Documente Academic

Documente Profesional

Documente Cultură

Fall Protection: Marnie Alfar

Încărcat de

Aviects Avie Jaro0 evaluări0% au considerat acest document util (0 voturi)

50 vizualizări42 paginirrrr

Titlu original

asdsrrrr

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentrrrr

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

50 vizualizări42 paginiFall Protection: Marnie Alfar

Încărcat de

Aviects Avie Jarorrrr

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 42

FALL PROTECTION

HSE International Consultancy Marnie Alfar

HEALTH SAFETY & ENVIRONMENT OSH Practitioner

Fall Speed vs. Reaction Time

In 1 second your body

will fall 16 feet (4.8 mts.)

Good body reaction time

= 0.5 seconds

Travel distance in 0.5

seconds = 4 feet (1.21mts.)

By the time you react your body will be 6½ feet

(2 mts) below where you were standing

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

When do you need Fall Protection

• Workmen working in unguarded surface above open pits or

tanks, steep slopes, moving machinery and similar locations,

or working from unguarded surfaces six (6) meters (20 ft.) or

more above water or ground, temporary or permanent floor

platform, scaffold construction or where otherwise exposed to

the possibility of falls hazardous to life or limb, shall be secured

by safety belts and life lines.

• Window washers or cleaners working outside buildings six (6)

meters (20 ft.) or more above the ground or other surfaces

unless protected from falling by other means, shall use safety

belts attached to suitable anchors.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

When do you need Fall Protection

• Workmen entering a sewer, flue, duct, or other similarly

confined places shall be provided and required to wear safety

belts with life lines attached and held by another person

stationed at the opening ready to respond to agreed signals.

• Workers who are required to climb and work on top of poles

six (6) meters or more shall use safety belts.

• In situations where safety belts and life lines in guarded

platforms and scaffolds or temporary floors are not feasible,

safety nets shall be provided and installed.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Types of Fall Protection

Systems

PASSIVE

ACTIVE

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

DIFFERENCE:

ACTIVE PASSIVE

are dynamic and require the Non-dynamic, stationary,

use of special equipment as and does not move, adapt,

well as worker participation or change when in or out of

PPE use.

Life lines Engineering Control

Work positioning device Perimeter guardrails

Personal Fall Arrest Safety Net

Equipment/Personal Fall Safety Monitors

Arrest System (PFAS)

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

LET’S GO PASSIVE

Perimeter guardrails

Safety Net

Safety Monitors

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Perimeter Guarding

A physical barrier that restricts a worker from entering a fall

hazard area.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Perimeter Guarding

• Perimeter guarding shall consist of a mid-rail, top-rail, toe-

board system.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

SAFETY NET

Standard requirements:

• Safety nets:

- Mesh ropes - shall not be less than 0.94 cm. (3/8 in.) diameter

- border ropes (perimeter) - not less than 1.90 cm. (3/4 in.)

diameter

- made of manila rope or other materials that can absorb the

impact of a falling body equally as nets fabricated from

manila rope of the dimensions specified.

• Mesh- not to exceed 15.25 cm. (6 in.)

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

SAFETY NET:

shall be equipped with adequately padded thimble sockets

or equivalent means of attachments.

Supports and anchorages shall be of sufficient size and

strength to catch any falling worker.

The nets shall be attached to sufficient supports outside and

beyond the area of possible fall and supported at sufficient

heights to prevent sagging to any solid object beneath when

cushioning the fall of a worker.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

SELF MONITORING SYSTEM

• Intended for low-slope roofing work.

• competent person to monitor the safety of

workers and to warn them when their work

puts them close to a fall hazard.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

SELF MONITORING SYSTEM

The safety monitor must:

Be competent in the recognition of fall hazards.

Warn workers when it appears that they are unaware of

fall hazards or when the workers are acting in an unsafe

manner.

Be on the same walking or working surfaces as the workers

and be able to see them.

Be close enough to the work operations to speak directly

with workers.

Have no other duties to distract them from their

monitoring function.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Employers must ensure that:

Mechanical equipment is not used or stored in areas

where safety monitoring systems are being used to

monitor workers engaged in roofing operations on low-

slope roofs.

No worker, other than one engaged in roofing work on low

slope roofs or one covered by a fall protection plan, enters

an area where a worker is being protected by a safety

monitoring system.

All workers in a controlled access zone have been

instructed to promptly comply with fall hazard warnings

issued by safety monitors.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

LET’S GO ACTIVE!

Personal Fall Arrest

Life lines

Work positioning device

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Fall Protection

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Personal Fall-Arrest Systems

• A Personal Fall-Arrest System

is a system used to arrest an

employee in a fall from a

working level.

• Any person ordered to work

with at height who has an

increase risk of falling off of

structures/buildings should

wear a personal fall arrest

system.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

ACTIVE FALL PROTECTION SYSTEM

FALL RESTRAINT FALL ARREST SYSTEM

• fixed-length lanyard (or dog • incorporate various types of

leash) to keep a worker’s lanyards, including rip stitch

centre of gravity from going lanyards and SRLs, all

over a fall hazard leading designed to stop a

edge. freefalling work from

impacting a lower level.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

ACTIVE FALL PROTECTION SYTEM

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Anchorage Points

• An anchorage is a secure point of attachment

for lifelines, lanyards or deceleration devices;

• Must be independent of any anchorage

being used for equipment tiebacks;

• Must be independent of the means of

supporting or suspending the worker;

• Must be capable of supporting at

least 5,000 pounds per worker;

• Sound anchorages include certified roof

anchors as well as structural members.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Improper Anchorage Points

• Standard Guardrails or Railings

• Ladders/Rungs

• Scaffolding

• Light Fixtures

• Conduit or Plumbing

• Ductwork or Pipe Vents

• Antennas or Satellite Dishes

• Anything else that you’re not sure of!

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Standard Requirements:

• Life lines shall be made of good quality manila

rope of at least 1.9 cm. (3/4 in.) diameter or

equivalent material such as nylon rope of at

least 1.27 cm. (1/2 in.) diameter and shall be

of sufficient strength to support a weight of

1140 kgs. (2,500 lbs.) without breaking.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

BODY WEAR: FULL BODY HARNESS

Ropes and straps

(webbing) used in lanyards,

lifelines, and strength

components of body belts

and body harnesses must

be made of synthetic fibers.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

PART OF FBH:

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Full Body Harness

• Must be the right size for you.

• The attachment point of a body

harness shall be located on the:

◦ Rear D-ring between shoulders when working

from a suspended scaffold or an aerial lift

◦ Front D-ring when working

from a bosun’s chair.

• Harness must be adjusted snugly starting with leg straps, then

waist, shoulders and chest.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Connectors

Device which is used to couple (connect)

parts of the system together.

independent component of the system

(such as a carabiner),

integral component of part of the system

(such as a buckle or D-ring sewn into a body

harness, or a snap-hook spliced or sewn to a

lanyard).

Snaphooks shall be a double locking-type.

-prevent disengagement from any component

part of the personal fall arrest system.

Screwgate carabiners and quick-link

connectors must be fully threaded.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

CONNECTING DEVICE

Locking type snap hooks may also be used when designed for

the following connections:

directly to webbing, rope, or wire rope;

to each other;

to a Dee-ring to which another snaphook or other connector

is attached;

to a horizontal lifeline;

or to any object which is incompatibly shaped or dimensioned

in relation to the snaphook, such that unintentional

disengagement could occur by the connected object being

able to depress the snaphook keeper and release itself.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Lanyards

• Used to connect a body harness to a

lifeline, rope-grab, or anchorage point.

• Shall be the appropriate length:

◦ Bosun’s chair – 2 feet or less

◦ Suspended scaffold – 3 to 4 feet

• Attach to:

◦ Rear D-ring on harness between shoulders when

working on suspended scaffolds and aerial lifts.

◦ Front D-ring when working from a bosun’s chair.

• Be protected against being cut or abraded.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Lifelines

• are used as a means of connecting other components of a

Personal Fall-Arrest System.

• shall be protected from contact with any surface that may

abrade, weaken, damage or sever it.

• shall be removed from service as recommended by the

manufacturer.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

LIFE LINES

• On suspended scaffolds or similar work platforms

with horizontal lifelines that may become vertical

lifelines, the devices used to connect to a horizontal

lifeline must be capable of locking in both directions

on the lifeline.

• Horizontal lifelines must be designed, installed, and

used under the supervision of a qualified person, as

part of a complete personal fall arrest system.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

LIFE LINES

• Vertical lifelines and lanyards

must have a minimum

breaking strength of 5,000

pounds.

• Lifelines must be protected

against being cut or abraded.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Rope-Grabs

• A Rope-Grab is a deceleration device

which travels on a lifeline and

automatically engages the lifeline

and locks to arrest the fall of an

employee.

• When securing the rope grab at the

work location, it should be raised

above eye level, securely engaging

the lifeline.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

LIFE LINES

• Self-retracting lifelines and

lanyards:

automatically limit free fall

distance to 2 feet-minimum

tensile load of 3,000 pounds

do not limit free fall distance

to 2 feet or less- minimum

tensile load of 5,000 pounds

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Inspection of Fall Protection Systems

The following criteria will be utilized to maintain all

equipment in good working condition:

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Full Body Harnesses

Inspect before each use.

◦ Assure that all hardware (ie. D-rings,

buckles, etc.) work properly and that

they do not have any sharp edges, burrs,

cracks or corrosion.

◦ Inspect webbing for wear, cuts, burns,

frayed edges or other damage.

◦ Inspect all stitching for abrasion and

wear to assure integrity.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Lanyards

Inspect before each use.

◦ Check lanyard material for cuts, burns, abrasions, kinks, knots, broken

stitches and excessive wear.

◦ Visually inspect shock absorber for any signs of damage.

◦ Verify that points where the lanyard attaches to the connectors are

free of defects.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Lifelines

Inspect before each use, checking for the

following:

◦ Glazing of the sheath caused by the fibers

being melted.

◦ Severe furring of the rope.

◦ Soft spots, caused by changes to the internal

structure of the core.

◦ Cutting of sheath fibers due to contact with

sharp edges.

◦ Any sign of the core showing through (rope

cores are always white).

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Connectors

Inspect before each use.

◦ Inspect the snap hooks for distortions in the

hook, locks, and eye.

◦ Verify that the keeper spring securely closes

the keeper latch.

◦ Test the locking mechanism to verify that

the keeper latch locks properly.

◦ Check carabiner for excessive wear,

distortion, and lock operation.

◦ Ensure that all locking mechanisms seat and

lock properly.

◦ Verify there are no cracks or pitted surfaces.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Care for Fall Arrest Systems

• Clean equipment after use.

• Air dry equipment, do not hang in direct

sunlight.

• Store equipment in a cool, dark, dry well

ventilated place.

• Do not alter equipment in any way.

• Use caution when using equipment around

moving machinery, electrical hazards, sharp

edges, chemical hazards and high heat

environment or flame.

• All components of a Personal Fall Arrest System

that are involved in a fall shall be immediately

removed from service and disposed of or

destroyed.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

Remember!

• Always use approved anchor points.

• Always make sure fall protection is

sufficient for the job.

• Always inspect your fall protection

system prior to each use.

• Do not use fall protection system to

carry materials or tools.

• Always tie off when coming within 6

feet of an unprotected edge.

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

POSITIONING DEVICE SYSTEM:

Positioning device system as a body belt or body harness system

rigged to allow a worker to be supported on an elevated vertical

surface, such as a wall, and work with both hands free while

leaning.

Body belt or body harness systems

must be secured to an anchorage

capable of supporting at least twice

the potential impact load of a

worker’s fall or 3,000 pounds,

whichever is greater.

Other components: Snaphooks, Dee-

rings, and Other Connectors

HSE International Consultancy

HEALTH SAFETY & ENVIRONMENT

S-ar putea să vă placă și

- Sir Gelena ReportDocument16 paginiSir Gelena ReportReinier VisayanaÎncă nu există evaluări

- Elevated Work : Presentation OnDocument33 paginiElevated Work : Presentation OnVasant Kumar VarmaÎncă nu există evaluări

- The Construction Safety Guide: Injury and Illness Prevention through DesignDe la EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignEvaluare: 4 din 5 stele4/5 (6)

- Fall ProtectionDocument4 paginiFall ProtectionnainaÎncă nu există evaluări

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesDe la EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- Fall Protection TRAINININGDocument20 paginiFall Protection TRAINININGJaime de la Gala100% (1)

- Elevated Work Rev.Document40 paginiElevated Work Rev.Anthony BasantaÎncă nu există evaluări

- Ali Al-SaadDocument17 paginiAli Al-SaadAls اي AlsÎncă nu există evaluări

- ENGLISH II - Class 6 - PPE For Working in HeightDocument59 paginiENGLISH II - Class 6 - PPE For Working in HeightCarlos Osorio VillabonaÎncă nu există evaluări

- Quick Card: What You Need To KnowDocument2 paginiQuick Card: What You Need To KnowRaffer Asis MorañoÎncă nu există evaluări

- Safety NoteDocument7 paginiSafety NoteYounis KhanÎncă nu există evaluări

- WAH 01 Working at Height Slide Presentation SSP.Document87 paginiWAH 01 Working at Height Slide Presentation SSP.Liya Staari100% (3)

- Fall ProtectionDocument34 paginiFall Protectionneo_chemistÎncă nu există evaluări

- Working at Heights Training ManualDocument10 paginiWorking at Heights Training ManualClyde K. LesoleÎncă nu există evaluări

- 2 Fall ProtectionDocument9 pagini2 Fall ProtectionGu YunruiÎncă nu există evaluări

- Best Practice Guidelines For Working at Height in New ZealandDocument25 paginiBest Practice Guidelines For Working at Height in New ZealandPerwez21Încă nu există evaluări

- Working at Height FINALDocument57 paginiWorking at Height FINALInnocent BhaikwaÎncă nu există evaluări

- Working at Heights: Engr. Jobelle B MalaygayDocument50 paginiWorking at Heights: Engr. Jobelle B MalaygayJohn Cedrik Retardo100% (1)

- Temporary Structure: Raymond G. Blanco DOLE OSH PractitionerDocument42 paginiTemporary Structure: Raymond G. Blanco DOLE OSH PractitionerAviects Avie JaroÎncă nu există evaluări

- Wind Energy Site SafetyDocument2 paginiWind Energy Site SafetyplewandÎncă nu există evaluări

- Appendix-B - Construction Safey Manual at ProjectsDocument112 paginiAppendix-B - Construction Safey Manual at ProjectsvinodÎncă nu există evaluări

- EHSEC Toolbox Talk Working at HeightsDocument11 paginiEHSEC Toolbox Talk Working at HeightsInnocent BhaikwaÎncă nu există evaluări

- Fall Prevention - Part 2 of 2Document97 paginiFall Prevention - Part 2 of 2anaperusquiaÎncă nu există evaluări

- FallPrevention2014 QuickCard PDFDocument2 paginiFallPrevention2014 QuickCard PDFRaffer Asis MorañoÎncă nu există evaluări

- Fall Protection GRP 4Document9 paginiFall Protection GRP 4Ruben SibayanÎncă nu există evaluări

- Fall Protection and Ladder SafetyDocument56 paginiFall Protection and Ladder SafetyKAii Magno GuiaÎncă nu există evaluări

- Fall Protection TrainingDocument48 paginiFall Protection Trainingazia100% (1)

- Fall Protection PDFDocument6 paginiFall Protection PDFheitormartÎncă nu există evaluări

- Working at HeightsDocument21 paginiWorking at HeightsSanjana GaneshÎncă nu există evaluări

- If Only I Was Wearing A Safety Harness !!Document22 paginiIf Only I Was Wearing A Safety Harness !!darkhorse1981100% (1)

- Fall Protection Guideline: Construction Safety Education ProgramDocument17 paginiFall Protection Guideline: Construction Safety Education ProgramhazopmanÎncă nu există evaluări

- Safeskill WAH CSE Rescue Module MaterialDocument104 paginiSafeskill WAH CSE Rescue Module MaterialManoj WaskelÎncă nu există evaluări

- Scaffolds: Anid Group Sarl ForDocument8 paginiScaffolds: Anid Group Sarl Forhamoody_007Încă nu există evaluări

- Fall ProtectionDocument30 paginiFall ProtectionTinzÎncă nu există evaluări

- 4 Fall Protection 1232217054413165 3Document18 pagini4 Fall Protection 1232217054413165 3vhlactaotaoÎncă nu există evaluări

- PZ TBT - Height Safety v2Document2 paginiPZ TBT - Height Safety v2AshishÎncă nu există evaluări

- Working at Height Rev 4Document71 paginiWorking at Height Rev 4Adrian Seng100% (2)

- SOP For Working at HeightDocument19 paginiSOP For Working at HeightShreedhar94% (18)

- 19 Personal Fall Protection: Travel-Restraint Systems Fall-Arrest SystemsDocument6 pagini19 Personal Fall Protection: Travel-Restraint Systems Fall-Arrest SystemsStill SatÎncă nu există evaluări

- Fluor U&O Project Fall Protection and Working at Heights TrainingDocument68 paginiFluor U&O Project Fall Protection and Working at Heights TrainingjhoniÎncă nu există evaluări

- 29 CFR PART 1926 Subpart M Fall ProtectionDocument43 pagini29 CFR PART 1926 Subpart M Fall ProtectionAls اي AlsÎncă nu există evaluări

- Working at HeightDocument47 paginiWorking at HeightPRITAM KUMARÎncă nu există evaluări

- Workingatheights 110623224858 Phpapp02Document21 paginiWorkingatheights 110623224858 Phpapp02naveeduddin2001Încă nu există evaluări

- Fall Arrest: Product CatalogueDocument60 paginiFall Arrest: Product CatalogueBorislav VulićÎncă nu există evaluări

- 10 - 004 - Fall ProtectionDocument23 pagini10 - 004 - Fall ProtectionUnique OfficerÎncă nu există evaluări

- Working at Heights - Harmonized - PolicyDocument15 paginiWorking at Heights - Harmonized - Policymohamed ibrahimÎncă nu există evaluări

- Basics of Work at Height and Preventive MeasuresDocument20 paginiBasics of Work at Height and Preventive Measuresigor_239934024Încă nu există evaluări

- Fall ProtectionDocument17 paginiFall ProtectionCh Azeem AhmadÎncă nu există evaluări

- Use of Full Body Harness With LanyardDocument3 paginiUse of Full Body Harness With LanyardSn Ahsan100% (1)

- 7 Electrical PDFDocument6 pagini7 Electrical PDFMohammed AtefÎncă nu există evaluări

- Office of State Human ResourcesDocument8 paginiOffice of State Human ResourcesMOHAMEDÎncă nu există evaluări

- 2.5 Fall ProtectionDocument52 pagini2.5 Fall ProtectionjantskieÎncă nu există evaluări

- Fall ProtectionDocument24 paginiFall Protectionmdfahad0047Încă nu există evaluări

- Ehs Policy and ProceduresDocument12 paginiEhs Policy and ProceduresAlvin James GuintoÎncă nu există evaluări

- Safe Access, Fall Protection and Fall PreventionDocument76 paginiSafe Access, Fall Protection and Fall PreventionMirwaliÎncă nu există evaluări

- Work at Height PDFDocument36 paginiWork at Height PDFdaddyanataÎncă nu există evaluări

- 28 - Scaffolding ProceduresDocument17 pagini28 - Scaffolding ProceduresLalit Tomar100% (1)

- Occupational Health Hazards: Raymond Gomez BlancoDocument113 paginiOccupational Health Hazards: Raymond Gomez BlancoAviects Avie JaroÎncă nu există evaluări

- Betonbau Philippines Inc. RCBM Bulacan Plant ProjectsDocument1 paginăBetonbau Philippines Inc. RCBM Bulacan Plant ProjectsAviects Avie JaroÎncă nu există evaluări

- 9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Document3 pagini9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Aviects Avie JaroÎncă nu există evaluări

- ATCS BOSH Batch 0617: Darell Jake A. Vergara Mar John G. GamuedaDocument1 paginăATCS BOSH Batch 0617: Darell Jake A. Vergara Mar John G. GamuedaAviects Avie JaroÎncă nu există evaluări

- ATCS Business Profile 2018Document20 paginiATCS Business Profile 2018Aviects Avie JaroÎncă nu există evaluări

- 9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Document3 pagini9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Aviects Avie JaroÎncă nu există evaluări

- Is Given To: Avie Training and Consultancy ServicesDocument3 paginiIs Given To: Avie Training and Consultancy ServicesAviects Avie JaroÎncă nu există evaluări

- Bosh Rainy Days PromoDocument1 paginăBosh Rainy Days PromoAviects Avie JaroÎncă nu există evaluări

- Bosh Cosh Ads Aug 2018Document2 paginiBosh Cosh Ads Aug 2018Aviects Avie JaroÎncă nu există evaluări

- OHSAS 18001 - Occupational Health and Safety Management SystemDocument31 paginiOHSAS 18001 - Occupational Health and Safety Management SystemAviects Avie JaroÎncă nu există evaluări

- Marnie Alfar: HSE International Consultancy OSH PractitionerDocument16 paginiMarnie Alfar: HSE International Consultancy OSH PractitionerAviects Avie JaroÎncă nu există evaluări

- Why Choose Avietcs?: Training FocusDocument1 paginăWhy Choose Avietcs?: Training FocusAviects Avie JaroÎncă nu există evaluări

- Site Inspection: Marnie AlfarDocument50 paginiSite Inspection: Marnie AlfarAviects Avie JaroÎncă nu există evaluări

- Occupational Health: Marnie AlfarDocument78 paginiOccupational Health: Marnie AlfarAviects Avie JaroÎncă nu există evaluări

- Occupational Safety and Health Standards: Regulatory RequirementsDocument53 paginiOccupational Safety and Health Standards: Regulatory RequirementsAviects Avie JaroÎncă nu există evaluări

- PPE: Hand Protection: © BLR® - Business & Legal Resources (1505)Document31 paginiPPE: Hand Protection: © BLR® - Business & Legal Resources (1505)Aviects Avie JaroÎncă nu există evaluări

- Call Us NOW For A Formal Proposal.: Industrial Safety and Allied Services ProviderDocument4 paginiCall Us NOW For A Formal Proposal.: Industrial Safety and Allied Services ProviderAviects Avie JaroÎncă nu există evaluări

- Toolbox Meeting: Raymond G. BlancoDocument19 paginiToolbox Meeting: Raymond G. BlancoAviects Avie JaroÎncă nu există evaluări

- Osh Programming: Marnie AlfarDocument35 paginiOsh Programming: Marnie AlfarAviects Avie JaroÎncă nu există evaluări

- 3NewCOSH ManualDocument136 pagini3NewCOSH ManualAviects Avie JaroÎncă nu există evaluări

- Male/Female Marketing Executives 18-31 SingleDocument2 paginiMale/Female Marketing Executives 18-31 SingleAviects Avie JaroÎncă nu există evaluări

- Temporary Structure: Raymond G. Blanco DOLE OSH PractitionerDocument42 paginiTemporary Structure: Raymond G. Blanco DOLE OSH PractitionerAviects Avie JaroÎncă nu există evaluări

- 003-March 2018 Training Schedule BataanDocument2 pagini003-March 2018 Training Schedule BataanAviects Avie Jaro100% (1)

- 003 MARCH 2018 TRAINING SCHEDULE BataanDocument2 pagini003 MARCH 2018 TRAINING SCHEDULE BataanAviects Avie Jaro100% (1)

- Economic in Loss ControlDocument15 paginiEconomic in Loss ControlAviects Avie Jaro0% (1)

- 00b1. HSE - BOSH Attendance SheetDocument2 pagini00b1. HSE - BOSH Attendance SheetAviects Avie JaroÎncă nu există evaluări

- August 05, 2018@bpsu Main Campus Balanga City BataanDocument1 paginăAugust 05, 2018@bpsu Main Campus Balanga City BataanAviects Avie JaroÎncă nu există evaluări

- AsdssssDocument1 paginăAsdssssAviects Avie JaroÎncă nu există evaluări

- Site General Evaccuation Drill: Petrokemya Abs ProjectDocument1 paginăSite General Evaccuation Drill: Petrokemya Abs ProjectAviects Avie JaroÎncă nu există evaluări

- Safety and Health Training: The History and Philosophy of Loss ControlDocument2 paginiSafety and Health Training: The History and Philosophy of Loss ControlAviects Avie JaroÎncă nu există evaluări

- Course Syllabus: Course Code Course Title ECTS CreditsDocument3 paginiCourse Syllabus: Course Code Course Title ECTS CreditsHanaa HamadallahÎncă nu există evaluări

- Malvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasDocument71 paginiMalvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasMary Cruz Meza CahuanaÎncă nu există evaluări

- Assignment 1Document3 paginiAssignment 1farhang_tÎncă nu există evaluări

- Assessment Questions: 1: Wash - Rinse and SanitizeDocument3 paginiAssessment Questions: 1: Wash - Rinse and SanitizeAna Margarita AycochoÎncă nu există evaluări

- Mockery Breed Murder Birds PDFDocument12 paginiMockery Breed Murder Birds PDFLautaro BojanichÎncă nu există evaluări

- Honeycomb Kevlar 49 (Hexcel)Document3 paginiHoneycomb Kevlar 49 (Hexcel)Julia GarciaÎncă nu există evaluări

- 18 Ray Optics Revision Notes QuizrrDocument108 pagini18 Ray Optics Revision Notes Quizrraafaf.sdfddfaÎncă nu există evaluări

- Curriculum Vitae - RadikaDocument3 paginiCurriculum Vitae - RadikaradikahendryÎncă nu există evaluări

- Astm C892 - 00Document5 paginiAstm C892 - 00reneeÎncă nu există evaluări

- 9 5 - 358 362 PDFDocument5 pagini9 5 - 358 362 PDFمالك مناصرةÎncă nu există evaluări

- Straight LineDocument15 paginiStraight LineAyanÎncă nu există evaluări

- Syllabus Unit Iv Unit Commitment and Economic DispatchDocument23 paginiSyllabus Unit Iv Unit Commitment and Economic DispatchBALAKRISHNANÎncă nu există evaluări

- DISPOSABLE GLOVES CATALOG 2023npDocument4 paginiDISPOSABLE GLOVES CATALOG 2023npTeodylee CruzÎncă nu există evaluări

- PPT DIARHEA IN CHILDRENDocument31 paginiPPT DIARHEA IN CHILDRENRifka AnisaÎncă nu există evaluări

- World's Standard Model G6A!: Low Signal RelayDocument9 paginiWorld's Standard Model G6A!: Low Signal RelayEgiÎncă nu există evaluări

- From Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesDocument15 paginiFrom Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesKayra MoslemÎncă nu există evaluări

- Improve On-Time DeliveriesDocument24 paginiImprove On-Time DeliveriesUdayÎncă nu există evaluări

- 41z S4hana2021 Set-Up en XXDocument46 pagini41z S4hana2021 Set-Up en XXHussain MulthazimÎncă nu există evaluări

- Module 1 Notes The White Bird Reading The Image Painting Analysis PDFDocument4 paginiModule 1 Notes The White Bird Reading The Image Painting Analysis PDFMelbely Rose Apigo BaduaÎncă nu există evaluări

- LG250CDocument2 paginiLG250CCarlosÎncă nu există evaluări

- Updated G10 Class Routine Effective From 12 January 2023Document1 paginăUpdated G10 Class Routine Effective From 12 January 2023NiloyÎncă nu există evaluări

- TNM History Updated June2017Document2 paginiTNM History Updated June2017Lucas AndreoÎncă nu există evaluări

- Inferring The Speaker's Tone, ModeDocument31 paginiInferring The Speaker's Tone, Modeblessilda.delaramaÎncă nu există evaluări

- GP1 Q1 Week-1Document18 paginiGP1 Q1 Week-1kickyknacksÎncă nu există evaluări

- Immigrant Italian Stone CarversDocument56 paginiImmigrant Italian Stone Carversglis7100% (2)

- Ali Erdemir: Professional ExperienceDocument3 paginiAli Erdemir: Professional ExperienceDunkMeÎncă nu există evaluări

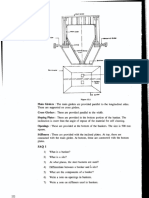

- Main Girders: CrossDocument3 paginiMain Girders: Crossmn4webÎncă nu există evaluări

- Liver: Anatomy & FunctionsDocument18 paginiLiver: Anatomy & FunctionsDR NARENDRAÎncă nu există evaluări

- Therapeutic Nutrition: Khien S. Sasi, RN, ManDocument33 paginiTherapeutic Nutrition: Khien S. Sasi, RN, ManKhien Sasi100% (4)

- Cross Talk Details and RoutingDocument29 paginiCross Talk Details and RoutingRohith RajÎncă nu există evaluări