Documente Academic

Documente Profesional

Documente Cultură

Occupational Safety Program

Încărcat de

Mayom Mabuong0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări11 paginiOccupational safety program needs to be integrated into the general operations of the firm / Co. / Organization. The firm as well needs a written policy on safety issues including hygiene measure and the safe use of PPE. It is a multidisciplinary effort, it requires the interaction of many groups in work environment.

Descriere originală:

Titlu original

6. Occupational safety program.ppt

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentOccupational safety program needs to be integrated into the general operations of the firm / Co. / Organization. The firm as well needs a written policy on safety issues including hygiene measure and the safe use of PPE. It is a multidisciplinary effort, it requires the interaction of many groups in work environment.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări11 paginiOccupational Safety Program

Încărcat de

Mayom MabuongOccupational safety program needs to be integrated into the general operations of the firm / Co. / Organization. The firm as well needs a written policy on safety issues including hygiene measure and the safe use of PPE. It is a multidisciplinary effort, it requires the interaction of many groups in work environment.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 11

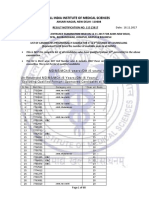

Occupational safety program

Margaret K. Semakula

Occupational safety program

Work place safety program needs to be integrated into

the general operations of the firm/Co./Organization.

The ethics of safety awareness and practices needs to be

cultivated into the daily operations.

There is also need to involve all stakeholders.

The firm as well needs a written policy on safety issues

including hygiene measure and the safe use of PPE. The

policy needs to be well disseminated to all workers.

Occupational safety program

First line supervisors should make constant checks

to ensure that the guidelines are adhered to.

It is a multidisciplinary effort, it requires the

interaction of many groups in work environment

and there fore requires a multidisciplinary

steering committees.

This committee establish goals, sets policies,

objectives and activities

Occupational safety program

There may also be need for departmental level safety

teams.

The program must encourage participants from the 1st

line supervisors and production workers.

Potential actor include (all levels of management,

program workers, safety directorate, all departments,

etc.).

Occupational safety program

The role of first line managers; these must provide the

policy framework for safety in a work place.

Their roles include;

1. A commitment to provide the best possible safety to all

employees.

2. A requirement that all occupational injuries are reported and

investigated.

3. Clear explanations to all employees of their exposures.

4. Regularly schedule systems of safety analyses.

5. Disciplinary procedures for employees who engage in un safe

behavoiur.

Occupational safety program

A sensitive and successful program ought to identify and

eliminate all hazards before accidents occur.

The program must examine all the macro and micro work

environments to identify potential sources of exposures

and accidents.

The program ought to study the entire unit of operation

to identify the risk prone processes and individuals most

at risk.

Occupational safety program

It should then design strategies to diminish the

potential for occurrence of the risk.

The process involves conducting a system safety

analysis.

Systems safety analysis; is a sub discipline of

safety engineering that is concerned with

occupational safety (processes) analysis.

Occupational safety program

The methodologies include job safety analysis.

It includes a team of specialists, workers and even the

design engineer if the job is complex.

Steps in job safety analysis

1. Break the job (small system) into components.

2. Identify possible hazards at each stage.

3. The worker then simulates or walk through each element,

explaining the details and describing the previous accidents or

near misses.

Occupational safety program

Certain operations pose high potential risks to workers

and environment or surrounding communities in all their

process.

This is more so in the petroleum industry and the

government usually issues standards for safety;

Develop a written description of potential hazards

Occupational safety program

Performing comprehensive analyses to

evaluate the hazards

Formalizing and enforcing safe operating

procedures

Instituting emergency response planning.

Thank you for listening

Any questions or concerns?

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- 1st Periodical Exam in Health 10Document2 pagini1st Periodical Exam in Health 10Jhackhie Mirasol Calibo100% (2)

- Work Place InspectionDocument24 paginiWork Place InspectionMayom MabuongÎncă nu există evaluări

- Lessons One To Ten From Ummah PDFDocument42 paginiLessons One To Ten From Ummah PDFMayom MabuongÎncă nu există evaluări

- Entrepreneurship & InnovationDocument31 paginiEntrepreneurship & InnovationSamruddhi KudalkarÎncă nu există evaluări

- HRM Case StudyDocument21 paginiHRM Case StudyNabil Eyg Iakini100% (1)

- Health Care Payment PDFDocument174 paginiHealth Care Payment PDFAshri Nur IstiqomahÎncă nu există evaluări

- Opening Statement Defense (Riki Jones v. Metro City) ArbellaDocument4 paginiOpening Statement Defense (Riki Jones v. Metro City) Arbellasarbella100% (2)

- BPC-IMS Gap Analysis Checklist Kajabi PDFDocument23 paginiBPC-IMS Gap Analysis Checklist Kajabi PDFSerkan CebeciogluÎncă nu există evaluări

- Warrap PresentationDocument20 paginiWarrap PresentationMayom MabuongÎncă nu există evaluări

- Code of ConductDocument5 paginiCode of ConductMuneerÎncă nu există evaluări

- Ruweng AADocument20 paginiRuweng AAMayom MabuongÎncă nu există evaluări

- Quick Guide To The Finance DProDocument24 paginiQuick Guide To The Finance DProMayom MabuongÎncă nu există evaluări

- DTG10 Transition - Stakeholders Meeting 16 07 2021Document20 paginiDTG10 Transition - Stakeholders Meeting 16 07 2021Mayom MabuongÎncă nu există evaluări

- Quick Guide To The Program DProDocument32 paginiQuick Guide To The Program DProMayom MabuongÎncă nu există evaluări

- The Nonprofit Growth GuideDocument25 paginiThe Nonprofit Growth GuideMayom MabuongÎncă nu există evaluări

- Leadership and Board EngagementDocument14 paginiLeadership and Board EngagementMayom MabuongÎncă nu există evaluări

- Eatern Equatoria State PresentationDocument24 paginiEatern Equatoria State PresentationMayom MabuongÎncă nu există evaluări

- 2018 A Roof Over My HeadDocument64 pagini2018 A Roof Over My HeadMayom MabuongÎncă nu există evaluări

- Zanchito Project Fiche 041-797 v3Document2 paginiZanchito Project Fiche 041-797 v3Mayom MabuongÎncă nu există evaluări

- Pollution of Water ResourcesDocument5 paginiPollution of Water ResourcesMayom MabuongÎncă nu există evaluări

- WBGS SS HIV Review Meeting - Presentation Template (Repaired)Document23 paginiWBGS SS HIV Review Meeting - Presentation Template (Repaired)Mayom MabuongÎncă nu există evaluări

- Workshop2 - Building Organizational CapacityDocument10 paginiWorkshop2 - Building Organizational CapacityMayom MabuongÎncă nu există evaluări

- Community and Health DevelopmentDocument2 paginiCommunity and Health DevelopmentMayom MabuongÎncă nu există evaluări

- Introduction To SIS-LMSDocument9 paginiIntroduction To SIS-LMSMayom MabuongÎncă nu există evaluări

- MRS 550 Ecclesiology and Church Leadership 12-1-21Document62 paginiMRS 550 Ecclesiology and Church Leadership 12-1-21Mayom MabuongÎncă nu există evaluări

- Unitaid Proposal Cover Page: If More Than One Partner, List On Separate LinesDocument38 paginiUnitaid Proposal Cover Page: If More Than One Partner, List On Separate LinesMayom MabuongÎncă nu există evaluări

- PMTCT NamibiaDocument17 paginiPMTCT NamibiaMayom MabuongÎncă nu există evaluări

- MRS 701 Traditional Religion 9-30-20aDocument33 paginiMRS 701 Traditional Religion 9-30-20aMayom MabuongÎncă nu există evaluări

- Waste Management RegulationsDocument65 paginiWaste Management RegulationsMayom MabuongÎncă nu există evaluări

- Stress TinaDocument26 paginiStress TinaMayom MabuongÎncă nu există evaluări

- MRS 633 Being Christian in A Secular Society 7-20-21Document64 paginiMRS 633 Being Christian in A Secular Society 7-20-21Mayom MabuongÎncă nu există evaluări

- The Banking Act 2012Document88 paginiThe Banking Act 2012Mayom MabuongÎncă nu există evaluări

- PUBLIC HEALTH LAW-PHA - Doc BCHDocument17 paginiPUBLIC HEALTH LAW-PHA - Doc BCHMayom MabuongÎncă nu există evaluări

- Employee EvaluationDocument22 paginiEmployee EvaluationMayom MabuongÎncă nu există evaluări

- List of Infectious DiseasesDocument3 paginiList of Infectious Diseases-Jixon DaquiganÎncă nu există evaluări

- Manual Chapter 5 Hygiene Promotion PDFDocument65 paginiManual Chapter 5 Hygiene Promotion PDFMayom MabuongÎncă nu există evaluări

- LSCDocument6 paginiLSCGautamÎncă nu există evaluări

- Solved Question Paper of Bihar Staff Selection Commission, Second Graduation Level Combined Competitive Examination (Preliminary Test) Exam Conducted On 16th February 2015Document17 paginiSolved Question Paper of Bihar Staff Selection Commission, Second Graduation Level Combined Competitive Examination (Preliminary Test) Exam Conducted On 16th February 2015GunjanÎncă nu există evaluări

- The DEFENCE of INSANITY - Comparative Analysis A Need For ReformDocument52 paginiThe DEFENCE of INSANITY - Comparative Analysis A Need For ReformShashi Bhushan SonbhadraÎncă nu există evaluări

- Revised AIS Rule Vol I Rule 06 2Document50 paginiRevised AIS Rule Vol I Rule 06 2Ramanathan SrinivasanÎncă nu există evaluări

- Servingitirght ManualDocument52 paginiServingitirght Manualdavychiu50% (2)

- Big Pharma Pricing and InnovationDocument20 paginiBig Pharma Pricing and Innovationnelly1Încă nu există evaluări

- Housing Schemes Form 1952 To 2018 and Their Objectives: WaterDocument12 paginiHousing Schemes Form 1952 To 2018 and Their Objectives: WaterRonakÎncă nu există evaluări

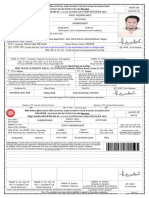

- Https Examinationservices - Nic.in Examsys22part2 Downloadadmitcard AdmitCardKVS - AspxDocument2 paginiHttps Examinationservices - Nic.in Examsys22part2 Downloadadmitcard AdmitCardKVS - AspxShubhamÎncă nu există evaluări

- Aiims PJG Jan 17 Result Merit Wise NetDocument68 paginiAiims PJG Jan 17 Result Merit Wise NetAjayÎncă nu există evaluări

- EUT 2008 - G. Alivizatos On EBU Exams & K. Schalk User On EU Health ProgrammeDocument1 paginăEUT 2008 - G. Alivizatos On EBU Exams & K. Schalk User On EU Health ProgrammeMohammed HusseinÎncă nu există evaluări

- RELLONDocument1 paginăRELLONJavicueÎncă nu există evaluări

- (6. Functions of Inspectors: Section 5 - Chief Inspector and InspectorsDocument4 pagini(6. Functions of Inspectors: Section 5 - Chief Inspector and InspectorsUmakant KumarÎncă nu există evaluări

- 4052271519Document2 pagini4052271519rohitÎncă nu există evaluări

- 10-26-16 EditionDocument28 pagini10-26-16 EditionSan Mateo Daily JournalÎncă nu există evaluări

- NFCC Specialised Housing GuidanceDocument342 paginiNFCC Specialised Housing GuidanceAaron FillisÎncă nu există evaluări

- Kingsman The Golden CircleDocument27 paginiKingsman The Golden CircleNur AmiraÎncă nu există evaluări

- CPR BrochureDocument2 paginiCPR BrochureMohd FahmiÎncă nu există evaluări

- MDR PDFDocument1 paginăMDR PDFLyka Jane BadeoÎncă nu există evaluări

- Bridge Final ProposalDocument14 paginiBridge Final ProposalDr. A B M Amrul KaishÎncă nu există evaluări

- "This Is How It Feels To Be Lonely" - A Report On Migrants and Refugees' Experiences With Loneliness in LondonDocument28 pagini"This Is How It Feels To Be Lonely" - A Report On Migrants and Refugees' Experiences With Loneliness in LondonMigrants OrganiseÎncă nu există evaluări

- Contracts TDFPS and SWKDocument296 paginiContracts TDFPS and SWKYvonne Larsen100% (1)

- RSA Environmental Legal and Compliance ReportDocument25 paginiRSA Environmental Legal and Compliance ReportrozadinoÎncă nu există evaluări

- From New Public Management To New Public Governance The Implications For A New Public ServiceDocument21 paginiFrom New Public Management To New Public Governance The Implications For A New Public ServiceIlhamBocorÎncă nu există evaluări

- IMI Employee Data Privacy NoticeDocument6 paginiIMI Employee Data Privacy NoticeAnonymous 5uQdy2raÎncă nu există evaluări