Documente Academic

Documente Profesional

Documente Cultură

1.6a Line Sizing Slides

Încărcat de

Sanju Chauhan0 evaluări0% au considerat acest document util (0 voturi)

64 vizualizări24 paginiThis document discusses common issues with line sizing in piping systems. It notes that 31% of large property damage losses are due to piping system failures. Some key issues covered include:

- Mass and energy balances that are missing important factors can lead to improperly sized lines.

- Guidelines around limiting line velocities are sometimes ignored, which can cause erosion or settling issues.

- Poor record keeping during engineering phases makes detailed design difficult.

- Two-phase and compressible fluid flows are often not well understood and can cause damaging pulsating or choked flows if not addressed properly.

- Maldistribution, water hammer, vortexing, and unexpected temperature effects must be considered to select the proper pipes

Descriere originală:

Titlu original

1.6a_Line_Sizing_Slides.ppt

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document discusses common issues with line sizing in piping systems. It notes that 31% of large property damage losses are due to piping system failures. Some key issues covered include:

- Mass and energy balances that are missing important factors can lead to improperly sized lines.

- Guidelines around limiting line velocities are sometimes ignored, which can cause erosion or settling issues.

- Poor record keeping during engineering phases makes detailed design difficult.

- Two-phase and compressible fluid flows are often not well understood and can cause damaging pulsating or choked flows if not addressed properly.

- Maldistribution, water hammer, vortexing, and unexpected temperature effects must be considered to select the proper pipes

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

64 vizualizări24 pagini1.6a Line Sizing Slides

Încărcat de

Sanju ChauhanThis document discusses common issues with line sizing in piping systems. It notes that 31% of large property damage losses are due to piping system failures. Some key issues covered include:

- Mass and energy balances that are missing important factors can lead to improperly sized lines.

- Guidelines around limiting line velocities are sometimes ignored, which can cause erosion or settling issues.

- Poor record keeping during engineering phases makes detailed design difficult.

- Two-phase and compressible fluid flows are often not well understood and can cause damaging pulsating or choked flows if not addressed properly.

- Maldistribution, water hammer, vortexing, and unexpected temperature effects must be considered to select the proper pipes

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 24

Where We Go Wrong

In Line Sizing

Dick Hawrelak

Presented to ES317Y in 1999 at UWO

Introduction

31% of large property damage

losses are caused by failures in

piping systems.

Some lines reach 60 inches in

diameter - larger than many

equipment items.

Mass and Energy Balances

MB & EB balances must include:

Normal mass balance - base case.

Start-up, shut down or upset dev’n.

Recycle of off-spec products.

Equipment bypass conditions.

MB for flare, fire water, sewers,

steam, condensate and CTW

headers.

Poor Line Sizing

Guidelines

Limiting line velocities not known

or ignored.

Velocity greater than 15 fps in CS

pipe can cause erosion.

Low velocities (< 3 fps) can cause

entrained solids to settle and plug

lines.

Poor Line Sizing

Engineering Discipline

Poor record keeping during Phase 3

prevents detailed follow-up in Phase

4 design stage.

PSV lines need to be checked in

Phase 4.

Pump lines need to be checked in

Phase 4.

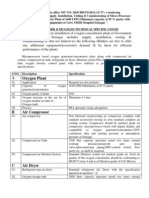

Poor Pipe Selection

Corrosiveness of fluid unknown.

At high temps, degradation may

produce acidic components. (La.

HumbleTherm example).

Pipe not suitable for unexpected cold

temperatures.

Pipe not suitable for unexpected

extreme high temperatures.

Choked Flow Of

Compressible Fluids

Compressible fluid flow not well

understood by process engineers.

Flows at Mach 1 (Sonic Flow) can

be destructive.

Choked Flow Example

1

Choked Flow Example

2

Two-Phase Flow

Two Phase Flow not well

understood by process engineers.

Horizontal Flow - Baker Chart.

Vertical Down Flow.

Vertical Up Flow.

Baker Chart

Horizontal, Two Phase Flow

Two-Phase Flow In

Vertical Down Flow

Piping

Siphons may form readily

May have damaging pulsating flow

Vertical Down Flow

Piping

Two-Phase Flow In

Vertical Up Flow Piping

May have damaging pulsating flow

4 ft. dia. Cooling tower inlet pipe

experiences severe vibration, fails

& floods plant

Vertical Up Flow Piping

Two-Phase Flow

Pressure Drop

Two phase flow pressure drops

may be higher than expected and

thereby limit performance.

Two-Phase Flashing

Fluids

Flashing liquids often not

considered during process design.

Two phase flow can be a complex,

transient problem.

Two-Phase Flow In

PSV Systems

PSVs are usually sized for single

phase flow.

Two phase flow can occur when

vessels operated above maximum

fill limit.

Two phase flow can occur when

flows are higher than expected.

Vortex Problems

Draining water from KO Pot to open

sewer during rain storm.

Flammable vapor entrained due to

formation of liquid vortex.

Lightning strikes near plant ISBL.

Sewer explodes, wrecks cold box in

Ammonia Plant.

One operator killed.

Maldistribution

Flow in reactor manifolds.

Flows in branched piping.

Flows in shell-side of exchangers.

Water Hammer

System or vessel design pressures

exceeded when EBV suddenly

stops flow.

EO transfer example.

See computer spreadsheet design

program.

Water Hammer Results

Typical Exam Problems

Which flow regime should you avoid

for horizontal, two phase flow?

If a liquid vortex forms on draining

from a vessel, what safety problems

can this create?

When can a PSV which is sized for

single phase flow experience two

phase flow?

Put Your Money Where

Your Mouth is!

S-ar putea să vă placă și

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe la EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentÎncă nu există evaluări

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7De la EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Încă nu există evaluări

- Pump Kits: More Than Just PumpsDocument12 paginiPump Kits: More Than Just PumpsleonardseniorÎncă nu există evaluări

- Ammonia How Much Catalyst Is Needed ForDocument10 paginiAmmonia How Much Catalyst Is Needed Forboris fernandezÎncă nu există evaluări

- The CFM 3156 and 3306 Are Ideal For Process Integration ApplicationsDocument2 paginiThe CFM 3156 and 3306 Are Ideal For Process Integration ApplicationsJosito HNÎncă nu există evaluări

- Recover NGLs by Extreme Cooling of Inlet Gas StreamsDocument7 paginiRecover NGLs by Extreme Cooling of Inlet Gas StreamsAhmed ElShoraÎncă nu există evaluări

- Hydrogenation Reactions GuideDocument8 paginiHydrogenation Reactions GuideBạch Trung PhúÎncă nu există evaluări

- Prospect of Hydrogen Production From Oil PalmDocument19 paginiProspect of Hydrogen Production From Oil PalmEmilio Jose Carrillo CardenasÎncă nu există evaluări

- Work Order Request Form On-Call Engineering Service: Proposal Price: Total Man-HourDocument1 paginăWork Order Request Form On-Call Engineering Service: Proposal Price: Total Man-HourKriengsak RuangdechÎncă nu există evaluări

- (Paper) Diffusers For Supersonic Wind Tunnels - LukasiewiczDocument10 pagini(Paper) Diffusers For Supersonic Wind Tunnels - LukasiewiczJoseXancopinca100% (1)

- Oxygen Plant: B Air CompressorDocument3 paginiOxygen Plant: B Air Compressorsumit11235Încă nu există evaluări

- How Important Is Surface Area .?Document7 paginiHow Important Is Surface Area .?john_serafica7104Încă nu există evaluări

- Storage Vacuum CollapseDocument7 paginiStorage Vacuum CollapsebehnamhfÎncă nu există evaluări

- Xu and FromentDocument9 paginiXu and FromentJhimmy Terceros100% (1)

- Distillation Column InternalsDocument7 paginiDistillation Column InternalsRicardo BecÎncă nu există evaluări

- Successful Start Up of The Worlds Newest FCCDocument14 paginiSuccessful Start Up of The Worlds Newest FCCEQP1210100% (1)

- Model For Calculating Steam Ejector PerformanceDocument15 paginiModel For Calculating Steam Ejector PerformanceMuhammad KhurramÎncă nu există evaluări

- Plate Hydraulic Design ExampleDocument53 paginiPlate Hydraulic Design ExampleChristopher RileyÎncă nu există evaluări

- The Fischer Tropsch Process 1950 - 200 - Mark E DryDocument15 paginiThe Fischer Tropsch Process 1950 - 200 - Mark E DryNalre OcehcapÎncă nu există evaluări

- Standard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USADocument9 paginiStandard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USAhlagos123Încă nu există evaluări

- Pede Proj 1Document28 paginiPede Proj 1Jibril hassen kedirÎncă nu există evaluări

- Pushing The Limits - Breakthrough in Pre-Reformer Design: Ingo Hanke and Norbert RingerDocument6 paginiPushing The Limits - Breakthrough in Pre-Reformer Design: Ingo Hanke and Norbert Ringervaratharajan g rÎncă nu există evaluări

- Roger A Fresh Look at Liquid-Liquid Extraction (Part 1)Document11 paginiRoger A Fresh Look at Liquid-Liquid Extraction (Part 1)RajendraÎncă nu există evaluări

- Multi-Effect Plate Distiller MEP SeriesDocument4 paginiMulti-Effect Plate Distiller MEP Seriesgochi bestÎncă nu există evaluări

- Selecting A Distillation Column Control StrategyDocument4 paginiSelecting A Distillation Column Control StrategyNethiyaaÎncă nu există evaluări

- Chemical Reactor Types: PFRs and CSTRsDocument2 paginiChemical Reactor Types: PFRs and CSTRsWancianSiaÎncă nu există evaluări

- Novel coker naphtha hydrotreatingDocument13 paginiNovel coker naphtha hydrotreatingGarry DavidÎncă nu există evaluări

- Thermocompressors: Engineered For EfficiencyDocument4 paginiThermocompressors: Engineered For EfficiencyAmir AbbaszadehÎncă nu există evaluări

- What Chemical Engineers Can Learn From Mother NatureDocument8 paginiWhat Chemical Engineers Can Learn From Mother NatureDiana BonyuetÎncă nu există evaluări

- Pump SkillsDocument1 paginăPump SkillsSaleem ChohanÎncă nu există evaluări

- Porous Sparger SizingDocument4 paginiPorous Sparger Sizingprav.saradaÎncă nu există evaluări

- GEA Product-Catalogue Brochure en Tcm11-22949Document128 paginiGEA Product-Catalogue Brochure en Tcm11-22949Santiago Nuñez SolisÎncă nu există evaluări

- Engineeringpractice-January2020 Compressed PDFDocument40 paginiEngineeringpractice-January2020 Compressed PDFPatricia.PÎncă nu există evaluări

- April04-Pump Maintenance Too HighDocument8 paginiApril04-Pump Maintenance Too Highho-faÎncă nu există evaluări

- 7-12-0011 Rev 5Document1 pagină7-12-0011 Rev 5cynideÎncă nu există evaluări

- Flue Gas Process - ScrubbingDocument8 paginiFlue Gas Process - ScrubbingR_M_M_Încă nu există evaluări

- EjectorDocument9 paginiEjectorManuel Gallegos CalderónÎncă nu există evaluări

- Room Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFDocument11 paginiRoom Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFAshpavi ArunÎncă nu există evaluări

- Structure PackingDocument8 paginiStructure PackingKalpesh MoreÎncă nu există evaluări

- Allowable Vapor Control ValveDocument9 paginiAllowable Vapor Control Valvejohn VilladaÎncă nu există evaluări

- ION Exchange ResinsDocument5 paginiION Exchange ResinsOniÎncă nu există evaluări

- SPE 94373 Optimize Separator Operating Pressures To Reduce Flash LossesDocument8 paginiSPE 94373 Optimize Separator Operating Pressures To Reduce Flash LossesArmando PedroÎncă nu există evaluări

- Dynamic Modeling of Heat Exchanger Tube RaptureDocument20 paginiDynamic Modeling of Heat Exchanger Tube RaptureRajesh NimmakayalaÎncă nu există evaluări

- Engineering Practice 2020 04Document35 paginiEngineering Practice 2020 04AUDIO CLIPS BLOGÎncă nu există evaluări

- Hydrocarbon Processing TOV Offer Advantages in Emergency Services PDFDocument4 paginiHydrocarbon Processing TOV Offer Advantages in Emergency Services PDFSu KaÎncă nu există evaluări

- Fuji Ring BlowerDocument55 paginiFuji Ring BlowerCarlos Davalos100% (1)

- List of FiguresDocument11 paginiList of FiguresShamsMohdÎncă nu există evaluări

- Role of Sparger Design in Mechanically Agitated Gas-Liquid ReacDocument8 paginiRole of Sparger Design in Mechanically Agitated Gas-Liquid ReacAriel AnnaÎncă nu există evaluări

- Themodynamic Model Selection For CHEMCADDocument19 paginiThemodynamic Model Selection For CHEMCADratnakar patharkarÎncă nu există evaluări

- AHLSTAR E Centerline Supported End Suction Single Stage Centrifugal PumpsDocument6 paginiAHLSTAR E Centerline Supported End Suction Single Stage Centrifugal PumpsAnonymous PsMDskÎncă nu există evaluări

- Vacuum Systems PDFDocument12 paginiVacuum Systems PDFSnigdha YadavÎncă nu există evaluări

- Graham - Lessons From The Field - Ejector SystemDocument5 paginiGraham - Lessons From The Field - Ejector SystemAnonymous DJrec2Încă nu există evaluări

- Application Data: PAC 353 Combustion Management Solutions Furnace (Draft) Pressure Control BenefitsDocument3 paginiApplication Data: PAC 353 Combustion Management Solutions Furnace (Draft) Pressure Control BenefitsmanishjainshahÎncă nu există evaluări

- Pressure DropDocument36 paginiPressure DropdesignselvaÎncă nu există evaluări

- EjectorsDocument5 paginiEjectorsJaykumarÎncă nu există evaluări

- Membrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngasDocument10 paginiMembrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngascurlychemÎncă nu există evaluări

- Scrubbing Tower DesignDocument10 paginiScrubbing Tower DesignPrathmesh GujaratiÎncă nu există evaluări

- Gas AbsorberDocument4 paginiGas Absorberraghavm8Încă nu există evaluări

- CE Refresher: Steam Tables and Typical Liquid VelocitiesDocument1 paginăCE Refresher: Steam Tables and Typical Liquid Velocitieshugo mendozaÎncă nu există evaluări

- Statistics for Process Control Engineers: A Practical ApproachDe la EverandStatistics for Process Control Engineers: A Practical ApproachÎncă nu există evaluări

- Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksDocument5 paginiMinimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksSanju ChauhanÎncă nu există evaluări

- Centrifugal Pump Problems ChecklistsDocument39 paginiCentrifugal Pump Problems ChecklistsionesqÎncă nu există evaluări

- Appendix 5 PDFDocument9 paginiAppendix 5 PDFjanelle ramdahinÎncă nu există evaluări

- ME349 Engineering Design Projects: Introduction To Materials SelectionDocument6 paginiME349 Engineering Design Projects: Introduction To Materials SelectionMehul KaklotarÎncă nu există evaluări

- Reformer BlowdownDocument1 paginăReformer BlowdownSanju ChauhanÎncă nu există evaluări

- Passivation and air filtration processesDocument7 paginiPassivation and air filtration processesSanju ChauhanÎncă nu există evaluări

- Sizing Tank Regulators Using Latest API 2000 7th EditionDocument11 paginiSizing Tank Regulators Using Latest API 2000 7th EditionparykoochakÎncă nu există evaluări

- Sizing Tank Blanketing Regulators Using Latest API 2000 7th Edition GuidelinesDocument1 paginăSizing Tank Blanketing Regulators Using Latest API 2000 7th Edition GuidelinesSanju ChauhanÎncă nu există evaluări

- Material Balance: Engineering Services by KBR Technical Services, IncDocument3 paginiMaterial Balance: Engineering Services by KBR Technical Services, IncSanju ChauhanÎncă nu există evaluări

- PDIL Pipe SpecificationDocument77 paginiPDIL Pipe SpecificationSanju ChauhanÎncă nu există evaluări

- MATIX Effluent Summary-Rev0Document1 paginăMATIX Effluent Summary-Rev0Sanju ChauhanÎncă nu există evaluări

- Develoment in Line With Chemical Priciples GoveringDocument2 paginiDeveloment in Line With Chemical Priciples GoveringSanju ChauhanÎncă nu există evaluări

- Process design basis for interphase processing facilityDocument7 paginiProcess design basis for interphase processing facilitySanju ChauhanÎncă nu există evaluări

- Calculationof Heat Loss Through A PipeDocument1 paginăCalculationof Heat Loss Through A PipeSanju ChauhanÎncă nu există evaluări

- Sanju Major Project ReportDocument72 paginiSanju Major Project ReportSanju ChauhanÎncă nu există evaluări

- ME8391 Engineering Thermodynamics QB - by EasyEngineering - Net 06 PDFDocument130 paginiME8391 Engineering Thermodynamics QB - by EasyEngineering - Net 06 PDFPayangaati PradeepÎncă nu există evaluări

- GR 8 DLP CompilationDocument38 paginiGR 8 DLP CompilationEliot CabornayÎncă nu există evaluări

- Ceramic Calculations Sample 3Document24 paginiCeramic Calculations Sample 3AkonSayagyiÎncă nu există evaluări

- Solution ThermoDocument9 paginiSolution ThermofarahanisiliasÎncă nu există evaluări

- Us 20140116695Document14 paginiUs 20140116695Lê CôngÎncă nu există evaluări

- Distribution CoefficientDocument16 paginiDistribution Coefficientapi-283054386100% (1)

- Vibration Level Switch SpecificationDocument12 paginiVibration Level Switch SpecificationPhạm Tấn PhướcÎncă nu există evaluări

- 3d Gas CoolingDocument9 pagini3d Gas CoolingvielmanwÎncă nu există evaluări

- HysysDocument36 paginiHysysRamiro ArcentalesÎncă nu există evaluări

- GENERAL CHEMISTRY Grade 12 ModuleDocument86 paginiGENERAL CHEMISTRY Grade 12 ModuleMarienne Ponciano70% (20)

- Chem 107 Test 1 ReviewDocument4 paginiChem 107 Test 1 ReviewSteven WalkerÎncă nu există evaluări

- LIPOSOMESDocument27 paginiLIPOSOMESHuma Hameed DogarÎncă nu există evaluări

- Principles of Processing Orange Juice - Orange BookDocument23 paginiPrinciples of Processing Orange Juice - Orange BookMaruriÎncă nu există evaluări

- Stability of Phases The Si-C-N-0 System: Harue Wada, Ming-Jong Wang, and Tseng-Ying Tien"Document4 paginiStability of Phases The Si-C-N-0 System: Harue Wada, Ming-Jong Wang, and Tseng-Ying Tien"radoslavoffÎncă nu există evaluări

- Binary Solubility of Phenol-Water SystemDocument11 paginiBinary Solubility of Phenol-Water SystemLinda MartianiÎncă nu există evaluări

- Phase Diagram of the Lead-Silver SystemDocument3 paginiPhase Diagram of the Lead-Silver SystemVora AyushÎncă nu există evaluări

- 2001 - Resurrection and The Eternal Life of The People Is Our Reality!Document202 pagini2001 - Resurrection and The Eternal Life of The People Is Our Reality!Lillyan29Încă nu există evaluări

- Saperation 1: Ass. Prof. Adnan Ripin Faculty of Chemical and Energy Engineering Universiti Teknologi MalaysiaDocument79 paginiSaperation 1: Ass. Prof. Adnan Ripin Faculty of Chemical and Energy Engineering Universiti Teknologi MalaysiaNurul AinÎncă nu există evaluări

- Marcet Boiler PDFDocument7 paginiMarcet Boiler PDFnorthsouth20Încă nu există evaluări

- Mahle Bilge Water Separator Type PPT-BWS:MESB 5,0 - 5ppm Final DrawingDocument40 paginiMahle Bilge Water Separator Type PPT-BWS:MESB 5,0 - 5ppm Final DrawingIgors VrublevskisÎncă nu există evaluări

- Hydrate Formation Utility Prediction ModelsDocument16 paginiHydrate Formation Utility Prediction ModelsAndrés Daniel GotopoÎncă nu există evaluări

- Benefits of Multi-Solvent NRTL Models in Aspen PlusDocument8 paginiBenefits of Multi-Solvent NRTL Models in Aspen PlusAli_F50Încă nu există evaluări

- Open Ended Lab ReportDocument18 paginiOpen Ended Lab ReportAbdullah IshaqÎncă nu există evaluări

- CH3140 Lecture Notes S1AY23-24 Set ADocument40 paginiCH3140 Lecture Notes S1AY23-24 Set AgoelsaarthakÎncă nu există evaluări

- Precipitation Module (TC-PRISMA) User GuideDocument55 paginiPrecipitation Module (TC-PRISMA) User GuideMiguel Angel Ojeda OreÎncă nu există evaluări

- Technical Manual 17Document36 paginiTechnical Manual 17WarlleyAntunesÎncă nu există evaluări

- Lix 860-I Ti Evh 0134 PDFDocument2 paginiLix 860-I Ti Evh 0134 PDFKittiphong KhunkruaÎncă nu există evaluări

- Nano FiltrationDocument8 paginiNano FiltrationEman El DsoukyÎncă nu există evaluări

- Process Engineering Course by Industry ExpertsDocument4 paginiProcess Engineering Course by Industry ExpertsShaikh ArbaazÎncă nu există evaluări

- Chemical Equilibrium Mixture Computations For Energetic Material Combustion in Closed VesselsDocument9 paginiChemical Equilibrium Mixture Computations For Energetic Material Combustion in Closed VesselssirusÎncă nu există evaluări