Documente Academic

Documente Profesional

Documente Cultură

Fmea Process

Încărcat de

Emperor89Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fmea Process

Încărcat de

Emperor89Drepturi de autor:

Formate disponibile

PROCESS FMEA

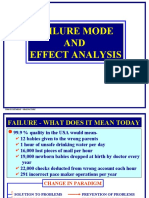

FAILURE MODE & EFFECT ANALYSIS

PFMEA

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 1.

PROCESS FMEA

Origin

FMEA

US-Space program and defence safety system in 1960’s

Common Definitions

Function :

Function of the item being analysed to meet the Design intent.

Includes information regarding the environment in which this

system operates.

Failure Mode:

A ‘Failure Mode’ is the manner in which a component, assembly or

system could potentially fail to meet the design intent. Typical

failure mode may includes, not limited to :

Yield; Fatigue; Material Instability; creep; wear; corrosion;

Cracked Deformed; Leaking.

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 2.

PROCESS FMEA

What is FMEA?

FMEA

FMEA is a systemised group of activities to:

1. recognise and evaluate the potential failure of a product /

process and its effects

2. identify actions which could eliminate or reduce the chance

of potential failure occurring

3. document the process

Why FMEA ?

1. For a company policy where continuous improvement is

emphasized for its product, process

2. FMEA is a living document

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 3.

PROCESS FMEA

Who should do FMEA?

FMEA

1. Cross Functional Team Effort – with a leader

2. Team of knowledgeable individuals Ex. Expertise in Design,

Mfg., Assly., Quality., etc.

3. Team should include representatives of sub-contractors and/or

customers

When FMEA should be done ?

1. Essence is timeliness

2. Pro-Active rather than reactive

3. Before process failure mode occurs

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 4.

FMEA PROCESS FMEA

Advantages of FMEA

1. Avoids late change crisis

2. Reduces or eliminates chance of

implementing corrective change

3. excellent technique for preventive action

4. interactive process which is never ending

Types of FMEA

1. System FMEA – Power transmission system

2. Design FMEA – Axle shaft

3. Process FMEA – Heat treatment

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 5.

FMEA PROCESS FMEA

QS-9000 requirements

• FMEA shall consider special characteristics

• Aiming defect prevention rather than defect detection

• Use FMEA manual & CFT approach

Potential – Process FMEA

Potential Means ‘Anticipated’

It is an analytical technique to assure that potential failure

mode and their associated causes have been considered and

addressed.

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 6.

FMEA PROCESS FMEA

FOR FMEA FORMAT

CLICK HERE

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 7.

EXPLANATIONS PROCESS FMEA

Process Potentia Potential

Function/ Requirements l Failure Effect(s) of

Mode Failure

• Specify the description and

Function of the process

• List out Outputs of the Process

Example

Process function / description

- Manual application of wax

inside door

- Machining of outer diameter

Requirements

- To cover inner door at minimum

thickness to retard corrosion

- Outer diameter, run-out, free

from tool mark

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 8.

PROCESS FMEA

Potential Failure Mode Potential Sev

EXPLANATIONS

Effect(s) of

Failure

Two Assumptions are

1. Consider all inputs are acceptable

2. Consider the Design is acceptable

• List the failure modes those are

possible to occur against the

requirements specified in the

previous column.

• Apart from Engg. Specification, what

would a customer consider

objectionable

• CUSTOMER is

- Next opn.

- Subsequent Opn.

- End user

Example

Bent, Diameter oversize, Diameter

undersize, Cracked, Deformed, Open

Circuited, Burred

OD not clear – Is it a failure mode in

machining of casting / forging?

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 9.

PROCESS FMEA

Potential Effect(s) of Failure Sev Class

EXPLANATIONS

• List the effects of failure in

- Next operation

- Subsequent operations

- Customer

- End user/ Environment

• Describe the effects using the

terminology specified in Severity rating

table

• For each failure mode, more than one

effect can be listed

Example

- Cannot locate

- Cannot face

- Does not fit

- Does not match

- Scrap, re-work

- Vehicle / item inoperable

- Loss of primary function

- Customer dissatisfaction

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 10.

PROCESS FMEA

Potential Cause(s)

EXPLANATIONS

Severity Class / Mechanism (s) of

Failure

• Assess the seriousness of the effect in

a 1-10 scale

• This rating applies to EFFECT only

(i.e. previous column)

• Consider the Design FMEA

• Consult subsequent Mfg./ Assembly

plant

• Safety related effects should be rated

in Nos.9 or 10

• While giving ranking consider only the

required criteria (i.e. next opn. /

vehicle)

FOR SEVIORITY RANKING

CLICK HERE

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 11.

EXPLANATIONS PROCESS FMEA

O

Potential

c

Cause(s) /

Classification c

Mechanism

u

(s) of Failure

r

• Classify special product

characteristics (e.g. critical,

key, major)

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 12.

EXPLANATIONS PROCESS FMEA

Current Current

Oc Process Process

Potential Cause(s) / Mechanism (s) of Failure

cur Control Control

prevention detection

• List the first level potential causes such as

- man

- machine

- tool

- process parameter

- fixture etc.

• List the root causes under the first level causes

using WHY? WHY? analysis

• Describe the causes in such a way that can be

eliminated or controlled

• Don’t use ambiguous statements such as

- operator mal-functioning

- fixture problem etc.

• Use the cause and effect diagram, if required

• consider input materials in last iteration of cause

analysis

Contd.….

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 13.

PROCESS FMEA

Current Current

O

Process Process

Potential Cause(s) / Mechanism (s) of Failure cc

Control Control

ur

Prevention detection

Example

Under Man

- Fails to clean

- Fails to assemble

- Fails to tight

- Mis-locate

Under machine

- inadequate lubrication

- excessive vibration

- excessive spindle run-out

Under process

- improper time / temperature

- inadequate gating / venting

Under design

- Symmetric design

- Difficult to assemble

Under Raw Material

- Mixed material

- New source

- Alternate material

- Excessive hardness

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 14.

PROCESS FMEA

Current

EXPLANATIONS

Current Proces

Process s FOR

Occurrence Controls Control OCCURANCE

preventi s

on Detecti RANKING

on

• Estimate the probability of

occurrence on a 1-10 scale

• Rate against each causes CLICK HERE

• Use past data as a basis

(cpk/rejection %) for ranking

• Document the basis of

occurrence ranking

• For a new process, if there is no

previous experience, use team

judgement

Don’t consider failure-detecting

measures while giving ranking

(100% inspection.)

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 15.

PROCESS FMEA

D

e

EXPLANATIONS

R

Current Process Control Current Process Control t

P

Prevention Detection e

N

c

t

• Type of Controls

Level Type Examples

P- Prevention of

Mistake proofing

Prevention causes

Detection of causes SPC, Visual

D- & leading to control etc. 100%

Detection corrective actions inspection, patrol

Detection of defect inspection

• List the existing controls, which can detect the causes or failure mode

• While listing, specify the frequency of detection measures

Examples

- Visual Check, one per shift for film thickness

- SPC chart five pieces in an hour

- On-line monitoring of crimping force

- Auto-control of temperature

- 100% on-line inspection

- Visual monitoring of Ammeter

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 16.

EXPLANATIONS PROCESS FMEA

Recommended

Detection RPN

Action

• Assess the probability of controls

listed in the previous column,

which will detect the cause or

failure mode

• While giving ranking, assume the

failure is occurred

• Don’t assume ranking is low

because the occurrence is low

• Random controls should not

influence detection ranking

• One detection ranking can be

assigned to multiple controls

FOR DETECTION RANKING

CLICK HERE

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 17.

EXPLANATIONS PROCESS FMEA

Responsibil

Recommen ity & Target

RPN

ded Action Completion

Date

• Risk Priority Number

is the multiplication of

severity x occurrence

x detection.

• While calculating

RPN, consider only

highest severity rating

of each failure mode

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 18.

EXPLANATIONS PROCESS FMEA

Responsibility

& Target Action

Recommended Action

Completion Results

Date

• Policy for RPN to take action

- define a target RPN and anything

above that can be considered for

action. For Ex. It can be 50.

Considering 95% of the failures are

attended

- consider only high priority no. for

take action and review periodically

• As a first priority, take action on causes

to reduce occurrence ranking

• The next priority is to consider action

on controls to reduce detection ranking

• severity ranking can be reduced by

- elimination of failure mode by

change in processes or design

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 19.

EXPLANATIONS PROCESS FMEA

Actio O D R

Responsibility & Target Se

ns c e P

Completion Date v

Taken c t N

• Specify the responsibility

and target completion date

for every actions identified

• During APQP, the FMEA

completion dates should be

prior to Production run

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 20.

EXPLANATIONS PROCESS FMEA

Action Results

Se Oc

Actions Taken Det RPN

v c

• Describe the verification results

• Where effectiveness measure is

required, specify the target date

accordingly

• After the assessment of the

actions taken, re-assess the

values of severity, occurrence,

detection and RPN

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 21.

EXPLANATIONS PROCESS FMEA

Follow up actions

The Process - responsible engineer is responsible for ensuring that all

actions recommended have been implemented or adequately addressed

. FMEA is a living document and should always reflect the latest design

level as well as the latest relevant actions.

The Process responsible engineer has several means of ensuring that

concerns are identified and that recommended actions are implemented .

they includes but not limited to followings :

1 Ensuring design requirements are achieved

2 Reviewing engineering drawings & specifications

3 Conforming incorporation in assembly / manufacturing

documentation &

4 Reviewing process FMEA & Control plans

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 22.

PROCESS FMEA

PROCESS FMEA QUALITY OBJECTIVES

POINTS TO CONSIDER

1 PROCESS IMPROVEMENTS: The FMEA drives process improvement as

primary objective. With an emphasis on Error / Mistake proofing solutions

2 HIGH RISK FAILURE MODES: The FMEA address all high-risk failure

modes as identified by FMEA team, with executable action plans. All other

failure modes are considered.

3 CONTROL PLANS: The pre launch and production Control Plan consider the

failure modes from the process FMEA.

4 INTEGRATION: The FMEA is integrated and consistent with process flow

diagram and the process control plan. The process FMEA considers the

design FMEA, if available as part of its analysis.

5 LESSONS LEARNED: The FMEA considered all major “ lessons learned “ as

input to failure mode identification

6 SPECIAL OR KEY CHARACTERISTICS: the FMEA identifies appropriate

key characteristics candidates as input to the key characteristics selection

process , if applicable due to company policy.

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 23.

DFMEA QUALITY OBJECTIVES PROCESS FMEA

7 TIMING: The FMEA is completed during the “ Window of opportunity “

where it could most efficiently impact the product design of product or

process.

8 TEAM: The right people participate as part of the FMEA team through

out the analysis and are adequately trained in FMEA methods

9 DOCUMENTATION: the FMEA is completely filled out “ by the book ”

including “ action plan ” and new RPN values.

10 TIME USAGE: Time spent by FMEA team as early as possible is an

effective & efficient use of time, with a value –added result. This

assumes recommended actions are identified as required and the

actions are implemented.

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 24.

PROCESS FMEA

Nathan & Nathan Consultants Pvt. Ltd. NNCPL/PPT/006 25.

S-ar putea să vă placă și

- 203 LSS Gbo - FmeaDocument47 pagini203 LSS Gbo - FmeaRocker byÎncă nu există evaluări

- FMEA TrainingDocument25 paginiFMEA Trainingmelimaulani-1Încă nu există evaluări

- Failure Mode AND Effect Analysis: TPM Secretariat - Orai FactoryDocument27 paginiFailure Mode AND Effect Analysis: TPM Secretariat - Orai FactorySunilÎncă nu există evaluări

- FMEADocument18 paginiFMEASeshagiri furt67% (3)

- DMAIC Cost ReductionDocument50 paginiDMAIC Cost Reductionrahulkaushikddps365Încă nu există evaluări

- Moudling Operation GSIC Process: MouldingDocument13 paginiMoudling Operation GSIC Process: MouldingBalakumaran MurugesanÎncă nu există evaluări

- Statistical Process ControlDocument34 paginiStatistical Process ControlSurya BakshiÎncă nu există evaluări

- Manufacturing Facilities A Complete Guide - 2019 EditionDe la EverandManufacturing Facilities A Complete Guide - 2019 EditionÎncă nu există evaluări

- Problem Solving - PdcaDocument61 paginiProblem Solving - PdcaNurul HidayahÎncă nu există evaluări

- 5S & Visual Workplace Management Workshop/TrainingDocument2 pagini5S & Visual Workplace Management Workshop/TrainingLeanAdvisors100% (4)

- FMEADocument29 paginiFMEAKarthik Kr100% (1)

- Fmea Overview and RoadmapDocument47 paginiFmea Overview and RoadmapLake HouseÎncă nu există evaluări

- FSC Fmea Failure Mode and Effect AnalysisDocument21 paginiFSC Fmea Failure Mode and Effect AnalysisVbaluyoÎncă nu există evaluări

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Document5 paginiFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123DanistergladwinÎncă nu există evaluări

- A3Document1 paginăA3chavesierra20081 SierraÎncă nu există evaluări

- Mistake ProofingDocument38 paginiMistake ProofingkotharideepÎncă nu există evaluări

- Setco Automotive LTD.: NP ChartDocument4 paginiSetco Automotive LTD.: NP ChartDisha ShahÎncă nu există evaluări

- GS-0002D, Design FMEADocument26 paginiGS-0002D, Design FMEAmesa142100% (1)

- Process Improvement For PET BottlesDocument9 paginiProcess Improvement For PET Bottlesjcmunevar1484Încă nu există evaluări

- APQP Internal Assessment Checklist: Development PhaseDocument3 paginiAPQP Internal Assessment Checklist: Development PhaseRandhir Kanwar100% (1)

- Article On Effective Operational ExcellenceDocument4 paginiArticle On Effective Operational Excellencealaissa cagubcobÎncă nu există evaluări

- Are We Doing Well SlidesDocument10 paginiAre We Doing Well SlidessahajÎncă nu există evaluări

- KPI OEE Downtime AnalyticsDocument16 paginiKPI OEE Downtime Analyticsrasa55555Încă nu există evaluări

- Statistical Process ControlDocument79 paginiStatistical Process ControlKrunal PandyaÎncă nu există evaluări

- QA Assistant Studio PFMEA ExampleDocument1 paginăQA Assistant Studio PFMEA ExampleIqraYounasÎncă nu există evaluări

- VSMDocument22 paginiVSMஅன்பு ஜோயல்Încă nu există evaluări

- Variation and DefectsDocument16 paginiVariation and DefectssushmaxÎncă nu există evaluări

- Chapter 5 - Control Chart For AttributesDocument28 paginiChapter 5 - Control Chart For AttributesAtirah AsnaÎncă nu există evaluări

- 4 Measure - Measurement System AnalysisDocument63 pagini4 Measure - Measurement System AnalysisSudhagarÎncă nu există evaluări

- Integrate FMEA and SPCDocument7 paginiIntegrate FMEA and SPCSridharan VenkatÎncă nu există evaluări

- FMEADocument64 paginiFMEAbipin.chouguleÎncă nu există evaluări

- 6BWSHR Working With Machines A2 Poster EnglishDocument1 pagină6BWSHR Working With Machines A2 Poster EnglishKhuda BukshÎncă nu există evaluări

- Poka-Yoke Team 4Document14 paginiPoka-Yoke Team 4Ratandeep PandeyÎncă nu există evaluări

- MeasureDocument51 paginiMeasureAshwani KumarÎncă nu există evaluări

- Application of Fmea Method in A Manufacturing Organization Focused On QualityDocument7 paginiApplication of Fmea Method in A Manufacturing Organization Focused On QualityRudra DasÎncă nu există evaluări

- 10 DMAIC ToolsDocument44 pagini10 DMAIC ToolsdanorahhhÎncă nu există evaluări

- 5y AnalysisDocument2 pagini5y AnalysispsathishthevanÎncă nu există evaluări

- Apqp Advanced Product Quality PlanningDocument27 paginiApqp Advanced Product Quality PlanningRajesh KumarÎncă nu există evaluări

- Current State of Quality in The Automotive Industry: Scott Gray Director, Quality Products and Services, AIAGDocument26 paginiCurrent State of Quality in The Automotive Industry: Scott Gray Director, Quality Products and Services, AIAGSelvaraj SÎncă nu există evaluări

- Measurement System AnalysisDocument80 paginiMeasurement System AnalysisVasant bhoknalÎncă nu există evaluări

- HA CEDAC Workshop INDO Kaizen PartDocument16 paginiHA CEDAC Workshop INDO Kaizen PartHardi BanuareaÎncă nu există evaluări

- MSA (Measurement System Analys)Document19 paginiMSA (Measurement System Analys)Dazslam New VersionÎncă nu există evaluări

- Error Proofing BasicsDocument16 paginiError Proofing BasicsJohn OoÎncă nu există evaluări

- Over View - Cost of QualityDocument31 paginiOver View - Cost of QualityAntony Illam100% (1)

- Opex VSM Training Module 100711001122 Phpapp02Document53 paginiOpex VSM Training Module 100711001122 Phpapp02Jesus Jose Hernandez GuerreroÎncă nu există evaluări

- SPCDocument49 paginiSPCJosephi_abbasÎncă nu există evaluări

- MAstering IATFDocument20 paginiMAstering IATFGyanesh_DBÎncă nu există evaluări

- Strategic Advice GuidanceDocument59 paginiStrategic Advice GuidancerazookÎncă nu există evaluări

- Rolled Throughput Yield (Training)Document7 paginiRolled Throughput Yield (Training)Madhavan RamÎncă nu există evaluări

- BMW FmeaDocument48 paginiBMW FmeaDearRed FrankÎncă nu există evaluări

- LEAN Execution OEEDocument11 paginiLEAN Execution OEEVergence Business Associates100% (7)

- ASQ - Design FMEADocument35 paginiASQ - Design FMEABESÎncă nu există evaluări

- Design Failure Mode and Effect Analysis - Case StuDocument13 paginiDesign Failure Mode and Effect Analysis - Case Stusanjay chamoliÎncă nu există evaluări

- Sensors and RFID: The Unbeatable Team For Advanced Error ProofingDocument13 paginiSensors and RFID: The Unbeatable Team For Advanced Error ProofingRamasubramanian SankaranarayananÎncă nu există evaluări

- 1.6.C DomDocument9 pagini1.6.C DomEmperor89Încă nu există evaluări

- 1.7.d DOMDocument6 pagini1.7.d DOMEmperor89Încă nu există evaluări

- 2.2.D DomDocument1 pagină2.2.D DomEmperor89Încă nu există evaluări

- 1 5 DDocument6 pagini1 5 DEmperor89Încă nu există evaluări

- Autonomous Coimbatore - 32 Degree: / Branch: BE / MECH Semester: / Year: V / III Subject Code & Title: 17MD11-DYNAMICS OF MACHINERY AssignmentDocument1 paginăAutonomous Coimbatore - 32 Degree: / Branch: BE / MECH Semester: / Year: V / III Subject Code & Title: 17MD11-DYNAMICS OF MACHINERY AssignmentEmperor89Încă nu există evaluări

- For The AY 2019-2020, Report Has To Be Prepared ForDocument2 paginiFor The AY 2019-2020, Report Has To Be Prepared ForEmperor89Încă nu există evaluări

- Department of Mechanical Engineering 18MD04-Kinematics of Machinery Module-3 Friction QuestionsDocument2 paginiDepartment of Mechanical Engineering 18MD04-Kinematics of Machinery Module-3 Friction QuestionsEmperor89Încă nu există evaluări

- 12m611 Automobile Technology LaboratoryDocument1 pagină12m611 Automobile Technology LaboratoryEmperor89Încă nu există evaluări

- Course Plan: Department of Mechanical EnginneringDocument10 paginiCourse Plan: Department of Mechanical EnginneringEmperor89Încă nu există evaluări

- 14M512-Dynamics of MachineryDocument1 pagină14M512-Dynamics of MachineryEmperor89Încă nu există evaluări

- Fmea DesignDocument29 paginiFmea DesignEmperor89100% (2)

- Shear Force & Bending Moment Diagrams (SSB)Document9 paginiShear Force & Bending Moment Diagrams (SSB)Emperor89Încă nu există evaluări

- 14M514.Metrology and Measurement Laboratory ManualDocument33 pagini14M514.Metrology and Measurement Laboratory ManualEmperor89Încă nu există evaluări

- Screw Conveyor CatlogueDocument148 paginiScrew Conveyor CatlogueEmperor89100% (1)

- Screw Flight Development CalculationDocument15 paginiScrew Flight Development CalculationEmperor8983% (6)

- INCOTERMSDocument2 paginiINCOTERMSjbconnerÎncă nu există evaluări

- To The Training On Presentation Skills: Revision No. NNCPL/PPT/PS/001 Version No. 1.0 Date: 01/07/08Document45 paginiTo The Training On Presentation Skills: Revision No. NNCPL/PPT/PS/001 Version No. 1.0 Date: 01/07/08Emperor89Încă nu există evaluări

- Boiler Efficiency PresentationDocument13 paginiBoiler Efficiency PresentationAhmad Sabree Abdul BasitÎncă nu există evaluări

- 2 EesyllDocument77 pagini2 EesyllDileepÎncă nu există evaluări

- Tutorial DistillationDocument3 paginiTutorial DistillationManu Indivare Nundoolall100% (1)

- CR EstimateDocument307 paginiCR EstimateGani AnosaÎncă nu există evaluări

- 03 Traversing Gear SlaveDocument69 pagini03 Traversing Gear SlaveDeMen NguyenÎncă nu există evaluări

- BS 131-7-1998Document21 paginiBS 131-7-1998Germán VSÎncă nu există evaluări

- Clinical Practice Guideline On Diagnosis and Treatment of Hyponatremia PDFDocument12 paginiClinical Practice Guideline On Diagnosis and Treatment of Hyponatremia PDFLuis Mochas HClÎncă nu există evaluări

- Ebook Remote Server ManagementDocument10 paginiEbook Remote Server ManagementPiruletoÎncă nu există evaluări

- Compliance Statement - FormDocument16 paginiCompliance Statement - Formaqil khanÎncă nu există evaluări

- En 2014 New Brochure WebDocument20 paginiEn 2014 New Brochure WebSasa NackovicÎncă nu există evaluări

- MPLS22LGDocument81 paginiMPLS22LGTerri DuranÎncă nu există evaluări

- Weather ForecastsDocument5 paginiWeather ForecastsGianina MihăicăÎncă nu există evaluări

- Lutron / Trane Bacnet Integration: QuantumDocument7 paginiLutron / Trane Bacnet Integration: QuantumthomasÎncă nu există evaluări

- Topic 4 Positioining V2Document39 paginiTopic 4 Positioining V2Aqilah Taufik100% (2)

- Quarter 1 Week 1Document6 paginiQuarter 1 Week 1GhghaaaÎncă nu există evaluări

- Fork LiftDocument4 paginiFork Lifttamer goudaÎncă nu există evaluări

- Actor-Network Theory and After - Jonh Law and John HassardDocument14 paginiActor-Network Theory and After - Jonh Law and John HassardGabriel RomanÎncă nu există evaluări

- Process Control Plan Excel TemplateDocument13 paginiProcess Control Plan Excel TemplateTalal NajeebÎncă nu există evaluări

- SME6024 Teaching Statistics & ProbabilityDocument18 paginiSME6024 Teaching Statistics & ProbabilityNurlailah IsmailÎncă nu există evaluări

- Technical Drafting I: (Manual Drafting) 2Nd SemesterDocument18 paginiTechnical Drafting I: (Manual Drafting) 2Nd SemesterhakkensÎncă nu există evaluări

- SMAC Actuators User ManualDocument52 paginiSMAC Actuators User ManualGabo DuarÎncă nu există evaluări

- The Effecto of Using Deductive ApproachDocument15 paginiThe Effecto of Using Deductive ApproachCarmela EstradaÎncă nu există evaluări

- Reviewer MathDocument6 paginiReviewer MathLuna Ronquillo100% (1)

- Brochure Cementindustrie PfeifferDocument24 paginiBrochure Cementindustrie Pfeifferdoxa maria0% (1)

- Student Management SystemDocument5 paginiStudent Management SystemRamesh Kumar60% (5)

- Circular Motion 1 QPDocument8 paginiCircular Motion 1 QPNovi Juniati PitrianaÎncă nu există evaluări

- Bomberman 93Document8 paginiBomberman 93Mike RussoÎncă nu există evaluări

- FMF-01-10-911-302 - 100 GPM - 60 HZ Electric Motor DriveDocument1 paginăFMF-01-10-911-302 - 100 GPM - 60 HZ Electric Motor DriveMarkÎncă nu există evaluări

- Switchgear and Protection May 2022Document1 paginăSwitchgear and Protection May 2022Sanapala RAJENDRA PRASADÎncă nu există evaluări

- Paragon Error Code InformationDocument19 paginiParagon Error Code InformationnenulelelemaÎncă nu există evaluări