Documente Academic

Documente Profesional

Documente Cultură

Installation of Megabolts As Primary Supports

Încărcat de

Jhan CabelloTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Installation of Megabolts As Primary Supports

Încărcat de

Jhan CabelloDrepturi de autor:

Formate disponibile

How megabolts installed as

primary support assist in

safely improving

development rates

ACARP Roadway Development Operators Workshops - October 2011

Introduction

Three types of megabolts installed from

continuous miner

● Post grouted megastrands – MW9

● Resin anchored, torque-tensioned megaflex bolts - TTX

● Resin anchored, post groutable fibreglass rib bolts

ACARP Roadway Development Operators Workshops - October 2011 2

MW9 Megabolt

● Most commonly

installed megabolt is

the barrel & wedge

version – MW9

● Fully bulbed using

spiral rib wire for max

load transfer

● Up to 11 m long cables

installed from miner in

LW installation roads

ACARP Roadway Development Operators Workshops - October 2011 3

MW9 – Nth Goonyella face road

ACARP Roadway Development Operators Workshops - October 2011 4

MW9 advantages

● 42 mm hole – no reaming

● Single 1,000 mm resin capsule

with resin retainer

● Resin pushed up hole with bolt

– no conduit

● Collar fittings attached after

bolt installed

● No bearing plate or bolt head to

catch on walkway

ACARP Roadway Development Operators Workshop 2011 5

MW9 advantages

● Tension within 5 mins of

installation

● Tension using system

hydraulics or intensifier

● 9 to 20 t pre-tension can be

achieved depending whether

system hydraulics or

intensifier used

● No air needed on miner

● Provides immediate point

anchor support of 57 t

ACARP Roadway Development Operators Workshop 2011 6

Important considerations

● Bolt is point anchored until

grouted

● Anchor length designed to

take capacity of bolt – depends

on rock type at anchor horizon

● Pull tests must be done to

determine if anchor can take

full capacity of bolt

● This ungrouted bolt is loaded

to 45-50 tonnes

ACARP Roadway Development Operators Workshop 2011 7

MW9 grouting

● Top down grouted using grout

lance – quickest grouting

method

● Grouting done within

designated time or distance

advanced – depends on

conditions

● Heavy conditions may require

grouting within 24 hrs

● Good conditions (intersections)

can be left for more than a week

ACARP Roadway Development Operators Workshop 2011 8

MW9 grouting

● Grout generally reaches

sufficient strength (30 to 40

MPa) within 24 hrs

● Readily & easily audited

● Regular auditing has greatly

improved quality of

installation

● Grouting non-compliance now

less than 5%

● Good installation reduces

likelihood of remedial roof

support

ACARP Roadway Development Operators Workshop 2011 9

MW9 developments

Mechanised insertion

● Lobster from Conway

Engineering

● Being used at Angus

Place

● Favourable reports so

far

ACARP Roadway Development Operators Workshop 2011 10

MW9 developments

Resin grouting using Minova

Carbothix

● Immediate roof support

● Remote pumping

● Quicker grouting

ACARP Roadway Development Operators Workshop 2011 11

Megaflex TTX

● Torque-tensioned

● TT bolt becoming more in

demand

● 56 t and 48 t versions

● 56 t generally requires 28

mm hole

● 48 t a 27 mm hole

ACARP Roadway Development Operators Workshop 2011 12

TTX – advantages

● No exposure to high

pressure tensioner

hydraulics

● Reduced injuries from

handling tensioners

● Quicker installation than

hydraulically tensioned

cables

● Combo dolly

ACARP Roadway Development Operators Workshops - October 2011 13

Combo dolly – no changing dollies

Mixing Tightening

Inner socket engages hex drive Outer socket engages nut

ACARP Roadway Development Operators Workshops - October 2011 14

TTX – advantages

● Roller race between nut &

washer reduces friction

● Race is shrouded to keep

bearing free of dirt or mud

● 7 t bolt tension from 320

Nm drill torque

● Minimal protrusion from

roof – important in low

seams

● Removing hex drive

reduces protrusion further

– as little as 115 mm

ACARP Roadway Development Operators Workshop 2011 15

TTX – advantages

● Wires are anchored in the bolt

head using button heads forged

on end of each wire – maintains

max collar strength

● B&W anchor typically reduces

cable collar capacity by approx

10%

ACARP Roadway Development Operators Workshop 2011 16

TTX – advantages

● Increased load transfer from

spiral wire

● Groutable version being

developed – will require 42

mm dia. hole

ACARP Roadway Development Operators Workshop 2011 17

Limitations of torque-tensioned cables

● Reduced bolt pre-tension compared to hydraulic

tensioning

● Possible use of torque multipliers

‐ Slows down installation

‐ Failure of torque multiplier can delay production

‐ Possible safety issues

● May need modifications to head-plate of drill mast to

accommodate bolt and/or dolly

● Full resin encapsulation difficult for cables > 4 m

● Load transfer lower than for bulbed cables

● If bulbed then larger hole dia. & bigger resin capsule

ACARP Roadway Development Operators Workshop 2011 18

Groutable FG rib bolt

● 42 t capacity

● Cuttable

● 42-45 mm drill hole

● Point anchored initially

● Breakout nut

● High torsion strength –

stalls rib bolting rigs

● 17 t collar capacity

● Shear strength of 14 t

● SG of 1.9 to 2.1 – separates

in washery

ACARP Roadway Development Operators Workshops - October 2011 19

Groutable FG rib dowel - advantages

● Immediate rib support

● Hollow centre - post groutable

with thixotropic grout

● Full encapsulation vital in

heavy rib conditions

● Easily audited

● No secondary rib support

required – maximises

development rates

ACARP Roadway Development Operators Workshops - October 2011 20

S-ar putea să vă placă și

- Hearts of WulinDocument231 paginiHearts of WulinAieie100% (1)

- D243 GEWI Pile System - Slab Connection PDFDocument1 paginăD243 GEWI Pile System - Slab Connection PDFSebastianÎncă nu există evaluări

- Cable Bolt Optimisation at Mine Bousquet-PaperDocument25 paginiCable Bolt Optimisation at Mine Bousquet-PaperKevin MarroquínÎncă nu există evaluări

- Samsung HT E6759w ZGDocument106 paginiSamsung HT E6759w ZGUngureanu Stefan RaymondÎncă nu există evaluări

- AL Liars Night 2018Document2 paginiAL Liars Night 2018Mike LlamasÎncă nu există evaluări

- Recent Advances in Excavation, Design and Support Methods: A Case Study of Mangdechhu Project, BhutanDocument10 paginiRecent Advances in Excavation, Design and Support Methods: A Case Study of Mangdechhu Project, Bhutandhan singhÎncă nu există evaluări

- DSI DYWIDAG Z 34.11 225 Permanent Bar Anchors enDocument20 paginiDSI DYWIDAG Z 34.11 225 Permanent Bar Anchors enjeff_56Încă nu există evaluări

- Wittig PDFDocument38 paginiWittig PDFProf YoupaÎncă nu există evaluări

- Probe WassaraDocument2 paginiProbe WassaraY.EbadiÎncă nu există evaluări

- BAUER Ductile PilesDocument8 paginiBAUER Ductile PilesRui TerrasÎncă nu există evaluări

- Dsi Usa Dywi-Drill Instruction Us 01Document32 paginiDsi Usa Dywi-Drill Instruction Us 01suvraÎncă nu există evaluări

- Anker Schroeder - Anchors For Marine Structures PDFDocument28 paginiAnker Schroeder - Anchors For Marine Structures PDFlokeshras12Încă nu există evaluări

- 3.0 Foam Drilling: 3.1 Make Up 3.2 Generation 3.3 Disposal 3.4 Drilling Practices 3.5 ProblemsDocument16 pagini3.0 Foam Drilling: 3.1 Make Up 3.2 Generation 3.3 Disposal 3.4 Drilling Practices 3.5 ProblemsShahin KhanÎncă nu există evaluări

- A Jetplus IndeDocument13 paginiA Jetplus IndeMelissa MorganÎncă nu există evaluări

- Bauer Review - 42 - en PDFDocument44 paginiBauer Review - 42 - en PDFDudee Daryan100% (1)

- 2015 European Product Applications To Field Drilling AppsDocument11 pagini2015 European Product Applications To Field Drilling AppsPeter LeanoÎncă nu există evaluări

- VSL PresentationDocument59 paginiVSL PresentationkmabdÎncă nu există evaluări

- CT-Bolt, M22 - 2014-03 - en - SmallDocument1 paginăCT-Bolt, M22 - 2014-03 - en - SmallLuca BrandiÎncă nu există evaluări

- TITAN ROOF (Self-Drilling Bolt Forepoling)Document3 paginiTITAN ROOF (Self-Drilling Bolt Forepoling)mypenta2008Încă nu există evaluări

- MHWirth PileTopDrillRigs Brochure Web2Document12 paginiMHWirth PileTopDrillRigs Brochure Web2geobyun100% (1)

- Slurry Wall PDF 02Document15 paginiSlurry Wall PDF 02Syufri HakimÎncă nu există evaluări

- Normet Microfine Cement Brochure Eng 0Document8 paginiNormet Microfine Cement Brochure Eng 0Sridhara GowdaÎncă nu există evaluări

- 91 Jun2016 NZGeoNews PDFDocument114 pagini91 Jun2016 NZGeoNews PDFAditya PrasadÎncă nu există evaluări

- Experience and Lesson From Using TBM in The HimalayaDocument7 paginiExperience and Lesson From Using TBM in The HimalayaVignesh AyyathuraiÎncă nu există evaluări

- Technical English: Engineer. Sánchez Espinoza Edwin Student. Torres Mendoza Juan Carlos Theme. Mining SupportDocument28 paginiTechnical English: Engineer. Sánchez Espinoza Edwin Student. Torres Mendoza Juan Carlos Theme. Mining SupportJeferson Israel TORRES MENDOZAÎncă nu există evaluări

- Ruukki Atlas Copco Rotex Stålpeledagen 2009Document68 paginiRuukki Atlas Copco Rotex Stålpeledagen 2009julio1051Încă nu există evaluări

- Dsi-Usa Dywidag MicropilesDocument16 paginiDsi-Usa Dywidag MicropilesfazyroshanÎncă nu există evaluări

- What Is Rock ReinforcementDocument3 paginiWhat Is Rock ReinforcementSantoshÎncă nu există evaluări

- Multi-Mode and Variable Density TBMs Latest Trends in DevelopmentsDocument13 paginiMulti-Mode and Variable Density TBMs Latest Trends in DevelopmentsAyman SobhyÎncă nu există evaluări

- Planning & Design of WCSDocument58 paginiPlanning & Design of WCSrajeevakumar100% (2)

- Tunnels and Mining - StabilizationDocument24 paginiTunnels and Mining - StabilizationAnonymous D8oJfxsngÎncă nu există evaluări

- Aker Wirth - Tunnel Boring Machines, Raise Boring and Full-Face Shaft Boring Machines - Mining Technology PDFDocument2 paginiAker Wirth - Tunnel Boring Machines, Raise Boring and Full-Face Shaft Boring Machines - Mining Technology PDFFord cellÎncă nu există evaluări

- Karuma Cavern DesignDocument6 paginiKaruma Cavern DesignBinodÎncă nu există evaluări

- Ion For Tunneling - Anand MinconsDocument38 paginiIon For Tunneling - Anand MinconsVinodh Kumar Yalla100% (1)

- Friction Factors For Large Conduits Flowing FullDocument77 paginiFriction Factors For Large Conduits Flowing FullJean BattellÎncă nu există evaluări

- Dsi Info 22 en PDFDocument172 paginiDsi Info 22 en PDFMauricio GutierrezÎncă nu există evaluări

- Achieving Fast EPB Advance in Mixed Ground: A Study of Contributing FactorsDocument13 paginiAchieving Fast EPB Advance in Mixed Ground: A Study of Contributing Factors117120022Încă nu există evaluări

- Micropile Presentation - SAS PDFDocument73 paginiMicropile Presentation - SAS PDFicabullangueroÎncă nu există evaluări

- Fore PoleDocument4 paginiFore PoleBilal MirÎncă nu există evaluări

- Borehole (Slurry) Mining of Coal, Uraniferous Sandstone, Oil Sands, and Phosphate OreDocument44 paginiBorehole (Slurry) Mining of Coal, Uraniferous Sandstone, Oil Sands, and Phosphate OreB1Încă nu există evaluări

- Underground Construction TechonologyDocument107 paginiUnderground Construction TechonologyJose David GarciaÎncă nu există evaluări

- Bill of Quantity For Drilling of Twenty BoreholesDocument1 paginăBill of Quantity For Drilling of Twenty BoreholesAnonymous OeoeVBmwÎncă nu există evaluări

- Measuring of Ground MovementsDocument40 paginiMeasuring of Ground MovementsAmit SinghÎncă nu există evaluări

- Dewatering Techniques PDFDocument20 paginiDewatering Techniques PDFsrinij maharjanÎncă nu există evaluări

- Proposed Method Statement For Ijen Geothermal ProjectDocument11 paginiProposed Method Statement For Ijen Geothermal ProjectAli Al MufidiÎncă nu există evaluări

- Evacuation Shaft 4 - Pump Test Method StatementDocument14 paginiEvacuation Shaft 4 - Pump Test Method Statementmrlee28Încă nu există evaluări

- Asphalt Core Rockfill Dams BrazilDocument33 paginiAsphalt Core Rockfill Dams BrazilFabiola AntoniaÎncă nu există evaluări

- Section 13 Constr Methodology and Estimates of CostDocument18 paginiSection 13 Constr Methodology and Estimates of CostFaruk AtalarÎncă nu există evaluări

- Static and Dynamic Behaviour of Raft of A BarrageDocument8 paginiStatic and Dynamic Behaviour of Raft of A BarrageTadigotla SasidharÎncă nu există evaluări

- Eddie Wong Aecom PDFDocument79 paginiEddie Wong Aecom PDFAishwarya Kumar100% (1)

- Uae Ground ImprovementDocument12 paginiUae Ground ImprovementMuhanad SalemÎncă nu există evaluări

- Design Aspects of Gates of DamDocument6 paginiDesign Aspects of Gates of DamdheeruÎncă nu există evaluări

- TERRATEC Microtunnelling Brochure PDFDocument5 paginiTERRATEC Microtunnelling Brochure PDFKhaled MaddallahÎncă nu există evaluări

- Meyco Hard Rock Mining enDocument12 paginiMeyco Hard Rock Mining enAlex SchoepfÎncă nu există evaluări

- Dywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)Document16 paginiDywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)sandycastleÎncă nu există evaluări

- Choice of TBM TypeDocument11 paginiChoice of TBM Typepratik raiÎncă nu există evaluări

- Hand Book of Geotechnical Investigation and Design Tables 228-236 PDFDocument9 paginiHand Book of Geotechnical Investigation and Design Tables 228-236 PDFachmad sidiqÎncă nu există evaluări

- VSL Threadbar SystemsDocument16 paginiVSL Threadbar SystemsNguyen Chau LanÎncă nu există evaluări

- CaissonsDocument30 paginiCaissonsYashu YashuÎncă nu există evaluări

- Structural Analysis 1: Statically Determinate StructuresDe la EverandStructural Analysis 1: Statically Determinate StructuresÎncă nu există evaluări

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980De la EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Încă nu există evaluări

- New Year's EveDocument1 paginăNew Year's EveEdyta MacÎncă nu există evaluări

- Thuyet Minh He Thong Dien Nhe - VNSDocument53 paginiThuyet Minh He Thong Dien Nhe - VNSViệt Dũng Đinh ĐỗÎncă nu există evaluări

- Slow Cooking Recipe EbookDocument22 paginiSlow Cooking Recipe EbookSonia Caliso100% (2)

- 2010 Double Bass ExcerptsDocument8 pagini2010 Double Bass ExcerptsSebastien SiroisÎncă nu există evaluări

- Literature Part 2Document53 paginiLiterature Part 2Neliza SalcedoÎncă nu există evaluări

- Deceitful CharactersDocument2 paginiDeceitful Characterslauren_alves_2Încă nu există evaluări

- Extra Vocabulary: I Love My Look Today!Document1 paginăExtra Vocabulary: I Love My Look Today!CeciBravoÎncă nu există evaluări

- S2-2nd Edit Unit-6 (6.4 Colours of Light)Document18 paginiS2-2nd Edit Unit-6 (6.4 Colours of Light)Kyaw Sit Nyein MaungÎncă nu există evaluări

- Enrique IglesiasDocument25 paginiEnrique IglesiasNagham Bazzi0% (1)

- Susi - Ben&BenDocument10 paginiSusi - Ben&BenMarc Christian Paraan FernandezÎncă nu există evaluări

- Unicast, Broadcast, and MulticastDocument2 paginiUnicast, Broadcast, and MulticastVictor BragaÎncă nu există evaluări

- Session 2 - English ViDocument20 paginiSession 2 - English ViMANUEL FELIPE HUERTAS PINGOÎncă nu există evaluări

- Hes 386 Poster Breanna CrockettDocument2 paginiHes 386 Poster Breanna CrockettManuel FerreiraÎncă nu există evaluări

- (Ebook) Star Wars Encyclopedia Galactica Vol 2Document68 pagini(Ebook) Star Wars Encyclopedia Galactica Vol 2gdq6280100% (2)

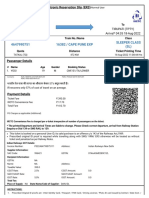

- Cape Pune Exp Sleeper Class (SL)Document2 paginiCape Pune Exp Sleeper Class (SL)Yogiswar Goud RathipinniÎncă nu există evaluări

- Dokumen Tips Ethio Telecom Teleom Itiens Arter Etio Teleom ItiensDocument22 paginiDokumen Tips Ethio Telecom Teleom Itiens Arter Etio Teleom ItiensYohannes LerraÎncă nu există evaluări

- Insulation Considered Is LRB 120 Kg/M3 Density, 100mm Thk. Suitable For 24SWG Aluminium SheetDocument1 paginăInsulation Considered Is LRB 120 Kg/M3 Density, 100mm Thk. Suitable For 24SWG Aluminium SheetPriya TanejaÎncă nu există evaluări

- PRINT - Service Manuals - Service Manual MC Kinley Eu GD 13 06 2019Document73 paginiPRINT - Service Manuals - Service Manual MC Kinley Eu GD 13 06 2019Sebastian PettersÎncă nu există evaluări

- Resume 2Document2 paginiResume 2api-699453949Încă nu există evaluări

- God Is Here by Darlene ZschechDocument1 paginăGod Is Here by Darlene ZschechEmanuel ScomparinÎncă nu există evaluări

- Crazy Gang PDFDocument3 paginiCrazy Gang PDFstartrekgameÎncă nu există evaluări

- Writing Unit Plan: Fractured Fairy TalesDocument16 paginiWriting Unit Plan: Fractured Fairy TaleslinneaannetteÎncă nu există evaluări

- S.No Name of The Student Reg - No Elective ChoosenDocument3 paginiS.No Name of The Student Reg - No Elective ChoosenHarshaÎncă nu există evaluări

- Ffenglrau - 24 2Document12 paginiFfenglrau - 24 2haileyyy86Încă nu există evaluări

- Chantons La Mlodie EspagnoleDocument4 paginiChantons La Mlodie EspagnoleKristinÎncă nu există evaluări

- Hubregt Industar 61 CleaningDocument45 paginiHubregt Industar 61 CleaningDino BajloÎncă nu există evaluări

- DessertsDocument3 paginiDessertseatlocalmenusÎncă nu există evaluări