Documente Academic

Documente Profesional

Documente Cultură

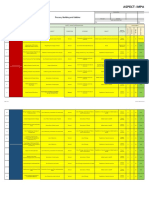

Causation Analysis Model

Încărcat de

Ella AgbettorDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Causation Analysis Model

Încărcat de

Ella AgbettorDrepturi de autor:

Formate disponibile

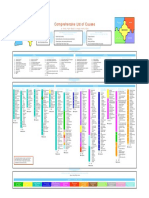

People Parts

Comprehensive List of Causes

A TOOL FOR ROOT CAUSE ANALYSIS Solutions

DESCRIPTION OF IMPLEMENTATION & RESEARCH PHASES: ANALYSIS PHASE:

INCIDENT EVIDENCE GATHERING IDENTIFICATION OF CRITICAL FACTORS

Document the type / severity of Gather relevant evidence Organise all evidence

event Positions Paper

Implementation phase = direct evidence (scene and witnesses) Map evidence

Cover the who / what / when / Research phase = indirect evidence (written sources) Identify critical factors

where / how as known at the time

Consider People / Parts / Position / Paper Use CLC to identify all immediate and root causes

POSSIBLE IMMEDIATE CAUSES

ACTIONS CONDITIONS

1. Following Procedures 2. Use of Tools or Equipment 3. Use of Protective Methods 4. Inattention / Lack of Awareness 5. Protective Systems 6. Tools, Equipment & Vehicles 7. Work Exposures to 8. Work Place Environment / Layout

1-1 Violation by individual 2-1 Improper use of equipment 3-1 Lack of knowledge of hazards present 4-1 Improper decision making or lack of judgment 5-1 Inadequate guards or protective devices 6-1 Defective equipment 7-1 Fire or explosion 8-1 Congestion or restricted motion

1-2 Violation by group 2-2 Improper use of tools 3-2 Personal protective equipment not used 4-2 Distracted by other concerns 5-2 Defective guards or protective devices 6-2 Inadequate equipment 7-2 Noise 8-2 Inadequate or excessive illumination

1-3 Violation by supervisor 2-3 Use of defective equipment (aware) 3-3 Improper use of proper personal protective 4-3 Inattention to footing and surroundings 5-3 Inadequate personal protective equipment 6-3 Improperly prepared equipment 7-3 Energized electrical systems 8-3 Inadequate ventilation

1-4 Operation of equipment without authority 2-4 Use of defective tools (aware) equipment 4-4 Horseplay 5-4 Defective personal protective equipment 6-4 Defective tools 7-4 Energized systems, other than electrical 8-4 Unprotected height

1-5 Improper position or posture for the task 2-5 Improper placement of tools, equipment or 3-4 Servicing of energized equipment 4-5 Acts of violence 5-5 Inadequate warning systems 6-5 Inadequate tools 7-5 Radiation 8-5 Inadequate work place layout

1-6 Overexertion of physical capability materials 3-5 Equipment or materials not secured 4-6 Failure to warn 5-6 Defective warning systems 6-6 Improperly prepared tools 7-6 Temperature extremes controls less than adequate

1-7 Work or motion at improper speed 2-6 Operation of equipment at improper speed 3-6 Disabled guards, warning systems or safety devices 4-7 Use of drugs or alcohol 5-7 Inadequate isolation of process or equipment 6-7 Defective vehicle 7-7 Hazardous chemicals displays less than adequate

1-8 Improper lifting 2-7 Servicing of equipment in operation 3-7 Removal of guards, warning systems or safety 4-8 Routine activity without thought 5-8 Inadequate safety devices 6-8 Inadequate vehicle for the purpose 7-8 Mechanical hazards labels less than adequate

1-9 Improper loading 2-8 Other devices 4-9 Other 5-9 Defective safety devices 6-9 Improperly prepared vehicle 7-9 Clutter or debris locations out of reach or sight

1-10 Shortcuts 3-8 Personal protective equipment not available 5-10 Other 6-10 Other 7-10 Storms or acts of nature conflicting information is presented

1-11 Other 3-9 Other 7-11 Slippery floors or walkways 8-6 Other

7-12 Other

POSSIBLE SYSTEM CAUSES

PERSONAL FACTORS JOB FACTORS

1. Physical Capability 2. Physical 3. Mental State 4. Mental Stress 5. Behavior 6. Skill Level 7. Training / Knowledge 8. Management / 9. Contractor Selection 10. Engineering / 11. Work Planning 12. Purchasing, Material 13. Tools & Equipment 14. Work Rules / Policies / 15. Communication

1-1 Vision deficiency Condition 3-1 Poor judgment 4-1 Preoccupation with 5-1 Improper performance is 6-1 Inadequate Transfer Supervision / Employee & Oversight Design 11-1 Inadequate work planning Handling & Material 13-1 Inadequate assessment Standards / Procedures (PSP) 15-1 Inadequate horizontal

1-2 Hearing deficiency 2-1 Previous injury or 3-2 Memory failure problems rewarded assessment of 7-1Inadequate knowledge Leadership 9-1 Lack of contractor pre- 10-1 Inadequate technical 11-2 Inadequate preventive Control of needs and risks 14-1 Lack of PSP for the task communication between

1-3 Other sensory illness 3-3 Poor coordination or 4-2 Frustration saves time or effort required skills transfer 8-1 Conflicting roles / qualifications design maintenance 12-1 Incorrect item received 13-2 Inadequate human lack of defined responsibility for peers

deficiency 2-2 Fatigue reaction time 4-3 Confusing directions avoids discomfort 6-2 Inadequate practice inability to responsibilities 9-2 Inadequate contractor design input assessment of needs inadequate factors / ergonomics PSP 15-2 Inadequate vertical

1-4 Reduced respiratory due to workload 3-4 Emotional / demands gains attention of skill comprehend unclear reporting pre-qualifications obsolete lubrication / specifications to considerations lack of job safety analysis communication between

capacity due to lack of disturbance 4-4 Conflicting directions 5-2 Improper supervisory 6-3 Infrequent inadequate instructor relationships 9-3 Inadequate contractor design input not servicing vendor 13-3 Inadequate standards or inadequate job safety analysis supervisor and person

1-5 Other permanent rest 3-5 Fears or phobias / demands example performance of skill qualifications conflicting reporting selection correct adjustment / inadequate specifications 14-2 Inadequate development of PSP 15-3 Inadequate

physical disabilities due to sensory 3-6 Low mechanical 4-5 Meaningless or 5-3 Inadequate identification 6-4 Lack of coaching on inadequate training relationship 9-4 Use of non-approved design input not assembly specifications on 13-4 Inadequate availability inadequate coordination with communication between

1-6 Temporary disabilities overload aptitude degrading activities of critical safe behaviors skill equipment unclear assignment of contractor available cleaning / requisition 13-5 Inadequate adjustment / process / equipment design different organizations

1-7 Inability to sustain 2-3 Diminished 3-7 Low learning 4-6 Emotional overload 5-4 Inadequate 6-5 Insufficient review of misunderstood responsibility 9-5 Lack of job oversight design output resurfacing inadequate control on repair / inadequate employee 15-4 Inadequate

body positions performance aptitude 4-7 Extreme judgment / reinforcement of critical instruction to instructions conflicting assignment of 9-6 Inadequate oversight inadequate 11-3 Inadequate repair changes to orders maintenance involvement in the development communication between

1-8 Restricted range of due to 3-8 Influenced by decision demands safe behaviors establish skill 7-2Inadequate recall of responsibility design input communication of unauthorized 13-6 Inadequate salvage and inadequate definition of work groups

9-7 Other

body movement temperature medication 4-8 Extreme proper performance training material improper or insufficient infeasible needed repair substitution reclamation corrective actions 15-5 Inadequate

6-6 Other o Not Applicable

1-9 Substance sensitivities extremes concentration / is criticized training not reinforced delegation of authority design output scheduling of work inadequate product 13-7 Inadequate removal / inadequate format for easy use communication between

3-9 Other o Not Applicable

or allergies due to oxygen perception demands inappropriate peer on the job 8-2 Inadequate leadership unclear examination of parts acceptance replacement of 14-3 Inadequate implementation of shifts

1-10 Inadequate size or deficiency o Not Applicable 4-9 Extreme boredom pressure inadequate refresher standards of design output not parts substitution requirements unsuitable items PSP, due to deficiencies 15-6 Inadequate

strength due to inadequate training frequency performance missing or correct 11-4 Excessive wear and tear no acceptance 13-8 No equipment record contradictory requirements communication methods

4-10 Other

1-11 Diminished capacity atmospheric performance 7-3 Inadequate training effort not enforced design output inadequate planning verification performed history confusing format 15-7 No communication

due to medication pressure o Not Applicable feedback inadequate training inadequate inconsistent for use 12-2 Inadequate research on 13-9 Inadequate equipment more than one action per step method available

variation inadequate program design accountability no independent extension of service materials / record history no check-off spaces provided 15-8 Incorrect instructions

1-12 Other

2-4 Blood sugar disciplinary process inadequate training inadequate or incorrect design review life equipment 13-10 Other inaccurate sequence of steps 15-9 Inadequate

o Not Applicable insufficiency 5-5 Inappropriate aggression goals / objectives performance feedback 10-2 Inadequate standards, improper loading 12-3 Inadequate mode or confusing instructions communication due to

2-5 Impairment due to 5-6 Improper use of inadequate new inadequate work site specifications, and / or use by untrained route of shipment o Not Applicable technical error / missing steps job turnover

drug or alcohol use production incentives employee orientation walk-through design criteria people 12-4 Improper handling of excessive references 15-10 Inadequate

5-7 Supervisor implied haste inadequate initial inadequate safety 10-3 Inadequate use for wrong materials potential situations not covered communication of safety

2-6 Other

5-8 Employee perceived training promotion assessment of purpose 12-5 Improper storage of 14-4 Inadequate enforcement of PSP and health data,

o Not Applicable haste inadequate means to 8-3 Inadequate correction of potential failure 11-5 Inadequate reference materials or spare parts inadequate monitoring of work regulations or

5-9 Other determine if qualified prior hazard / incident 10-4 Inadequate ergonomic materials or publications 12-6 Inadequate material inadequate supervisory guidelines

for job 8-4 Inadequate identification of design 11-6 Inadequate audit / packaging knowledge 15-11 Standard terminology

o Not Applicable 7-4 No training provided worksite / job hazards 10-5 Inadequate monitoring inspection / monitoring 12-7 Material shelf life inadequate reinforcement not used

need for training not 8-5 Inadequate management of of construction no documentation exceeded non-compliance not corrected 15-12 Verification /

identified change system 10-6 Inadequate no correction 12-8 Improper identification of 14-5 Inadequate communication of PSP repeat back techniques

training records 8-6 Inadequate incident assessment of responsibility hazardous materials incomplete distribution to work not used

incorrect or out of date reporting / investigation operational readiness assigned 12-9 Improper salvage groups 15-13 Messages too long

new work methods system 10-7 Inadequate monitoring no accountability for and / or waste disposal inadequate translation to 15-14 Speech interference

introduced without 8-7 Inadequate or lack of safety of initial operation corrective action 12-10 Inadequate use of safety appropriate languages

15-15 Other

training meetings 10-8 Inadequate evaluation 11-7 Inadequate job placement and health data incomplete integration with

decision made not to 8-8 Inadequate performance and / or documentation appropriate personnel training o Not Applicable\

12-11 Other

train measurement & of change not identified out of date revisions still in use

assessment appropriate personnel o Not Applicable 14-6 Other

7-5 Other 10-9 Other

8-9 Other not available o Not Applicable

For each identified critical factor, consider if any of the listed root o Not Applicable o Not Applicable appropriate personnel

cause categories apply. If 'yes,' circle the specific root cause. o Not Applicable not provided

If none of the root causes in the category apply, then check the 'not

applicable' box at the bottom of the column. 11-8 Other

o Not Applicable

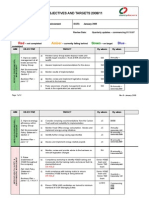

CORRECTIVE PHASE: PROPOSALS FOR CORRECTIVE ACTION

Align with Getting HSE Right elements

ELEMENTS OF GETTING HSE RIGHT

Leadership and Accountability Risk Assessment and People, Training and Working with Facilities Design and Operations and Maintenance Management of Information and Customers and Community and Stakeholder Crisis and Emergency Incidents Analysis and Assessment, Assurance

Management Behaviours Contractors and Others Construction Change Documentation Products Awareness Management Prevention and Improvement

Form 3862 Rev 1 Feb 99

S-ar putea să vă placă și

- HSE Committee Meeting Rev1Document25 paginiHSE Committee Meeting Rev1Khaled Ismail100% (1)

- CSP2017-Safety Audit PlanDocument14 paginiCSP2017-Safety Audit PlanGaryÎncă nu există evaluări

- CLC - Poster Causas ACR PDFDocument1 paginăCLC - Poster Causas ACR PDFMiguel Romero75% (4)

- Aspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesDocument4 paginiAspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesSir ZenÎncă nu există evaluări

- Ppe Matrix Hsm-frm520Document1 paginăPpe Matrix Hsm-frm520VictorÎncă nu există evaluări

- Technical Safety EngineeringDocument85 paginiTechnical Safety EngineeringElla Agbettor100% (3)

- Behavior Based Safety ChecklistDocument5 paginiBehavior Based Safety Checklistvictor100% (1)

- Comprehensive List of CausesDocument1 paginăComprehensive List of CausesTuan VuÎncă nu există evaluări

- Health and Safety Objectives 2009Document4 paginiHealth and Safety Objectives 2009mujahid1137100% (1)

- Safety Training Needs Assessment FormDocument7 paginiSafety Training Needs Assessment FormArnab NagÎncă nu există evaluări

- Occupational Hazard Identification and Risk Assessment Rating SheetDocument4 paginiOccupational Hazard Identification and Risk Assessment Rating SheetSir ZenÎncă nu există evaluări

- Vanish Magic Magazine VANISH MAGIC MAGAZINE 58 May 2019Document118 paginiVanish Magic Magazine VANISH MAGIC MAGAZINE 58 May 2019mick byrnes100% (1)

- Updated Technical SafetyDocument122 paginiUpdated Technical SafetyElla Agbettor100% (2)

- Updated Technical SafetyDocument122 paginiUpdated Technical SafetyElla Agbettor100% (2)

- Checklist Walk Down InspectionDocument1 paginăChecklist Walk Down InspectionaspambudiÎncă nu există evaluări

- Oil & Gas UK Guidelines On Risk Related Decision Making - Issue 2 July 2014Document25 paginiOil & Gas UK Guidelines On Risk Related Decision Making - Issue 2 July 2014Ella Agbettor100% (2)

- Procedure For Permit To WorkDocument16 paginiProcedure For Permit To WorkVictor Thembinkosi Makhubele100% (1)

- Incident Investigation - Five WhyDocument1 paginăIncident Investigation - Five WhytanoycometÎncă nu există evaluări

- Incident Investigation: AMEC Earth & Environmental Monthly Safety Training Program March 2009Document42 paginiIncident Investigation: AMEC Earth & Environmental Monthly Safety Training Program March 2009Nikkolai Kirril Gementiza UguisÎncă nu există evaluări

- IMS Audit Nov 2012 Observation SheetDocument4 paginiIMS Audit Nov 2012 Observation SheetNilesh NigadeÎncă nu există evaluări

- Environmental Aspect Identification and Impact AnalysisDocument3 paginiEnvironmental Aspect Identification and Impact AnalysisAnonymous r3SWKnHbw100% (1)

- Comprehensive List of Causes PDFDocument1 paginăComprehensive List of Causes PDFReda MashalÎncă nu există evaluări

- Behavioral Based Safety Observation Checklist: ErgonomicsDocument2 paginiBehavioral Based Safety Observation Checklist: ErgonomicsRyan CyrillaÎncă nu există evaluări

- Plant Safety ChecklistDocument19 paginiPlant Safety ChecklistAbhishek PalÎncă nu există evaluări

- Fpso Asset Integrity Part 2Document17 paginiFpso Asset Integrity Part 2Ella AgbettorÎncă nu există evaluări

- ROOT CAUSE Analysis Model PDFDocument1 paginăROOT CAUSE Analysis Model PDFRoy Situmorang100% (1)

- List of Documents ISO 45001 Transition Toolkit EN PDFDocument3 paginiList of Documents ISO 45001 Transition Toolkit EN PDFAquino SianiparÎncă nu există evaluări

- Brief HSE Procedures ContentsDocument2 paginiBrief HSE Procedures Contentsarifayee-1Încă nu există evaluări

- Safe Lifting ProcedureDocument48 paginiSafe Lifting ProcedureAlex Sandro Borges Pereira100% (1)

- SEL HSE P 003 Change Management Guideline Rev03Document6 paginiSEL HSE P 003 Change Management Guideline Rev03tyoÎncă nu există evaluări

- Action TrackingDocument9 paginiAction TrackingElla AgbettorÎncă nu există evaluări

- Root Cause Analysis ToolDocument1 paginăRoot Cause Analysis ToolZakiSaa0% (1)

- HSE - Operation Controls ABE-HSE-OP-01Document6 paginiHSE - Operation Controls ABE-HSE-OP-01Faisal RazaÎncă nu există evaluări

- Cause AnalysisDocument1 paginăCause Analysisfathul syaafÎncă nu există evaluări

- CLC Poster AWDocument1 paginăCLC Poster AWmharja100% (2)

- Work at Height Permit Form-2020Document2 paginiWork at Height Permit Form-2020Ebrahsm Elshenawy100% (1)

- Hse Assessment ReportDocument143 paginiHse Assessment ReportSerkan Dölen0% (1)

- Flow Zone Indicator Guided Workflows For PetrelDocument11 paginiFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- Jurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Document3 paginiJurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Anonymous kWfNFb100% (1)

- E PAKATSDocument1 paginăE PAKATSAlvee AlzhariffÎncă nu există evaluări

- AI-PS Element Guide No 13Document10 paginiAI-PS Element Guide No 13rwerwerwÎncă nu există evaluări

- HSE Training HistoryDocument4 paginiHSE Training HistoryAnonymous 1wDPsonÎncă nu există evaluări

- 14 RCAT - Root Cause Analysis TechniquesDocument3 pagini14 RCAT - Root Cause Analysis TechniquesDanny Durham100% (1)

- BBTTCC Safety Observation CardDocument1 paginăBBTTCC Safety Observation CardKaavi MaharajÎncă nu există evaluări

- Daily HSSE Report TemplateDocument2 paginiDaily HSSE Report TemplateBadr JLASSI100% (1)

- SAF 016 PRO Personal+Protective+EquipmentDocument40 paginiSAF 016 PRO Personal+Protective+EquipmentAnton SusiloÎncă nu există evaluări

- Comprehensive List of Causes: A Tool For Root Cause AnalysisDocument2 paginiComprehensive List of Causes: A Tool For Root Cause Analysissheerazali100% (2)

- Lockout/Tagout (Loto) Checklist: 1. Scope of WorkDocument3 paginiLockout/Tagout (Loto) Checklist: 1. Scope of WorkPutri UnaÎncă nu există evaluări

- QEHS ManualDocument100 paginiQEHS ManualRob WillestoneÎncă nu există evaluări

- General Industrial Safety Inspection Checklist Document No: Date Modified: Revision: 0Document9 paginiGeneral Industrial Safety Inspection Checklist Document No: Date Modified: Revision: 0ابو محمدÎncă nu există evaluări

- Notes Transfer of Thermal EnergyDocument12 paginiNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessDocument2 pagini"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillÎncă nu există evaluări

- Management of ChangeDocument85 paginiManagement of ChangeHerik renaldoÎncă nu există evaluări

- Pss Maersk GR FpsoDocument7 paginiPss Maersk GR FpsoElla AgbettorÎncă nu există evaluări

- Pss Maersk GR FpsoDocument7 paginiPss Maersk GR FpsoElla AgbettorÎncă nu există evaluări

- Fpso Asset IntegrityDocument18 paginiFpso Asset IntegrityElla Agbettor0% (1)

- Inherently SafeDocument24 paginiInherently SafeElla AgbettorÎncă nu există evaluări

- Comprehensive List of Causes: A Tool For Root Cause AnalysisDocument1 paginăComprehensive List of Causes: A Tool For Root Cause AnalysisChandru75% (4)

- RCA ChartDocument1 paginăRCA ChartShezi BhattiÎncă nu există evaluări

- ABS MOC Guidance NotesDocument60 paginiABS MOC Guidance NotesElla AgbettorÎncă nu există evaluări

- ROG-HSE-PRO-003, Rev 00 - Waste Management ProcedureDocument15 paginiROG-HSE-PRO-003, Rev 00 - Waste Management ProcedurevladÎncă nu există evaluări

- Iodide and Bromide Ions in Brackish Water, Seawater, and Brines D 3869 - 04Document12 paginiIodide and Bromide Ions in Brackish Water, Seawater, and Brines D 3869 - 04stevgonÎncă nu există evaluări

- ISO 14001 Aspect - Impact AnalysisDocument13 paginiISO 14001 Aspect - Impact Analysiskalan1983100% (1)

- List of Record - HseDocument2 paginiList of Record - HseMohd FadlyÎncă nu există evaluări

- New Incident Reporting MatrixDocument2 paginiNew Incident Reporting MatrixRohan Shelar100% (2)

- Permit To DigDocument3 paginiPermit To DigMarco DonatiÎncă nu există evaluări

- Pre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuDocument18 paginiPre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuRifky Haikal RamadhanÎncă nu există evaluări

- Hse Communication OgunleyeDocument16 paginiHse Communication OgunleyeOlusola OgunleyeÎncă nu există evaluări

- Aspects & Impacts - ISO: Lins Switch Boards Pvt. LTD BangaloreDocument9 paginiAspects & Impacts - ISO: Lins Switch Boards Pvt. LTD BangaloreVirendra SahdevÎncă nu există evaluări

- PP-HSE-FORM-005 PTW-Confined SpaceDocument2 paginiPP-HSE-FORM-005 PTW-Confined SpaceDimas Dwi SwarnaÎncă nu există evaluări

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument4 paginiSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartponggoooÎncă nu există evaluări

- OHS Baseline Risk Assessment - Catering Contract October 2021Document18 paginiOHS Baseline Risk Assessment - Catering Contract October 2021denoiÎncă nu există evaluări

- NCR Form ExampleDocument1 paginăNCR Form ExampleFrank BarnesÎncă nu există evaluări

- Training Matrix Site ABDocument1 paginăTraining Matrix Site ABDewa SyafirÎncă nu există evaluări

- Safe System Of Work A Complete Guide - 2020 EditionDe la EverandSafe System Of Work A Complete Guide - 2020 EditionÎncă nu există evaluări

- 1 - The Nature of Project ManagementDocument12 pagini1 - The Nature of Project ManagementElla AgbettorÎncă nu există evaluări

- Welcome To Sheq FoundationDocument8 paginiWelcome To Sheq FoundationElla AgbettorÎncă nu există evaluări

- PSS Total ElginDocument7 paginiPSS Total ElginElla AgbettorÎncă nu există evaluări

- PDF KatalogDocument48 paginiPDF KatalogElla AgbettorÎncă nu există evaluări

- Pss Cidade SaoDocument25 paginiPss Cidade SaoElla AgbettorÎncă nu există evaluări

- Process Safety Series 1 - BP Texas City: Sharing The ExperienceDocument7 paginiProcess Safety Series 1 - BP Texas City: Sharing The ExperienceElla AgbettorÎncă nu există evaluări

- 6minpilates RevDocument11 pagini6minpilates RevElla AgbettorÎncă nu există evaluări

- Definition of On-Site and Off-Site Explosion LoadingDocument28 paginiDefinition of On-Site and Off-Site Explosion LoadingElla AgbettorÎncă nu există evaluări

- FPSO Forum 2010 - Duggal (Final To GLND)Document18 paginiFPSO Forum 2010 - Duggal (Final To GLND)Ella AgbettorÎncă nu există evaluări

- Layout Issues and MitigationDocument23 paginiLayout Issues and MitigationElla AgbettorÎncă nu există evaluări

- QRA Model Is Made Up of These WorkbooksDocument33 paginiQRA Model Is Made Up of These WorkbooksElla AgbettorÎncă nu există evaluări

- Safety GuidelineDocument17 paginiSafety GuidelineQhsef Karmaveer Jyoteendra VaishnavÎncă nu există evaluări

- Topic Five: Risk Assessment & ManagementDocument54 paginiTopic Five: Risk Assessment & ManagementElla AgbettorÎncă nu există evaluări

- Alert 48Document2 paginiAlert 48Ella AgbettorÎncă nu există evaluări

- Azure Machine Learning StudioDocument17 paginiAzure Machine Learning StudioNurain IsmailÎncă nu există evaluări

- Assessment of Diabetic FootDocument7 paginiAssessment of Diabetic FootChathiya Banu KrishenanÎncă nu există evaluări

- Coding Decoding Sheet - 01 1678021709186Document9 paginiCoding Decoding Sheet - 01 1678021709186Sumit VermaÎncă nu există evaluări

- Presentation AcetanilideDocument22 paginiPresentation AcetanilideNovitasarii JufriÎncă nu există evaluări

- Asme b16-25Document22 paginiAsme b16-25JamesÎncă nu există evaluări

- Case AnalysisDocument2 paginiCase AnalysisJessa San PedroÎncă nu există evaluări

- Psle Science Keywords !Document12 paginiPsle Science Keywords !Aftertea CarousellÎncă nu există evaluări

- Karl MarxDocument4 paginiKarl Marxeirvine noah isidroÎncă nu există evaluări

- Bravo MRI II Operation ManualDocument45 paginiBravo MRI II Operation ManualLuis100% (1)

- Recruitment and Selection in Canada 7Th by Catano Wiesner Full ChapterDocument22 paginiRecruitment and Selection in Canada 7Th by Catano Wiesner Full Chaptermary.jauregui841100% (51)

- Line Differential Protection Red670Document8 paginiLine Differential Protection Red670igorsfaceÎncă nu există evaluări

- G-3 L-17 Internal QuestionsDocument4 paginiG-3 L-17 Internal QuestionsActivity MLZS BarhÎncă nu există evaluări

- Investigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseDocument5 paginiInvestigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseEditor IJTSRDÎncă nu există evaluări

- CS402 Mcqs MidTerm by Vu Topper RMDocument50 paginiCS402 Mcqs MidTerm by Vu Topper RMM. KhizarÎncă nu există evaluări

- Surface Finish Measurement NotesDocument32 paginiSurface Finish Measurement NotesAneez ShresthaÎncă nu există evaluări

- Hypothesis Testing - IDocument36 paginiHypothesis Testing - Isai revanthÎncă nu există evaluări

- Document List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Document18 paginiDocument List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Naceri Mohamed RedhaÎncă nu există evaluări

- 1n5711 RF Detector Diode 70v PIV DatasheetDocument3 pagini1n5711 RF Detector Diode 70v PIV DatasheetgordslaterÎncă nu există evaluări

- Influence of Aesthetics Attributes of Brand Web Pages On Customer Brand EngagementDocument22 paginiInfluence of Aesthetics Attributes of Brand Web Pages On Customer Brand EngagementNOOR AKMA AIDAÎncă nu există evaluări

- Welcome To Our 2Nd Topic: History of VolleyballDocument6 paginiWelcome To Our 2Nd Topic: History of VolleyballDharyn KhaiÎncă nu există evaluări

- GSD Puppy Training Essentials PDFDocument2 paginiGSD Puppy Training Essentials PDFseja saulÎncă nu există evaluări

- Hevi-Bar II and Safe-Lec 2Document68 paginiHevi-Bar II and Safe-Lec 2elkabongscribdÎncă nu există evaluări

- 3 Curvilinear MotionDocument50 pagini3 Curvilinear Motiongarhgelh100% (1)

- BITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball TesterDocument10 paginiBITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball Testerakash chÎncă nu există evaluări

- 1F-Korean-Nami Mun - Miles From NowhereDocument4 pagini1F-Korean-Nami Mun - Miles From NowhereNeil PatelÎncă nu există evaluări

- Chapter 7: Protein Function Part I: Myoglobin and HemoglobinDocument27 paginiChapter 7: Protein Function Part I: Myoglobin and HemoglobineliÎncă nu există evaluări