian,

sgolzarian@husky.ca

905-951-5000, Ext. 3550

Husky website: www.husky.ca

56

S-ar putea să vă placă și

- Scrap Reduction EFD MQPDocument117 paginiScrap Reduction EFD MQPFranzMigÎncă nu există evaluări

- Steering Committee A Complete Guide - 2019 EditionDe la EverandSteering Committee A Complete Guide - 2019 EditionÎncă nu există evaluări

- The Why Factor: Winning with Workforce IntelligenceDe la EverandThe Why Factor: Winning with Workforce IntelligenceÎncă nu există evaluări

- Routsis Injection Molding ReferenceDocument176 paginiRoutsis Injection Molding ReferenceRupesh PillaiÎncă nu există evaluări

- Sot Sc70 OcapDocument63 paginiSot Sc70 OcapPBlurnz005100% (2)

- Kaizen ToolsDocument11 paginiKaizen Toolssinghpune19100% (1)

- Marico's brands and businessDocument26 paginiMarico's brands and businesstanyaÎncă nu există evaluări

- Injection Molding BasicsDocument26 paginiInjection Molding BasicsVIGNESH100% (1)

- How To Improve Oee PerformanceDocument9 paginiHow To Improve Oee PerformanceMuhammad Usman HaidarÎncă nu există evaluări

- Lean Manufacturing Principles Rexroth Bosch GroupDocument16 paginiLean Manufacturing Principles Rexroth Bosch GroupGarmentLearnerÎncă nu există evaluări

- SPC For Injection MouldingDocument121 paginiSPC For Injection MouldingKaixin Go100% (1)

- VSM TemplateDocument5 paginiVSM TemplateFrank Rojas100% (1)

- VSM - High-Mix - Low-Volume PDFDocument18 paginiVSM - High-Mix - Low-Volume PDFMurugan BalaramanÎncă nu există evaluări

- Lean Assessment2Document18 paginiLean Assessment2Yenaro CortesÎncă nu există evaluări

- Lean Daily Management & Visual Management - PT. Sukses Bersama Sinar GemilangDocument16 paginiLean Daily Management & Visual Management - PT. Sukses Bersama Sinar GemilangRifki Rizal DerrianÎncă nu există evaluări

- Going Beyond LeanDocument7 paginiGoing Beyond Leanลูกหมู ตัวที่สามÎncă nu există evaluări

- Molding Parameter Record RevDocument26 paginiMolding Parameter Record Revapi-37326090% (1)

- Operational ExcellenceDocument24 paginiOperational ExcellencemaheshÎncă nu există evaluări

- Injection Molding MethodsDocument23 paginiInjection Molding MethodsKi SeyÎncă nu există evaluări

- Daily Production Meeting Doing It LeanDocument10 paginiDaily Production Meeting Doing It LeanypraviÎncă nu există evaluări

- Job Shop VSMDocument47 paginiJob Shop VSMCalos Alberto Leal MojicaÎncă nu există evaluări

- Troubleshooting Injection Moulding Process ProblemsDocument24 paginiTroubleshooting Injection Moulding Process ProblemsKaixin Go50% (2)

- Packaging: A Few Specialists Mastered by OnlyDocument12 paginiPackaging: A Few Specialists Mastered by OnlyJeremy NorthÎncă nu există evaluări

- World Class ManufacturingDocument10 paginiWorld Class ManufacturingAhmed ElgazarÎncă nu există evaluări

- Troubleshooting Injection MouldingDocument140 paginiTroubleshooting Injection MouldingFernando Angiolini100% (1)

- Injection Molding Training ProgramsDocument25 paginiInjection Molding Training ProgramsSyed Mujtaba Ali BukhariÎncă nu există evaluări

- Mold Qualification FLowchart - FIMMTECH INCDocument1 paginăMold Qualification FLowchart - FIMMTECH INCCuco Martinez100% (1)

- Principles of World Class ManufacturingDocument171 paginiPrinciples of World Class Manufacturinglakshmigsr6610100% (1)

- Leadership - Three OpEx Questions You Need To Know The Answers ToDocument26 paginiLeadership - Three OpEx Questions You Need To Know The Answers Tomilou88Încă nu există evaluări

- Blow Molding Design GuidelineDocument5 paginiBlow Molding Design GuidelineAhmed Zidane100% (2)

- OEE and KPI OptimizationDocument61 paginiOEE and KPI OptimizationEdson Vargas100% (5)

- Lean Manufacturing Implementation - Lean Supply ChainDocument19 paginiLean Manufacturing Implementation - Lean Supply ChainSangram67% (3)

- Cellular LayoutsDocument10 paginiCellular Layoutssidd88Încă nu există evaluări

- Moulding Defects 1 PDFDocument158 paginiMoulding Defects 1 PDFAmolPagdal96% (46)

- New Product Development: Strategy, Tactics & Process Strategy, Tactics & ProcessDocument32 paginiNew Product Development: Strategy, Tactics & Process Strategy, Tactics & ProcessNoel MosesÎncă nu există evaluări

- Injection Molding Pocket BookDocument67 paginiInjection Molding Pocket BookKathirrasuÎncă nu există evaluări

- Injection Molding Scrap ReductionDocument57 paginiInjection Molding Scrap ReductionkggganiÎncă nu există evaluări

- Introduction To OEE: (Overall Equipment Effectiveness)Document95 paginiIntroduction To OEE: (Overall Equipment Effectiveness)Junjie ChenÎncă nu există evaluări

- Reduce inventory A3Document1 paginăReduce inventory A3Krunal PandyaÎncă nu există evaluări

- Lean Suggested Readings and ReferencesDocument30 paginiLean Suggested Readings and ReferencessigmasundarÎncă nu există evaluări

- Applying PDCA A3 Thinking and Problem SolvingDocument23 paginiApplying PDCA A3 Thinking and Problem SolvingAndrei Timofeev100% (2)

- Plastic Molding DefectsDocument17 paginiPlastic Molding DefectsNavya GowdaÎncă nu există evaluări

- Plastic Injection MoldingDocument36 paginiPlastic Injection MoldingChacaquair Mutiara100% (1)

- Pressure Requirements: Flow LengthDocument43 paginiPressure Requirements: Flow Lengthanirudha_jewalikar1100% (2)

- BMW Spartanburg Plant ExcellenceDocument9 paginiBMW Spartanburg Plant Excellencequycoctu100% (1)

- Injection Mould Design For PVCDocument7 paginiInjection Mould Design For PVCbile_taseÎncă nu există evaluări

- Yamazumi Process Modeling Tool AdaptiveBMS For ManufacturingDocument10 paginiYamazumi Process Modeling Tool AdaptiveBMS For ManufacturingYeoh KhÎncă nu există evaluări

- Injection Moulding - Quality Molded PartsDocument28 paginiInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Strengthening Administrative Functions through MAKIGAMI AnalysisDocument28 paginiStrengthening Administrative Functions through MAKIGAMI AnalysisUmashankar GautamÎncă nu există evaluări

- Design and Analysis of Injection Mould with Hot Runner SystemDocument17 paginiDesign and Analysis of Injection Mould with Hot Runner SystemKiran KumarÎncă nu există evaluări

- Nozzle E1 215-225 215-225 E2 220-230 220-230 E3 200-210 200-210 Hopper E4 175-185 175-185Document1 paginăNozzle E1 215-225 215-225 E2 220-230 220-230 E3 200-210 200-210 Hopper E4 175-185 175-185KodhansÎncă nu există evaluări

- The Plan For Every PartDocument7 paginiThe Plan For Every PartAlpha SamadÎncă nu există evaluări

- Lean Six Sigma Asq Road MapDocument2 paginiLean Six Sigma Asq Road Maphj100% (4)

- 02 Preform QualityDocument32 pagini02 Preform QualityMuhammad Noman Mehboob100% (1)

- Early Equipment Management (EEM) Continuous Improvement For Projects by Dennis McCarthyDocument299 paginiEarly Equipment Management (EEM) Continuous Improvement For Projects by Dennis McCarthyRobson LimeiraÎncă nu există evaluări

- Setup Reduction... : Case Studies in Becoming LeanDocument51 paginiSetup Reduction... : Case Studies in Becoming LeanfoofoolÎncă nu există evaluări

- 17PME328E: Process Planning and Cost EstimationDocument48 pagini17PME328E: Process Planning and Cost EstimationDeepak MisraÎncă nu există evaluări

- KaizenDocument40 paginiKaizenAshish KulkarniÎncă nu există evaluări

- Using Breakover Devices in Triac and SCR Gate Control CircuitsDocument37 paginiUsing Breakover Devices in Triac and SCR Gate Control CircuitsAnnalyn Duculan SoriaÎncă nu există evaluări

- O Engineers 3rd Issue Oct 2017Document51 paginiO Engineers 3rd Issue Oct 2017arsalanhamidÎncă nu există evaluări

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDocument321 pagini(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManÎncă nu există evaluări

- Graviner MK6 Oil Mist DetectorDocument4 paginiGraviner MK6 Oil Mist DetectorDhanielÎncă nu există evaluări

- Makerere University Civil Engineering Assignment on Nalubaale DamDocument8 paginiMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiÎncă nu există evaluări

- 24th Annual International Pittsburgh Coal 2007 WixDocument10 pagini24th Annual International Pittsburgh Coal 2007 WixAmauche OgeÎncă nu există evaluări

- Spe 21970 MSDocument13 paginiSpe 21970 MSasu jaranÎncă nu există evaluări

- Introduction to Chemistry Exam 2 Practice Problems TitleDocument6 paginiIntroduction to Chemistry Exam 2 Practice Problems TitlebenyÎncă nu există evaluări

- American Zettler AZ8 1CH 24DSEDocument4 paginiAmerican Zettler AZ8 1CH 24DSEadiegooscarÎncă nu există evaluări

- Mantrac Egypt ProfileDocument9 paginiMantrac Egypt ProfilenabilredascribdÎncă nu există evaluări

- Dna60 PDFDocument15 paginiDna60 PDFAc IdÎncă nu există evaluări

- Measuring Instrument Accuracy LimitsDocument2 paginiMeasuring Instrument Accuracy LimitsDan DanubiusÎncă nu există evaluări

- Pump Mechanical Seals GuideDocument41 paginiPump Mechanical Seals GuideArief Hidayat100% (1)

- Kinetic and Potential Energy PracticeDocument1 paginăKinetic and Potential Energy Practicealchemist2000Încă nu există evaluări

- Projects Oil and Gas BrochureDocument20 paginiProjects Oil and Gas BrochureRussel John RamosÎncă nu există evaluări

- Revision Notes For Science Chapter 12 - Electricity (Class 10th) - askIITiansDocument4 paginiRevision Notes For Science Chapter 12 - Electricity (Class 10th) - askIITianshariom sharmaÎncă nu există evaluări

- Hajar Trading and Technical Services: Risk AssessmentDocument10 paginiHajar Trading and Technical Services: Risk Assessmentwinston11Încă nu există evaluări

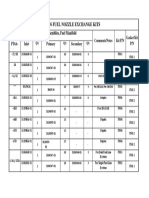

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocument1 paginăPt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchÎncă nu există evaluări

- General-Purpose Steam Turbines (Amendments/Supplements To Api 611)Document27 paginiGeneral-Purpose Steam Turbines (Amendments/Supplements To Api 611)BiswasÎncă nu există evaluări

- Electrical Properties of Materials Mod-1Document18 paginiElectrical Properties of Materials Mod-1Darshan rajÎncă nu există evaluări

- 568100Document2 pagini568100Talha TariqÎncă nu există evaluări

- Line Sizing GuidelinesDocument31 paginiLine Sizing Guidelinesc_nghia100% (3)

- VXA 700 Owner ManualDocument68 paginiVXA 700 Owner ManualjohnÎncă nu există evaluări

- Wa500-6 Sen00236-04d PDFDocument1.705 paginiWa500-6 Sen00236-04d PDFanggie100% (4)

- Dose Complete CatalogueDocument272 paginiDose Complete CatalogueBerkan OranusÎncă nu există evaluări

- Folio SainsDocument15 paginiFolio SainsMohammad Afifi Rohman80% (5)

- U3 Oxidation and Reduction PPT WatermarkDocument45 paginiU3 Oxidation and Reduction PPT Watermarkapi-125934329Încă nu există evaluări

- European Design Guide For Tensile Surface StructuresDocument16 paginiEuropean Design Guide For Tensile Surface StructuresAngel Sullyvan100% (1)

- CH 3 Gas Refrigeration CycleDocument20 paginiCH 3 Gas Refrigeration CycleMeleseÎncă nu există evaluări

- Pressure MeasurementDocument19 paginiPressure MeasurementShadmanSakiefHridoyÎncă nu există evaluări