Documente Academic

Documente Profesional

Documente Cultură

3.3 E-OLSS Control Valve

Încărcat de

eko sunaryoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

3.3 E-OLSS Control Valve

Încărcat de

eko sunaryoDrepturi de autor:

Formate disponibile

E-OLSS: Control Valve.

Section 3.3

Section 3.3 E-OLSS

E-OLSS Control Valve

Control Valve.

The valve is a Open centre Load

Sensing System with the jet sensors

installed into the control valve.

Jet Sensors detect the flow of return

oil passing through the control valve

and returning to tank. The two

pressures Pt and Pd are sent to the

NC valve.

The main relief valve maintains

maximum work pressure.

Built into the control valves are the

straight travel, arm throttle and swing

priority valves.

Two Stage

relief

Section 3.3 E-OLSS

E-OLSS Control Valve

Jet Sensors: Levers in Neutral

Oil carry over from the control valve flow through the jet sensors.

When levers are in the neutral position there is a small flow from the pump returning to

tank.

The jet stream coming out of the Jet Sensor Orifice is uninterrupted filling Pt sense line

back to NC valve.

Jet Sensor Out-put

Pressure Pt Jet Sensor Out-put

Pressure Pd

Jet Stream

Orifice

Section 3.3 E-OLSS

E-OLSS Control Valve

Jet Sensors: Levers Operated.

As the machine starts to operate the oil flow in the control valve increases.

When the differential pressure

Pt – Pd reaches 15 Kg/cm2 (at 40 l/min) the relief valve opens.

Now almost all the carry over oil (Qc) is being discharged through the relief valve.

A small amount is passing through Jet Sensor Orifice.

Pt (Jet Sensor

output pressure)

Pt

Pd (Back pressure)

Pd

Pump

pressure Qc

Section 3.3 E-OLSS

E-OLSS Control Valve

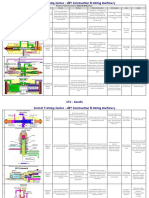

Straight Travel Valve (PC1250-7).

The straight travel valve is installed into

the control valve.

It acts to prevent and deviation in the

direction of travel if the boom, arm, or

bucket are operated when the machine

is traveling.

Section 3.3 E-OLSS

E-OLSS Control Valve

Travel operating Independently

The straight travel solenoid is de-

energised, so no pilot pressure is

flowing to the spool.

Ports P1 and P2 are not connected each

circuit remains independent.

Section 3.3 E-OLSS

E-OLSS Control Valve

When travel and work

equipment are operated

together.

The straight travel solenoid is

excited and pilot pressure is flowing

to spool (6), pushing it across to the

left.

Ports P1 and P2 are now

interconnected so the same amount

of oil is delivered to both travel

motors evenly.

This prevents travel deviation.

Section 3.3 E-OLSS

E-OLSS Control Valve

Straight

Travel Control Valve (PC200-5)

Built into the control valve are:

1. Straight Travel valve.

2. Arm Throttle valve.

3. Swing Priority valve.

The control valve is manufactured in

two halves, they are bolted together

sharing common galleries.

Swing

Priority

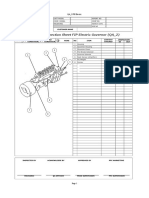

Section 3.3 E-OLSS

E-OLSS Control Valve

Arm Operated Independently Arm and Boom

Arm Throttle Valve.

When the arm control lever and boom control lever are operated at the same time,

most of the pressure oil flows t the arm circuit, where the load is less.

When this happens the arm throttle valve is switched and the flow of oil to the arm

control valve is restricted.

Section 3.3 E-OLSS

E-OLSS Control Valve

When Swing is not operated When Swing is operated with

with Arm circuit. Arm Circuit.

Swing Priority Valve.

When operating swing and arm at the same time, most of the oil flows to the arm which

has less load. The flow to the swing circuit is reduced so arm speed is fast.

To prevent this the swing priority valve is switched to restrict the flow of pressure oil

to the arm control valve.

Section 3.3 E-OLSS

E-OLSS Control Valve

Text

Section 3.3 E-OLSS

E-OLSS

End of

E - OLSS

Section 3.3 E-OLSS

S-ar putea să vă placă și

- 3.2 E-OLSS PumpDocument19 pagini3.2 E-OLSS PumpEko Sunaryo92% (13)

- 3 3 E OLSS Control ValveDocument12 pagini3 3 E OLSS Control ValveSumitomo ExcavatorÎncă nu există evaluări

- D85EX-15 Power TrainDocument29 paginiD85EX-15 Power TrainQuy Le Thanh100% (2)

- LS Circuit IntroductionDocument18 paginiLS Circuit IntroductionMuhammad DaniÎncă nu există evaluări

- Fan Motor D155ax-6 Lmf75 Test 50495Document12 paginiFan Motor D155ax-6 Lmf75 Test 50495Interclima SpaÎncă nu există evaluări

- 2.6 CLSS Electronics.Document7 pagini2.6 CLSS Electronics.Riahi Rezeg100% (2)

- 2.3 CLSS Control ValveDocument17 pagini2.3 CLSS Control ValveSatria Fajri100% (5)

- 2.2 CLSS PumpsDocument47 pagini2.2 CLSS PumpsKevine Khaled100% (2)

- PPM Rebuild Unit Manual: Testing MethodDocument15 paginiPPM Rebuild Unit Manual: Testing MethodNGUYENTHEPHAT100% (2)

- PPM Rebuild Unit Manual: Testing MethodDocument17 paginiPPM Rebuild Unit Manual: Testing MethodNGUYENTHEPHAT100% (1)

- D375A-6 Cooling SystemDocument26 paginiD375A-6 Cooling Systemalcowo100% (3)

- Pilot Pressure Proportional Control (PPC)Document16 paginiPilot Pressure Proportional Control (PPC)Muhammad Dani100% (1)

- 00 - Main Pump ControlDocument24 pagini00 - Main Pump ControlSatria Fajri50% (2)

- D85EX-15 Hydraulic SystemDocument6 paginiD85EX-15 Hydraulic SystemQuy Le Thanh100% (1)

- Pump Control PW200 220-7Document21 paginiPump Control PW200 220-7Teknik Makina100% (1)

- EEN00008-00 HPV160+160 (190+190cc) PC450-7 Pump TestDocument27 paginiEEN00008-00 HPV160+160 (190+190cc) PC450-7 Pump TestNGUYENTHEPHAT100% (3)

- CLSS Control ValveDocument17 paginiCLSS Control Valvedoan luc100% (3)

- Test Manual EEN00015-00Document21 paginiTest Manual EEN00015-00Alex Bravo100% (2)

- PC210LC-11 SEN06695-01 Hydraulic SystemDocument125 paginiPC210LC-11 SEN06695-01 Hydraulic SystemdatphuongÎncă nu există evaluări

- PPM REBUILT UNIT MANUAL II TESTING METHOD FOR HPV95+95 PUMPDocument22 paginiPPM REBUILT UNIT MANUAL II TESTING METHOD FOR HPV95+95 PUMPNGUYENTHEPHAT100% (3)

- D375A-6 Work EquipmentDocument42 paginiD375A-6 Work Equipmentalcowo100% (3)

- PPM REBUILT UNIT MANUAL TESTING METHODDocument22 paginiPPM REBUILT UNIT MANUAL TESTING METHODAlonso Inostroza100% (1)

- CLSS Control Valve: Features, Advantages & Circuit DiagramDocument17 paginiCLSS Control Valve: Features, Advantages & Circuit DiagramIan Deltrax80% (5)

- Quality Assurance: Running-In / Run-In OperationDocument14 paginiQuality Assurance: Running-In / Run-In OperationX'mix Đreamer100% (1)

- Sebh539010 S PC750-6 PPDocument15 paginiSebh539010 S PC750-6 PPmax100% (1)

- PC200-8 ImprovementDocument57 paginiPC200-8 Improvementdedy imran100% (10)

- 4 SH130-5 Hydraulic VerDocument60 pagini4 SH130-5 Hydraulic VerHeri handrias100% (2)

- 03.hyd System Part1Document69 pagini03.hyd System Part1Samidi100% (5)

- Testing Methods For Rebuild UnitsDocument8 paginiTesting Methods For Rebuild UnitsBhone ThantÎncă nu există evaluări

- Komatsu 125 3 Engine InjectorDocument27 paginiKomatsu 125 3 Engine Injectorhaimay118Încă nu există evaluări

- 1.6 Hoses, Pipes & FittingsDocument17 pagini1.6 Hoses, Pipes & FittingsKevine Khaled100% (2)

- OLSS & EOLSS Valves - S&F - A3 SizeDocument4 paginiOLSS & EOLSS Valves - S&F - A3 Sizeprem sagar100% (3)

- SV540 Shop Manual CompressedDocument306 paginiSV540 Shop Manual CompressedMarvin Figueroa100% (1)

- Training Module On Equipment Lay OutDocument6 paginiTraining Module On Equipment Lay OutPrudz100% (6)

- PC200-8 ImprovementDocument57 paginiPC200-8 Improvementdedy imran100% (1)

- CLSSDocument74 paginiCLSSSurya Prakash100% (9)

- Pump Device Kel.1Document20 paginiPump Device Kel.1Ahmad MubarokÎncă nu există evaluări

- PC200-7 Service Jan2002Document61 paginiPC200-7 Service Jan2002Edi Kuswari100% (6)

- Directional Control Valves (DCV) GuideDocument18 paginiDirectional Control Valves (DCV) Guidedoan luc100% (1)

- LS Circuit IntroductionDocument18 paginiLS Circuit IntroductionSatria Fajri75% (4)

- Hydraulic Circuit Diagram PC1250-8R PDFDocument1 paginăHydraulic Circuit Diagram PC1250-8R PDFBambang Esa100% (4)

- D155AX 6 IntroductionDocument123 paginiD155AX 6 Introductionzl100% (8)

- D85EX-15 Hydraulic FanDocument9 paginiD85EX-15 Hydraulic FanQuy Le Thanh67% (3)

- PPM Rebuilt Unit Manual: Testing MethodDocument35 paginiPPM Rebuilt Unit Manual: Testing MethodNGUYENTHEPHAT100% (3)

- Komatsu PC200Document15 paginiKomatsu PC200Kevine Khaled100% (4)

- CLSS & ECLSS Valves - S&F - A3 SizeDocument4 paginiCLSS & ECLSS Valves - S&F - A3 Sizeprem sagar100% (1)

- Hydraulic Excavator Attachment Circuit DiagramDocument6 paginiHydraulic Excavator Attachment Circuit DiagramPrudz100% (3)

- PC200/200LC-8M0 Product Bulletin Highlights Fuel Efficiency GainsDocument37 paginiPC200/200LC-8M0 Product Bulletin Highlights Fuel Efficiency GainsLinbergÎncă nu există evaluări

- Hd465-7eo SM Sen01081-08 PDFDocument1.613 paginiHd465-7eo SM Sen01081-08 PDFJorge Rodolfo Yanez EscuderoÎncă nu există evaluări

- ENGINE RUNS ROUGH TROUBLESHOOTINGDocument25 paginiENGINE RUNS ROUGH TROUBLESHOOTINGJuanto100% (1)

- L.H. 5-Spool Control ValveDocument47 paginiL.H. 5-Spool Control ValveSamidi100% (1)

- Portal Komatsu Pc210-10m0Document69 paginiPortal Komatsu Pc210-10m0Olab BolaÎncă nu există evaluări

- PM PC1250SP-8Document25 paginiPM PC1250SP-8Teguh Imam AdriÎncă nu există evaluări

- PC600 - PC600LC-7 Uebm002600 - 0403Document674 paginiPC600 - PC600LC-7 Uebm002600 - 0403Michał BujaraÎncă nu există evaluări

- Rebuilt Unit Testing MethodsDocument12 paginiRebuilt Unit Testing MethodsChristian Moreno100% (1)

- Ut e PDFDocument12 paginiUt e PDFYadiÎncă nu există evaluări

- Control Valve Jet Sensors & Relief Valve OperationDocument12 paginiControl Valve Jet Sensors & Relief Valve OperationEko Sunaryo92% (13)

- 3-2-Way Pneumatic ValveDocument6 pagini3-2-Way Pneumatic ValveĐặng Trung AnhÎncă nu există evaluări

- Hydraulic Control ValvesDocument22 paginiHydraulic Control ValvesUdayanka Madushan100% (2)

- Assignment No 3 IHPDocument6 paginiAssignment No 3 IHPJaid KhanÎncă nu există evaluări

- 11 Building Block PDFDocument18 pagini11 Building Block PDFeko sunaryoÎncă nu există evaluări

- 11 Building Block PDFDocument18 pagini11 Building Block PDFeko sunaryoÎncă nu există evaluări

- Electrical System: Service Data AlternatorDocument22 paginiElectrical System: Service Data Alternatoreko sunaryoÎncă nu există evaluări

- Maintenance For NK-550VRDocument14 paginiMaintenance For NK-550VReko sunaryoÎncă nu există evaluări

- 10 IC ApplicationDocument18 pagini10 IC Applicationeko sunaryoÎncă nu există evaluări

- (Shrinked) - Marketing Winch Presentation (Introduction)Document15 pagini(Shrinked) - Marketing Winch Presentation (Introduction)eko sunaryoÎncă nu există evaluări

- QA_2 FIP Electric Governor Inspection ReportDocument1 paginăQA_2 FIP Electric Governor Inspection Reporteko sunaryo100% (1)

- CurvaDocument1 paginăCurvaeko sunaryoÎncă nu există evaluări

- Assembly Fip Electical: JakartaDocument5 paginiAssembly Fip Electical: Jakartaeko sunaryoÎncă nu există evaluări

- Performance DataDocument1 paginăPerformance Dataeko sunaryoÎncă nu există evaluări

- CanDocument17 paginiCaneko sunaryoÎncă nu există evaluări

- Sub Bab IB Bipolar Junction TransistorDocument14 paginiSub Bab IB Bipolar Junction Transistoreko sunaryoÎncă nu există evaluări

- TI 07 006 DF AdjustmentDocument12 paginiTI 07 006 DF Adjustmenteko sunaryoÎncă nu există evaluări

- CRI Pump & ControllerDocument5 paginiCRI Pump & Controllereko sunaryo100% (1)

- Weapons of The Waffen-SS - From Small Arms To TanksDocument1 paginăWeapons of The Waffen-SS - From Small Arms To Tankseko sunaryoÎncă nu există evaluări

- Product Catalogue - RotaryDocument36 paginiProduct Catalogue - Rotaryeko sunaryoÎncă nu există evaluări

- New Generation KOMATSU Engines: Establishing a Global Service Network for Common Rail TechnologyDocument18 paginiNew Generation KOMATSU Engines: Establishing a Global Service Network for Common Rail Technologyeko sunaryoÎncă nu există evaluări

- Testing & Adjusting: SAA6D140/125-CRIDocument20 paginiTesting & Adjusting: SAA6D140/125-CRIeko sunaryo100% (1)

- Compressor X Ah 4 P To EnglishDocument23 paginiCompressor X Ah 4 P To Englisheko sunaryoÎncă nu există evaluări

- Trouble Code Indication Procedure Trouble Code Erasure ProcedureDocument2 paginiTrouble Code Indication Procedure Trouble Code Erasure Procedureeko sunaryoÎncă nu există evaluări

- BR 1Document66 paginiBR 1eko sunaryoÎncă nu există evaluări

- CRI Test Harness PDFDocument2 paginiCRI Test Harness PDFeko sunaryoÎncă nu există evaluări

- Ea PDFDocument5 paginiEa PDFeko sunaryoÎncă nu există evaluări

- PLC Roc F9 C9Document10 paginiPLC Roc F9 C9eko sunaryoÎncă nu există evaluări

- CatSEBU7457!01!01 EnglishDocument126 paginiCatSEBU7457!01!01 Englisheko sunaryoÎncă nu există evaluări

- Atlas Copco ROC F9-TH System DescriptionDocument87 paginiAtlas Copco ROC F9-TH System Descriptioneko sunaryo100% (2)

- CatSEBU7502 05 EnglishDocument122 paginiCatSEBU7502 05 Englisheko sunaryo100% (1)

- 9852 1707 01a Operator's Instructions ROC F9Document164 pagini9852 1707 01a Operator's Instructions ROC F9eko sunaryo75% (4)

- 9852 1696 01 Maintenance Schedules ROC F7Document53 pagini9852 1696 01 Maintenance Schedules ROC F7eko sunaryo100% (2)

- Docking Report Hb. Orchid 04Document2 paginiDocking Report Hb. Orchid 04Aditya Permana PutraÎncă nu există evaluări

- Surface PreparationDocument13 paginiSurface PreparationDacher Daniel100% (1)

- PS-490 a-S-H Double Roll GrinderDocument2 paginiPS-490 a-S-H Double Roll GrinderKetan PathakÎncă nu există evaluări

- Six SigmaDocument145 paginiSix SigmaMaria LopezÎncă nu există evaluări

- General Specifications (Civil Works)Document22 paginiGeneral Specifications (Civil Works)Richard FallegaÎncă nu există evaluări

- Dimensions: VAZ-2T1-FK-V1Document1 paginăDimensions: VAZ-2T1-FK-V1richard_qrÎncă nu există evaluări

- Perkins 500P PDFDocument5 paginiPerkins 500P PDFsaleemÎncă nu există evaluări

- Recoil Offgrid - August, September 2015Document116 paginiRecoil Offgrid - August, September 2015oiii88Încă nu există evaluări

- Automatic Operators Catalog 2009Document82 paginiAutomatic Operators Catalog 2009DoorhanÎncă nu există evaluări

- Motor Starting Analysis ImpactsDocument2 paginiMotor Starting Analysis ImpactsBhavik PrajapatiÎncă nu există evaluări

- Application Tip: Using 2 Paralleling OptionDocument3 paginiApplication Tip: Using 2 Paralleling OptionMohamed MeeranÎncă nu există evaluări

- Construction EstimatorDocument2 paginiConstruction Estimatorapi-76938856Încă nu există evaluări

- May 2011 IssueDocument102 paginiMay 2011 IssuePumper MagazineÎncă nu există evaluări

- Teadit GR 1520: Product InformationDocument1 paginăTeadit GR 1520: Product Informationunnamed90Încă nu există evaluări

- Module #4 Circuit Protection OverviewDocument56 paginiModule #4 Circuit Protection OverviewReymart ManablugÎncă nu există evaluări

- Bioreactor Design Specifications for 100 Ton Per Day Bioethanol ProductionDocument18 paginiBioreactor Design Specifications for 100 Ton Per Day Bioethanol ProductionAndriyaniÎncă nu există evaluări

- Tube Rupture in A Natural Gas HeaterDocument4 paginiTube Rupture in A Natural Gas HeaterSrinivas BobbyÎncă nu există evaluări

- Byelaws of MohaliDocument42 paginiByelaws of MohaliAkshay GuptaÎncă nu există evaluări

- Amerian CVDocument6 paginiAmerian CVpayamamerian5200Încă nu există evaluări

- Multi-Storey Precast Concrete Framed Structures Kim S ElliottDocument4 paginiMulti-Storey Precast Concrete Framed Structures Kim S ElliottAiman BadhrulhishamÎncă nu există evaluări

- Adel Resume.Document4 paginiAdel Resume.adelsamhanÎncă nu există evaluări

- 2012 Leatherman Military CatalogDocument28 pagini2012 Leatherman Military CatalogMario LopezÎncă nu există evaluări

- Submittal For Materials: 1. MATERIAL DESCRIPTION (One Item Only On This Form) : S.No Material Name Company Name AddressDocument1 paginăSubmittal For Materials: 1. MATERIAL DESCRIPTION (One Item Only On This Form) : S.No Material Name Company Name AddressharishÎncă nu există evaluări

- CM4626 Espresso Machine PDFDocument28 paginiCM4626 Espresso Machine PDFMic X100% (1)

- Steel PipesDocument16 paginiSteel PipesAdam GordonÎncă nu există evaluări

- Aula 21 - Irganox 1010Document2 paginiAula 21 - Irganox 1010Kaiomax2000100% (1)

- Wheel Loader: Inspection Parameter ChecklistDocument4 paginiWheel Loader: Inspection Parameter ChecklistSonofwill Auger OdagledÎncă nu există evaluări

- Consolidated Question Bank 4Document3 paginiConsolidated Question Bank 4Ajitsingh JagtapÎncă nu există evaluări

- ASCE2011Madhu ManderDocument4 paginiASCE2011Madhu ManderNattalia RomeroÎncă nu există evaluări

- DatasheetDocument6 paginiDatasheetTuVLÎncă nu există evaluări