Documente Academic

Documente Profesional

Documente Cultură

Polyester

Încărcat de

AobscDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Polyester

Încărcat de

AobscDrepturi de autor:

Formate disponibile

History

Forms

Manufacturing Process

Properties

Future

Uses

DEFINITION

Polyester (aka Terylene) is a category of polymers

which contain the ester functional group in their

main chain.

Polyester is currently defined as:

Long chain polymers chemically composed of

at least 85% by weight of an ester and a

dihydric alcohol and terephthalic acid. The

name polyester refers to the linkage of

several monomers (esters) within the fiber.

HISTORY

In 1926, United States-based E.I. du Pont de Nemours and Co. began

research into very large molecules and synthetic fibers

W.H. Carothers, centered on what became nylon, the first synthetic fiber.

1939-41, British research chemists took interest in the du Pont

studies and conducted their own research in the laboratories of Calico

Printers Association, Ltd. This work resulted in the creation of the

polyester fiber known in England as Terylene.

In 1946, du Pont purchased the right to produce this polyester fiber in

the United States.

The company conducted some further developmental work, and in

1951, began to market the fiber under the name Dacron

RAW MATERIALS

Coal

Air

Water

Petroleum

FORMS OF POLYESTER

1. Filament

2. Staple

3. Tow

4. Fiberfill

USES OF DIFFERENT FORM IN DIFFERENT

PLACES

1. In the filament form, each individual strand of polyester

fiber is continuous in length, producing smooth-surfaced

fabrics

2. In staple form, filaments are cut to short, predetermined

lengths. In this form polyester is easier to blend with other

fibers

3. Tow is a form in which continuous filaments are drawn

loosely together

4. Fiberfill is the voluminous form used in the manufacture of

quilts, pillows, and outerwear

Microscopic View

DIFFERENT STRUCTURES OF POLYESTER

STRUCTURE AND APPERANCE

COLOURLESS AND TRANSPARENT

SMOOTH AND LUSTURUOS

SHAPE AS WE REQIURE

SHINY GLASSROD LIKE

POLYESTER FIBER CHARACTERISTICS

Strong

Resistant to stretching and shrinking

Resistant to most chemicals

Quick drying

Crisp and resilient when wet or dry

Wrinkle resistant

Mildew resistant

Abrasion resistant

Retains heat-set pleats and crease

Easily washed

POLYESTER BLENDS

Polyester and Cotton

1. Resist wrinkles

2. Resist stains

3. Retain shape

POLYESTER BLENDS

Polyester and Wool

1. Wrinkle resistance

2. Shape retention

3. Increase durability

POLYESTER BLENDS

Polyester and Rayon

1. More durable

2. Shape retention

3. More resilience

MANUFACTURING FILAMENT YARN

Polymerization

Drying

Melt spinning

Drawing the fiber

Winding

Polymerization

To form polyester, dimethyl terephthalate is first reacted with

ethylene glycol in the presence of a catalyst at a temperature of 302-

410F (150-210C).

The resulting chemical, a monomer (single, non-repeating molecule)

alcohol, is combined with terephthalic acid and raised to a

temperature of 472F (280C). Newly-formed polyester, which is

clear and molten, is extruded through a slot to form long ribbons.

Drying

After the polyester emerges from polymerization, the long molten

ribbons are allowed to cool until they become brittle. The material is

cut into tiny chips and completely dried to prevent irregularities in

consistency.

MELT SPINNING

Polymer chips are melted at 500-518F (260-270C) to

form a syrup-like solution. The solution is put in a metal

container called a spinneret and forced through its tiny

holes, which are usually round, but may be pentagonal or

any other shape to produce special fibers. The number of

holes in the spinneret determines the size of the yarn, as

the emerging fibers are brought together to form a single

strand.

At the spinning stage, other chemicals may be added to

the solution to make the resulting material flame

retardant, antistatic, or easier to dye.

Drawing the fiber

When polyester emerges from the spinneret, it is soft and

easily elongated up to five times its original length. This

increases the strength, tenacity, and resilience of the fiber.

This time, when the filaments dry, the fibers become solid

and strong instead of brittle.

Drawn fibers may vary greatly in diameter and length, Also,

as the fibers are drawn, they may be textured or twisted to

create softer or duller fabrics.

Winding

After the polyester yarn is drawn, it is wound on large

bobbins or flat-wound packages, ready to be woven into

material.

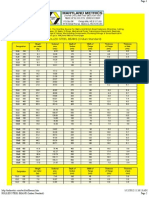

PHYSICAL PROPERTIES

Specific weight 1.22-1.38 gm/cm

Tenacity up to 85 cN/tex

Moisture regain 0.2-0.5 %

Heat Resist 150-200 C

Sunlight better resistance

Insects no effect

CHEMICAL PROPERTIES

Acids: At room temperature, PET is resistant to organic and moderate

strength mineral acids. At high temperatures, PET strength loss in

moderate strength acids can be appreciable. Strong acids such as

concentrated sulfuric acid dissolve and depolymerize PET.

Alkalies: Polyester bers have good resistance to weakly alkaline

chemicals and moderate resistance to stronglyalkaline chemicals at room

temperature. PET bers are attacked by strongly alkaline substances.

Organic Solvents: PET bers are generally insoluble in organic

solvents, including cleaning uids.

DEMAND FOR POLYESTER

FUTURE

Biodegradable and biocompatible poly(3-hydroxybutyrate-

co-3-hydroxyvalerate) (PHBV), a copolymer of microbial

polyester, was fabricated as a Nano fibrous mat by electro

spinning

The researchers have developed a process in which

polyester is dramatically strengthened with a material

known as a liquid crystalline polymer. The liquid crystalline

polymer used in the research is called Vectra , a plastic

material similar to Kevlar that is five times stronger than

steel. Polyester is used because its chemical structure is

ideal for making bonds with the liquid crystalline polymer

SOME MAJOR POLYESTER FIBER USES

Apparel: Every form of clothing

Home Furnishings: Carpets, curtains, draperies,

sheets and pillow cases, wall coverings, and

upholstery

Other Uses: hoses, power belting, ropes and

nets, thread, tire cord, auto upholstery, sails,

floppy disk liners, and fiberfill for various products

including pillows and furniture

S-ar putea să vă placă și

- PolyesterDocument50 paginiPolyesterFiaz jutt100% (1)

- Polyester Fiber Manufacturing and PropertiesDocument20 paginiPolyester Fiber Manufacturing and Propertiesamala31100% (1)

- Synthetic Fibers: Understanding Polyester Fabric Properties and UsesDocument33 paginiSynthetic Fibers: Understanding Polyester Fabric Properties and UsesChaudhary Shahzad ZahoorÎncă nu există evaluări

- Polyester Fabric Guide: History, Manufacturing, Types & UsesDocument19 paginiPolyester Fabric Guide: History, Manufacturing, Types & UsesChetal BholeÎncă nu există evaluări

- PolyesterDocument25 paginiPolyesterahsen_hasan100% (2)

- Polyester Fibers: Fig.1: Production of Polyethylene TerephthalateDocument12 paginiPolyester Fibers: Fig.1: Production of Polyethylene TerephthalateShailendra Mishra100% (1)

- Design and Study of Manufacturing of Polyester Plant Using Pta and MegDocument8 paginiDesign and Study of Manufacturing of Polyester Plant Using Pta and MegUgurÎncă nu există evaluări

- History of Polyurethane DevelopmentDocument9 paginiHistory of Polyurethane DevelopmentAli AhsanÎncă nu există evaluări

- PolyesterDocument7 paginiPolyesterkgaviolaÎncă nu există evaluări

- PolyesterDocument7 paginiPolyesterRanjan KumarÎncă nu există evaluări

- Rhodopsin Dyes For Polyamide by RDNDocument96 paginiRhodopsin Dyes For Polyamide by RDNSaidul KarimÎncă nu există evaluări

- Polyester YarnDocument6 paginiPolyester Yarnnil006100% (1)

- Composite Nonwovens For Hygiene and Medical ApplicationsDocument9 paginiComposite Nonwovens For Hygiene and Medical ApplicationsSariyyaHeydarovaÎncă nu există evaluări

- PlasticDocument9 paginiPlasticCarla CampiÎncă nu există evaluări

- Fiber and YarnDocument38 paginiFiber and YarnPutri Mayangsari100% (1)

- Oligomer ProblemDocument4 paginiOligomer ProblemMonjur MorshedÎncă nu există evaluări

- Types of PolymerizationDocument27 paginiTypes of PolymerizationMizanul IslamÎncă nu există evaluări

- BindersDocument4 paginiBindersSariyyaHeydarovaÎncă nu există evaluări

- ISOCYNATEDocument4 paginiISOCYNATETry Julianda ErmayaÎncă nu există evaluări

- Acrylic FiberDocument9 paginiAcrylic FiberNeeraj JainÎncă nu există evaluări

- Flexible Foam Buyers Guide.Document7 paginiFlexible Foam Buyers Guide.Yo GoldÎncă nu există evaluări

- Chemical Binders for Nonwoven FabricsDocument11 paginiChemical Binders for Nonwoven FabricskarpagsÎncă nu există evaluări

- Analysis of SpandexDocument11 paginiAnalysis of SpandexJuan CubasÎncă nu există evaluări

- Facts About PET - 25 March 2013Document7 paginiFacts About PET - 25 March 2013Cátia CoelhoÎncă nu există evaluări

- PolyethyleneDocument17 paginiPolyethylenePrateek Mall100% (1)

- Fiber Consumption in Nonwovens1Document12 paginiFiber Consumption in Nonwovens1gowrikathirÎncă nu există evaluări

- PolyacetalDocument16 paginiPolyacetalChakma SHIMULÎncă nu există evaluări

- Recent Advancements in Dyestuff IndustryDocument85 paginiRecent Advancements in Dyestuff IndustryPranjal AgarwalÎncă nu există evaluări

- SpandexDocument1 paginăSpandexNavnath PingaleÎncă nu există evaluări

- Polyurethane Chemicals in AlbertaDocument53 paginiPolyurethane Chemicals in AlbertaAhmed M. AbdElraheem100% (2)

- Polymer Blends and Composites: Chemistry and TechnologyDe la EverandPolymer Blends and Composites: Chemistry and TechnologyÎncă nu există evaluări

- Recent Developments in The Chemistry of Halogen-Free Flame Retardant PolymersDocument52 paginiRecent Developments in The Chemistry of Halogen-Free Flame Retardant PolymersThinh DangÎncă nu există evaluări

- Polypropylene PP PlasticDocument8 paginiPolypropylene PP PlasticRyan VasquezÎncă nu există evaluări

- PolyesterDocument432 paginiPolyesterMohsaAzhÎncă nu există evaluări

- Lecture 5 Operation Pretreatment Process of TextileDocument16 paginiLecture 5 Operation Pretreatment Process of TextileTamer Farouk KhalifaÎncă nu există evaluări

- Manufacturing End Uses: Riaz-Ul-Haq 060820-054Document12 paginiManufacturing End Uses: Riaz-Ul-Haq 060820-054Kasra GolbanÎncă nu există evaluări

- Mixed Outlook For Synthetic Polymers inDocument4 paginiMixed Outlook For Synthetic Polymers indr tamerÎncă nu există evaluări

- Microcellular Shoes Ole SystemsDocument10 paginiMicrocellular Shoes Ole SystemsA Mahmood100% (1)

- Greening Bangladesh's Textile IndustryDocument11 paginiGreening Bangladesh's Textile IndustryGizele RaoÎncă nu există evaluări

- Disperse Dyes For Printing On PolyesterDocument2 paginiDisperse Dyes For Printing On PolyesterFathi Mustafa100% (1)

- Reactol 1717 EDocument1 paginăReactol 1717 EbuninaÎncă nu există evaluări

- Ullmann's Fibers GuideDocument38 paginiUllmann's Fibers GuidembstutextileÎncă nu există evaluări

- History of PlasticDocument3 paginiHistory of PlasticVikneshwaran BalakrishnanÎncă nu există evaluări

- Natural PolymersDocument2 paginiNatural PolymersRoshdy AbdelRassoulÎncă nu există evaluări

- Silane Terminated Polyurethanes 2009-09-07Document24 paginiSilane Terminated Polyurethanes 2009-09-07Franco Carli100% (1)

- Application of Polypropylene in Technical TextilesDocument11 paginiApplication of Polypropylene in Technical TextilesDr Muhammad Mushtaq Mangat100% (1)

- Project Report On Pet Bottle Recycled Into PolyesterDocument7 paginiProject Report On Pet Bottle Recycled Into PolyesterEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Foam TypesDocument12 paginiFoam TypesRolaxÎncă nu există evaluări

- Polyester Polyol From Recycled PETDocument3 paginiPolyester Polyol From Recycled PETA MahmoodÎncă nu există evaluări

- How Ingredients Influence Unsaturated Polyester PropertiesDocument28 paginiHow Ingredients Influence Unsaturated Polyester Propertiesresinc100% (4)

- Eco-profiles of European Plastics Industry Polyurethane Flexible FoamDocument18 paginiEco-profiles of European Plastics Industry Polyurethane Flexible Foamakukerank100% (1)

- Introduction to Nylon Fibre: Properties & UsesDocument3 paginiIntroduction to Nylon Fibre: Properties & UsesDebasish GhoshÎncă nu există evaluări

- Tencel Fiber Properties Under 40 CharactersDocument1 paginăTencel Fiber Properties Under 40 Charactersnil006Încă nu există evaluări

- Coating Application in TextileDocument49 paginiCoating Application in TextilerehanabbaciÎncă nu există evaluări

- Biopolymers Facts and StatisticsDocument48 paginiBiopolymers Facts and StatisticsMohit100% (1)

- Reduce Styrene Migration from UP ResinsDocument2 paginiReduce Styrene Migration from UP Resinsgunawan refiadi0% (1)

- Non WovenDocument7 paginiNon WovenCarlos Ernesto Aguilar LópezÎncă nu există evaluări

- PlasticDocument48 paginiPlasticRaihanHaronÎncă nu există evaluări

- Bio-Based PolyurethaneDocument2 paginiBio-Based PolyurethaneDoris de GuzmanÎncă nu există evaluări

- 5 - FlaxDocument30 pagini5 - FlaxHassaan ShamshadÎncă nu există evaluări

- The Genetics of DiversityDocument1 paginăThe Genetics of DiversityAobscÎncă nu există evaluări

- Fueled For Life Article QuestionsDocument1 paginăFueled For Life Article QuestionsAobscÎncă nu există evaluări

- Body's Defender Goes On The AttackDocument1 paginăBody's Defender Goes On The AttackAobscÎncă nu există evaluări

- Rome Transition To EmpireDocument2 paginiRome Transition To EmpireAobscÎncă nu există evaluări

- Finally, The Spleen Gets Some RespectDocument1 paginăFinally, The Spleen Gets Some RespectAobscÎncă nu există evaluări

- Flower Week Re-Write (Synthesis)Document3 paginiFlower Week Re-Write (Synthesis)AobscÎncă nu există evaluări

- Rome Transition To EmpireDocument2 paginiRome Transition To EmpireAobscÎncă nu există evaluări

- Finally, The Spleen Gets Some RespectDocument1 paginăFinally, The Spleen Gets Some RespectAobscÎncă nu există evaluări

- Endocrine WebquestDocument1 paginăEndocrine WebquestAobscÎncă nu există evaluări

- Singer Essay Rough DraftDocument3 paginiSinger Essay Rough DraftAobscÎncă nu există evaluări

- Polymer Powerpoint CompDocument36 paginiPolymer Powerpoint CompKristianus Rendra PamayuÎncă nu există evaluări

- This Is Your Brain On DrugsDocument2 paginiThis Is Your Brain On DrugsAobscÎncă nu există evaluări

- Answers To Physics A Final Exam Review Packet IIDocument8 paginiAnswers To Physics A Final Exam Review Packet IIAobscÎncă nu există evaluări

- Oxidation NumbersDocument6 paginiOxidation NumbersAobscÎncă nu există evaluări

- Chapter 27 NotesDocument4 paginiChapter 27 NotesAobscÎncă nu există evaluări

- L8 Logistics ManagementDocument41 paginiL8 Logistics ManagementShahmien SevenÎncă nu există evaluări

- Roller Cone Bits CatalogDocument32 paginiRoller Cone Bits Catalogruzzo2003100% (2)

- Cement Grouted Rock BoltsDocument28 paginiCement Grouted Rock BoltsBhaskar ReddyÎncă nu există evaluări

- Inventory BasicsDocument63 paginiInventory BasicsMaulikÎncă nu există evaluări

- Penstock Erection Procedure - SUHEPDocument7 paginiPenstock Erection Procedure - SUHEPPrasanta MallaÎncă nu există evaluări

- Effects of ISO 9001 On Efficiency of Firms A Conceptual FrameworkDocument4 paginiEffects of ISO 9001 On Efficiency of Firms A Conceptual FrameworkInternational Journal of Innovative Science and Research Technology100% (1)

- Machining 2Document19 paginiMachining 2Kah KiatÎncă nu există evaluări

- Project Report-Small Scale IndDocument10 paginiProject Report-Small Scale Inddhiraj53Încă nu există evaluări

- Cold StorageDocument5 paginiCold StorageNilesh ThoraveÎncă nu există evaluări

- A 159 - 83 (2015)Document5 paginiA 159 - 83 (2015)phaindikaÎncă nu există evaluări

- CAT 4162 5 UK ParflangeDocument270 paginiCAT 4162 5 UK ParflangeKamil KościelakÎncă nu există evaluări

- Buffoli Booklet - USA PhoscoatingDocument138 paginiBuffoli Booklet - USA PhoscoatingMark GarrettÎncă nu există evaluări

- Anette MullerDocument33 paginiAnette MullerBianca CalderónÎncă nu există evaluări

- M&E Fittings and AccessoriesDocument9 paginiM&E Fittings and AccessoriesRachel IngramÎncă nu există evaluări

- En Standard SpecificationDocument33 paginiEn Standard SpecificationSimbu ArasanÎncă nu există evaluări

- 247 DIN EN 13858 Engl PDFDocument15 pagini247 DIN EN 13858 Engl PDFAlejo Leal100% (4)

- Young Touchstone FHF-SSF CatalogueDocument8 paginiYoung Touchstone FHF-SSF Catalogueangie2702Încă nu există evaluări

- Nptel - Ac.in Courses 112103174 Module1 Lec2 1Document2 paginiNptel - Ac.in Courses 112103174 Module1 Lec2 1ErPriyeRanjanÎncă nu există evaluări

- Universal Strap Clamp and Mould Clamp CatalogueDocument22 paginiUniversal Strap Clamp and Mould Clamp Catalogueanujkumartyagi9275Încă nu există evaluări

- Concrete LiningDocument17 paginiConcrete LiningEtha MargarethaÎncă nu există evaluări

- Leaded Tin Bronze C54400Document3 paginiLeaded Tin Bronze C54400nfcastingsÎncă nu există evaluări

- Lean Toolbox 0304Document3 paginiLean Toolbox 0304bhplibÎncă nu există evaluări

- 5 Flooring PDFDocument6 pagini5 Flooring PDFMasoudRmdnÎncă nu există evaluări

- Petrochemical IndonesiaDocument43 paginiPetrochemical IndonesiaElfara PuspitaÎncă nu există evaluări

- EtchingDocument2 paginiEtchingAmiirah MuddhooÎncă nu există evaluări

- Marketing Strategy Assessment Paper Box HandicraftsDocument11 paginiMarketing Strategy Assessment Paper Box HandicraftsNhoel RsÎncă nu există evaluări

- Microstructure Exp. 1: Metals and CompositesDocument29 paginiMicrostructure Exp. 1: Metals and CompositesR-wah LarounetteÎncă nu există evaluări

- WPC120 PDFDocument2 paginiWPC120 PDFHamzaHashimÎncă nu există evaluări

- Rolled Steel Beams (Indian Standard)Document3 paginiRolled Steel Beams (Indian Standard)Sandip JadhavÎncă nu există evaluări

- Corrosion Prevent at Ion TechnologyDocument12 paginiCorrosion Prevent at Ion TechnologyandraspappÎncă nu există evaluări