Documente Academic

Documente Profesional

Documente Cultură

Metrology Slides

Încărcat de

தமிழன்0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări39 paginimetrology measurement notes

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentmetrology measurement notes

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări39 paginiMetrology Slides

Încărcat de

தமிழன்metrology measurement notes

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 39

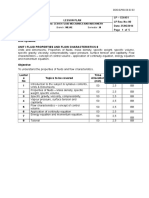

Metrology

Metrology is the science of measurement

Dimensional metrology is that branch of

Metrology which deals with measurement of

dimensions of a part or workpiece (lengths,

angles, etc.)

Dimensional measurements at the required

level of accuracy are the essential link

between the designers intent and a delivered

product.

Aspects of Metrology

Reference standard metrology

Engineering Metrology

Basic Measurement Devices

Surface Plates

Test Stands

Dial Gages

Micrometers and Verniers

Gage Blocks

Dimensional Metrology Needs

Linear measurements

Angular measurements

Geometric form measurements

Roundness

Straightness

Cylindricity

Flatness, etc

Dimensional Metrology Needs

Geometric relationships

Parallel, perpendicular, etc.

Concentric, runout, etc.

Controlled surface texture

Communicating Dimensional

Metrology Needs

Geometric Dimensioning and

Tolerancing (GDT)

The language of dimensional

metrology

Standard symbols, etc., on part

drawings.

Specification of Linear

Tolerances

Angular Specifications

Angular Tolerances

Flatness Specification

Flatness Tolerances

Straightness Specification

Straightness Tolerance

Roundness Specification

Roundness applies to every section

Roundness Tolerances

Surface Profile Without

Datums

Line Profile Without Datums

Surface Profile with Datums

Profile of a line with datums is similar

Surface Profile with Datums

Cylindricity Specifications

Cylindricity Tolerances

Surface Texture Specification

Surface Texture

Perpendicularity Specification

Perpendicularity Measurements

Parallelism Specification

Parallelism Measurements

Concentricity Specification

Concentricity Tolerances

Concentricity Measurements

Concentricity Measurements

Circular Runout Specifications

Circular Runout Tolerances

Total Runout Specifications

Total Runout Tolerances

Position Specifications

Position Tolerances

Simulated Datum

Datum Selection

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Validation of A 60-Level Modular Multilevel Converter Model - Overview of Offline and Real-Time HIL Testing and ResultsDocument6 paginiValidation of A 60-Level Modular Multilevel Converter Model - Overview of Offline and Real-Time HIL Testing and Resultsதமிழன்Încă nu există evaluări

- Modular Multi LevelDocument15 paginiModular Multi Levelதமிழன்Încă nu există evaluări

- p185 PDFDocument24 paginip185 PDFதமிழன்Încă nu există evaluări

- Different Power Supplies For Different Machines: H.-J. EckoldtDocument20 paginiDifferent Power Supplies For Different Machines: H.-J. Eckoldtதமிழன்Încă nu există evaluări

- Unit Syllabus: Unit I Fluid Properties and Flow Characteristics 8Document6 paginiUnit Syllabus: Unit I Fluid Properties and Flow Characteristics 8தமிழன்Încă nu există evaluări

- XRDDocument19 paginiXRDதமிழன்Încă nu există evaluări

- Selecting and Constructing Data Collection Instruments: IpdetDocument59 paginiSelecting and Constructing Data Collection Instruments: Ipdetதமிழன்Încă nu există evaluări