Documente Academic

Documente Profesional

Documente Cultură

Performance Test

Încărcat de

Yassine HamzaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Performance Test

Încărcat de

Yassine HamzaDrepturi de autor:

Formate disponibile

g

Power Systems - Oil & Gas

Training Center

Customer

Due to the influence of many elements on the

performance of compressors and to the fact that

it is never possible to perform tests in the exact

contractual conditions, there exist standards to

be applied in carrying out tests and there exist

procedures allowing the performance values

found at one or more operating points near to

the contractually guaranteed point to be brought

to the exact conditions of said guaranteed point.

A performance test on a centrifugal compressor

normally serves to verify the absorbed power

brought to contractual conditions or to verify the

flow rate prior to compressor surge.

Power Systems - Oil & Gas

Customer

Training Center

Have the operating conditions of the plant sufficiently near to

design conditions. Standards ASME PTC10 establish the

maximum deviations from the contractual values for the

conditions of the gas on inlet to the compressor :

2% for molecular weight

8% for density

5% for absolute pressure

8% for absolute temperature

2% for velocity

Power Systems - Oil & Gas

Customer

Training Center

Bring the compressor to the RPM indicated on the operating

curve relevant to the guaranteed point, characterized by volume

flow and head. At this speed readings will be taken at three

points :

1. with volume flow approximately similar to that of

the guaranteed point,

2. with volume flow about 10% higher than that of the

guaranteed point,

3. with volume flow about 10% lower than that of the

guaranteed point.

To reach these points, one hour is sufficient.

Power Systems - Oil & Gas

Customer

Training Center

With the machine at operating speed, make the number of readings specified

at the frequency required by contract or by the test specification (normally 4

sets of readings at a distance of 5 or 10 minutes from each other) on the

following values : for each compression stage.

1. Barometric pressure

2. Compressor speed (RPM)

3. Suction pressure

4. Suction temperature

5. Discharge pressure

6. Discharge temperature

7. Pressure upstream of the flow meter device

8. Temperature upstream of the flow meter device

9. Pressure drop on the device

During testing of the various points, one or more samples of the compressed

gas shall be taken and analyzed.

Power Systems - Oil & Gas

Training

Center

Verifying minimum

flow prior

to surge

Customer

Bring the compressor to the speed at which it is to be tested. Operate

on the plant so as to progressively decrease the flow treated by the

compressor. The simplest way to do this is to close the compressor

discharge with the anti-surge valve on regulation and then, with

extreme prudence and keeping vibrations under constant control,

change the set of the anti-surge regulator until the machine shows

the first symptoms of surge

NOTE : This procedure is possible only if there exists a flow

metering device which detects recycled flow as well, that is, which is

placed between the return of the anti-surge line and the compressor

suction, and thus measures the flow that is treated by the machine in

every conditions.

Effect continuously, until the machine begins to show marked

symptoms of surge (high vibrations and instability in flow) and

consider valid for the test the reading just previous to the one

showing symptoms of instability.

Power Systems - Oil & Gas

Training Center

Customer

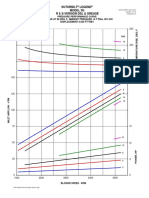

For reporting the conditions observed during testing of the

guaranteed point conditions, proceed as follows:

After having determined the values of His t and Qt at the 3

test points, utilizing calculation programs based on the

equations B.W.R.S., trace on a graph, the length of curve

that passes through these points and verify whether this

curve passes through the guaranteed point, identified by

Hisc and Qc. In the negative case, the curve must be brought

to a speed N such that it passes through the guaranteed

point, applying the laws of similitude:

Power Systems - Oil & Gas

Training Center

Customer

LAWS OF SIMILITUDE

Qi N t

Qi ' N c

H is ,i

H is ,i '

Nt

Nc

i = 1, 2, 3

Pis ,i

Pis ,i '

Nt

Nc

Power Systems - Oil & Gas

Training Center

Customer

Qi' = (Nc/Nt) Qi

His,i' = (Nc/Nt)2 His,i

Pis,i' = (Nc/Nt)3 Pis,i

Power Systems - Oil & Gas

Training Center

P1

P2

H is ,1'

is ,1

H is , 2 '

is , 2

c Q1' Pmc '

c Q 2 ' Pmc '

P2

Customer

H is , 2 '

is , 2

c Q 2 ' Pmc '

Nc

Pmc ' Pmc

Nt

Power Systems - Oil & Gas

Training Center

H is H pol

H eff

is pol

P 2 ( gas )

H is , 2 '

is , 2

c Q 2 '

P1( gas )

P 3( gas )

Customer

H is ,1'

is ,1

H is , 3'

is , 3

c Q1'

c Q 3'

Power Systems - Oil & Gas

Training Center

Customer

Pturbine-shaft = Pgas / mcmg

mc = 0.99

mg = 0.98

fPT = 1 / [%P/(100)]

fPp = 1013.25 / pt(mBar)

fPsuction = 1/1 + { [psuc,t(mmH2O)%Psuc ] / 100100

}

fPexhaust = 1 / 1 + { [pex,t(mmH2O)%Pex ] /

100100 }

ISO Conditions (15 C and 1013.25 mBar)

ISO power PC = Pt fPTfPp fPsuctionfPexhaust

Power Systems - Oil & Gas

Training Center

Customer

HR = (Mc Hi) / [CT (LT - LC)]

fHR.T = 1 / [%HR/(100)]

fHRsuc = 1/1 + { [psuc,t(mmH2O)

%HRsuc ]/100100 }

fPexhaust = 1/1 + { [pex,t(mmH2O)

%HRex ]/100100 }

ISO Conditions (15 C and 1013.25 mBar)

ISO HRc = HRt fHR.T fHRsuction fHRexhaust

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Gei 41040MDocument28 paginiGei 41040MPhong leÎncă nu există evaluări

- Fundamentals of Thermodynamics Solutions ch09Document198 paginiFundamentals of Thermodynamics Solutions ch09Cierré No'Middlename Jones75% (4)

- Co2 Flooding SystemDocument31 paginiCo2 Flooding SystemMallareddy Marri100% (1)

- GP 43-50 - Pigging Pig Launchers and ReceiversDocument43 paginiGP 43-50 - Pigging Pig Launchers and Receiverseliealtawil100% (2)

- Q4-WEEK 1-Boyle's LawDocument34 paginiQ4-WEEK 1-Boyle's LawAdonis SanielÎncă nu există evaluări

- Onshore Knockout Drum GuidanceDocument2 paginiOnshore Knockout Drum Guidanceneil_nhÎncă nu există evaluări

- Mroy Pump Catalogue PDFDocument6 paginiMroy Pump Catalogue PDFTitus FelixÎncă nu există evaluări

- CH 60 CH 100 Service and Parts ManualDocument36 paginiCH 60 CH 100 Service and Parts ManualAnonymous zIC52xKlÎncă nu există evaluări

- Combustion Chamber DesignDocument19 paginiCombustion Chamber DesignPRAVEENÎncă nu există evaluări

- Boiler Powerpoint 2003Document70 paginiBoiler Powerpoint 2003Sahil Mishra100% (1)

- Design of A Methanol-To-Olefinprocess Using Aspen Hysys: Material and Energy BalancesDocument9 paginiDesign of A Methanol-To-Olefinprocess Using Aspen Hysys: Material and Energy BalancesAbdulwahab GIWAÎncă nu există evaluări

- Me2121-2 Performance Evaluation of Air-Conditioners (E1-03-01)Document11 paginiMe2121-2 Performance Evaluation of Air-Conditioners (E1-03-01)hybri8Încă nu există evaluări

- Sacimem Steam Trap SurveyDocument40 paginiSacimem Steam Trap Surveyrakotographie zeÎncă nu există evaluări

- Iocl Haldia ReportDocument99 paginiIocl Haldia ReportSnehasisDasÎncă nu există evaluări

- UBP-B Series CatalogueDocument4 paginiUBP-B Series CatalogueDoni RahmatÎncă nu există evaluări

- Engineering Thermodynamics ProblemsDocument3 paginiEngineering Thermodynamics Problemsdhruv0010% (1)

- Sutorbilt Legend Model 3H R & S-Version DSL & GreaseDocument1 paginăSutorbilt Legend Model 3H R & S-Version DSL & GreaseJosue UrgilésÎncă nu există evaluări

- Guideline Pump SystemDocument16 paginiGuideline Pump SystemBehroozRaadÎncă nu există evaluări

- Ozone Layer and Its DepletionDocument14 paginiOzone Layer and Its DepletionChirag MaruÎncă nu există evaluări

- Compressor ExhausterDocument4 paginiCompressor ExhausterJeeva RajÎncă nu există evaluări

- Me 6302 HW 3Document2 paginiMe 6302 HW 3dsblendo0% (1)

- Fuel System: Components, Working Principles, Symptoms and Emission ControlsDocument3 paginiFuel System: Components, Working Principles, Symptoms and Emission ControlsJuan HernandezÎncă nu există evaluări

- MRO Stop Industrial Supply LinecardDocument2 paginiMRO Stop Industrial Supply LinecardMROstop.comÎncă nu există evaluări

- Comparison of Gas Dehydration Methods Based On Energy Consumption PDFDocument6 paginiComparison of Gas Dehydration Methods Based On Energy Consumption PDFABULARA2K6Încă nu există evaluări

- (Chapter 1) Fluid Mechanics For Mechanical EngineeringDocument38 pagini(Chapter 1) Fluid Mechanics For Mechanical EngineeringAnn Razon0% (1)

- Investigation Into The Effect of Tip Clearance On Centrifugal Compressor PerformanceDocument10 paginiInvestigation Into The Effect of Tip Clearance On Centrifugal Compressor PerformancekhknimaÎncă nu există evaluări

- Appendix 8.5 Equipment DatasheetsDocument20 paginiAppendix 8.5 Equipment DatasheetsIboniks Beponpiks DabondatskiÎncă nu există evaluări

- EbaraDocument10 paginiEbarachu42Încă nu există evaluări

- Tool Data SheetDocument1 paginăTool Data SheetMostafa NabilÎncă nu există evaluări

- Diff Parts of A Boiler - 220308 - 154756Document3 paginiDiff Parts of A Boiler - 220308 - 154756Dhruvi PadmaniÎncă nu există evaluări