Documente Academic

Documente Profesional

Documente Cultură

06.production Charts and Systems - Gomez, Manalo

Încărcat de

mia palacio0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări21 paginixsfdf

Titlu original

06.Production Charts and Systems_Gomez,Manalo

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentxsfdf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări21 pagini06.production Charts and Systems - Gomez, Manalo

Încărcat de

mia palacioxsfdf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 21

PRODUCTION CHARTS

AND SYSTEMS

By: Gomez &

Manalo

Objectives:

Understanding Kinds of Production Charts

Identify the Production Systems

Understanding Two Types of Production System

Things that needed to consider in manpower assignment

Identify the number of manpower needed

Identify the number of machine needed

Production Charts

Charts that used in production to check/analyze the

scenario.

Kinds of Production Charts

• Man-Machine Chart

• The Project Layout Chart

• The Load or Bar Chart

• The Progress Chart

• Curve Charts

• Gantt Chart

Man-Machine Chart

The Project Layout Chart

The Load or Bar Chart

The Progress Chart

Curve Charts

Gantt Chart

GANTT CHART

e.g.

Production Systems

any of the methods used in industry to create goods

and services from various resources.

Manpower Assignment (Manpower planning)

very vital process

defined as a strategy for the procurement, development, allocation and

utilization of enterprise’s human resources

done to ensure the health of the business, credibility of the business and

growth of the business

done to ensure the health of the business, credibility of the business and

growth of the business

How many people Needed?

In this operation (casting the handle), the 05 indicates the operation

number. Usually, 05 is the first operation of each part.The 500 is the pieces

per hour standard. This operator should produce 500 pieces per hour. The

2.0 is the hours required to produce 1,000 pieces. At 500 pieces per

hour, it would take 2 hours to make 1,000 pieces. How many people would

be required to cast 2,000 handles per shift?

Machine Selection

One of the first questions raised when setting up a new

operationor starting production on a new product is,

“How many machines do we need?”

Units= 2000 wagons

Production Time=8 hours

Down time= 50 mins

Previous performance = 75%

Standard time = .400 mins per wagon body

Always round up to the next whole number. In the

preceding example, you would buy three machines. (Never

round down on your own. You will be building a bottleneck

in your plant.) This information is critical to the facility design.

S-ar putea să vă placă și

- Chapter 2 Day 15.1Document38 paginiChapter 2 Day 15.1HOÀNG PHẠM HUYÎncă nu există evaluări

- Lean Assignment 1Document11 paginiLean Assignment 1Vinoth Palaniswamy67% (6)

- Operation Bulletin: Lamia Anzum B.SC in Ipe, Sust Assistant Consultant, PPCGDocument17 paginiOperation Bulletin: Lamia Anzum B.SC in Ipe, Sust Assistant Consultant, PPCGইমরানুল শহীদ আলভীÎncă nu există evaluări

- Lesson 3 Importance and Uses of Time Study StudentDocument16 paginiLesson 3 Importance and Uses of Time Study StudentAllona Jean Pacquiao DayapÎncă nu există evaluări

- Production and Operations Management: Chelliah SriskandarajahDocument38 paginiProduction and Operations Management: Chelliah SriskandarajahKumar AashishÎncă nu există evaluări

- 12 Steps R 20031Document24 pagini12 Steps R 20031Tom WhybotherÎncă nu există evaluări

- 04 Capacity PlanningDocument19 pagini04 Capacity PlanningSalman AshrafÎncă nu există evaluări

- Capacity PlanningDocument29 paginiCapacity PlanningVicky Pandey67% (6)

- Formula#1Document13 paginiFormula#1AuraÎncă nu există evaluări

- Concept of Industrial Engineering (IE)Document27 paginiConcept of Industrial Engineering (IE)subbirÎncă nu există evaluări

- Articulo de SistemasDocument5 paginiArticulo de SistemasMariana PalenciaÎncă nu există evaluări

- October 2019process PlaningstionqueDocument8 paginiOctober 2019process Planingstionquekandasamy sivamuruganÎncă nu există evaluări

- 06 PPC Ch6 Capacity PlanningDocument20 pagini06 PPC Ch6 Capacity PlanningziadatzÎncă nu există evaluări

- Functions of Production Planning and ControlDocument5 paginiFunctions of Production Planning and ControlWidya Nila VelayatiÎncă nu există evaluări

- Facility Design: Facilities and Layout PlanningDocument36 paginiFacility Design: Facilities and Layout PlanningYasin Abdul HafiidhÎncă nu există evaluări

- Course Mba - 2 Semester Subject Assignment MB0044 - Set 1: Production and Operations ManagementDocument14 paginiCourse Mba - 2 Semester Subject Assignment MB0044 - Set 1: Production and Operations ManagementDantham ConpolwedsonÎncă nu există evaluări

- Current Scenario at Apparel Manufacturing ShopfloorDocument15 paginiCurrent Scenario at Apparel Manufacturing ShopfloorSanya MohindraÎncă nu există evaluări

- Industrial & System Engineering (MMV 14003) : C1: IntroductionDocument38 paginiIndustrial & System Engineering (MMV 14003) : C1: IntroductionMohd FairuzÎncă nu există evaluări

- Subject: Production and Operation Management Subject Code: MB0044 Assignment Set - 1Document13 paginiSubject: Production and Operation Management Subject Code: MB0044 Assignment Set - 1amit8214Încă nu există evaluări

- Capital or Machine ProductivityDocument91 paginiCapital or Machine ProductivitySarah Baylon100% (1)

- 15me62t U1 SyDocument17 pagini15me62t U1 SySeema PintoÎncă nu există evaluări

- Complete Semister 2nd 1 SetDocument90 paginiComplete Semister 2nd 1 SetNavin JalwaniaÎncă nu există evaluări

- BBA 305 - Production Management-Notes 1Document15 paginiBBA 305 - Production Management-Notes 1Snehash Sinha67% (6)

- Cbmec Midterm LessonsDocument7 paginiCbmec Midterm LessonsMyunimintÎncă nu există evaluări

- Product, Process and Schedule DesignDocument69 paginiProduct, Process and Schedule DesignIram Chavira100% (1)

- Value Stream Mapping On Gear Manufacturing CompanyDocument7 paginiValue Stream Mapping On Gear Manufacturing CompanyAmandeep SinghÎncă nu există evaluări

- Production & Operations Management: Course: Master of Business Administration (MBA)Document11 paginiProduction & Operations Management: Course: Master of Business Administration (MBA)Dinesh Reghunath RÎncă nu există evaluări

- CH - 3 Inventory MGMTDocument12 paginiCH - 3 Inventory MGMTVartika AgarwalÎncă nu există evaluări

- MB0044 Set 1Document12 paginiMB0044 Set 1Bela JadejaÎncă nu există evaluări

- Productio N &operati Ons Manage MentDocument110 paginiProductio N &operati Ons Manage MentPrathap VasuÎncă nu există evaluări

- FP Lec 3Document42 paginiFP Lec 3engbabaÎncă nu există evaluări

- Toyota Inventory ManagementDocument26 paginiToyota Inventory ManagementHarshGarbyal63% (16)

- PM FinalDocument74 paginiPM FinalarunimdrÎncă nu există evaluări

- Lean Glossary of TermsDocument16 paginiLean Glossary of TermskrishnaÎncă nu există evaluări

- Gizmoz Study CaseDocument4 paginiGizmoz Study CaseInge Monica100% (1)

- What Are The Components of Systems Productivity? Explain How CAD and CIM Help in Improving Productivity. AnsDocument15 paginiWhat Are The Components of Systems Productivity? Explain How CAD and CIM Help in Improving Productivity. AnsSatprit SinghÎncă nu există evaluări

- 1 PDFDocument58 pagini1 PDFMK ReddyÎncă nu există evaluări

- Production StudiesDocument40 paginiProduction StudiessdvikkiÎncă nu există evaluări

- Benefits Parallel ProcessingDocument4 paginiBenefits Parallel ProcessingAnnaKarenina56Încă nu există evaluări

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowDe la EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowEvaluare: 4 din 5 stele4/5 (1)

- Lean ManufacturingDocument69 paginiLean ManufacturingVinay InavoluÎncă nu există evaluări

- Unit 1 1. What Is Operation Management? Discuss About Scope and Objectives?Document48 paginiUnit 1 1. What Is Operation Management? Discuss About Scope and Objectives?Sudheer NaiduÎncă nu există evaluări

- PMu 2Document10 paginiPMu 2chidambaram_57473284Încă nu există evaluări

- Project Report On TPS in Brakes India PVT LTDDocument21 paginiProject Report On TPS in Brakes India PVT LTDChandru Paramasivam100% (2)

- Project Report On Tps in Brakes India PVT LTDDocument21 paginiProject Report On Tps in Brakes India PVT LTDkumaran100% (1)

- Ans - All SubjectDocument3 paginiAns - All SubjectEmad Al-AmadÎncă nu există evaluări

- 05-Chapter 5 Automated Work Cells and CIM Systems FinalDocument33 pagini05-Chapter 5 Automated Work Cells and CIM Systems FinalBenu MadhabÎncă nu există evaluări

- Assignment 3 - 174660920-145 - PomDocument10 paginiAssignment 3 - 174660920-145 - PomUMAR FAROOQÎncă nu există evaluări

- Chapter 10-Eneman20Document4 paginiChapter 10-Eneman20Reynald John PastranaÎncă nu există evaluări

- Production & Operations ManagementDocument11 paginiProduction & Operations ManagementDinesh Reghunath RÎncă nu există evaluări

- Production & Planning - SynopsisDocument22 paginiProduction & Planning - Synopsisbrijesh99Încă nu există evaluări

- FP Lec 3 (Compatibility Mode)Document25 paginiFP Lec 3 (Compatibility Mode)yehyaÎncă nu există evaluări

- Capacity Planning Chapter 4Document33 paginiCapacity Planning Chapter 4Alfred WijayaÎncă nu există evaluări

- Lec 1 Production SystemsDocument39 paginiLec 1 Production SystemslympazzkarimiÎncă nu există evaluări

- CCCCCCCCCCCCCCCCCCCCCCCCC CCC: Ôc" C Ôc C C C C C CC Ôcc C C C C C Ôc C C CC C C C C C C C C C C C C C CDocument21 paginiCCCCCCCCCCCCCCCCCCCCCCCCC CCC: Ôc" C Ôc C C C C C CC Ôcc C C C C C Ôc C C CC C C C C C C C C C C C C C CAnjesh KumarÎncă nu există evaluări

- 1.PPC IntroductionDocument70 pagini1.PPC IntroductionAbhinav ReddyÎncă nu există evaluări

- Job & Mass ProductionDocument1 paginăJob & Mass ProductionSandy SiddarthÎncă nu există evaluări

- How to Create Continuous Production Flow?: Toyota Production System ConceptsDe la EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsEvaluare: 5 din 5 stele5/5 (1)

- Practical Guide To Production Planning & Control [Revised Edition]De la EverandPractical Guide To Production Planning & Control [Revised Edition]Evaluare: 1 din 5 stele1/5 (1)

- Lecture 3. Descriptive StatisticsDocument29 paginiLecture 3. Descriptive Statisticsmia palacioÎncă nu există evaluări

- Full File at Http://testbankshop - eu/OM-5-5th-Edition-Collier-Test-BankDocument12 paginiFull File at Http://testbankshop - eu/OM-5-5th-Edition-Collier-Test-Bankmia palacioÎncă nu există evaluări

- Lecture 3. Descriptive StatisticsDocument10 paginiLecture 3. Descriptive Statisticsmia palacioÎncă nu există evaluări

- Plant Location and Buildings WrittenDocument16 paginiPlant Location and Buildings Writtenmia palacioÎncă nu există evaluări

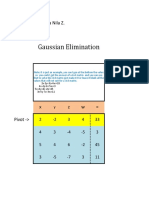

- Palacio, Maria Nila Gauss JordanDocument23 paginiPalacio, Maria Nila Gauss Jordanmia palacioÎncă nu există evaluări

- Critical Review: Metals in Cigarette SmokeDocument5 paginiCritical Review: Metals in Cigarette Smokemia palacioÎncă nu există evaluări

- Sr611 Use Shell Aggregates b54Document24 paginiSr611 Use Shell Aggregates b54mia palacioÎncă nu există evaluări

- Bernette Ramirez Mariano Bernette Ramirez MarianoDocument1 paginăBernette Ramirez Mariano Bernette Ramirez Marianomia palacioÎncă nu există evaluări

- Studies On Coconut Sapal Iii. Mannan in The Developing NutDocument4 paginiStudies On Coconut Sapal Iii. Mannan in The Developing Nutmia palacioÎncă nu există evaluări

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)