Documente Academic

Documente Profesional

Documente Cultură

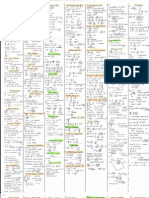

Ammo Flowchart

Încărcat de

jameswillifordDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ammo Flowchart

Încărcat de

jameswillifordDrepturi de autor:

Formate disponibile

Supported Unit picks up

ammo from Distro PLT

at BAB and signs for

ammo with DA 5515

Support unit

Ammo is drawn

from the ASP and

put in the BAB on

DA 581 DISTRO

PLT

Training

Executed

Supporte

d Unit

Ammo is

drawn from

BAB

DISTRO

PLT

Distro PLT Drops off ammo

to supported unit at TA/RG

and supported unit signs

for ammo with DA 5515

DISTRO PLT

Within two working

days, supported unit

coordinates with FSC

for dunnage turn in in

Distro PLT bay. Distro

PLT oversees dunnage

sifting, ensures proper

separation, and

weighs dunnage.

Clears DA 5515 of

DODICS with required

dunnage turn in

complete. DISTRO

PLT & Support Unit

Ammunition

delivered to

TA/RG

Supported

Unit

Supported Unit brings

dunnage to Curahee MP

and stores dunnage in

assigned dunnage storage

area Supported Unit

Returns to

TA/RG to

recover

adequate

dunnage to

complete turn

in for

remaining

DODICs

Dunnage policed

and residual live

ammunition

repackaged

Supported Unit

If ammo handlers

available,

supported unit links

up with Distro PLT

FSC NCO inspects

at BAB and returns

repackaged Ammo;

live ammunition

626 BSB reseals

Supported Unit

repacked

ammunition

FSC Distro PLT picks

DISTRO PLT

up live ammunition

Training

Executed

Supporte

d Unit

Turns in

ammunition

and

dunnage to

ASP within 5

working

days of

training

completion

Shortages below

100% will be

explained on DA

5811R and presented

to BC for signature.

Dunnage below 90%

or 100% for items

that require 1/1 turn

in will not be

from RG/TA

DISTRO PLT

Required DA 5811Rs

submitted to ASP within

2 working days.

Document closed and

DA 581 cleared

Ammunition Draw and Receipt Decision Flow-Chart

1

Do you need

ammunition for

training

No requirements

Is ammunition

allotted IAW BN

TMR?

Does the

supported unit

have ammo

handlers?

Is spare

ammunition

available from a

previous ammo

document?

Is another Curahee

unit overforecasting?

4

Unit ready for

training

Coordinate T+4 for FSC

ammunition delivery to

TA/RG on date of training

during TMR

Coordinate with S3

LAND/AMMO to

reserve

ammunition for

training.

Can supported unit have Soldiers

attend required online courses for

ammo transport before training?

Coordinate with FSC XO for at hoc

delivery

Speak with S3

LAND/AMMO for

ammunition

coordination.

Ammunition Dunnage and Ammo Turn In Flow-Chart

1

Did you expend all

ammunition?

Have you repacked all

ammunition into original

configuration?

Are you capable of

repacking ammunition

(ie-do you have all of the

required material)?

Expend

ammunition

unable to be

properly repacked.

Have you

separated

dunnage by DODIC

and type as per

ammo SOP?

Separate dunnage

by DODIC and type

per ammo SOP.

Do you have all

required dunnage

to include at lease

90%?

Unit ready for turn

in

Have you

exhausted all

available options

to recover all

required dunnage

and quantity as

required?

Contact Distro PLT

PL and S3 AMMO

NCOIC for further

guidance

Continue to search

until all options

are exhausted or

dunnage

requirements have

been met.

Ammunition Accountability Matrix

Firer/ Junior Enlisted

Solider Executor

Police ammunition expended; clear equipment of live ammunition prior to departure from range or changing to

blank ammunition; repack unused ammunition IAW Ammo SOP and supervisor guidance

First-line supervisor/

Fire Team Leader

Police ammunition expended; clear subordinate and personnel equipment prior to departure from range or

changing to blank ammunition; supervise repacking of ammunition IAW Ammo SOP

Squad Leader

Supervise brass and ammo inspections; clear personal equipment of brass and ammo prior to departure from

range or changing to blank ammunition; supervise repacking of ammunition IAW Ammo SOP

Platoon Sergeant

Validate brass and ammo inspections; clear personal equipment of brass and ammo prior to departure from range

or changing to blank ammunition; validate repacked ammunition IAW Ammo SOP

Platoon Leader

Validate brass and ammo inspections; Clear personal equipment of brass and ammo prior to departure from range

or changing to blank ammunition; validate repacked ammunition IAW Ammo SOP

Range RSO

Verify that brass and ammo inspections occur to standard; validate correct ammunition issued (blank or live); aid

Range OIC in ammunition coordination in any way required

Range OIC

Inventory and sign for range ammunition on DA 5515 from FSC or Company Ammo handler; Spot check and

validate brass and ammo inspections; spot check issued ammunition and ammunition issue process; coordinate

for ammunition draw and turn in; forecast ammunition requirements for range; provide range attendees plan for

dunnage reclamation; ensure adequate dunnage is policed and turned in to clear DA 5515 for range; Ensure

periodic inventories of ammunition completed on range

Company Ammo

Handler

Pick up ammunition from BAB; Validate and verify range ammunition operations are within CAM REG and QUASAS

standards; instruct and provide guidance on ammunition repacking; inventory and sign for ammunition for range

at BAB; Return residual live ammunition to BAB following completion of range;

Company XO

Coordinate for FSC ammunition movement T+4; Attend TRM and forecast company ammunition requirements IAW

company training plan; coordinate with FSC if Range OIC does not for dunnage turn in; track DA 5515s within

company until they are closed out

Distro PLT PL

Coordinate with Range OICs to ensure ammunition arrives at the correct location and time IOT facilitate training;

Supervise guard changeovers for FASPs; ensure BN AMMO NCOIC is kept appraised of open DA 581s and turn in

status and pending requirements; communicate with BN AMMO NCOIC IOT forecast need for DA 5811Rs; Ensure

FSC XO is aware of assets O/H for Distro PLT IOT aid in planning for ammunition support and movement; provide

concept of support for CL V for battalion training or training requiring battalion level FASP

Distro PLT Ammo

NCO

Receive dunnage and verify that dunnage is properly configured for turn in IAW Ammo SOP and enough dunnage

is present; Inventory and issue/receive live ammunition; Provide guidance for ammunition repacking; provide CL V

movement support if required; Turning in and drawing ammunition to and from the ASP IAW applicable DA 581

FSC XO

Coordinate with supported company XOs for CL V movement and other support; aid in the development of CL V

Concept of Support; Attend TRM and provide capability understanding to supported unit IAW briefed information

from DISTRO PL.

BN S3 AMMO NCO

Ensure Ammunition requests to ASP are sent; manage battalion ammunition; publish ammunition allocation

S-ar putea să vă placă și

- ACOG and M68 Cheat SheetDocument2 paginiACOG and M68 Cheat SheetjameswillifordÎncă nu există evaluări

- Fraserburgh Past & Present-John Cranna (Illustrated)Document561 paginiFraserburgh Past & Present-John Cranna (Illustrated)Clear As Mud100% (1)

- Paradigm's Rwby TTRPG v1.21Document53 paginiParadigm's Rwby TTRPG v1.21Miss MarahÎncă nu există evaluări

- Andrew's Intermediate Mechanics Cheat SheetDocument2 paginiAndrew's Intermediate Mechanics Cheat Sheetdodge_kevinÎncă nu există evaluări

- Conventional Ammunition Unit Operations - FM 9-38Document101 paginiConventional Ammunition Unit Operations - FM 9-38Robert SuteuÎncă nu există evaluări

- SB 742-1Document363 paginiSB 742-1Heina Galvez100% (1)

- Jason Gilliam - TBX Evaluation Testing in The M151 Warhead As Risk Reduction For The APKWSDocument15 paginiJason Gilliam - TBX Evaluation Testing in The M151 Warhead As Risk Reduction For The APKWSNikeShoxxxÎncă nu există evaluări

- Javelin 162 BrochureDocument2 paginiJavelin 162 Brochurescifidiscovery100% (2)

- Trijicon ECOS ManualDocument30 paginiTrijicon ECOS Manual64ssqax7100% (1)

- TM 11 5830 263 10Document89 paginiTM 11 5830 263 10Peter LauÎncă nu există evaluări

- Quartermaster Handbook Troop17Document25 paginiQuartermaster Handbook Troop17s_wenrichÎncă nu există evaluări

- The Cape Town Principles and Best PracticesDocument8 paginiThe Cape Town Principles and Best PracticesVicente LanaÎncă nu există evaluări

- Ammo ROC Drill AgendaDocument66 paginiAmmo ROC Drill AgendaDoradÎncă nu există evaluări

- 2D//Uuqft7: M119 Howtizer Saddle Gun Fire Finite Element AnalysisDocument19 pagini2D//Uuqft7: M119 Howtizer Saddle Gun Fire Finite Element Analysissol-negroÎncă nu există evaluări

- USBCTDocument209 paginiUSBCTthe_lefterÎncă nu există evaluări

- DAPam 385-63 (30 Jan 2012)Document239 paginiDAPam 385-63 (30 Jan 2012)aytrydezÎncă nu există evaluări

- Mil-C-3066c Cartridge Caliber 0.5 m8 - Api - m20 - Apit (Jan 1995)Document25 paginiMil-C-3066c Cartridge Caliber 0.5 m8 - Api - m20 - Apit (Jan 1995)YHonglee YhongleeÎncă nu există evaluări

- 4051 F597 PRC320 Modification InstructionsDocument103 pagini4051 F597 PRC320 Modification InstructionsColin ChristieÎncă nu există evaluări

- 57 MM APFSDS (2,000 M)Document2 pagini57 MM APFSDS (2,000 M)ImperialÎncă nu există evaluări

- FM 23-91 Mortar GunneryDocument202 paginiFM 23-91 Mortar Gunnerytmt IngÎncă nu există evaluări

- Ada 202911Document125 paginiAda 202911Joao Gabriel AbreuÎncă nu există evaluări

- NAVSEA Crane KeyMod™ vs. M-LOK™ Modular Rail System Comparison MAY 2017 (Caleb McGee) .Compressed PDFDocument43 paginiNAVSEA Crane KeyMod™ vs. M-LOK™ Modular Rail System Comparison MAY 2017 (Caleb McGee) .Compressed PDFrobculÎncă nu există evaluări

- Cataloging HANDBOOK for Army SupplyDocument87 paginiCataloging HANDBOOK for Army Supplyphoe_nix_chimeraÎncă nu există evaluări

- Carl-Gustaf M4 Training MhowDocument134 paginiCarl-Gustaf M4 Training Mhowwmsenevirathneuk100% (1)

- Projectile, 155-Millimeter: Illuminating, M485 SeriesDocument3 paginiProjectile, 155-Millimeter: Illuminating, M485 SeriesHijk MarouÎncă nu există evaluări

- Blank 2404 UnprotectedDocument15 paginiBlank 2404 UnprotectedSaintjinx21Încă nu există evaluări

- Navmc 3500 - 44a PT 4Document200 paginiNavmc 3500 - 44a PT 4taylorÎncă nu există evaluări

- INS-MON of Fuze FFV 447Document21 paginiINS-MON of Fuze FFV 447Vikas Chandra100% (1)

- History of Redeye MissileDocument245 paginiHistory of Redeye MissileChonk LeeÎncă nu există evaluări

- B GL 385 017pt 001Document232 paginiB GL 385 017pt 001sergey62Încă nu există evaluări

- M1a1a2 PDFDocument14 paginiM1a1a2 PDFTufan YamanÎncă nu există evaluări

- Ada 224998Document61 paginiAda 224998LalÎncă nu există evaluări

- AppaDocument3 paginiAppaAcaDumaÎncă nu există evaluări

- TM 750 116Document78 paginiTM 750 1161Y875Încă nu există evaluări

- Camouflage PatternS OEFDocument4 paginiCamouflage PatternS OEFLUDICOVEK100% (1)

- The 5.56 X 45mm - 2006 - A Chronology of Development (Part 17) - by Daniel WattersDocument35 paginiThe 5.56 X 45mm - 2006 - A Chronology of Development (Part 17) - by Daniel Wattersblowmeasshole1911Încă nu există evaluări

- Fuze OverviewDocument13 paginiFuze OverviewAnonymous jIzz7woS6Încă nu există evaluări

- TM 43 0001 38Document240 paginiTM 43 0001 38Chainarong KongchanÎncă nu există evaluări

- TM-9-1290-262-10 Aiming CircleDocument95 paginiTM-9-1290-262-10 Aiming CircleHari IswantoÎncă nu există evaluări

- TM 11-5855-238-10Document181 paginiTM 11-5855-238-10sergey62Încă nu există evaluări

- Rocket Study - Lesson Learned Vietnam 1968Document45 paginiRocket Study - Lesson Learned Vietnam 1968FrancescoÎncă nu există evaluări

- Cross Reference List Stage Lamp JenboDocument2 paginiCross Reference List Stage Lamp JenboDiegoMoralesÎncă nu există evaluări

- TM-11-5820-401-10-2-HR Radio VRC 46Document297 paginiTM-11-5820-401-10-2-HR Radio VRC 46Thoukididis ThoukididouÎncă nu există evaluări

- CAG ReportDocument79 paginiCAG ReportRashi MathurÎncă nu există evaluări

- Russian TM-62M (Metal) Anti Tank Mine: Von D.J. HarmsDocument2 paginiRussian TM-62M (Metal) Anti Tank Mine: Von D.J. Harmsntphuoc694Încă nu există evaluări

- ATP 4-35.1 (FM 4-30.13) Techniques For Munitions Handlers (31 May 2013) PDFDocument134 paginiATP 4-35.1 (FM 4-30.13) Techniques For Munitions Handlers (31 May 2013) PDFMalikHodzicÎncă nu există evaluări

- Foreign Firing Table FT-F-82-2 Soviet Mortar 82 MM Models 1936Document26 paginiForeign Firing Table FT-F-82-2 Soviet Mortar 82 MM Models 1936محمد الهاشميÎncă nu există evaluări

- Howitzer Medium Towed m198Document468 paginiHowitzer Medium Towed m198Mark AbÎncă nu există evaluări

- Aquila AN-PVS-12Document2 paginiAquila AN-PVS-12NORDBÎncă nu există evaluări

- TEK Batarya 107 122 IngilizceDocument4 paginiTEK Batarya 107 122 IngilizceEugen PinakÎncă nu există evaluări

- General Dynamics - Phalanx Close-In Weapon System (Ciws)Document1 paginăGeneral Dynamics - Phalanx Close-In Weapon System (Ciws)YamveaÎncă nu există evaluări

- Flight Testing For A 155mm Base Burn ProjectileDocument46 paginiFlight Testing For A 155mm Base Burn ProjectilefoxinboxfoxÎncă nu există evaluări

- Main Control Panel of Tank M60A3Document39 paginiMain Control Panel of Tank M60A3Haerul ImamÎncă nu există evaluări

- 30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Document16 pagini30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Anonymous jIzz7woS6Încă nu există evaluări

- Brazil M109 Overview Brief CIBld 12 Nov 13Document21 paginiBrazil M109 Overview Brief CIBld 12 Nov 13Edson Zuchetto100% (1)

- TM - 9-1005-226-14 TruncatedDocument4 paginiTM - 9-1005-226-14 TruncatedJonathan BraeckelÎncă nu există evaluări

- Apg 77Document9 paginiApg 77Francisco BuenoÎncă nu există evaluări

- Rifle Platoon Basic Load OEF XIIDocument26 paginiRifle Platoon Basic Load OEF XIIwygrrteÎncă nu există evaluări

- 105mm DCIPMDocument17 pagini105mm DCIPMjohnny_cashedÎncă nu există evaluări

- N0016411RJQ94 11RJQ94 PerfSpecDocument26 paginiN0016411RJQ94 11RJQ94 PerfSpecSamar SamerÎncă nu există evaluări

- TM 11-2731 Installation of Radio and Interphone Equipment in Carriage, Motor, 90-mm Gun, M36, M36B1, or M36B2 1945Document30 paginiTM 11-2731 Installation of Radio and Interphone Equipment in Carriage, Motor, 90-mm Gun, M36, M36B1, or M36B2 1945beppefranzÎncă nu există evaluări

- Emperical Method For Predicting Wheeled Vehicle PerfomanceDocument4 paginiEmperical Method For Predicting Wheeled Vehicle PerfomanceMari MuthuÎncă nu există evaluări

- TC 1 251 Part 1 Chapters - 1 4Document375 paginiTC 1 251 Part 1 Chapters - 1 4chinna kranthiÎncă nu există evaluări

- 1st BCT Ammunition SOPDocument52 pagini1st BCT Ammunition SOPTroop PetrieÎncă nu există evaluări

- MC - 2019 - 12Document27 paginiMC - 2019 - 12RLDDD PRO10Încă nu există evaluări

- fm6 22Document188 paginifm6 22Daniel PerrefortÎncă nu există evaluări

- An Analysis of Napoleonic Successes and Failures During The Peninsular War From May 1808 To January 1809 Through An Application of Clausewitz's Reciprocal Actions of WarDocument23 paginiAn Analysis of Napoleonic Successes and Failures During The Peninsular War From May 1808 To January 1809 Through An Application of Clausewitz's Reciprocal Actions of Warjameswilliford100% (1)

- Large Army Roster 40kDocument2 paginiLarge Army Roster 40kjameswillifordÎncă nu există evaluări

- BFG Additional Ships Compendium 1.4Document68 paginiBFG Additional Ships Compendium 1.4dshanejÎncă nu există evaluări

- Robotech Character SheetDocument8 paginiRobotech Character SheetChris PattersonÎncă nu există evaluări

- Briefing 7-15-16Document17 paginiBriefing 7-15-16LUIÎncă nu există evaluări

- Shooting Industry in New WorldDocument156 paginiShooting Industry in New WorldEduardo B. OzorioÎncă nu există evaluări

- Third Battle of PanipatDocument18 paginiThird Battle of Panipatabhas123Încă nu există evaluări

- Inquisimunda Void PiratesDocument9 paginiInquisimunda Void PiratesMathieu Couval100% (2)

- Left 4 Dead 2 CheatsDocument3 paginiLeft 4 Dead 2 CheatsYoga Jay Bee PaiyanÎncă nu există evaluări

- Jules Vernes Submarine NautilusDocument42 paginiJules Vernes Submarine NautilusMark BobsinÎncă nu există evaluări

- FA Registration AF IndividualDocument1 paginăFA Registration AF IndividualNiksr GnoÎncă nu există evaluări

- Police Varification Form Anupraman FormDocument8 paginiPolice Varification Form Anupraman Forms bansalÎncă nu există evaluări

- (Article) AFP To NGO Human RightsDocument3 pagini(Article) AFP To NGO Human RightsJC GÎncă nu există evaluări

- KISI-KISI UJIAN AKHIR SEKOLAH BAHASA INGGRISDocument11 paginiKISI-KISI UJIAN AKHIR SEKOLAH BAHASA INGGRISUsman HakimÎncă nu există evaluări

- Chris Hinson CV LamorDocument9 paginiChris Hinson CV LamorPaul HeathÎncă nu există evaluări

- Strike Legion Planetary Operations Revised EditionDocument107 paginiStrike Legion Planetary Operations Revised EditionThomas Wall Jr.0% (1)

- FM 11-50 Combat Communications Within The Division (Heavy and Light)Document237 paginiFM 11-50 Combat Communications Within The Division (Heavy and Light)Mark Cheney100% (2)

- Faceplate June2021Document20 paginiFaceplate June2021john tomÎncă nu există evaluări

- Torg - Infiniverse Magazine 31Document11 paginiTorg - Infiniverse Magazine 31JasonLocklerÎncă nu există evaluări

- 2000 Pts - Blood Angels: Name # GRP WS BS S T Wo I A LD Save CostDocument4 pagini2000 Pts - Blood Angels: Name # GRP WS BS S T Wo I A LD Save CostTod MillerÎncă nu există evaluări

- Ny Lista de Precios Inicial 2014Document3 paginiNy Lista de Precios Inicial 2014alex_mathiÎncă nu există evaluări

- 6.way - Of.the - Wicked - (The Wages of Sin)Document110 pagini6.way - Of.the - Wicked - (The Wages of Sin)memyslg100% (10)

- Redacted FOIA Requested CIA EngDocument3 paginiRedacted FOIA Requested CIA Engmary engÎncă nu există evaluări

- Danilevskii, G. P. Moscow in Flames (1917)Document326 paginiDanilevskii, G. P. Moscow in Flames (1917)Jose MuñozÎncă nu există evaluări

- District Profile Kavrepalanchok 2074Document169 paginiDistrict Profile Kavrepalanchok 2074Sajan ShresthaÎncă nu există evaluări

- American and British English Pronunciation Differences - WikipediaDocument16 paginiAmerican and British English Pronunciation Differences - WikipediaFADI AL-MAKTRYÎncă nu există evaluări

- 1988 Soviet Army Scout Close CombatDocument13 pagini1988 Soviet Army Scout Close CombatRedguard1976100% (2)

- WWII 42nd Infantry DivisionDocument185 paginiWWII 42nd Infantry DivisionCAP History Library100% (2)

- SMS Grosser Kurfürst: History German EmpireDocument5 paginiSMS Grosser Kurfürst: History German Empiresdfkj dsuisdÎncă nu există evaluări