Documente Academic

Documente Profesional

Documente Cultură

JF302 Material Technology TOPIC 1 Material Structure and Binary Alloy System

Încărcat de

Ah Tiang0 evaluări0% au considerat acest document util (0 voturi)

52 vizualizări26 paginiJF302 Material Technology

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentJF302 Material Technology

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

52 vizualizări26 paginiJF302 Material Technology TOPIC 1 Material Structure and Binary Alloy System

Încărcat de

Ah TiangJF302 Material Technology

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 26

BAB 1

JF302

MATERIAL TECHNOLOGY 1

Material Structure and

Binary Alloy System

1.0 Material Structure and Element

Periodical Table (EPT)

1.11 Terminology

a. Atom

The smallest component of an element having thechemical properties

of the element, consisting of a nucleuscontaining combinations of

neutrons and protons and one or more electrons bound to the nucleus

by electrical attraction; the number of protons determines the identity of

the element.

b. Element

Consists of only one kind of atom,

Cannot be broken down into a simpler type of matter by either physical or

chemical means, and

can exist as either atoms (e.g. argon) or molecules (e.g., nitrogen).

c. Mixture

Consists of two or more different elements and/or compounds

physically intermingled,

Can be separated into its components by physical means, and

Often retains many of the properties of its components.

d. Compound

Consists of atoms of two or more different elements bound

together,

Can be broken down into a simpler type of matter (elements) by

chemical means (but not by physical means),

1.12 Atomic number and atomic mass

Atomic number

The number of protons in the nucleus of an atom. Since atoms are

electrically neutral, the numbers of protons equal the number of

electrons in an atom.

Atomic number = Number of protons = Number of electrons

Atomic Mass

The sum of the number of protons and neutrons in the nucleus of

an atom.

Mass number = Number of protons + Number neutrons

1.1.3 Total number of atomic orbits/Shells

The electronic structure of an atom shows/tells us how the

electrons in an atom are arranged in their electron shells. The rule

below applies;

The 1st shell can contain a maximum of 2 electrons.

The 1st shell is the shell closest to the nucleus

The 2nd shell can contain a maximum of 8 electrons.

The 3rd shell can contain a maximum of 8 electrons

Electron

Shell

2nd shell

3rd shell

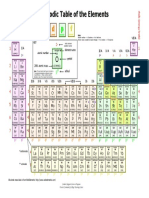

ELEMENT PERIODIC TABLE

1.1.4 Elements sequence in EPT

Each element in the periodic table is characterized by its atomic

number.

An element is composed of atoms. All the atoms in one element are

identical and similar. All elements in periodic table are arranged in

increasing atomic number.

Horizontal columns in the periodic table are call groups. Vertical

rows are called Periods. There are 8 groups (Groups I-VIII) and 7

periods.

Elements in Groups I-III are metals(except for Boron) and Groups VVIII consist mainly of non-metals. Elements in Group IV contain both

metals and non-metals.

All elements in the same GROUP have the same number of valence

electrons.

1.1.4 Elements sequence in EPT

Atomic

Atomic

number

number

14

Atomic

Atomic

mass

mass

Element

Element

Nitrogen

2:5

Symb

Symb

ol

ol

Electron

Electron

configuration

configuration

1.15 CRYSTAL STRUCTURE

a. Simple Cube

b. Body Cubic Centre

8 atom at the corner of cube x 1/8 = 1

atom

8 atom at the corner of

cube x 1/8 = 1 atom

1 atom at the middle of cube

atom

total

EXAMPLE: SC= table salt

(NaCl)

= 1

= 2 atom

EXAMPLE : BCC

=

chromium, Molybdenum,

titanium and tungsten.

9

c. Face Cubic Center (FCC)

EXAMPLE: FCC

=

aluminum, Cuprum, GOLD and

nikel.

8 atom at the corner of cube x 1/8

=

1 atom

6 atom at the face of cube x

= 3 atom

total

= 4 atom

d. Hexagonal closed packed(FCC)

EXAMPLE: HCP

=

Berilium, magnesium and

zink.

12 atom at the corner of atom x

1/6 =

2 atom

2 atom at the face of cube x 1/2

= 1 atom

3 atom at the middle = 3 atom

total

=6

10

1.1.6 Crystallization process

a)

b)

c)

d)

Crystals - A crystal or crystalline solid is a solid material whose

constituent atoms, molecules, or ions are arranged in an orderly

repeating pattern extending in all three spatial dimensions.

Lattice The smallest group of atoms showing the characteristic

lattice structure of a particular metal is known as a unit cell. It is the

building block of crystal, and a single crystal can have many unit

cell.

Grain - A given block of metal may contain millions of individual

crystals, called grains. Each grain has its own unique lattice

orientation.

Grain boundary - When the block is cooled from the molten state

and begin to solidify, nucleation of individual crystals occurs at

random positions and orientations throughout the liquid. As the

crystals grow the finally interfere with each other, forming at their

interface a surface defect a grain boundary.

11

1.1.7 Type of bonds

a) Ionic bond / electrovalent

One electron is completely

transferred.

The

electrostatic attraction is

what holds the iron together.

Na

Cl

Atoms lose or gain electrons to attain a complete outer shell of electrons.

An ionic bond is formed when electrons are lost and gained by two or more

atoms.

When atoms lose electrons they become positive ions

When atomsgain electrons they become negative ions

Ionic bonds are formed between metals and non - metals.

12

b) Covalent bond

Cl

Cl

(

a) Cl2 .

O

(b) O2.

Covalent chemical bonds involve the sharing of a pair of valence

electrons by two atoms, in contrast to the transfer of electrons in

ionic bonds. Such bonds lead to stable molecules if they share

electrons in such a way as to create a noble gas configuration for

each atom.

Hydrogen gas forms the simplest covalent bond in the diatomic

hydrogen molecule. The halogens such as chlorine also exist as

diatomic gases by forming covalent bonds

13

c) Metallic bond

The properties of metals suggest that their atoms possess strong

bonds, yet the ease of conduction of heat and electricity suggest that

electrons can move freely in all directions in a metal. The general

observations give rise to a picture of "positive ions in a sea of

electrons" to describe metallic bonding. The metallic bond accounts

for many physical characteristics of metals, such as strength,

malleability, ductility, conduction of heat and electricity.

14

1.2 Solidification of Metal and Alloy

1.2.1 Solidification phase

(d)Grain

(b)Dendri

(c)Dendrite

te

When the temperature of the liquid metal has dropped sufficiently below its

(a)Necleus

freezing point, stable aggregates or nuclei appear spontaneously at various points

in the liquid. As cooling continues, more atoms tend to freeze, and they may attach

themselves to already existing nuclei or form new nuclei of their own. Each nucleus

grows by the attraction of atoms from the liquid into its space lattice. Crystal

growth continues in three dimensions, the atoms attaching themselves in certain

preferred directions, usually along the axes of a crystal. This gives rise to a

characteristic treelike structure which is called dendrite. Since each nucleus is

formed by chance, the crystal axes are pointed at random and the dendrites will

grow in different directions in each crystal. Finally, as the amount of liquid

decreases, the gaps between the arms of the dendrite will be filled and the growth

of the dendrite will be mutually obstructed by that of its neighbors.

15

1.2.2 Differentiation between metal and alloy

Pure Metal is made up of only one element ( Periodic table of

elements ).

Alloy is a mixture of metals, or metal and non-metal, for

example Brass is an alloy which is made up of copper and zinc,

two different elements.

Both alloy and metal are good conductors of heat, but alloy

has a relatively high melting point when compared to that of

metals

16

1.2.3 Formation of solid solution

A solid solution is formed when two metals are completely soluble

in liquid state and also completely soluble in solid state. In other

words, when homogeneous mixtures of two or more kinds of

atoms (of metals) occur in the solid state, they are known as solid

solutions. The more abundant atomic form is referred as solvent

and the less abundant atomic form is referred as solute.

For example sterling silver (92.5 percent silver and the remainder

copper) is a solid solution of silver and copper. In this case silver

atoms are solvent atoms whereas copper atoms are solute atoms.

Another example is brass.

Brass is a solid solution of copper (64 percent) and zinc (36

percent). In this case copper atoms are solvent atoms whereas

zinc atoms are solute atoms.

17

1.2.4 Substitutional and Interstitial Solid Solution

Substitutional solid solutions.

If the atoms of the solvent or parent metal are replaced in the

crystal lattice by atoms of the solute metal then the solid solution

is known as substitutional solid solution. For example, copper

atoms may substitute for nickel atoms without disturbing the

F.C.C. structure of nickel.

(a)

18

1.2.4 Substitutional and Interstitial Solid Solution

(b) Interstitial solid solutions.

In interstitial solid solutions, the solute atom does not displace a

solvent atom, but rather it enters one of the holes or interstices

between the solvent atoms. An excellent example is iron-carbon

system

19

1.2.5 Solidification of pure metal and alloy according to

the cooling curve

a)

Solidification of pure metals

A pure metal solidifies at one fixed temperature, a fact which

can be checked by plotting a cooling curve.

A cooling curve may be obtained by melting a small

amount of a metal and recording the temperature drop at

suitable time intervals as this metal solidifies (the metal

must be allowed to cool very slowly i.e. under equilibrium

conditions) .

We can then plot a graph of temperature against time to

give us the cooling curve for that particular metal

20

1.2.5 Solidification of pure metal and alloy according to

the cooling curve

a)

Solidification of pure metals

21

1.2.5 Solidification of pure metal and alloy according to

the cooling curve

a)

Solidification of pure metals

At temperatures above and below line "ab" the curve falls

smoothly.

When the solidification temperature is reached, the temperature

remains constant for some time thus giving rise to the step "ab" in

the curve.

Down to "a"the temperature of the liquid drops in a regular

manner as heat is being lost to the surroundings at a nearly

constant rate.

The step "ab" is due to latent heat. This leads to zero change in

temperature until the last drop of liquid has solidified.

After no more latent heat is available the solid continues to cool in

a regular manner giving the smooth curve "bc".

22

1.2.5 Solidification of pure metal and alloy according to

the cooling curve

b) Solidification of Alloy

Unlike pure metals alloys solidify over a range of temperatures.

Below the temperature at which the alloy begins to solidify and the

temperature when it is completely solidified the alloy gradually

becoming stiffer as the lower limit of the solidification range is

approached.

Therefore for any alloy there is a definite temperature at which

solidification begins and an equally definite point where it ends.

These two points are known as the "arrest points".

As two metals may be alloyed in many different compositions i.e.

you could have 80% A and 20% B or 60%A and 40% B it stands to

reason that the cooling curves for all these alloys will be different.

Shown here are a selection of cooling curves for an alloy of Lead and

Tin.

23

1.2.5 Solidification of pure metal and alloy according to

the cooling curve

b) Solidification of Alloy

24

1.2.6 Phase diagram and cooling curve of Solid solution

25

1.2.6 Phase diagram and cooling curve of Solid solution

The phase fields in equilibrium diagrams depend on the

particular systems being depicted.

Liquidus - Set of solubility curves that represents locus of

temperatures above which all compositions are liquid.

Solidus - Represents set of solubility curves that denotes the

locus of temperatures below which all compositions are solid.

Equilibrium phase diagrams - Represent the relationships

between temperature and the compositions and the quantities of

phases at equilibrium.

Composition - the percentage content of certain ingredients put

in a substance. With the presence of percent composition of these

materials can cause changes in phases, properties and the micro

structure of materials.

26

S-ar putea să vă placă și

- John DaltonDocument5 paginiJohn DaltonTerraza de IbajayÎncă nu există evaluări

- JJ310 STRENGTH OF MATERIAL Chapter 4 (A) Bending StressDocument16 paginiJJ310 STRENGTH OF MATERIAL Chapter 4 (A) Bending StressAh Tiang50% (2)

- An Introduction to Physics (Material Science Metallurgy)De la EverandAn Introduction to Physics (Material Science Metallurgy)Încă nu există evaluări

- Chapter 2-Material Structure and BondingDocument34 paginiChapter 2-Material Structure and BondingMohd AziziÎncă nu există evaluări

- When A Metal Forms An Ionic CompoundDocument8 paginiWhen A Metal Forms An Ionic CompoundUmar Farouq Mohammed GalibÎncă nu există evaluări

- Chemical Bonding and Molecular Geometry: Chapter OutlineDocument68 paginiChemical Bonding and Molecular Geometry: Chapter OutlineMaden betoÎncă nu există evaluări

- Metal Structure and Bonding in MaterialsDocument95 paginiMetal Structure and Bonding in MaterialsTeptep GonzalesÎncă nu există evaluări

- Metals and Their CompoundsDocument10 paginiMetals and Their CompoundsDravid AryaÎncă nu există evaluări

- 05 Particles (2) Molecules and Ions 2009Document5 pagini05 Particles (2) Molecules and Ions 2009api-270859210% (1)

- Atomic Structure-1Document62 paginiAtomic Structure-1Wildan PriatnaÎncă nu există evaluări

- Pert 13 Gaya IntermolekulerDocument138 paginiPert 13 Gaya IntermolekulerNatasyaxoÎncă nu există evaluări

- Periodic PropertiesDocument19 paginiPeriodic Propertiesnamannn555Încă nu există evaluări

- Ja Das Ist MetallDocument4 paginiJa Das Ist MetallLeon EversÎncă nu există evaluări

- Atomic Theory - Part 1Document13 paginiAtomic Theory - Part 1satish_trivediÎncă nu există evaluări

- Periodic Table of ElementsDocument8 paginiPeriodic Table of ElementsFran CineÎncă nu există evaluări

- Minerals 2Document38 paginiMinerals 2java arunÎncă nu există evaluări

- The Periodic Table (PT) : O-LevelDocument23 paginiThe Periodic Table (PT) : O-Levelleticia karungiÎncă nu există evaluări

- Internal Assignment No. 1 Paper Code: CH - 201 Paper Title: Inorganic Chemistry Q. 1. Answer All The QuestionsDocument57 paginiInternal Assignment No. 1 Paper Code: CH - 201 Paper Title: Inorganic Chemistry Q. 1. Answer All The QuestionsRahul meenaÎncă nu există evaluări

- AOS1: The Periodic Table: Atomic Theory RevisionDocument6 paginiAOS1: The Periodic Table: Atomic Theory RevisionNicola NguyenÎncă nu există evaluări

- The Structure of Solids: RK ChowdaryDocument27 paginiThe Structure of Solids: RK Chowdaryrkchowdary007Încă nu există evaluări

- Course: BIO 101: Introduction To Biology Matter and ElementsDocument9 paginiCourse: BIO 101: Introduction To Biology Matter and ElementsAhamadul Islam OnonnoÎncă nu există evaluări

- States of Matter: Atomic Number Mass NumberDocument2 paginiStates of Matter: Atomic Number Mass Numberdan964Încă nu există evaluări

- Unit 6 Periodic Table and Bonding AeDocument24 paginiUnit 6 Periodic Table and Bonding AeRomu RaiÎncă nu există evaluări

- 41GATE Material For Chemistry - OptDocument70 pagini41GATE Material For Chemistry - OptSanthi SriÎncă nu există evaluări

- Bonding and Naming CompoundsDocument10 paginiBonding and Naming CompoundsDaniel BerryÎncă nu există evaluări

- Condensed Matter Physics Materials Science Greek Solid Long-Range Order Crystal Glass Glass Transition Gels Thin FilmsDocument6 paginiCondensed Matter Physics Materials Science Greek Solid Long-Range Order Crystal Glass Glass Transition Gels Thin FilmsimnasÎncă nu există evaluări

- Bio 110 - Ch2Document30 paginiBio 110 - Ch2محسن الشاطريÎncă nu există evaluări

- General Chemistry PPT-2Document29 paginiGeneral Chemistry PPT-2Temesgen SilabatÎncă nu există evaluări

- Metals: Physical Properties of MetalDocument6 paginiMetals: Physical Properties of MetalAllen Jierqs SanchezÎncă nu există evaluări

- Metal: Iron, Shown Here As Fragments and A 1 CM Cube, Is An Example of A Chemical Element That Is A MetalDocument26 paginiMetal: Iron, Shown Here As Fragments and A 1 CM Cube, Is An Example of A Chemical Element That Is A MetalStefan LavricÎncă nu există evaluări

- Chemical Bonding and Lewis StructureDocument26 paginiChemical Bonding and Lewis StructureCassandra Nicole SalasinaÎncă nu există evaluări

- Metallic BondingDocument26 paginiMetallic BondingAlaa HafizÎncă nu există evaluări

- Chapter 2 The Structure of Atom: 2.1 MatterDocument7 paginiChapter 2 The Structure of Atom: 2.1 MatterXenon NeonÎncă nu există evaluări

- CHAPTER 5.SCIENCE.10thDocument7 paginiCHAPTER 5.SCIENCE.10thSagar SinghÎncă nu există evaluări

- Chapter 1, REVIEW OF QUONTAM THEORYDocument13 paginiChapter 1, REVIEW OF QUONTAM THEORYPAUL NDIRITUÎncă nu există evaluări

- Chapter 2 Chem IDocument16 paginiChapter 2 Chem IStudy LionÎncă nu există evaluări

- 4 Lewis Dot Structure and Types of BondDocument71 pagini4 Lewis Dot Structure and Types of BondEren Micaella100% (1)

- Bonding and StructureDocument9 paginiBonding and StructureRija MughalÎncă nu există evaluări

- Periodic Table GR Xi Part2Document72 paginiPeriodic Table GR Xi Part2spyrax the legendÎncă nu există evaluări

- Unit 5 Elements and Compounds: J. FidalgoDocument32 paginiUnit 5 Elements and Compounds: J. FidalgohumanÎncă nu există evaluări

- CH2 BondingDocument17 paginiCH2 BondingDoc CrocÎncă nu există evaluări

- L03 (Electron Shell) 01Document6 paginiL03 (Electron Shell) 01amy.like.cooking.77Încă nu există evaluări

- كتابDocument187 paginiكتابdalyrazan60Încă nu există evaluări

- Band Theory of SolidsDocument75 paginiBand Theory of Solidsmk.manishkhatreeÎncă nu există evaluări

- Metal (Disambiguation)Document37 paginiMetal (Disambiguation)mosesÎncă nu există evaluări

- 20 Page GCSE To AS Transition BookletDocument20 pagini20 Page GCSE To AS Transition BookletHanaÎncă nu există evaluări

- Chemistry in Action Note PackageDocument21 paginiChemistry in Action Note Packageapi-235471411Încă nu există evaluări

- 3 Matter and MineralsDocument22 pagini3 Matter and Mineralsshain begumÎncă nu există evaluări

- Metallic BondDocument5 paginiMetallic BondDinak ConsultingÎncă nu există evaluări

- Chemistry Revision Notes-LibreDocument17 paginiChemistry Revision Notes-LibreShridhar MathadÎncă nu există evaluări

- Metallic BondingDocument3 paginiMetallic BondingBern BilazonÎncă nu există evaluări

- The Periodic Table and PeriodicityDocument12 paginiThe Periodic Table and PeriodicityNisha JodhanÎncă nu există evaluări

- GC1 Lesson 3 Atoms Molecules and Ions 3 The Periodic TableDocument31 paginiGC1 Lesson 3 Atoms Molecules and Ions 3 The Periodic TableYeri KimÎncă nu există evaluări

- 2020 Ag 6866Document12 pagini2020 Ag 6866MUHAMMAD USAMAÎncă nu există evaluări

- Atoms Elements and Periodic TableDocument13 paginiAtoms Elements and Periodic Tableapi-422428700100% (1)

- 1409302977chemical BondingDocument83 pagini1409302977chemical Bondingparmodcobra360Încă nu există evaluări

- MLN 02Document18 paginiMLN 02Anand K. MouryaÎncă nu există evaluări

- Handbook No.1Document125 paginiHandbook No.1Dhinakar AnnaduraiÎncă nu există evaluări

- GCSE Chemistry Revision: Cheeky Revision ShortcutsDe la EverandGCSE Chemistry Revision: Cheeky Revision ShortcutsEvaluare: 4.5 din 5 stele4.5/5 (3)

- JJ310 STRENGTH OF MATERIAL Chapter 6 TorsionDocument21 paginiJJ310 STRENGTH OF MATERIAL Chapter 6 TorsionAh Tiang0% (1)

- JJ303 Report TigDocument10 paginiJJ303 Report TigAh Tiang67% (9)

- JJ308 REPORT Layout and Piping of The Steam Power Plant SystemDocument9 paginiJJ308 REPORT Layout and Piping of The Steam Power Plant SystemAh Tiang86% (7)

- JJ310 STRENGTH OF MATERIAL Chapter 4 (B) Bending StressDocument14 paginiJJ310 STRENGTH OF MATERIAL Chapter 4 (B) Bending StressAh TiangÎncă nu există evaluări

- JJ310 STRENGTH OF MATERIAL Chapter 5 (B) Beam DeflectionDocument18 paginiJJ310 STRENGTH OF MATERIAL Chapter 5 (B) Beam DeflectionAh TiangÎncă nu există evaluări

- JJ310 STRENGTH OF MATERIAL Chapter 5 (A) Beam DeflectionDocument20 paginiJJ310 STRENGTH OF MATERIAL Chapter 5 (A) Beam DeflectionAh TiangÎncă nu există evaluări

- JJ311 MECHANICAL OF MACHINE CH 5 BalancingDocument26 paginiJJ311 MECHANICAL OF MACHINE CH 5 BalancingAh Tiang33% (3)

- JJ310 STRENGTH OF MATERIAL Chapter 3 (A) Shear Force & Bending Moment ADocument22 paginiJJ310 STRENGTH OF MATERIAL Chapter 3 (A) Shear Force & Bending Moment AAh TiangÎncă nu există evaluări

- JJ310 STRENGTH OF MATERIAL Chapter 1 (A) Forces On MaterialDocument18 paginiJJ310 STRENGTH OF MATERIAL Chapter 1 (A) Forces On MaterialAh Tiang100% (1)

- JJ311 MECHANICAL OF MACHINE CH 4 FrictionDocument12 paginiJJ311 MECHANICAL OF MACHINE CH 4 FrictionAh Tiang100% (2)

- JJ310 STRENGTH OF MATERIAL Chapter 1 (B) Forces On MaterialDocument20 paginiJJ310 STRENGTH OF MATERIAL Chapter 1 (B) Forces On MaterialAh TiangÎncă nu există evaluări

- JJ310 STRENGTH OF MATERIAL Chapter 2 Thermal Stresses and Composite BarsDocument20 paginiJJ310 STRENGTH OF MATERIAL Chapter 2 Thermal Stresses and Composite BarsAh Tiang50% (6)

- JJ311 MECHANICAL OF MACHINE CH 3 Velocity and Acceleration DiagramDocument31 paginiJJ311 MECHANICAL OF MACHINE CH 3 Velocity and Acceleration DiagramAh Tiang100% (1)

- JJ306 Autodesk Inventor Week 2 - Project 2 - Flange Manifold PartDocument42 paginiJJ306 Autodesk Inventor Week 2 - Project 2 - Flange Manifold PartAh TiangÎncă nu există evaluări

- JJ306 Autodesk Inventor Week 2 - Project 3 - Air Cover PartDocument21 paginiJJ306 Autodesk Inventor Week 2 - Project 3 - Air Cover PartAh TiangÎncă nu există evaluări

- JJ311 Mechanical of Machine CH 1 HoistDocument15 paginiJJ311 Mechanical of Machine CH 1 HoistAh Tiang100% (3)

- JJ311 MECHANICAL OF MACHINE CH 2 Simple Harmonic MotionDocument38 paginiJJ311 MECHANICAL OF MACHINE CH 2 Simple Harmonic MotionAh Tiang100% (3)

- BA201 Engineering Mathematic UNIT7 - Matrices OperationDocument28 paginiBA201 Engineering Mathematic UNIT7 - Matrices OperationAh TiangÎncă nu există evaluări

- JF302 Material Technology Topic 4 Mechanical TestDocument4 paginiJF302 Material Technology Topic 4 Mechanical TestAh TiangÎncă nu există evaluări

- PassYear - JJ207 Thermodynamic - SesiJun2012Document7 paginiPassYear - JJ207 Thermodynamic - SesiJun2012Ah TiangÎncă nu există evaluări

- BA201 Engineering Mathematic UNIT8 - Cramer's Rule and Inverse Matrix MethodDocument14 paginiBA201 Engineering Mathematic UNIT8 - Cramer's Rule and Inverse Matrix MethodAh TiangÎncă nu există evaluări

- BA201 Engineering Mathematic UNIT2 - Measures of Central TendencyDocument19 paginiBA201 Engineering Mathematic UNIT2 - Measures of Central TendencyAh TiangÎncă nu există evaluări

- Wait There's MoreDocument3 paginiWait There's MoreLionel Amistoso MargalloÎncă nu există evaluări

- AP Chemistry Review QuestionsDocument151 paginiAP Chemistry Review QuestionsKevin To100% (1)

- Electron Configuration: Edgar F. CariñoDocument20 paginiElectron Configuration: Edgar F. CariñoLea JotojotÎncă nu există evaluări

- Cells: Molecules and Mechanisms (Official)Document283 paginiCells: Molecules and Mechanisms (Official)Axolotl Academic Publishing CoÎncă nu există evaluări

- The Hydrogen Atom (Document31 paginiThe Hydrogen Atom (Debora PaskarinaÎncă nu există evaluări

- Electronic Structure of Atoms... Discussion.Document14 paginiElectronic Structure of Atoms... Discussion.Caryl Ann C. SernadillaÎncă nu există evaluări

- 2 13 Ionisation EnergiesDocument6 pagini2 13 Ionisation EnergiesRobertLiu100% (2)

- Fundamental of Organic ChemistryDocument11 paginiFundamental of Organic ChemistryBernie Suarez100% (1)

- Module 2 20140621 - 2 Physics - Konvertiert - SGDocument150 paginiModule 2 20140621 - 2 Physics - Konvertiert - SGAnandaMandalÎncă nu există evaluări

- Thevenin y Norton 11Document54 paginiThevenin y Norton 11Alexander CejudoÎncă nu există evaluări

- Structure of Atoms - MJHDocument50 paginiStructure of Atoms - MJHHumayer MahmudÎncă nu există evaluări

- No Ans Regular Assignment of Atomic Structure XI Chapter 2Document4 paginiNo Ans Regular Assignment of Atomic Structure XI Chapter 2manojwarlaniÎncă nu există evaluări

- Handout of Atomic StructureDocument12 paginiHandout of Atomic StructureIshraqi IlyasÎncă nu există evaluări

- Classification of Elements and Periodicity in Properties WorksheetDocument5 paginiClassification of Elements and Periodicity in Properties WorksheetLakshmi NarayanaÎncă nu există evaluări

- SchrodingerDocument42 paginiSchrodingerkninyangknÎncă nu există evaluări

- IGCSE Unit 3 NotesDocument6 paginiIGCSE Unit 3 NotesmayurbuddyÎncă nu există evaluări

- Periodic Table of The Elements: IA Viii A KEYDocument1 paginăPeriodic Table of The Elements: IA Viii A KEYJanna MendezÎncă nu există evaluări

- HKDSE Chemistry Bridging Programe 1BDocument99 paginiHKDSE Chemistry Bridging Programe 1Bthe222100% (1)

- Electrical Engineering Science 1 - 230419 - 164951Document109 paginiElectrical Engineering Science 1 - 230419 - 164951Akogun ElizabethÎncă nu există evaluări

- STPM Chemistry Form 6Document5 paginiSTPM Chemistry Form 6BabasChong100% (1)

- Periodic TableDocument7 paginiPeriodic TableMurali SambhuÎncă nu există evaluări

- What Are Valence ElectronsDocument3 paginiWhat Are Valence ElectronsJeanisil CerenoÎncă nu există evaluări

- 4.12 F. Y. B. Sc. ChemistryDocument18 pagini4.12 F. Y. B. Sc. ChemistryJonnyJamesÎncă nu există evaluări

- Chemistry of LifeDocument87 paginiChemistry of LifeJahlani Jamilah Smothers-PughÎncă nu există evaluări

- FireworksDocument9 paginiFireworksBrittany KellyÎncă nu există evaluări

- Electronic Structure of MatterDocument21 paginiElectronic Structure of MatterRosé ParkÎncă nu există evaluări

- Periodic Table & Periodicity-NeetDocument48 paginiPeriodic Table & Periodicity-NeetResonance Dlpd88% (41)

- Reading Material 2 Basic ChemistryDocument15 paginiReading Material 2 Basic ChemistryCj IsoÎncă nu există evaluări

- Structure NotesDocument5 paginiStructure NotesNeil HandaÎncă nu există evaluări

- Chemistry - Atomic Structure - Gaseous State - Complete ModuleDocument122 paginiChemistry - Atomic Structure - Gaseous State - Complete Moduleruchir angraÎncă nu există evaluări