Documente Academic

Documente Profesional

Documente Cultură

Electrolysis Fuel Cell: 50 Ma/cm 100 Ma/cm 200 Ma/cm

Încărcat de

Mario Loria RayaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Electrolysis Fuel Cell: 50 Ma/cm 100 Ma/cm 200 Ma/cm

Încărcat de

Mario Loria RayaDrepturi de autor:

Formate disponibile

2.

0

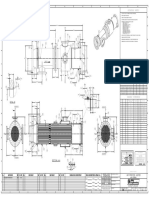

Figure 6. Impedance Spectroscopy of a URFC in

1.8 mode electrolyzer at room temperature and 1.5 V.

Hydrogen energy storage systems coupled to renewable power 1.6

sources are being proposed as a means to increase energy

1.4

independence, improve domestic economies, and reduce

E = 1.5 V

greenhouse gas emissions from stationary and mobile fossil-fueled 1.2

2

sources. New technologies for production and utilization of

- Zi / cm

hydrogen as energy carrier are electrolysers 1-3 and fuel cells 4,5, 1.0

respectively. Both processes may alternatively occur in the same 0.8

device based on a proton exchange membrane (PEM). This device is

called unitized regenerative fuel cell (URFC). Compared with conventional secondary batteries, 0.6

URFCs advantages rely on high energy density, long-term energy storage, durability and 0.4

Rs + Rp

environmental protection. Whereas in comparison to the separate fuel cell and electrolyzer

0.2 Rs

based systems, URFCs are significantly more compact and they allow considerable system

simplification. Moreover, URFC devices are characterized by rapid start up, they can operate 10 mHz

0.0 10kHz

efficiently at low temperature without the need of cumbersome power consuming auxiliaries and

can provide stable operation even in the presence of a large number of start up/ shut down 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

cycles. 2

Zr / cm

boiling water

Heat filtered NaOH H2IrCl6

treatment

400C 2.0

1.8

t = 10 min t = 10 min

1.6

Becker (100 mL) 1 mL

50 mg 25 mL Ultrasounds Figure 8. Time-stability test under electrolysis mode at 1.8 V

T= 70 C 0.5 M 1.4

IrO2 ethylene glycol and room temperature for the MEA based on Pt/ IrO2 (50:50

H2PtCl6

wt % ) electrocatalyst. The inset shows the fuel cell 1.2 Electrolysis

polarization and power density curves before and after the

t = 10 min E/ V 1.0 Fuel Cell

stability test at room temperature.

0.6 0.8

Washed with

NaOH 0.6

water T=80C t 0.55

and filtered pH

1.2 0.4

-2

Current density / A cm

0.5 Before time test @ 1.8 V

1 0.2

After time test @ 1.8 V

0.8

Potential / V

0.45 0.0

0.6 -100 0 100 200 300 400 500 600

-2

11

Figure 2. Variation of Pt crystallite size

0.4 0.4 j / mA cm

10 as a function of pH for a reaction time of

IrO2 0.2

10 min.

Pt 9

Pt Crystallite Size / nm

0.35 0

8

0 0.1 0.2 0.3 0.4

Intensity / a.u.

7 Current density / mA cm -2

f

0.3

Figure 7. URFC polarization curves at room

6

0 20 40 60 80 100 120 temperature of the MEA based on Pt/ IrO2 ( 50:50

e 5

Time / h

wt % ) electrocatalyst.

d 4

c 3

b 2

a

10 20 30 40 50 60 70 80 90 100 110 1

2 4 6 8 10 12

E FC

RT

2 / degree EFC : cell voltage fuel cell

pH

EWE: cell voltage water

EWE

IrO2 Pt

8.0

IrO2

electrolyzer

IrO2

Intensity / a.u.

50 7.5

Pt

7.0

IrO2

40 6.5

Table 1. Results of round-trip energy efficiency .

Pt

Pt

Crystallite size / nm

f 6.0

5.5

50 mA/cm2 100 mA/cm2 200 mA/cm2

% Pt wt.

30

20 40 60 80 100

5.0

2 / degree

4.5

20

Figure 1. Powder XRD patterns of Pt-IrO2 at different pH 4.0

Figure 3. XRF variation of percent by weight of Pt with

values: a) 3, b) 5, d) 9, e) 10 and f) 11.7.

respect to time at T = 70 C and variation of crystallite

size at pH 11.7. 10

3.5 47 % 37 % 30 %

3.0

2.5

0

10 20 30 40 50 60

Time / min

A)

70

60

IrO2 50 C)

number

Pt

40

30

The development of high energy density, efficient, non polluting energy storage systems is fundamental for

20

renewable power sources. A new process for synthesizing a nanosized Pt/IrO2 electrocatalyst for URFCs was

Intensity / a. u.

10

0

3 3.5 4 4.5 5 5.5 6 6.5 developed. An advance with respect to the state of the art was achieved since a chemical deposition of Pt

Pt Diameter / nm

nanoparticles onto an IrO2 support was obtained without modifying the oxidation state of Ir. Whereas, a common

80

b 70

60 D)

approach to avoid modification of IrO2 status consists in the mechanical mixing of Pt and IrO2 nanopowders. TEM

50

observation showed an intimate contact between Pt and IrO2 phases as required for a dual function catalyst

number

40

30

20

10

operating in both electrolysis (oxygen evolution) and fuel cell (oxygen reduction) modes. Electrochemical data

a 0

5 5.6 6 7 7.5 8 8.5 9 showed good performance at room temperature and atmospheric pressure, as required for operation in conjunction

20 40 60 80 100 IrO2 Diameter / nm

2 / degree

with renewable power sources, especially in the electrolyzer mode. To reduce the asymmetry of the overpotential for

Figure 4. Powder XRD patterns of IrO2 via colloidal process

Figure 5. HR-TEM images of sample Pt-IrO2 50:50 wt. at different magnifications: A) 330 kx, B)

570 kx, C) Particle size distribution for Pt and D) Particle size distribution for IrO2.

operation under electrolysis and fuel cell mode, it appears appropriate to tailor the catalyst composition as well as

(a) and Pt-IrO2 (~ 50:50 wt. %) via polyol ultrasonic the hydrophilic/hydrophobic properties of the Ti-grid backing layer. However, to reduce the occurrence of corrosion

process (b).

phenomena, it is also necessary to avoid any increase of the maximum operating potential of the unitized

regenerative fuel cell.

[1] E. Rasten, G. Hagen, R. Tunold, Electrochim. Acta, 2003, 48, 3945.

References

[2] A. de Oliveira-Sousa, M.A.S. da Silva, S.S. Machado, L.A. Avaca, P. de Lima-Neto, Electrochim. Acta, 2000, 45,

The authors acknowledge the support of bilateral CNR (Italy) -CONACYT (Mexico) joint agreement 4467.

2009-2011 (project Aric/Arriaga Hurtado). J.C. Cruz and L.G. Arriaga thank the Mexican Council for [3] J. C. Cruz, V. Baglio, S. Siracusano, R. Ornelas, L. Ortiz-Frade, L. G. Arriaga, V. Antonucci, A. S. Aric, J.

Science and Technology (Conacyt, Fomix-Zacatecas 81728) for financial support. The efforts addressed Nanopart. Res., 2011, 13, 1639.

[4]A. Morozan, B. Jousselme, S. Palacin, Energy & Environmental Science, 2011, 4, 1238.

by Tozzi Renewable Energy to this research topic are also acknowledged. CNR-ITAE authors

[5]W. Zhang, P. Sherrell, A.I. Minett, J.M. Razal, Energy & Environmental Science, 2010, 3 1286.

acknowledge financial support from the FIRB MIUR Project Rinnova.s

S-ar putea să vă placă și

- Bella CiaoDocument2 paginiBella CiaoBert LietaertÎncă nu există evaluări

- Don't You Worry 'Bout A Thing: Trumpet 1Document1 paginăDon't You Worry 'Bout A Thing: Trumpet 1Cre ArqÎncă nu există evaluări

- Wikipediacommons44dperiodic Table Large - SVGDocument1 paginăWikipediacommons44dperiodic Table Large - SVGrowinaescalante13Încă nu există evaluări

- Ir2020 Circuit DiagramDocument36 paginiIr2020 Circuit Diagramluis1984bolÎncă nu există evaluări

- SI FUERA COMO AYER - ViolaDocument1 paginăSI FUERA COMO AYER - ViolaMaria Jose UribeÎncă nu există evaluări

- Direct Ammonia Fuel CellDocument1 paginăDirect Ammonia Fuel CellParijat MishraÎncă nu există evaluări

- JEE Main Quiz-18 (Student Copy)Document12 paginiJEE Main Quiz-18 (Student Copy)ashutosh.mishra0051Încă nu există evaluări

- BebêDocument2 paginiBebêEveraldo Fonseca LeiteÎncă nu există evaluări

- Primix Carpet SectionDocument1 paginăPrimix Carpet SectionvijjaiksinghÎncă nu există evaluări

- Fur Elise: Clavierstuck in A Minor - Woo 59Document4 paginiFur Elise: Clavierstuck in A Minor - Woo 59LUZÎncă nu există evaluări

- Para Elisa PianoDocument4 paginiPara Elisa PianoLUZÎncă nu există evaluări

- Fur Elise: Clavierstuck in A Minor - Woo 59Document4 paginiFur Elise: Clavierstuck in A Minor - Woo 59marioÎncă nu există evaluări

- Load Schedule PB1 Load Schedule PB2,3,4,5 Unit 01 UNIT 02-03-04-05Document1 paginăLoad Schedule PB1 Load Schedule PB2,3,4,5 Unit 01 UNIT 02-03-04-05domin domÎncă nu există evaluări

- Chiquito Team Band Lejos de Ti Trombon 2Document1 paginăChiquito Team Band Lejos de Ti Trombon 2manueldelunaÎncă nu există evaluări

- Mozart - Sonata 1 9Document1 paginăMozart - Sonata 1 9Alvaro ClavelÎncă nu există evaluări

- SIGN 456: Red Reflective Vinyl Sticker White Reflective Vinyl StickerDocument1 paginăSIGN 456: Red Reflective Vinyl Sticker White Reflective Vinyl StickerTAHAÎncă nu există evaluări

- Warriors TooManyZoozDocument1 paginăWarriors TooManyZoozferrandÎncă nu există evaluări

- (Free Scores - Com) - Jones Richard Boree Bourra 173961Document1 pagină(Free Scores - Com) - Jones Richard Boree Bourra 173961Dennis ZhouÎncă nu există evaluări

- Sweet Stellar ChristmasDocument1 paginăSweet Stellar ChristmasEstela Blanco RomanÎncă nu există evaluări

- Riff Piano-Típico Jam PDFDocument1 paginăRiff Piano-Típico Jam PDFDaren AmazoÎncă nu există evaluări

- CRL Clear View Glass Wall Office SystemDocument8 paginiCRL Clear View Glass Wall Office SystemSarinÎncă nu există evaluări

- ZSWatch KicadDocument1 paginăZSWatch KicadDanut StanciuÎncă nu există evaluări

- Set-Back Area Handed Over To M.C.G.M.: M/S B.H. Wadhwa & CoDocument1 paginăSet-Back Area Handed Over To M.C.G.M.: M/S B.H. Wadhwa & CoSiddhesh JamsandekarÎncă nu există evaluări

- 4560 Chess Endgames (1999) - PUZZLES To SOLVE - Laszlo PolgarDocument760 pagini4560 Chess Endgames (1999) - PUZZLES To SOLVE - Laszlo PolgarRafael Molina Salazar100% (3)

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 paginăGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResÎncă nu există evaluări

- Smoke On The Water PDFDocument2 paginiSmoke On The Water PDFsafaxabilÎncă nu există evaluări

- Oil&Gas Sector AnalysisDocument7 paginiOil&Gas Sector AnalysisAMEY PATALEÎncă nu există evaluări

- Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow DiagramDocument1 paginăAlim Knit (BD) LTD.: Recommended Process & Hydraulic Flow DiagramKamrul HasanÎncă nu există evaluări

- Jesus de La Villa - 101 Endgames You Must Know - PUZZLES TO SOLVE PDFDocument60 paginiJesus de La Villa - 101 Endgames You Must Know - PUZZLES TO SOLVE PDFCarlos Alejandro Chavez100% (3)

- Don't You Worry 'Bout A Thing: ClarinetDocument2 paginiDon't You Worry 'Bout A Thing: ClarinetCre ArqÎncă nu există evaluări

- Bach JS - Aria From Suite en D - Piano Flute Score DM2Document4 paginiBach JS - Aria From Suite en D - Piano Flute Score DM2pierre hamonÎncă nu există evaluări

- Shubert MoldeDocument1 paginăShubert MoldeEdwin FloresÎncă nu există evaluări

- Huaynos Guti Sax TDocument2 paginiHuaynos Guti Sax TCarlos Alberto Jamanca PalmaÎncă nu există evaluări

- Tita TrombonDocument1 paginăTita TrombonJorge HernandezÎncă nu există evaluări

- 5.70 Jr. Jose Carlos Mariategui: Pp. Jj. Tupac AmaruDocument1 pagină5.70 Jr. Jose Carlos Mariategui: Pp. Jj. Tupac AmaruRai Meza IllanesÎncă nu există evaluări

- A1 A2 A3 A4: Vicinity MapDocument1 paginăA1 A2 A3 A4: Vicinity MapDan Czar T. JuanÎncă nu există evaluări

- Banaha PianoDocument2 paginiBanaha PianoMontse GCÎncă nu există evaluări

- Marciata Dordinanza Per Tutte Le Musiche Del Granducato Di Toscana Egisto MosellDocument2 paginiMarciata Dordinanza Per Tutte Le Musiche Del Granducato Di Toscana Egisto Mosellchesstimeitis6969Încă nu există evaluări

- The Chrysanthemum: Clarinet in B 2Document2 paginiThe Chrysanthemum: Clarinet in B 2Vanesa Huerta PoloÎncă nu există evaluări

- CRL Cascade Glass Wall Office SystemDocument7 paginiCRL Cascade Glass Wall Office SystemSarinÎncă nu există evaluări

- Documentation PHENIX LIBERTY Anglais V05.00Document2 paginiDocumentation PHENIX LIBERTY Anglais V05.00klemionka2Încă nu există evaluări

- Detail B: General NotesDocument8 paginiDetail B: General NotesDaniel Francisco Castro AcevedoÎncă nu există evaluări

- BWV 1068Document2 paginiBWV 1068Jakub OlszewskiÎncă nu există evaluări

- Evans - Chess Endgame Quiz - 200 Chess Endgame Puzzles To Warm Up Your Mind TO SOLVE - BWC PDFDocument34 paginiEvans - Chess Endgame Quiz - 200 Chess Endgame Puzzles To Warm Up Your Mind TO SOLVE - BWC PDFpablomatusÎncă nu există evaluări

- The Mineral Content of US Drinking and Municipal Water: Pamela Pehrsson, Kristine Patterson, and Charles PerryDocument1 paginăThe Mineral Content of US Drinking and Municipal Water: Pamela Pehrsson, Kristine Patterson, and Charles Perrysherio amrousyÎncă nu există evaluări

- VivaceDocument1 paginăVivaceSucrose BoyÎncă nu există evaluări

- (Free Scores - Com) Purcell Henry Trumpet Tune Cebell Sebell Landscape Format 2573 154927Document2 pagini(Free Scores - Com) Purcell Henry Trumpet Tune Cebell Sebell Landscape Format 2573 154927LinusÎncă nu există evaluări

- 18 Oberena2 PDFDocument13 pagini18 Oberena2 PDFJose Carlos Hernandez AlarconÎncă nu există evaluări

- Wide Putin Song (Piano) (Song For Denise (Maxi Version) )Document4 paginiWide Putin Song (Piano) (Song For Denise (Maxi Version) )Pablo NievaÎncă nu există evaluări

- Lighting Layout Lighting Layout: General Notes and SpecificationsDocument1 paginăLighting Layout Lighting Layout: General Notes and SpecificationsRobin PacultadÎncă nu există evaluări

- CPS - 235imh A-102 R19 190118Document1 paginăCPS - 235imh A-102 R19 190118Abu Muhammad Al-AnsariÎncă nu există evaluări

- Music For Ballet Class Traditional To Contemporary-Vol1 PDFDocument12 paginiMusic For Ballet Class Traditional To Contemporary-Vol1 PDFGisela Gregori100% (1)

- Ejemplo Elevación Diseño GeométricoDocument1 paginăEjemplo Elevación Diseño GeométricoLeonidas Alfredo Quispe HuamaniÎncă nu există evaluări

- Minuet in D: Cello and PianoDocument2 paginiMinuet in D: Cello and PianoLucas FreitasÎncă nu există evaluări

- Lundú Amazonense: Arnaldo RebelloDocument2 paginiLundú Amazonense: Arnaldo RebelloHeder Marchetti PereiraÎncă nu există evaluări

- Reference Architecture ABB Ability Platform V1.3 - CompleteDocument5 paginiReference Architecture ABB Ability Platform V1.3 - CompleteCarlos BotelloÎncă nu există evaluări

- Risk Factors of Urinary Tract Infection After Ureteral Stenting For Patients With Renal Colic During PregnancyDocument25 paginiRisk Factors of Urinary Tract Infection After Ureteral Stenting For Patients With Renal Colic During PregnancyJosaphat NuñezÎncă nu există evaluări

- 232 Chess Mating Patterns You Should Memorize - For TEACHERSDocument39 pagini232 Chess Mating Patterns You Should Memorize - For TEACHERSSalem ELsayed Abdel Aziz100% (1)

- Instant Assessments for Data Tracking, Grade 5: MathDe la EverandInstant Assessments for Data Tracking, Grade 5: MathÎncă nu există evaluări

- Stable Pure-Iodide Wide-Band-Gap Perovskites For Efficient Si Tandem Cells Via Kinetically Controlled Phase EvolutionDocument17 paginiStable Pure-Iodide Wide-Band-Gap Perovskites For Efficient Si Tandem Cells Via Kinetically Controlled Phase EvolutionPeter GuoÎncă nu există evaluări

- TAMU - Pemex Offshore DrillingDocument42 paginiTAMU - Pemex Offshore Drillingdriller22100% (1)

- Lectures 2-3: Energy Levels of The Hydrogen Atom So FarDocument13 paginiLectures 2-3: Energy Levels of The Hydrogen Atom So FardwyphyÎncă nu există evaluări

- Particle Size Effect On The Hydrophobicity and The Natural Floatability of MolybdeniteDocument105 paginiParticle Size Effect On The Hydrophobicity and The Natural Floatability of MolybdeniteAgustín F. Correa100% (1)

- Chapter 5 - Chemical BondingDocument6 paginiChapter 5 - Chemical BondingSudhan NairÎncă nu există evaluări

- Physical States of Matter: Long Answers QuestionsDocument7 paginiPhysical States of Matter: Long Answers QuestionsMussadiq RehmanÎncă nu există evaluări

- Chem 64 Problem Set 2: Molecular Symmetry and Group Theory: N H N N NH H H CL CL BR CL G) orDocument3 paginiChem 64 Problem Set 2: Molecular Symmetry and Group Theory: N H N N NH H H CL CL BR CL G) orIpungÎncă nu există evaluări

- Engro's Experience With Implementation of A S-300 Converter During A Normal T/ADocument10 paginiEngro's Experience With Implementation of A S-300 Converter During A Normal T/Avaratharajan g rÎncă nu există evaluări

- Fator de Watson KW Ie50312a018Document5 paginiFator de Watson KW Ie50312a018Luiz Roberto TerronÎncă nu există evaluări

- Exp 22 PDFDocument12 paginiExp 22 PDFCherieCheungÎncă nu există evaluări

- 2-Ethylhexyl Acrylate: Technical Information PetrochemicalsDocument2 pagini2-Ethylhexyl Acrylate: Technical Information PetrochemicalsnurparinÎncă nu există evaluări

- HysysDocument36 paginiHysysRamiro ArcentalesÎncă nu există evaluări

- CHM 111 PDFDocument136 paginiCHM 111 PDFSreenivasuluÎncă nu există evaluări

- CEB2072 Chemical Engineering Lab 2: Experiment Group Group MembersDocument36 paginiCEB2072 Chemical Engineering Lab 2: Experiment Group Group MembersGrace ChowÎncă nu există evaluări

- Synthesis of Acetylsalicylic Acid (Aspirin)Document7 paginiSynthesis of Acetylsalicylic Acid (Aspirin)Nor Ashikin IsmailÎncă nu există evaluări

- 05.2 Activation Energy and Enthalpy ChangeDocument17 pagini05.2 Activation Energy and Enthalpy ChangeanthorÎncă nu există evaluări

- Cooling Load UERM CANTEENDocument52 paginiCooling Load UERM CANTEENHenry San PedroÎncă nu există evaluări

- Hot Cracking Investigation During Laser Welding of High Strength Steels With Multi Scale Modelling ApproachDocument9 paginiHot Cracking Investigation During Laser Welding of High Strength Steels With Multi Scale Modelling Approacharjun prajapatiÎncă nu există evaluări

- Book 1A-1CDocument13 paginiBook 1A-1CWONG EVELYNE JADEÎncă nu există evaluări

- CC19 Group 1 Lab Report 4Document11 paginiCC19 Group 1 Lab Report 4PHƯỚC DƯƠNG THANHÎncă nu există evaluări

- Expt 1 Chem 1 .Document45 paginiExpt 1 Chem 1 .Farhatul Abrar AnandaÎncă nu există evaluări

- Lecture 4: Chemistry of Silicate Melts and Minerals: Chemical Thermodynamics, Melting, MineralogyDocument50 paginiLecture 4: Chemistry of Silicate Melts and Minerals: Chemical Thermodynamics, Melting, MineralogySunny OoiÎncă nu există evaluări

- Patent Application Publication (10) Pub. No.: US 2006/0260356A1Document4 paginiPatent Application Publication (10) Pub. No.: US 2006/0260356A1reynerÎncă nu există evaluări

- Phisical Propertis Palm and Cooking OilDocument10 paginiPhisical Propertis Palm and Cooking OilArifin HidayatÎncă nu există evaluări

- Chapter Eight Semiconductor Crystals: ElementsDocument50 paginiChapter Eight Semiconductor Crystals: ElementsKhanh Nguyen HuuÎncă nu există evaluări

- Comparison of Crystal Structures Among CAAC-InGaZnO, nc-InGaZnO, and Solution-Processed InGaZnODocument4 paginiComparison of Crystal Structures Among CAAC-InGaZnO, nc-InGaZnO, and Solution-Processed InGaZnORabbi HasnatÎncă nu există evaluări

- Exploring Enthalpy Entropy and Free EnergyDocument8 paginiExploring Enthalpy Entropy and Free Energynoobiekids2016Încă nu există evaluări

- Skew T Adiabatic Diagram: Temperature in Degrees CelsiusDocument1 paginăSkew T Adiabatic Diagram: Temperature in Degrees CelsiusMihai Mirel RusuÎncă nu există evaluări

- The Properties of MaterialsDocument705 paginiThe Properties of Materialsvu0007Încă nu există evaluări