Documente Academic

Documente Profesional

Documente Cultură

Fixed Resin Cement

Încărcat de

ShereenAssaad0 evaluări0% au considerat acest document util (0 voturi)

26 vizualizări18 paginifixed

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentfixed

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

26 vizualizări18 paginiFixed Resin Cement

Încărcat de

ShereenAssaadfixed

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 18

Resin cements continue to evolve with

refinements engineered by the manufacturers.

One of the big changes in recent years has been

the development of all-in-one resin cements,

which are said to eliminate the need for a dentin

bonding system when placing indirect

restorations.

These cements are variously la-beled as all-in-one

cements, universal cements, self-adhesive

cements, or adhesive cements. The classification

by the manufacturers is not always clear, because

traditional resin cements are now called adhesive

cements as well.

Nevertheless, it appears that there are now two

groups of resin cements: a group that requires a dentin

bonding system before use and a group of cements for

which the use of a bonding agent is optional.

The bonding mechanism of these resins is based on an

acid-base link to the calcium in hydroxyapatite in

dentin and enamel while maintaining the physical

properties of resin cementan approach that makes

the bonding to dentin similar to a resin-modified glassionomer cement without the need of the glassionomer component.

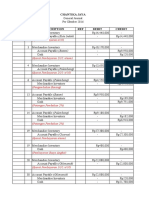

1 A list of current self-adhesive resin cements is given

inTable 1.

Figure 1 New incremental dual dispenser

for RelyX Unicem.

PHYSICAL PROPERTIES OF RESIN CEMENTS

There exists an international standard, ISO 4049, that sets forth a

group of minimum standards for the physical properties of resin

cements,2 including the self-adhesive cements. These standards are

identical to the ANSI/ADA specification No. 27.3

The ISO standard addresses primarily resin-based composites, but

includes specific requirements for resin-based luting agents. Even

though the ISO standard is a voluntary one, many manufacturers of

resin cements are in compliance with the ISO standard and indicate

that on the package or the enclosed literature.

The ISO standard requires a minimum value for the transverse

flexural strength (50 MPa), radiopacity (equivalent to aluminum),

and a limit on solubility in water. At this time there is no

requirement on adhesive properties; however, most manufacturers

report adhesive strength as measured by the shear bond strength

test.4 In selecting a resin cement, compliance with the ISO standard

is a good starting point.

COMPOSITION OF RESIN CEMENTS AND SELF-ADHESIVE RESIN

CEMENTS

Resins in this case are defined as blends of polymerizable

monomers of methacrylates, dimethacrylates, and

polymethacrylates (which have recently been included into the

blend as well). For the self-adhesive resin cements, additions to the

resin blend consist of highly acidic resin monomers,

monomethacrylates, multifunctional methacrylates, and at least

one of the new cements includes 4-methacryl-oxyethyl trimellitic

acid (4-MET).

The inclusion of the acidic monomers creates a self-etching resin,

increasing the adhesive properties. This concept of self-etching

finds its origin in the development of the self-etching adhesives.

Further additives are included to increase the bond strength to

metals (eg, 4-MET) and to resins that bond to ceramic interfaces.

The first highly acidic monomer was an acrylic chain on which

phosphoric acid groups were grafted. Since then, other acidic

monomers have been introduced. The goal is to include the dentin

bonding agent and a ceramic bonding system or metal bonding

system into the resin cement and have the entire assembly

polymerized at once.

Several manufacturers have included a fluoride component as

well.5,6 This practice is of dubious value, as the acrylate resins are

very hydrophobic. The mechanisms of fluoride release and of

maintaining low water absorption are mutually exclusive. Cement

that meets the ISO standard on water solubility cannot release a

clinically effective amount of fluoride. One manufacturer carefully

states that its product "contains" fluoride and claims a release of 7

ppm to 9 ppm independent of the exposed surface area.5 In the

authors opinion, whether a cement contains fluoride or not should

not be a factor in the product selection of resin-based cements.

For two of the products in Table 1 (EMBRACE Wetbond,

Pulpdent Corporation, Watertown, MA; and MonoCem SelfAdhesive Resin Cement, Shofu Dental Corporation, Menlo Park, CA),

it is recommended that the cement be applied to moist dentin, not

dry dentin.5,6 It is claimed that the uncured resin is hydrophilic, but

that the cured resin is hydrophobic.7 The authors hope to

investigate this claim and report the findings in the near future.

The viscosity of the resin cements have been significantly reduced

over the last few years. The reason for the change is primarily the

introduction of new delivery systems (see next section). To achieve

these low viscosities, the particle size of the inorganic fillers has

been greatly reduced. Most cements now have an average particle

size well below 1 m. Submicron or nanofiller particles are

becoming a significant component of resin cements and

composites.

The filler content of the cement is kept at or below 50% by volume.

The second step in reducing the viscosity was obtained by using

very low molecular weight monomers as diluents (2hydroxyethylmethacrylate [HEMA], tetraethyleneglycol

dimethacrylate [TEGDMA]).

The result of using these diluents is that the polymerization

shrinkage of the cement increases to about 4% by volume (1.2%

linearly), which is of little consequence for cement.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Mechanisms of Alloxan-And Streptozotocin-Induced DiabetesDocument11 paginiThe Mechanisms of Alloxan-And Streptozotocin-Induced DiabetesOktaviani Fitria Susanti SusantiÎncă nu există evaluări

- StompIO-1 User ManualDocument92 paginiStompIO-1 User ManualFederico Maccarone50% (2)

- MJ1000-Motorola IncDocument4 paginiMJ1000-Motorola IncFrancisco DiazÎncă nu există evaluări

- Self-Certification and Medical Examiner's Certificate ReportingDocument2 paginiSelf-Certification and Medical Examiner's Certificate ReportingcatrutterÎncă nu există evaluări

- Detailed Bank StatementDocument4 paginiDetailed Bank StatementJavita CertificationsÎncă nu există evaluări

- Kantian vs Utilitarian Ethics in BusinessDocument2 paginiKantian vs Utilitarian Ethics in BusinessChris Connors67% (3)

- Life of A Loan, GM FinancialDocument12 paginiLife of A Loan, GM Financialed_nycÎncă nu există evaluări

- Visual Design-Composition and Layout PrinciplesDocument5 paginiVisual Design-Composition and Layout PrinciplesRadyÎncă nu există evaluări

- Domestic Ro Price List 2021Document6 paginiDomestic Ro Price List 2021den oneÎncă nu există evaluări

- PT Amar Sejahtera General LedgerDocument6 paginiPT Amar Sejahtera General LedgerRiska GintingÎncă nu există evaluări

- IAS Physics SB1 Practs CP1 Student SheetDocument3 paginiIAS Physics SB1 Practs CP1 Student Sheethussain azizÎncă nu există evaluări

- QSF HRM F03 Job Application FormDocument2 paginiQSF HRM F03 Job Application Formjohn MÎncă nu există evaluări

- Commercial and EsplanadeDocument2 paginiCommercial and EsplanadeDanica Mae AmicayÎncă nu există evaluări

- Manual D00125190 1 PDFDocument114 paginiManual D00125190 1 PDFnimish_845588906Încă nu există evaluări

- Difference Between Offer and Invitation To TreatDocument5 paginiDifference Between Offer and Invitation To TreatBrian Okuku Owinoh100% (2)

- See Repair Manual PDFDocument1.050 paginiSee Repair Manual PDFJorge MonteiroÎncă nu există evaluări

- About 1,61,00,00,000 Results (0.20 Seconds) : All Books Shopping Videos More Settings ToolsDocument2 paginiAbout 1,61,00,00,000 Results (0.20 Seconds) : All Books Shopping Videos More Settings Toolsupen097Încă nu există evaluări

- Clinical ChemistryDocument23 paginiClinical ChemistryRezzy Mae Panadero OraÎncă nu există evaluări

- Eskom Tariff Book - 2018-19Document54 paginiEskom Tariff Book - 2018-19Sandro MasakiÎncă nu există evaluări

- Page 34-45 BLK PicDocument12 paginiPage 34-45 BLK PicMihir MehraÎncă nu există evaluări

- Animal HusbandryDocument69 paginiAnimal HusbandryKabi RockÎncă nu există evaluări

- Tools and Techniques For Implementing Integrated Performance Management Systems PDFDocument36 paginiTools and Techniques For Implementing Integrated Performance Management Systems PDFDobu KolobingoÎncă nu există evaluări

- Wang Yunshan ReflectionDocument4 paginiWang Yunshan Reflectionapi-286742915100% (1)

- Blackman Et Al 2013Document18 paginiBlackman Et Al 2013ananth999Încă nu există evaluări

- Terms and conditions for FLAC 3D licensingDocument2 paginiTerms and conditions for FLAC 3D licensingseif17Încă nu există evaluări

- Wagga Wagga Health and Knowledge Precinct Final ReportDocument102 paginiWagga Wagga Health and Knowledge Precinct Final ReportDaisy HuntlyÎncă nu există evaluări

- Training MatrixDocument4 paginiTraining MatrixJennyfer Banez Nipales100% (1)

- Metkon Micracut 151 201 enDocument4 paginiMetkon Micracut 151 201 enmuqtadirÎncă nu există evaluări

- Over 20 free and paid Pathfinder 2E character sheet optionsDocument1 paginăOver 20 free and paid Pathfinder 2E character sheet optionsravardieresudÎncă nu există evaluări

- Crack Detection & RepairDocument5 paginiCrack Detection & RepairHaftay100% (1)