Documente Academic

Documente Profesional

Documente Cultură

Engineering Safe Oil and Gas Facilities

Încărcat de

robigedDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Engineering Safe Oil and Gas Facilities

Încărcat de

robigedDrepturi de autor:

Formate disponibile

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Twelve Steps to Engineering Safe Oil and

Gas Facilities

Based on SPE 141974

By: Jim Johnstone and Jim Curfew Contek Solutions LLC

Presenter: Mike Leonard VP of Special Projects Contek Solutions LLC

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Twelve Steps to Engineering Safe Oil and

Gas Facilities

1.Set a Design Standards Policy

2.Lay Out the Site for Safety

3.Personnel Safety

4.Design Piping Properly

5.Select the Proper Pressure Vessel

6.Picking the Right Tank

7.Specifying Rotating Equipment for Safety

8.Relief-System Design is Critical

9.Determining the Right Electrical-Area Classification

10.Design the Instrumentation and Control System for Safety

11.Conduct a Process Hazard Analysis

12.Design Verification and Commissioning

2

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Get Management On Board

Are you following the High Road?

Does the company have personnel with facility safety

engineering experience?

Is cost a barrier to safety?

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

1. Set a Design Standards Policy

What Standards to Follow?

Communicate to ALL

Example Statement: All facilities will be

designed in accordance with good industry

design practices and codes, and to also meet all

regulatory requirements.

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

2. Lay out the Site for Safety

Vents, Flares, Fired

Equipment, Engines,

Vessels, Tanks, Offices

and Control Equipment

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Spacing Guidelines

Reference: PIP PNE 00003 Process Units and Offsite Layout

Guide

6

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

3. Personnel Safety

Exit Routes

Stairs

Platforms

Guarding

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

4. Design Piping Properly

B31.3 Process Piping

B31.4 Liquid Pipelines

B31.8 Gas Pipelines

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

5. Select the Proper Pressure Vessel

ASME Section VIII Division 1

10

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

6. Picking the Right Tank

Fiberglass or Steel?

Atmospheric or Low Pressure?

11

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

7. Specifying Rotating Equipment for Safety

Pumps

IC Engines

Compressors

Electric Motors

12

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

8. Relief System Design is Critical

Capacity

Types

Sizing

System Design

Vent or Flared

13

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

9. Determining the Right Electrical Area

Classification

API RP 500

NFPA 497

Oil Tank

Vent

Wellhead

Division 2: 5' R

Separator

Division 1: Inside of Tank

Division 2: Inside of Berm

Division 1: 5' R

Division 2: 10' R

Compressor

Division 2: 10' R

Division 1

Division 2

Division 2: 10' R

14

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

15

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

10. Design the Instrumentation and Control

System for Safety

Levels of Protection

16

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Safe Alarm and Control Systems

Condition

Cause

Effect

Primary Protection

Secondary Protection

Location of

Safety Devices

Overpressure

High inflow pressure;

thermal expansion

Sudden rupture or leak

PSH

PSV

Gas vapor section

Leak

Corrosion, erosion,

mechanical failure,

rupture, external

damage

Release of

hydrocarbons to the

atmosphere

PSL to shut off inflow;

Check Valve to prevent

backflow; LSL on an

atmospheric tank or

vessel

Sump/drain system;

LSH on sump system

PSL in vapor

section; LSL at

lowest point in

atmospheric tank

Liquid Overflow

High liquid inflow;

Upstream failure of a

device; Blockage of

liquid outflow

Overpressure or excess

liquids in downstream

devices; Release of

hydrocarbons to

atmosphere

LSH

Sump/drain system;

LSH on sump system

LSH at high point

in vessel or tank

Gas Blowby

Failure of liquid level

system; opening of

bypass

Overpressure of

downstream

components

LSL

Safety devices on

downstream component

LSL at lowest

point in vessel or

tank

Underpressure

Withdrawal in excess of

inflow; thermal

contraction when

blocked in

Collapse of the

component; leak

Atmospheric vessels:

vent; Pressurized

vessels: gas makeup

system

Atmospheric vessels:

second vent or PSV;

Pressurized vessels:

PSL to shut off inflow

and outflow

PSL at highest

practical point;

PSVs and Vents in

accordance with

good Eng.

Practices

17

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

11. Conducting a Process Hazard Analysis

Obtain Drawings

Select type of PHA

Incorporate results into final design

18

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

19

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

12. Design Verification and Commissioning

Pre-Startup Safety Review (PSSR)

Site Punch List

20

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Conclusions and Recommendations

21

Contek Solutions LLC

ENGINEERING ENVIRONMENT SAFETY MANAGEMENT SYSTEMS

Questions?

22

S-ar putea să vă placă și

- Guidelines for Integrating Process Safety into Engineering ProjectsDe la EverandGuidelines for Integrating Process Safety into Engineering ProjectsÎncă nu există evaluări

- Essential Practices for Managing Chemical Reactivity HazardsDe la EverandEssential Practices for Managing Chemical Reactivity HazardsÎncă nu există evaluări

- Inherent SafetyDocument50 paginiInherent SafetyChing-Liang ChenÎncă nu există evaluări

- Buncefield Presentation CIDocument93 paginiBuncefield Presentation CIapicar_66100% (1)

- Oil and Gas Plants Operation AspectsDocument36 paginiOil and Gas Plants Operation Aspectsvioflorex4100% (1)

- Reusing Produced Water (SPE White Paper) PDFDocument6 paginiReusing Produced Water (SPE White Paper) PDFMubin Ashraf Sheikh100% (1)

- HAZOP Report Issue 1Document71 paginiHAZOP Report Issue 1achyutÎncă nu există evaluări

- PSM 6 - Element 1 - Process Safety Culture (v3)Document29 paginiPSM 6 - Element 1 - Process Safety Culture (v3)Ahmed HamadÎncă nu există evaluări

- What Is Process Safety EngineeringDocument3 paginiWhat Is Process Safety EngineeringCLPWC100% (11)

- PSM Auditing (Presentation)Document25 paginiPSM Auditing (Presentation)kanakarao1100% (1)

- 3.2 HazopDocument66 pagini3.2 Hazops sanjai100% (1)

- Process Hazards Analysis MethodsDocument1 paginăProcess Hazards Analysis MethodsRobert MontoyaÎncă nu există evaluări

- Training Program On Basic Process Engineering Practices: April 28, 2015 1Document26 paginiTraining Program On Basic Process Engineering Practices: April 28, 2015 1jackÎncă nu există evaluări

- Flaring and Venting Reduction Guideline (October Release)Document71 paginiFlaring and Venting Reduction Guideline (October Release)Behnam HosseinzadehÎncă nu există evaluări

- Safety in Process Plant DesignDocument8 paginiSafety in Process Plant DesignKannanGKÎncă nu există evaluări

- Assignment 1Document9 paginiAssignment 1TejasÎncă nu există evaluări

- Hazop Oil & GasDocument71 paginiHazop Oil & GasBryan K. Aylas Paredes100% (5)

- Commisioning Plant CourseDocument25 paginiCommisioning Plant CoursePoncho RmzÎncă nu există evaluări

- Intro Process SafetyDocument39 paginiIntro Process SafetyTamilchelvam Murogayah100% (1)

- PSM Best Practices Workshop - Pre-Startup Safety Review PresentationDocument15 paginiPSM Best Practices Workshop - Pre-Startup Safety Review PresentationRod Lafrades100% (1)

- 2013-04-Beacon - Have You Heard A Pressure Relief Valve Chatter?Document1 pagină2013-04-Beacon - Have You Heard A Pressure Relief Valve Chatter?sl1828Încă nu există evaluări

- Hazards in A RefineryDocument25 paginiHazards in A Refinerymujeebtalib100% (1)

- HSE - Loss Prevention in The Petrochemical and Chemical-Process High-Tech Industries in TaiwanDocument8 paginiHSE - Loss Prevention in The Petrochemical and Chemical-Process High-Tech Industries in TaiwanLandryÎncă nu există evaluări

- Wyn032 PDFDocument21 paginiWyn032 PDFWahjudi MuhammadÎncă nu există evaluări

- Webinar K3 2021 - PSSRDocument20 paginiWebinar K3 2021 - PSSRZulkarnaenUchiha100% (1)

- OSHA (PSM) Standard, 29 CFR 1910.119 - PSM of Highly Hazardous ChemicalsDocument7 paginiOSHA (PSM) Standard, 29 CFR 1910.119 - PSM of Highly Hazardous ChemicalsKG Shim50% (2)

- HazidDocument91 paginiHazidrusticrage2883100% (4)

- Lesson Learnt From Aiche Paper'sDocument49 paginiLesson Learnt From Aiche Paper'sSyed Sheraz Hussain100% (1)

- A Guide To The COMAHDocument145 paginiA Guide To The COMAHMahmoud ElghayishÎncă nu există evaluări

- Olefins From Conventional and Heavy FeedstocksDocument27 paginiOlefins From Conventional and Heavy FeedstocksTaylorÎncă nu există evaluări

- HSE - Failure Rates For Underground Gas StorageDocument34 paginiHSE - Failure Rates For Underground Gas StorageGermanteÎncă nu există evaluări

- Hazop Basic ConceptsDocument14 paginiHazop Basic ConceptsClaudio Sobarzo100% (1)

- 14 Rick Engler CSB Organizational ChangeDocument24 pagini14 Rick Engler CSB Organizational Changefzegarra1088Încă nu există evaluări

- Introduction To Oil and Gas Process Safety EngineeringDocument16 paginiIntroduction To Oil and Gas Process Safety EngineeringPanji Kumala Setiawan100% (1)

- Hazop: Hazard & Operability StudiesDocument51 paginiHazop: Hazard & Operability StudiesFSBollÎncă nu există evaluări

- Emergency Response and Disaster Management Plan (Erdmp)Document25 paginiEmergency Response and Disaster Management Plan (Erdmp)Dinesh KanukolluÎncă nu există evaluări

- Risk Based Process SafetyDocument5 paginiRisk Based Process Safetykanakarao1Încă nu există evaluări

- Safety in The Oil and Gas IndustryDocument40 paginiSafety in The Oil and Gas IndustryMeg CariñoÎncă nu există evaluări

- Risk Based Process Safety DesignDocument13 paginiRisk Based Process Safety DesignVan SotÎncă nu există evaluări

- HAZID PresentationDocument11 paginiHAZID PresentationAlvian FachrurroziÎncă nu există evaluări

- HIPPSDocument8 paginiHIPPSAmit PandhareÎncă nu există evaluări

- Process Safety ManagementDocument85 paginiProcess Safety ManagementFaiz Abdullah50% (2)

- Bow Tie PSMDocument22 paginiBow Tie PSMcrj 2000Încă nu există evaluări

- Day 2 - Hazop MethodsDocument65 paginiDay 2 - Hazop Methodstaufany99Încă nu există evaluări

- (III) PSSR Procedure (Rev00)Document19 pagini(III) PSSR Procedure (Rev00)ahmedÎncă nu există evaluări

- The Use of Hazop Techniques in Applied Hazard ProcessesDocument72 paginiThe Use of Hazop Techniques in Applied Hazard Processesamidi5555913Încă nu există evaluări

- Hazop Training GuideDocument9 paginiHazop Training GuideAli RizviÎncă nu există evaluări

- Process and Plant Safety HazardsDocument71 paginiProcess and Plant Safety Hazardsapi-2614241788% (17)

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocument39 paginiHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (2)

- Tech Safety Vs HSE EngineerDocument5 paginiTech Safety Vs HSE EngineerIrsyad Ilhami100% (1)

- HAZOP TrainingDocument131 paginiHAZOP Trainingtamilnaduchennai100% (14)

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28De la EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Încă nu există evaluări

- Introduction To ReliefsDocument50 paginiIntroduction To Reliefsthiviya100% (1)

- An Eurotherm HVACDocument46 paginiAn Eurotherm HVACrobert_kerr_29Încă nu există evaluări

- Ts0708 6 ShutdownDocument45 paginiTs0708 6 Shutdownuserscribd2011Încă nu există evaluări

- Safety in Control DesignDocument23 paginiSafety in Control DesignAdityajai SinghÎncă nu există evaluări

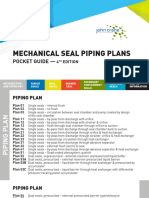

- API Mechanical Seal Piping Plan Booklet LORES 4C MAR2016Document90 paginiAPI Mechanical Seal Piping Plan Booklet LORES 4C MAR2016Kamlesh Kamlesh Etwaro100% (1)

- Well IntegrityDocument17 paginiWell Integritymustafaelsaid21Încă nu există evaluări

- Safety in Control DesignDocument23 paginiSafety in Control Designchempraveen4uÎncă nu există evaluări

- Ambush Rules of Play OCR PDFDocument40 paginiAmbush Rules of Play OCR PDFrobigedÎncă nu există evaluări

- White Good Install TuesdayDocument24 paginiWhite Good Install TuesdayM Ahmed LatifÎncă nu există evaluări

- BELTSTAT v7.0 User ManualDocument147 paginiBELTSTAT v7.0 User Manualleomar61Încă nu există evaluări

- R821 10Document8 paginiR821 10robigedÎncă nu există evaluări

- R821 10Document8 paginiR821 10robigedÎncă nu există evaluări

- MagVFC Variable Frequency Controller Installation & Owner's ManualDocument26 paginiMagVFC Variable Frequency Controller Installation & Owner's ManualrobigedÎncă nu există evaluări

- Calculations For Insulated Piping Systems - SiddiquiDocument5 paginiCalculations For Insulated Piping Systems - Siddiquirobiged0% (1)

- Thermomechanical Response of A Viscoelastic BeamDocument27 paginiThermomechanical Response of A Viscoelastic BeamrobigedÎncă nu există evaluări

- Positive Discipline: A Guide For ParentsDocument64 paginiPositive Discipline: A Guide For ParentsrobigedÎncă nu există evaluări

- FmecaDocument46 paginiFmecarobigedÎncă nu există evaluări

- Basic Calculations Piping System Design PDFDocument14 paginiBasic Calculations Piping System Design PDFjeff_shawÎncă nu există evaluări

- Mining Equipment MaintenanceDocument93 paginiMining Equipment Maintenancerobiged100% (3)

- A Mathematical Programming Model For Optimal Layout Considering QDocument37 paginiA Mathematical Programming Model For Optimal Layout Considering QrobigedÎncă nu există evaluări

- Bunding GuidelinesDocument5 paginiBunding GuidelinesmohanumaÎncă nu există evaluări

- 26 PumpsDocument28 pagini26 PumpsrobigedÎncă nu există evaluări

- Cyclones BasicsDocument10 paginiCyclones Basicschris.mwabaÎncă nu există evaluări

- Solar Water Pumping A HandbookDocument134 paginiSolar Water Pumping A Handbookrobiged100% (2)

- Solar Water Pumping A HandbookDocument134 paginiSolar Water Pumping A Handbookrobiged100% (2)

- Single Stage Sag-Ag Milling DesignDocument11 paginiSingle Stage Sag-Ag Milling DesignrobigedÎncă nu există evaluări

- Mechanical Engineering 201303Document90 paginiMechanical Engineering 201303robigedÎncă nu există evaluări

- ANSI HI Pump Standard 2.6 Vertical Pump TestsDocument48 paginiANSI HI Pump Standard 2.6 Vertical Pump Testsrobiged100% (3)

- Services Hot Water Provisions For Commercial BuildingsDocument52 paginiServices Hot Water Provisions For Commercial Buildingsrobiged100% (1)

- HI Pump Standard 2.1-2.2 Vertical Pumps For Nomentclature & DefinitionsDocument38 paginiHI Pump Standard 2.1-2.2 Vertical Pumps For Nomentclature & DefinitionsrobigedÎncă nu există evaluări

- An Introduction To Pipeline PiggingDocument12 paginiAn Introduction To Pipeline Piggingrobiged100% (2)

- Centrifugal Pump Operation at Off Design Conditions-Karassik1 PDFDocument5 paginiCentrifugal Pump Operation at Off Design Conditions-Karassik1 PDFhirenkumar patelÎncă nu există evaluări

- Successful Design of The NICO CMPDocument10 paginiSuccessful Design of The NICO CMProbigedÎncă nu există evaluări

- Centrifugal Pump Operation at Off-Design Conditions2-3Document5 paginiCentrifugal Pump Operation at Off-Design Conditions2-3robigedÎncă nu există evaluări

- Centrifugal Pump Operation at Off-Design Conditions3-3Document6 paginiCentrifugal Pump Operation at Off-Design Conditions3-3robigedÎncă nu există evaluări

- HAMMER V8i User's GuideDocument1.062 paginiHAMMER V8i User's Guiderobiged100% (7)

- Tutorial 2 Organizing DataDocument2 paginiTutorial 2 Organizing Datazurila zakariaÎncă nu există evaluări

- Mapeh 10 1 Grading Examination: E. Modern NationalismDocument3 paginiMapeh 10 1 Grading Examination: E. Modern NationalismMildred Abad SarmientoÎncă nu există evaluări

- Full Download Test Bank For Nursing A Concept Based Approach To Learning Volume II 3rd Edition 3rd Edition PDF Full ChapterDocument36 paginiFull Download Test Bank For Nursing A Concept Based Approach To Learning Volume II 3rd Edition 3rd Edition PDF Full Chaptersignor.truss.j26uk100% (17)

- Mycesmm2 Quiz: Please Circle Your Answer! Time Allocated To Answer Is 30 MinutesDocument2 paginiMycesmm2 Quiz: Please Circle Your Answer! Time Allocated To Answer Is 30 MinutesSi Qian LuiÎncă nu există evaluări

- Sample Emg/Ncv Report - Normal StudyDocument5 paginiSample Emg/Ncv Report - Normal StudyPhysiotherapist AliÎncă nu există evaluări

- Carcinoma of Prostate: Dr. Saadat Hashmi Consultant UrologistDocument48 paginiCarcinoma of Prostate: Dr. Saadat Hashmi Consultant UrologistMuhammad ArsalÎncă nu există evaluări

- QMS - 001 Compliance of RecordsDocument4 paginiQMS - 001 Compliance of Recordsedgardovrgs3169Încă nu există evaluări

- Morgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Document386 paginiMorgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Tsiory RanaivosonÎncă nu există evaluări

- O/W: Mayne To Reward The Willing: Mayne Pharma Group (MYX)Document8 paginiO/W: Mayne To Reward The Willing: Mayne Pharma Group (MYX)Muhammad ImranÎncă nu există evaluări

- ThreeDocument6 paginiThreeapi-340425056Încă nu există evaluări

- AASHTO Digital Publications: Instructions Located HereDocument2 paginiAASHTO Digital Publications: Instructions Located HereMinn LwinÎncă nu există evaluări

- Contextual Marketing Based On Customer Buying Pattern In: Nesya Vanessa and Arnold JaputraDocument12 paginiContextual Marketing Based On Customer Buying Pattern In: Nesya Vanessa and Arnold Japutraakshay kushÎncă nu există evaluări

- Denon DHT-T100 Ver 3 PDFDocument34 paginiDenon DHT-T100 Ver 3 PDFboroda241083% (6)

- HEM Duplex Cooling MotorDocument4 paginiHEM Duplex Cooling MotorAbhishek Kumar Pandey1Încă nu există evaluări

- DMD 2018 Stem and Non Stem Checklist Effective 2020-2021Document8 paginiDMD 2018 Stem and Non Stem Checklist Effective 2020-2021Elle DyÎncă nu există evaluări

- Assessment of Reading Comprehension 2Document8 paginiAssessment of Reading Comprehension 2Kutu DemangÎncă nu există evaluări

- Kf22Qt Sec4 FRDDocument21 paginiKf22Qt Sec4 FRDMauro PerezÎncă nu există evaluări

- Hindustan Coca-Cola Beverages PVT LTD B-91 Mayapuri Industrial Area Phase-I New DelhiDocument2 paginiHindustan Coca-Cola Beverages PVT LTD B-91 Mayapuri Industrial Area Phase-I New DelhiUtkarsh KadamÎncă nu există evaluări

- Chapter 8 Sensation and PerceptionDocument66 paginiChapter 8 Sensation and Perceptionapi-726122866Încă nu există evaluări

- Ielts ReadingDocument7 paginiIelts ReadingTrọng Nguyễn DuyÎncă nu există evaluări

- TympanometerDocument12 paginiTympanometerAli ImranÎncă nu există evaluări

- Vision Medilink Product DetailsDocument4 paginiVision Medilink Product DetailsRaj SekarÎncă nu există evaluări

- Conditional Type 0Document16 paginiConditional Type 0marore100% (1)

- Civrev2 2019 Case TitlesDocument3 paginiCivrev2 2019 Case TitlesAnne VallaritÎncă nu există evaluări

- M 17Document5 paginiM 17amhm2000100% (1)

- CT VT Basics SonnenbergDocument71 paginiCT VT Basics SonnenbergAnonymous OCDJg17Z67% (3)

- Review of Documents On Seismic Strengthening of Existing BuildingsDocument12 paginiReview of Documents On Seismic Strengthening of Existing Buildingsm7j7a7Încă nu există evaluări

- Mouse HardyweinbergDocument5 paginiMouse Hardyweinbergapi-477617112Încă nu există evaluări

- LF1325LC 装机准备要求 LF1325LC installation requirementsDocument12 paginiLF1325LC 装机准备要求 LF1325LC installation requirementsEliasDraÎncă nu există evaluări

- Program Thành TrungDocument3 paginiProgram Thành TrungQuốc HuyÎncă nu există evaluări