Documente Academic

Documente Profesional

Documente Cultură

11 CH 11

Încărcat de

nikunjpatel12345Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

11 CH 11

Încărcat de

nikunjpatel12345Drepturi de autor:

Formate disponibile

Decision Making and

Relevant Information

Chapter

11

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 1

Learning Objective 1

Use the five-step decision

process to make decisions.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 2

Information and the

Decision Process

A decision model is a formal method

for making a choice, often involving

quantitative and qualitative analysis.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 3

Five-Step Decision Process

Historical Costs

Step 1. Gather Information

Other Information

Step 2. Make Predictions Specific Predictions

Feedback

Step 3. Choose an Alternative

Step 4. Implement the Decision

Step 5. Evaluate Performance

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 4

Learning Objective 2

Differentiate relevant

from irrelevant

costs and revenues in

decision situations.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 5

The Meaning of Relevance

Relevant costs and relevant revenues are

expected future costs and revenues that

differ among alternative courses of action.

Historical costs Sunk costs

Differential income Differential costs

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 6

Learning Objective 3

Distinguish between quantitative

and qualitative factors in decisions.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 7

Quantitative and Qualitative

Relevant Information

Quantitative factors

Financial Nonfinancial

Qualitative factors

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 8

One-Time-Only

Special Order Example

The Bismark Co. manufacturing plant has a

production capacity of 44,000 towels each month.

Current monthly production is 30,000 towels.

Costs can be classified as either variable or fixed

with respect to units of output.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 9

One-Time-Only

Special Order Example

Variable Fixed

Costs Costs

Per Unit Per Unit

Direct materials $6.50 $ -0-

Direct labor .50 1.50

Manufacturing costs 1.50 3.50

Total $8.50 $5.00

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 10

One-Time-Only

Special Order Example

Total fixed direct manufacturing labor is $45,000.

Total fixed overhead is $105,000.

Marketing costs per unit are $7

($5 of which is variable).

What is the full cost per towel?

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 11

One-Time-Only

Special Order Example

Variable ($8.50 + $5.00): $13.50

Fixed: 7.00

Total $20.50

A hotel in San Juan has offered to buy

5,000 towels from Bismark Co. at

$11.50/towel for a total of $57,500.

No marketing costs will be incurred.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 12

One-Time-Only

Special Order Example

What are the relevant costs of making the towels ?

$8.50 × 5,000 = $42,500 incremental costs

What are the incremental revenues ?

$57,500 – $42,500 = $15,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 13

Learning Objective 4

Beware of two potential

problems in

relevant-cost analysis.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 14

Two Potential Problems in

Relevant-Cost Analysis

1 2

Incorrect general Misleading

assumptions: unit-cost data:

All variable costs Include

are relevant. irrelevant costs.

All fixed costs Use same unit

are irrelevant. costs at different

output levels.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 15

Outsourcing versus Insourcing

Outsourcing is Insourcing is

purchasing goods producing goods

and services from or providing services

outside vendors. within the organization.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 16

Make-or-Buy Decisions Example

Bismark Co. also manufactures bath accessories.

Management is considering producing a part it

needs (#2) or buying a part produced

by Towson Co. for $0.55.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 17

Make-or-Buy Decisions Example

Bismark Co. has the following costs

for 150,000 units of Part #2:

Direct materials $ 28,000

Direct labor 18,500

Mixed overhead 29,000

Variable overhead 15,000

Fixed overhead 30,000

Total $120,500

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 18

Make-or-Buy Decisions Example

Mixed overhead consists of material

handling and setup costs.

Bismark Co. produces the 150,000 units

in 100 batches of 1,500 units each.

Total material handling and setup costs

equal fixed costs of $9,000 plus variable

costs of $200 per batch.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 19

Make-or-Buy Decisions Example

What is the cost per unit for Part #2?

$120,500 ÷ 150,000 units = $0.8033/unit

Should Bismark Co. manufacture the part

or buy it from Towson Co.?

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 20

Make-or-Buy Decisions Example

Bismark Co. anticipates that next year the

150,000 units of Part #2 expected to be

sold will be manufactured in 150

batches of 1,000 units each.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 21

Make-or-Buy Decisions Example

Variable costs per batch are expected to

decrease to $100.

Bismark Co. plans to continue to produce

150,000 next year at the same variable

manufacturing costs per unit as this year.

Fixed costs are expected to remain the

same as this year.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 22

Make-or-Buy Decisions Example

What is the variable manufacturing cost per unit?

Direct material $28,000

Direct labor 18,500

Variable overhead 15,000

Total $61,500

$61,500 ÷ 150,000 = $0.41 per unit

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 23

Make-or-Buy Decisions Example

Expected relevant cost to make Part #2:

Manufacturing $61,500

Material handling and setups 15,000*

Total relevant cost to make $76,500

*150 × $100 = $15,000

Cost to buy: (150,000 × $0.55) $82,500

Bismark Co. will save $6,000 by making the part.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 24

Make-or-Buy Decisions Example

Now assume that the $9,000 in fixed clerical

salaries to support material handling and

setup will not be incurred if Part #2 is

purchased from Towson Co..

Should Bismark Co. buy the part or make the part?

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 25

Make-or-Buy Decisions Example

Relevant cost to make:

Variable $76,500

Fixed 9,000

Total $85,500

Cost to buy: $82,500

Bismark would save $3,000 by buying the part.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 26

Learning Objective 5

Explain the opportunity-cost

concept and why it is

used in decision making.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 27

Opportunity Costs,

Outsourcing, and Constraints

Assume that if Bismark buys the part from

Towson, it can use the facilities previously

used to manufacture Part #2 to produce

Part #3 for Krysta Company.

The expected additional future operating

income is $18,000.

What should Bismark Co. do?

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 28

Opportunity Costs,

Outsourcing, and Constraints

Bismark Co. has three options regarding Krysta:

1. Make Part #2 and do not make Part #3.

2. Buy Part #2 and do not make Part #3.

3. Buy the part and use the facilities to produce

Part #3.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 29

Opportunity Costs,

Outsourcing, and Constraints

Expected cost of obtaining 150,000 parts:

Buy Part #2 and do not make Part #3: $82,500

Buy Part #2 and make Part #3:

$82,500 – $18,000 = $64,500

Make Part #2: $76,500

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 30

Opportunity Costs,

Outsourcing, and Constraints

Opportunity cost is the contribution to income

that is forgone (rejected) by not using a

limited resource in its next-best alternative use.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 31

Opportunity Costs,

Outsourcing, and Constraints

Assume that annual estimated Part #2

requirements for next year is 150,000.

Cost per purchase order is $40.

Cost per unit when each purchase is

1,500 units = $0.55.

Cost per unit when each purchase is equal

to or greater than 150,000 = $0.54.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 32

Opportunity Costs,

Outsourcing, and Constraints

Average investment in inventory is either:

(1,500 × .55) ÷ 2 = $412.50 or

(150,000 × $0.54) = $40,500

Annual interest rate for investment in

government bonds is 6%.

$412.50 × .06 = $24.75

$40,500 × .06 = $2,430

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 33

Opportunity Costs,

Outsourcing, and Constraints

Option A: Make 100 purchases of 1,500 units:

Purchase order costs: (100 × $40) $ 4,000.00

Purchase costs: (150,000 × $0.55) $82,500.00

Annual interest income: $ 24.75

Relevant costs: $86,524.75

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 34

Opportunity Costs,

Outsourcing, and Constraints

Option B: Make 1 purchase of 150,000 units:

Purchase order costs: (1 × $40) $ 40

Purchase costs: (150,000 × $0.54) $81,000

Annual interest income: $ 2,430

Relevant costs: $83,470

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 35

Learning Objective 6

Know how to choose which

products to produce when there

are capacity constraints.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 36

Product-Mix Decisions

Under Capacity Constraints

Per unit Product #2 Product #3

Sales price $2.11 $14.50

Variable expenses 0.41 13.90

Contribution margin $1.70 $ 0.60

Contribution margin ratio 81% 4%

Bismark Co. has 3,000 machine-hours available.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 37

Product-Mix Decisions

Under Capacity Constraints

One unit of Prod. #2 requires 7 machine-hours.

One unit of Prod. #3 requires 2 machine-hours.

What is the contribution of each product

per machine-hour?

Product #2: $1.70 ÷ 7 = $0.24

Product #3: $0.60 ÷ 2 = $0.30

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 38

Learning Objective 7

Discuss what managers

must consider when

adding or discontinuing

customers and segments.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 39

Profitability, Activity-Based

Costing, and Relevant Costs

Mountain View Furniture supplies furniture

to two local retailers – Stevens and Cohen.

The company has a monthly capacity

of 3,000 machine-hours.

Fixed costs are allocated on the basis of revenues.

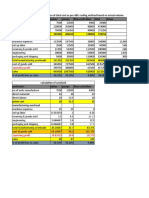

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 40

Profitability, Activity-Based

Costing, and Relevant Costs

Stevens Cohen

Revenues $200,000 $100,000

Variable costs 70,000 60,000

Fixed costs 100,000 50,000

Total operating costs $170,000 $110,000

Operating income $ 30,000 $(10,000)

Machine-hours required 2,000 1,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 41

Profitability, Activity-Based

Costing, and Relevant Costs

Total

Revenues $300,000

Variable costs 130,000

Fixed costs 150,000

Total operating costs $280,000

Operating income $ 20,000

Machine-hours required 3,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 42

Profitability, Activity-Based

Costing, and Relevant Costs

Should Mountain View Furniture drop the Cohen

business, assuming that dropping Cohen would

decrease its total fixed costs by 10%?

New fixed costs would be:

$150,000 – $15,000 = $135,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 43

Profitability, Activity-Based

Costing, and Relevant Costs

Stevens Alone

Revenues $200,000

Variable costs 70,000

Fixed costs 135,000

Total operating costs $205,000

Operating income $ (5,000)

Machine-hours required 3,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 44

Profitability, Activity-Based

Costing, and Relevant Costs

Cohen’s business is providing a

contribution margin of $40,000.

$40,000 decrease in contribution margin

– $15,000 decrease in fixed costs

= $25,000 decrease in operating income.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 45

Profitability, Activity-Based

Costing, and Relevant Costs

Assume that if Mountain View Furniture drops

Cohen’s business it can lease the excess capacity

to the Perez Corporation for $70,000.

Fixed costs would not decrease.

Should Mountain View Furniture lease to Perez?

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 46

Learning Objective 8

Explain why the book value

of equipment is irrelevant in

equipment-replacement decisions.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 47

Equipment-Replacement

Decisions Example

Existing Replacement

Machine Machine

Original cost $80,000 $105,000

Useful life 4 years 4 years

Accumulated depreciation $50,000

Book value $30,000

Disposal price $14,000

Annual costs $46,000 $ 10,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 48

Equipment-Replacement

Decisions Example

Ignoring the time value of money and

income taxes, should the company

replace the existing machine?

The cost savings over a 4-year period will be

$36,000 × 4 = $144,000.

Investment = $105,000 – $14,000 = $91,000

$144,000 – $91,000 = $53,000

advantage of the replacement machine.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 49

Learning Objective 9

Explain how conflicts can arise

between the decision model

used by a manager and the

performance evaluation model

used to evaluate the manager.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 50

Decisions and

Performance Evaluation

What is the journal entry to sell the existing machine?

Cash 14,000

Accumulated Depreciation 50,000

Loss on Disposal 16,000

Machine 80,000

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 51

Decisions and

Performance Evaluation

In the real world would the manager

replace the machine?

An important factor in replacement decisions

is the manager’s perceptions of whether the

decision model is consistent with how the

manager’s performance is judged.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 52

Decisions and

Performance Evaluation

Top management faces a challenge – that is,

making sure that the performance-evaluation

model of subordinate managers is consistent

with the decision model.

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 53

End of Chapter 11

©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 54

S-ar putea să vă placă și

- Introduction To Management Accounting 13/eDocument41 paginiIntroduction To Management Accounting 13/eAnadi SethÎncă nu există evaluări

- Practical Investment Management by Robert.A.Strong Slides ch08Document28 paginiPractical Investment Management by Robert.A.Strong Slides ch08mzqaceÎncă nu există evaluări

- Decision Making and Relevant InformationDocument48 paginiDecision Making and Relevant InformationDwidarÎncă nu există evaluări

- Accounting For Decision Making: Course InstructorDocument32 paginiAccounting For Decision Making: Course InstructorFaizan ShahidÎncă nu există evaluări

- Horngren PricingDocument41 paginiHorngren Pricingpresentasi1Încă nu există evaluări

- 11 CH 04 CAJob Order Costing 4 VDocument29 pagini11 CH 04 CAJob Order Costing 4 Viqbal kurniawanÎncă nu există evaluări

- 11 CH 04Document61 pagini11 CH 04nikunjpatel12345100% (1)

- Job Order CostingDocument22 paginiJob Order CostingMuhammad MansoorÎncă nu există evaluări

- Job Order CostingDocument31 paginiJob Order CostingDian AnjaniÎncă nu există evaluări

- CHAPTER 5 Cost Analysis and Pricing DecisionsDocument47 paginiCHAPTER 5 Cost Analysis and Pricing DecisionsTewodros TafereÎncă nu există evaluări

- Pricing Decisions and Cost ManagementDocument44 paginiPricing Decisions and Cost ManagementsabaÎncă nu există evaluări

- 11ch14 - 2Document40 pagini11ch14 - 2Dinda AfifahÎncă nu există evaluări

- Kalkulasi Biaya Persediaan Dan Analisis KapasitasDocument30 paginiKalkulasi Biaya Persediaan Dan Analisis KapasitasNisa Utami MardiyyaÎncă nu există evaluări

- An Introduction To Cost Terms and PurposesDocument56 paginiAn Introduction To Cost Terms and PurposesAbeer Al-bedaiwyÎncă nu există evaluări

- An Introduction To Cost Terms and PurposesDocument56 paginiAn Introduction To Cost Terms and Purposespatel RoshaniÎncă nu există evaluări

- Flexible Budgets, Variances, and Management Control: II: Cost Accounting 11/eDocument54 paginiFlexible Budgets, Variances, and Management Control: II: Cost Accounting 11/eBetelehem ZenawÎncă nu există evaluări

- Decision Making and Relevant InformationDocument54 paginiDecision Making and Relevant InformationAvinash KumarÎncă nu există evaluări

- Intro To Cost Acctg Chapter 1Document37 paginiIntro To Cost Acctg Chapter 1Djohn DefinitelyÎncă nu există evaluări

- 11ch02 An Introduction To Cost Term and PurposeDocument56 pagini11ch02 An Introduction To Cost Term and PurposeKasih YanÎncă nu există evaluări

- Activity-Based Costing and Activity-Based ManagementDocument60 paginiActivity-Based Costing and Activity-Based ManagementpinakindpatelÎncă nu există evaluări

- Basic Cost Accounting ConceptsDocument16 paginiBasic Cost Accounting ConceptsabbasÎncă nu există evaluări

- The Accountant's Role in The OrganizationDocument53 paginiThe Accountant's Role in The Organizationnikunjpatel12345Încă nu există evaluări

- The Accountant's Role in The OrganizationDocument53 paginiThe Accountant's Role in The OrganizationSiing LiingÎncă nu există evaluări

- 01 The Accountant's Role in The OrganizationDocument53 pagini01 The Accountant's Role in The OrganizationStpÎncă nu există evaluări

- Flexible Budgets, Variances, and Management Control: IDocument57 paginiFlexible Budgets, Variances, and Management Control: IJowjie TVÎncă nu există evaluări

- Joint and by Product CostingDocument48 paginiJoint and by Product CostingXyne FernandezÎncă nu există evaluări

- Chapter 07Document67 paginiChapter 07Abdulwasiq BaigÎncă nu există evaluări

- Capital BudgetingDocument22 paginiCapital BudgetingBradÎncă nu există evaluări

- Cost Allocation, Customer-Profitability Analysis, and Sales-Variance AnalysisDocument60 paginiCost Allocation, Customer-Profitability Analysis, and Sales-Variance AnalysisYuni MelaniÎncă nu există evaluări

- Cost Management Systems and Activity-Based CostingDocument36 paginiCost Management Systems and Activity-Based CostingmarihomenonÎncă nu există evaluări

- Process CostingDocument66 paginiProcess CostingshofiaalifahamidahÎncă nu există evaluări

- Performance Measurement, Compensation, and Multinational ConsiderationsDocument60 paginiPerformance Measurement, Compensation, and Multinational ConsiderationsPurvish ShahÎncă nu există evaluări

- Just-in-Time Production Slides PDFDocument11 paginiJust-in-Time Production Slides PDFBradÎncă nu există evaluări

- Chapter 3 CVPDocument37 paginiChapter 3 CVPfekadeÎncă nu există evaluări

- Process Costing: 17 - 1 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/FosterDocument29 paginiProcess Costing: 17 - 1 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/FosterChristine ManabaÎncă nu există evaluări

- Relevant Information and Decision Making: Marketing DecisionsDocument46 paginiRelevant Information and Decision Making: Marketing DecisionsAsad RehmanÎncă nu există evaluări

- Cost Allocation, Customer-Profitability Analysis, and Sales-Variance AnalysisDocument60 paginiCost Allocation, Customer-Profitability Analysis, and Sales-Variance AnalysismsarojiniÎncă nu există evaluări

- 11 CH 17 Process Costing 6 VDocument28 pagini11 CH 17 Process Costing 6 Viqbal kurniawanÎncă nu există evaluări

- Capital Budgeting and Cost AnalysisDocument54 paginiCapital Budgeting and Cost AnalysisMUHMMAD ARSALAN 13728Încă nu există evaluări

- Capital Budgeting and Cost AnalysisDocument54 paginiCapital Budgeting and Cost AnalysisemmyindraÎncă nu există evaluări

- The Accountant's Role in The OrganizationDocument53 paginiThe Accountant's Role in The OrganizationSahrish IqbalÎncă nu există evaluări

- Factory OverheadDocument21 paginiFactory OverheadJuvi CruzÎncă nu există evaluări

- Four Common Measures of Economic PerformanceDocument29 paginiFour Common Measures of Economic PerformanceDiana Faye CaduadaÎncă nu există evaluări

- Capital Budgeting and Cost AnalysisDocument54 paginiCapital Budgeting and Cost AnalysisAnggari SaputraÎncă nu există evaluări

- Cost Management: Don R. Hansen Maryanne M. MowenDocument80 paginiCost Management: Don R. Hansen Maryanne M. MowenNurul Meutia SalsabilaÎncă nu există evaluări

- Chap 11Document21 paginiChap 11Ashak Anowar MahiÎncă nu există evaluări

- 3 - Hansen - CH 4.ppt-Dikonversi PDFDocument80 pagini3 - Hansen - CH 4.ppt-Dikonversi PDFRamaÎncă nu există evaluări

- Cost12eppt - 04 Job CostingDocument20 paginiCost12eppt - 04 Job Costingfriska13Încă nu există evaluări

- Cost Accounting E12 PPT ch02Document22 paginiCost Accounting E12 PPT ch02Bharata H. BatahanÎncă nu există evaluări

- ©2005 Prentice Hall Business Publishing, Introduction To Management Accounting 13/e, Horngren/Sundem/Stratton 3 - 1Document36 pagini©2005 Prentice Hall Business Publishing, Introduction To Management Accounting 13/e, Horngren/Sundem/Stratton 3 - 1vahid teymooriÎncă nu există evaluări

- Chapter 3Document36 paginiChapter 3Kerrisha JohnÎncă nu există evaluări

- 11ch21 Capital BudgetingDocument54 pagini11ch21 Capital BudgetingLi'ilzam NuurÎncă nu există evaluări

- Introduction To Management AccountingDocument33 paginiIntroduction To Management Accountinghemanth20032001Încă nu există evaluări

- 1314 IBMS-IBO-FIN Lecture Week 3Document27 pagini1314 IBMS-IBO-FIN Lecture Week 3LucaBoselliÎncă nu există evaluări

- 11 CH 20Document57 pagini11 CH 20Nitin WakodeÎncă nu există evaluări

- Introduction To Cost Behavior and Cost-Volume RelationshipsDocument52 paginiIntroduction To Cost Behavior and Cost-Volume RelationshipsMahammad YusifÎncă nu există evaluări

- Distinguish Between Flexible Budgets and Master (Static) BudgetsDocument48 paginiDistinguish Between Flexible Budgets and Master (Static) BudgetsSheila NajlaÎncă nu există evaluări

- Chapter 3Document11 paginiChapter 3Trang Lê Thị ThùyÎncă nu există evaluări

- Cost & Managerial Accounting II EssentialsDe la EverandCost & Managerial Accounting II EssentialsEvaluare: 4 din 5 stele4/5 (1)

- Management Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageDe la EverandManagement Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageEvaluare: 5 din 5 stele5/5 (1)

- Master Budget and Responsibility AccountingDocument59 paginiMaster Budget and Responsibility AccountingEjaz ShahidÎncă nu există evaluări

- Activity-Based Costing and Activity-Based ManagementDocument60 paginiActivity-Based Costing and Activity-Based ManagementpinakindpatelÎncă nu există evaluări

- 11 CH 04Document61 pagini11 CH 04nikunjpatel12345100% (1)

- An Introduction To Cost Terms and PurposesDocument56 paginiAn Introduction To Cost Terms and PurposesAbeer Al-bedaiwyÎncă nu există evaluări

- The Accountant's Role in The OrganizationDocument53 paginiThe Accountant's Role in The Organizationnikunjpatel12345Încă nu există evaluări

- Poha UnitDocument2 paginiPoha UnitBharat PatelÎncă nu există evaluări

- Cost Accounting - Course Study Guide. (Repaired)Document9 paginiCost Accounting - Course Study Guide. (Repaired)syed Hassan100% (1)

- Audit of Inventories - Roque 2018Document60 paginiAudit of Inventories - Roque 2018Renelyn David69% (13)

- Overhead Cost AccountingDocument55 paginiOverhead Cost AccountingKakarla achyuthÎncă nu există evaluări

- Hampton Freeze, Inc. Balance Sheet 31-Dec-16 AssetsDocument23 paginiHampton Freeze, Inc. Balance Sheet 31-Dec-16 AssetsAman ShahÎncă nu există evaluări

- Entrepreneurship 10: Quarter 3 - Module 2 (Lesson 1&2)Document20 paginiEntrepreneurship 10: Quarter 3 - Module 2 (Lesson 1&2)Sirhcmonne Jacob Posadas50% (2)

- Intermediate Accounting I - Ppe AnswersDocument3 paginiIntermediate Accounting I - Ppe AnswersJoovs Joovho50% (2)

- Process Costing - Chapter 4Document18 paginiProcess Costing - Chapter 4Asadullahil GalibÎncă nu există evaluări

- CostingDocument14 paginiCostingSHEFALI RATURIÎncă nu există evaluări

- Quality Costs in Construction: Case of Qom Monorail Project in IranDocument6 paginiQuality Costs in Construction: Case of Qom Monorail Project in IranALEXANDER GUZMÁN MANZANOÎncă nu există evaluări

- Acctg 13 - Midterm ExamDocument8 paginiAcctg 13 - Midterm ExamMary Grace Castillo AlmonedaÎncă nu există evaluări

- FINAL YCA GuidelinesDocument48 paginiFINAL YCA GuidelinesDr. Erwin HandokoÎncă nu există evaluări

- Key Benchmarks For Manufacturing Companies - Chief Executive ResearchDocument9 paginiKey Benchmarks For Manufacturing Companies - Chief Executive ResearchRichard CK LeloonÎncă nu există evaluări

- Wilkerson Company ABCDocument4 paginiWilkerson Company ABCrajyalakshmiÎncă nu există evaluări

- QB 305E Cost Work AccountingDocument34 paginiQB 305E Cost Work Accountingshubham singhÎncă nu există evaluări

- Test1 ReviewDocument8 paginiTest1 Reviewghsoub777Încă nu există evaluări

- Cost Concepts and ClassificationsDocument6 paginiCost Concepts and ClassificationsNailiah MacakilingÎncă nu există evaluări

- Relevant Costing Exercises - KingDocument7 paginiRelevant Costing Exercises - KingAlexis KingÎncă nu există evaluări

- Chapter 13 Managerial AccountingDocument69 paginiChapter 13 Managerial Accountingphryxsos100% (2)

- Leslie Company Manufacturing Department Cost of Production Report For January Materials Conversion CostDocument8 paginiLeslie Company Manufacturing Department Cost of Production Report For January Materials Conversion Costmaica G.Încă nu există evaluări

- Cost Accounting AssigDocument6 paginiCost Accounting AssigHamse HusseinÎncă nu există evaluări

- Cost Control Techniques - Marginal CostingDocument34 paginiCost Control Techniques - Marginal CostingsiddhhiphopperÎncă nu există evaluări

- Profitable Disposable Products Manufacturing Business Ideas. Starting Your Own Production Business of Thermocol Plate, Dona, Thali and Glass...... - 648122Document77 paginiProfitable Disposable Products Manufacturing Business Ideas. Starting Your Own Production Business of Thermocol Plate, Dona, Thali and Glass...... - 648122Sunayana GuptaÎncă nu există evaluări

- (MAC1) Job Order CostingDocument10 pagini(MAC1) Job Order CostingBSA 1-2 RUIZ, MARC BRIAN S.Încă nu există evaluări

- Page - 1: Re-Order Level Average Stock LevelDocument18 paginiPage - 1: Re-Order Level Average Stock Levelgagan vermaÎncă nu există evaluări

- Welding Economics and Management WFC 212-1Document59 paginiWelding Economics and Management WFC 212-1ibrahim mustaphaÎncă nu există evaluări

- Cup-Management Advisory ServicesDocument7 paginiCup-Management Advisory ServicesJerauld BucolÎncă nu există evaluări

- Problem 5-51 BlocherDocument2 paginiProblem 5-51 BlocherAlif ArmadanaÎncă nu există evaluări

- Variance Analysis: Study Questions and Answers Are On Page 4 and Pages 5-11Document21 paginiVariance Analysis: Study Questions and Answers Are On Page 4 and Pages 5-11Andy OcegueraÎncă nu există evaluări

- Pt. Tata Bara Utama: SalesDocument44 paginiPt. Tata Bara Utama: Salesaliyah29Încă nu există evaluări