Documente Academic

Documente Profesional

Documente Cultură

Creating an Assembly Line Program

Încărcat de

Neagoe CristianTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Creating an Assembly Line Program

Încărcat de

Neagoe CristianDrepturi de autor:

Formate disponibile

Creating a Program for an Assembly Line

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.1

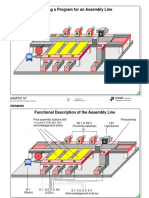

Functional Description of the Assembly Line

Final assembly stations with Preassembly

‘occupied‘ indicator and INI 1 to INI 3 LB1

acknowledgement button (Proximity switches) Light barrier

M1 H 1, H 2, H 3, H4 S 1, S 2, S 3, S 4

(Motor) (LEDs) (Acknowledgement buttons)

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.2

Program Structure

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.3

Configuration of the S7-300 Training Area

Version A

(16 channel

I/O modules)

Module --> PS CPU DI 16 DI 16 DO 16 DO 16 DI 16 DO 16 AI/AO4

Slot No. --> 1 2 4 5 6 7 8 9 10

I/O Address --> 0 4 8 12 16 20 352

Version B

(32 channel

I/O modules)

Module --> PS CPU DI 32 DO 32 DI8/DO8 AI 2

Slot No. --> 1 2 4 5 6 7

I/O Address --> 0 4 8 304

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.4

The Assembly Line

INI 1 to INI 3 LB1

(Proximity switches) Light barrier

M1 H 1, H 2, H 3, H4 S 1, S 2, S 3, S 4

(Motor) (LEDs) (Acknowledgement buttons)

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.5

Exercise: Creating a Project

Enter project

name here

and confirm

with "OK"

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.6

Exercise: Reading Out the Actual Configuration and Adapting It

Step What to Do Result

1 Start the SIMATIC Manager The tool is started

2 Open the project "My_Project" The project structure is displayed

3 Load the actual configuration using A new HW station is created

PLC -> Upload Station

4 Rename the station you inserted to

"My_Station"

Check whether the correct

5 ???

modules (order number) are entered

6 Enter the correct order numbers The CPU‘s parameter blocks

for the modules are displayed

Select the following parameters: The CPU and the analog module are

7 - CPU: flash. freq. MB 10, MPI networked assigned parameters

- Analog mod.: diagn. inter. channel 0/1

8 Save, compile and

load the configuration

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.7

Exercise: Importing a Symbol Table

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.8

Exercise: Checking the Sensors and Actuators of the Assembly Line

32 channel training unit

16 channel training unit

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.9

Procedure for Creating a Program

Define task

Docu-

menta-

Determine hardware tion

Define program structure

(Structogram)

Create program (LAD,FBD, STL)

Debug

Program test

Debug

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.10

Selection of the Appropriate CPU

1. Rough estimate using the following formula:

Number of instructions = (I+O)x logic nesting depth

2. Using the electronic catalog CA 01 to help make selections

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.11

Structogram for Program Creation

Define task

Define program structure

Parameter-assignable block?

Yes No

Define block parameters ./.

Create program

Errors exist?

Yes No

Debug ./.

Program test

Errors exist?

Yes No

Debug

./.

Repeat as long as there are errors

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.12

Elements of the Structogram (1)

Function Symbol

Structure block

SB

(Sequence)

SB 1

Series of SB 2

Sequences :

SB 3

Condition

Real Y N

Alternation

SB y SB n

Condition

Conditional Y N

Alternation

SB y ./.

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.13

Elements of the Structogram (2)

Function Symbol

1

2

Variable V= . . .

Multiple

3

branch,

Case n

SB 1 SB 2 SB 3 SB n

Start/End-

Condition SB

controlled

loop Condition

SB

SB 1

Jump out

of the loop Condition

SB 2

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.14

Structogram for the Operating Mode Section

yes I 0.0 = "1"

no

System On, Set output ./.

Q8.1(Q4.1)

yes I 0.1 = "0"

no

System On, Reset ./.

output Q8.1 (Q4.1)

Q8.1 (Q4.1)="1" and

I 0.4="0" and I 0.5="1"

yes no

Manual mode, Set output ./.

Q8.2 (Q4.2)

Q8.1 (Q4.1)="0" or

I 0.4="1" and I 0.5="1"

yes no

Manual mode, Reset ./.

output Q8.2 (Q4.2)

Q8.1 (Q4.1)="1" and

I 0.4="1" and I 0.5="1"

yes no

Automatic mode, Set ./.

output Q8.3 (Q4.3)

Q8.1 (Q4.1)="0" or

I 0.4="0" and I 0.5="1"

yes no

Automatic mode, Reset ./.

Q8.3(Q4.3)

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.15

Exercise: Programming the Assembly Line (Mode Selection)

System ON/OFF: Manual/Automatic mode:

I 0.0 = Start (Mom.-cont. swith with NO function) I 0.4 = Manual /Automatic (Switch)

I 0.1 = Stop (Mom.-cont. switch with NC function) I 0.5 = Adopt operating mode

(Mom.-cont. switch with NO

function)

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.16

Exercise: Create a Structogram for the Conveyor Movement

yes

no

./.

yes

no

./.

yes

no

./.

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.17

Exercise: Programming the Assembly Line (Conveyor Movement)

Manual/Automatic mode:

I 0.0 = Start (Mom.-cont. switch with NO function) I 0.4 = Manual /Automatic (Switch)

I 0.1 = Stop (Mom.-cont. switch with NC function) I 0.5 = Adopt operating mode (Mom.-cont.

switch with NO function)

I 0.2 = Jog foreward (M.-c. sw. with NO)

I 0.3 = Jog back (M.-c. sw. with NC func.)

Q20.5 (Q8.5) Conveyor belt forward <-- Q20.4 (Q8.4) LED H 4

Q20.6 (Q8.6) Conveyor belt back -->

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.18

Exercise: Programming the Assembly Line (Automatic Mode)

Manual /Automatic mode:

I 0.0 = Start (Mom.-cont. switch with NO function) I 0.4 = Manual /Automatic (Switch)

I 0.1 = Stop (Mom.-cont. switch with NC function) I 0.5 = Adopt operating mode (Mom.-cont.

switch with NO function)

I 0.2 = Jog foreward (M.-c. sw. with NO f.)

I 0.3 = Jog back (M.-c. sw. with NC func.)

I 16.5 to I 16.7 (I 8.5 to I 8.7) Proximity switches INI 1to INI 3 I 16.0 (I 8.0) Light barrier

Q20.7 (Q8.7) Horn

Q20.1 to Q20.3 (Q8.1 to Q8.3) LEDs H1 to H 3

I 16.1 to I 16.3 (I 8.1 to I 8.3) Acknowledgement switches S 1 to S 3

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.19

Exercise: Programming the Assembly Line (Statistic)

Quantity Bay 1 MW 100

Quantity Bay 2 MW 102

Quantity Bay 3 MW 104

Total quantity MW 106

% of prod. capacity Bay 1 MW 110

% of prod. capacity Bay 2 MW 112

% of prod. capacity Bay 3 MW 114

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.20

Exercise: Programming the Assembly Line (Display)

BCD coded BCD coded

pushwheel button digital display

0 00 2 0 0 0 3

0 00 0 Display EEEE

0 00 1 Display Parts Bay 1

0 00 2 Display Parts Bay 2

0 00 3 Display Parts Bay 3

0 00 4 Display Total Parts

0 00 5 Display EEEE

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.21

Exercise: Programming the Assembly Line (Startup)

OB 100

Network 1: RLO „0“

bit memory

Network 2: RLO „1“

bit memory

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.22

Additional Exercise: Programming the Assembly Line (Saving Data)

Save data every day at 16:10 (4:10 p.m.)

DB 10

Quantity Bay 1

Quantity Bay 2

Quantity Bay 3

Total quantity

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.23

Additional Exercise: Programming the Assembly Line

(Checking the Weight)

SIMATIC S7 Date: 18.08.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2000. All rights reserved. File: PRSERV_01E.24

S-ar putea să vă placă și

- PRSERV - 05E - SW Commissioning and TroubleshootingDocument12 paginiPRSERV - 05E - SW Commissioning and TroubleshootingNeagoe CristianÎncă nu există evaluări

- Digital Operations: CMP IDocument34 paginiDigital Operations: CMP INeagoe CristianÎncă nu există evaluări

- Documenting, Saving, Archiving: Simatic S7Document22 paginiDocumenting, Saving, Archiving: Simatic S7Neagoe CristianÎncă nu există evaluări

- PRO1 02E Training UnitsDocument11 paginiPRO1 02E Training UnitsLộc QuangÎncă nu există evaluări

- SERV1 04e SIMATICManagerDocument18 paginiSERV1 04e SIMATICManagerNeagoe CristianÎncă nu există evaluări

- S7 Automation SolutionsDocument25 paginiS7 Automation SolutionsNeagoe CristianÎncă nu există evaluări

- 663Document9 pagini663Ali Padaryam100% (1)

- Hardware Commissioning ChecklistDocument33 paginiHardware Commissioning ChecklistChihebJmaaÎncă nu există evaluări

- SERV1 01E SystemFamilyDocument44 paginiSERV1 01E SystemFamilynyamai20008234Încă nu există evaluări

- Digital Operations: Simatic S7Document35 paginiDigital Operations: Simatic S7SeVictor Rudas Caja100% (1)

- PRO1 13E Organzation BlocksDocument14 paginiPRO1 13E Organzation BlocksLộc QuangÎncă nu există evaluări

- Rewiring A User Program: Simatic S7Document16 paginiRewiring A User Program: Simatic S7Neagoe CristianÎncă nu există evaluări

- SCOUT TIA en-US PDFDocument330 paginiSCOUT TIA en-US PDFALEF -BEITÎncă nu există evaluări

- SERV1 01e SystemFamilyDocument19 paginiSERV1 01e SystemFamilyNeagoe CristianÎncă nu există evaluări

- SCE - EN - 040-020 - R1209 - Startup S7-SCLDocument30 paginiSCE - EN - 040-020 - R1209 - Startup S7-SCLBen Hur FabriÎncă nu există evaluări

- Sce 031 100 FC Programming s7 1200 r1709 enDocument54 paginiSce 031 100 FC Programming s7 1200 r1709 enandersonÎncă nu există evaluări

- 0 IK-PBSYS Cover15 V201Document1 pagină0 IK-PBSYS Cover15 V201Isai Anguiano33% (3)

- Siemens Automation Training CoursesDocument22 paginiSiemens Automation Training CoursesNeagoe CristianÎncă nu există evaluări

- Infoplc Net Sitrain 15 Documenting Saving ArchivingDocument26 paginiInfoplc Net Sitrain 15 Documenting Saving ArchivingBijoy RoyÎncă nu există evaluări

- PRO1 - 18E - What's Next PDFDocument6 paginiPRO1 - 18E - What's Next PDFLộc QuangÎncă nu există evaluări

- SIMOTION Service and Diagnostics en-US PDFDocument118 paginiSIMOTION Service and Diagnostics en-US PDFMazarel Aurel100% (1)

- SCE - EN - 051-300 PID Control S7-1200 - R1709Document50 paginiSCE - EN - 051-300 PID Control S7-1200 - R1709Nguyễn Duy ThànhÎncă nu există evaluări

- Serv1 06e HW ComDocument16 paginiServ1 06e HW ComNeagoe CristianÎncă nu există evaluări

- PRO2 - 11E - Solution SuggestionsDocument61 paginiPRO2 - 11E - Solution SuggestionsmikeÎncă nu există evaluări

- Programming Steps and Transitions: Simatic S7Document21 paginiProgramming Steps and Transitions: Simatic S7Irfan GaniÎncă nu există evaluări

- Serv1 - 11e - Introduction To Profibus DP and HmiDocument28 paginiServ1 - 11e - Introduction To Profibus DP and HmiAhmed KhairiÎncă nu există evaluări

- PROFIBUS Diagnostic Bundle for SIMATIC S7Document10 paginiPROFIBUS Diagnostic Bundle for SIMATIC S7Marius Nicusor PopescuÎncă nu există evaluări

- Graphic Screens (1) : Simatic HmiDocument120 paginiGraphic Screens (1) : Simatic HmiHenrique XavierÎncă nu există evaluări

- SERV1 09e BinaryOpDocument21 paginiSERV1 09e BinaryOpNeagoe CristianÎncă nu există evaluări

- PRO1 09E Introduction HMIDocument24 paginiPRO1 09E Introduction HMILộc QuangÎncă nu există evaluări

- SISTRAIN PRO3 02E FBs Multi Instances - 2 PDFDocument32 paginiSISTRAIN PRO3 02E FBs Multi Instances - 2 PDFSam eagle goodÎncă nu există evaluări

- SITRAIN - Logo! in Details (v6.1)Document146 paginiSITRAIN - Logo! in Details (v6.1)Jorge_Andril_5370100% (2)

- SITRAIN: Learn automation technology skills for Industry 4.0Document20 paginiSITRAIN: Learn automation technology skills for Industry 4.0bahmanÎncă nu există evaluări

- SITRAIN-S5 Upload-Step by StepDocument12 paginiSITRAIN-S5 Upload-Step by StepJorge_Andril_5370Încă nu există evaluări

- SCE en 011-101 Hardware Configuration S7-1200 R1709Document56 paginiSCE en 011-101 Hardware Configuration S7-1200 R1709shailesh284Încă nu există evaluări

- 00 - Register 20 deDocument1 pagină00 - Register 20 deahijado motaÎncă nu există evaluări

- Microsoft PowerPoint - 02 CommissioningDocument10 paginiMicrosoft PowerPoint - 02 CommissioningคุณทองดำÎncă nu există evaluări

- 01 IK IESYS e Communications OverviewDocument12 pagini01 IK IESYS e Communications OverviewHernando AlborÎncă nu există evaluări

- Sce 092 300 Opc Ua s7 1500 r1807 en - Compressed PDFDocument48 paginiSce 092 300 Opc Ua s7 1500 r1807 en - Compressed PDFOmkar Deshpande100% (1)

- Serv2 04e FC FBDocument27 paginiServ2 04e FC FBMarinel MoraruÎncă nu există evaluări

- Training Courses For SIMATIC S7-1500 in The TIA PortalDocument2 paginiTraining Courses For SIMATIC S7-1500 in The TIA PortalAssaad100% (1)

- SERV1 05E SymbolicDocument14 paginiSERV1 05E SymbolicAhmed KhairiÎncă nu există evaluări

- PRO1 10E Introduction MicromasterDocument20 paginiPRO1 10E Introduction MicromasterLộc QuangÎncă nu există evaluări

- 00 Register 20 en - SDocument1 pagină00 Register 20 en - SDanielÎncă nu există evaluări

- Analog Value Processing: High LevelDocument16 paginiAnalog Value Processing: High LevelMinh Chấp HuỳnhÎncă nu există evaluări

- 09 - CP342 5 DP MasterDocument18 pagini09 - CP342 5 DP MasterIsai AnguianoÎncă nu există evaluări

- PRO2 01eDocument14 paginiPRO2 01eghita_gabrielÎncă nu există evaluări

- SIMOTION - An Overview of Siemens' Motion Control SystemDocument17 paginiSIMOTION - An Overview of Siemens' Motion Control SystemWanderley Terci EstevesÎncă nu există evaluări

- 02 - 012-001 Firmware Update With SIMATIC S7-1500-En PDFDocument33 pagini02 - 012-001 Firmware Update With SIMATIC S7-1500-En PDFJerryÎncă nu există evaluări

- 01 PROFIBUS TechnologyDocument27 pagini01 PROFIBUS TechnologyIsai AnguianoÎncă nu există evaluări

- Sinamics Drivesim Basic Doc v105 enDocument136 paginiSinamics Drivesim Basic Doc v105 enJordan Pintado100% (1)

- 1 06 Comm STARTER PDFDocument25 pagini1 06 Comm STARTER PDFDanielÎncă nu există evaluări

- SCE EN 010-050 R1209 S7-1200 Analog ValuesDocument34 paginiSCE EN 010-050 R1209 S7-1200 Analog ValuesAlu menzikenÎncă nu există evaluări

- Block Technology (1) : SitrainDocument46 paginiBlock Technology (1) : SitrainEmerson KleemÎncă nu există evaluări

- 6 - Block Architecture and The LAD-STL-FBD EditorDocument27 pagini6 - Block Architecture and The LAD-STL-FBD EditorMichele BacocchiaÎncă nu există evaluări

- PRO1 01E SystemFamilyDocument39 paginiPRO1 01E SystemFamilySeVictor Rudas CajaÎncă nu există evaluări

- PRO1 10E IntroductionMicromasterDocument22 paginiPRO1 10E IntroductionMicromasterSeVictor Rudas CajaÎncă nu există evaluări

- Symbols: Simatic S7Document14 paginiSymbols: Simatic S7mhaioocÎncă nu există evaluări

- ST-SERV3 V58 enDocument262 paginiST-SERV3 V58 enAhmed Khairy100% (3)

- Training Units Addressing SetupDocument10 paginiTraining Units Addressing SetupING. OSCAR PACHECOÎncă nu există evaluări

- Pioneer Deh-1600ubb UgDocument100 paginiPioneer Deh-1600ubb UgFilipe BrandãoÎncă nu există evaluări

- Sitrain Information and Training For Automation and Drives: Very Good Average Sufficient Not Good SufficientDocument3 paginiSitrain Information and Training For Automation and Drives: Very Good Average Sufficient Not Good SufficientNeagoe CristianÎncă nu există evaluări

- S7 Automation SolutionsDocument25 paginiS7 Automation SolutionsNeagoe CristianÎncă nu există evaluări

- Rewiring A User Program: Simatic S7Document16 paginiRewiring A User Program: Simatic S7Neagoe CristianÎncă nu există evaluări

- Block Architecture and Block Editor: OB1 FB FC FBDocument25 paginiBlock Architecture and Block Editor: OB1 FB FC FBNeagoe CristianÎncă nu există evaluări

- SERV1 09e BinaryOpDocument21 paginiSERV1 09e BinaryOpNeagoe CristianÎncă nu există evaluări

- SERV1 09e BinaryOpDocument21 paginiSERV1 09e BinaryOpNeagoe CristianÎncă nu există evaluări

- Siemens Automation Training CoursesDocument22 paginiSiemens Automation Training CoursesNeagoe CristianÎncă nu există evaluări

- Block Architecture and Block Editor: OB1 FB FC FBDocument25 paginiBlock Architecture and Block Editor: OB1 FB FC FBNeagoe CristianÎncă nu există evaluări

- Serv1 06e HW ComDocument16 paginiServ1 06e HW ComNeagoe CristianÎncă nu există evaluări

- SERV1 08e SymbolsDocument15 paginiSERV1 08e SymbolsNeagoe CristianÎncă nu există evaluări

- SERV1 09e BinaryOpDocument21 paginiSERV1 09e BinaryOpNeagoe CristianÎncă nu există evaluări

- Hardware Configuration: Simatic S7Document25 paginiHardware Configuration: Simatic S7Neagoe CristianÎncă nu există evaluări

- SERV1 03e Install-MaintainDocument31 paginiSERV1 03e Install-MaintainNeagoe CristianÎncă nu există evaluări

- Hardware Configuration: Simatic S7Document25 paginiHardware Configuration: Simatic S7Neagoe CristianÎncă nu există evaluări

- Instructor S Guide ST-7PRSERV, A5.2: Project Structure - SolutionsDocument2 paginiInstructor S Guide ST-7PRSERV, A5.2: Project Structure - SolutionsNeagoe CristianÎncă nu există evaluări

- SERV1 01e SystemFamilyDocument19 paginiSERV1 01e SystemFamilyNeagoe CristianÎncă nu există evaluări

- SERV1 03e Install-MaintainDocument31 paginiSERV1 03e Install-MaintainNeagoe CristianÎncă nu există evaluări

- Profibus Diagnostic PDFDocument10 paginiProfibus Diagnostic PDFNeagoe CristianÎncă nu există evaluări

- SERV1 02e TrainingUnitsDocument7 paginiSERV1 02e TrainingUnitsNeagoe CristianÎncă nu există evaluări

- A Guide To Building Outdoor StairsDocument5 paginiA Guide To Building Outdoor StairssurfsandÎncă nu există evaluări

- 06 Synchronisation CAF BlockDocument13 pagini06 Synchronisation CAF BlockNeagoe CristianÎncă nu există evaluări

- Creating an Assembly Line ProgramDocument24 paginiCreating an Assembly Line ProgramNeagoe CristianÎncă nu există evaluări

- Introduction To PROFIBUS and Profinet: Andy Verwer Technical Officer For PROFIBUS UK Verwer Training & Consultancy LTDDocument31 paginiIntroduction To PROFIBUS and Profinet: Andy Verwer Technical Officer For PROFIBUS UK Verwer Training & Consultancy LTDNeagoe CristianÎncă nu există evaluări

- 04 Standard Rotary Pulse EncoderDocument8 pagini04 Standard Rotary Pulse EncoderNeagoe CristianÎncă nu există evaluări

- Add A RadiatorDocument6 paginiAdd A RadiatormickyalemuÎncă nu există evaluări

- Strength Vision Diversity Team: VF CorporationDocument55 paginiStrength Vision Diversity Team: VF Corporationmanisha_jha_11Încă nu există evaluări

- Basic Calculus: Quarter 3 - Module 3Document12 paginiBasic Calculus: Quarter 3 - Module 3Norman LoÎncă nu există evaluări

- Airbus A321-100 Lufthansa: Recolored by Cibula Papercraft 2019Document7 paginiAirbus A321-100 Lufthansa: Recolored by Cibula Papercraft 2019Siva Adithya100% (2)

- Sports Management Masters Thesis TopicsDocument7 paginiSports Management Masters Thesis Topicsaflnwcaabxpscu100% (2)

- UPE Universal Couplings and Flange AdaptorsDocument8 paginiUPE Universal Couplings and Flange AdaptorsnoormohammedahÎncă nu există evaluări

- Sophie Greenberg ResumeDocument1 paginăSophie Greenberg Resumeapi-317439954Încă nu există evaluări

- Case Study On Barriers To CommunicationDocument3 paginiCase Study On Barriers To CommunicationDivya Gill100% (1)

- Fiitjee: JEE (Advanced) - 2019Document16 paginiFiitjee: JEE (Advanced) - 2019Jyotiraditya BoseÎncă nu există evaluări

- Internship Guidelines MEDocument8 paginiInternship Guidelines MESrinivas SreekantanÎncă nu există evaluări

- Varicose Veins Treatment and DiagnosisDocument19 paginiVaricose Veins Treatment and DiagnosisnadiaÎncă nu există evaluări

- KPSC Assistant Professor in CS Question PaperDocument22 paginiKPSC Assistant Professor in CS Question PaperBabaÎncă nu există evaluări

- 41 PRODUCTION LINES Preguntas Cap1 Parte 1Document4 pagini41 PRODUCTION LINES Preguntas Cap1 Parte 1HysteriDanRoadzÎncă nu există evaluări

- Managerial Accounting InsightsDocument147 paginiManagerial Accounting InsightsSiddhantSinghÎncă nu există evaluări

- #SocializingheritageDocument38 pagini#SocializingheritageMiguel A. González LópezÎncă nu există evaluări

- Panasonic PT Dw640esDocument0 paginiPanasonic PT Dw640esAnonymous 1sYEEzÎncă nu există evaluări

- Tshooting DNS and Exchange 2000Document78 paginiTshooting DNS and Exchange 2000RamRyanÎncă nu există evaluări

- Department of Labor: Form WH-516 EnglishDocument1 paginăDepartment of Labor: Form WH-516 EnglishUSA_DepartmentOfLabor100% (1)

- Prospects and Challenges of Tourism in NepalDocument12 paginiProspects and Challenges of Tourism in NepalShrestha MilanÎncă nu există evaluări

- RFBT-13 (Banking Laws)Document10 paginiRFBT-13 (Banking Laws)Alliah Mae ArbastoÎncă nu există evaluări

- VECV Infra NormsDocument10 paginiVECV Infra Normsvikrantnair.enarchÎncă nu există evaluări

- CraneDocument27 paginiCranemsk7182Încă nu există evaluări

- Principles of Marketing Philip Kotler and Gary ArmstrongDocument16 paginiPrinciples of Marketing Philip Kotler and Gary ArmstrongDavid Achilles DamienÎncă nu există evaluări

- Entreprenuership - Case Example 1 Double HappinessDocument2 paginiEntreprenuership - Case Example 1 Double HappinessRonan FerrerÎncă nu există evaluări

- IFRS Reporting Standards PakistanDocument7 paginiIFRS Reporting Standards Pakistanamna hafeezÎncă nu există evaluări

- Ista 2BDocument5 paginiIsta 2Bduygu9merve100% (1)

- Knight EnchanterDocument2 paginiKnight EnchanterGiampiero Magalli100% (1)

- Bio (DWCL Main) - NoapplicDocument16 paginiBio (DWCL Main) - NoapplicPRC Board100% (1)

- BEA 242 Introduction To Econometrics Group Assignment (Updated On 10 May 2012: The Change in Highlighted)Document4 paginiBEA 242 Introduction To Econometrics Group Assignment (Updated On 10 May 2012: The Change in Highlighted)Reza Riantono SukarnoÎncă nu există evaluări

- Resumen 4 y 5 InglesDocument10 paginiResumen 4 y 5 InglesBilly YaniÎncă nu există evaluări

- Brucella Spp. Virulence Factors: and ImmunityDocument17 paginiBrucella Spp. Virulence Factors: and ImmunityBlanca SolisÎncă nu există evaluări