Documente Academic

Documente Profesional

Documente Cultură

02 - Lean Project Selection & Implementation Flow Chart

Încărcat de

Yo GoldTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

02 - Lean Project Selection & Implementation Flow Chart

Încărcat de

Yo GoldDrepturi de autor:

Formate disponibile

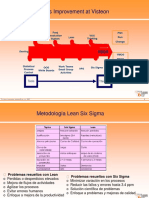

Work Cell #20

OEE = Overall Equipment

Effectiveness

(50% x 63.8% x 98.5% = 31.4%)

Project Selection / Tool

Flow Diagram

Value Stream Map

Equipment Equipment Quality

Availability Effectiveness ( Good product

produced )

= 50% = 63.8% Labor = 98.5%

Dir.

Lbr

Work Cell is only Takt Time

loaded to 50% IDL

capacity Hidden Factory / Re-

PPM Takt Time / Line

SIGMA VALUE ( Kaizen /CCF) work Balancing

Lean Tools

OEE Six Sigma Project

( Kaizen / CCF)

Combine Work On-

SIGMA/DPMO/RTY

Time

Cell with similar

Ship

process Scrap / Defects

Supply Re-evaluate

Spend

(Kaizen) process for Six

Prem Sigma Oppty

Freight

Re-evaluate

PPM

process for Work Cell Defect Reduction

Six Sigma Oppty Cycle Time Raw Material

KPIV's Organization

Capability OEE

Material Flow Lean Tools

Work Cell has ( 5S / Kaizen ) Six Sigma Project On-

Dock to Dock

excessive SIGMA VALUE / Time

downtime. DPMO

Ship

Work Place Balanced Work

Organization

Changeover Unscheduled Lean Tools Lean Tools Re-evaluate

Down Time Maintenance ( Kaizen/5S ) ( Kaizen/CCF/5S ) process for Six

Sigma Oppty

Cycle Time PPM

Lean Tools Lean Tools Lean Tools Improvements

(SMED) ( 5S ) (TPM) Process Capability

OEE

Raw Mtl.

Capability Operational Metrics

On-

Six Sigma Project Time

Six Sigma Project Ship

SIGMA VALUE

SIGMA VALUE/ Prem

DPMO Re-evaluate Freight

process for Six

OEE Sigma Oppty

Lean Project implementation flow chart

Value Stream Mapping Define Waste

Select Lean Tool Kaizen Workshop

Create Continuous Flow

SMED Workshop

5S/Vis Mgt Workshop

TPM Identify the Project

Support Functions give

help as required

S-ar putea să vă placă și

- BB wk1 130 The 12 Step Breakthrough StrategyDocument20 paginiBB wk1 130 The 12 Step Breakthrough StrategyFernando MartínÎncă nu există evaluări

- 1448 Data Gmet6 25eph Pfep Tuggers Forkfree 191022Document121 pagini1448 Data Gmet6 25eph Pfep Tuggers Forkfree 191022Gustavo FerrerÎncă nu există evaluări

- Asset Management A Complete Guide - 2020 EditionDe la EverandAsset Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- Enbridge Case Study Paper - 2018Document16 paginiEnbridge Case Study Paper - 2018stevehuppert100% (1)

- Forecasting Method Toshiba Corporation AtionDocument21 paginiForecasting Method Toshiba Corporation AtionTanvir JahanÎncă nu există evaluări

- Application of Lean Manufacturing Techniques For The Design of The Aircraft Assembly LineDocument117 paginiApplication of Lean Manufacturing Techniques For The Design of The Aircraft Assembly Linesuperreader94Încă nu există evaluări

- How To Improve Oee PerformanceDocument9 paginiHow To Improve Oee PerformanceMuhammad Usman HaidarÎncă nu există evaluări

- Productivity and Reliability-Based Maintenance Management, Second EditionDe la EverandProductivity and Reliability-Based Maintenance Management, Second EditionÎncă nu există evaluări

- VE2Document90 paginiVE2Avinash M. KatkarÎncă nu există evaluări

- KPI OEE Downtime AnalyticsDocument16 paginiKPI OEE Downtime Analyticsrasa55555Încă nu există evaluări

- Enterprise Dynamics TutorialDocument66 paginiEnterprise Dynamics TutorialBaracÎncă nu există evaluări

- Kaizen Blitz: An Introduction and Some Words of CautionDocument3 paginiKaizen Blitz: An Introduction and Some Words of Cautionpjanssen2306Încă nu există evaluări

- Five Steps To Improve ProductivityDocument2 paginiFive Steps To Improve ProductivityManojÎncă nu există evaluări

- Let's Drink A Coffee To Talk About: The Raci MatrixDocument4 paginiLet's Drink A Coffee To Talk About: The Raci MatrixJohann MenesesÎncă nu există evaluări

- Operations Intelligence Complete Self-Assessment GuideDe la EverandOperations Intelligence Complete Self-Assessment GuideÎncă nu există evaluări

- Toyota's 5-Step Process for Continuous Improvement ImplementationDocument6 paginiToyota's 5-Step Process for Continuous Improvement Implementationdbryant1435100% (1)

- Chapter 6 Master Production SchedulingDocument29 paginiChapter 6 Master Production SchedulingHarshad_SÎncă nu există evaluări

- 100 years of Quality management evolutionDocument1 pagină100 years of Quality management evolutionGenGyan Global Business Solutions Pvt LtdÎncă nu există evaluări

- Manpower Planning or Human Resource Planning is the Process of Systematically Forecasting the Future Demand and Supply for Employees and the Deployment of Their Skills Within the Strategic Objectives of the OrganizationDocument2 paginiManpower Planning or Human Resource Planning is the Process of Systematically Forecasting the Future Demand and Supply for Employees and the Deployment of Their Skills Within the Strategic Objectives of the Organizationmishrasneha76439Încă nu există evaluări

- Performance Measurement Analysis of Injection Molding Machine JSW J450AD Using Methods Overall Effectiveness (OEE) and Failure Mode Effect Analysis (FMEA) in The Plastics IndustryDocument7 paginiPerformance Measurement Analysis of Injection Molding Machine JSW J450AD Using Methods Overall Effectiveness (OEE) and Failure Mode Effect Analysis (FMEA) in The Plastics IndustryInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Critical Path Method A Complete Guide - 2020 EditionDe la EverandCritical Path Method A Complete Guide - 2020 EditionÎncă nu există evaluări

- Quality Function DeploymentDocument8 paginiQuality Function DeploymentNivedh VijayakrishnanÎncă nu există evaluări

- Module Comparison MatrixDocument4 paginiModule Comparison Matrixdear123Încă nu există evaluări

- Improve Work FormDocument4 paginiImprove Work FormambicaÎncă nu există evaluări

- Change Request FlowDocument1 paginăChange Request Flowyash shahÎncă nu există evaluări

- Lean Six Sigma 2 - Pan LearnDocument12 paginiLean Six Sigma 2 - Pan LearnAmy BlandÎncă nu există evaluări

- KPI For Lean Implementation in Manufacturing PDFDocument14 paginiKPI For Lean Implementation in Manufacturing PDFHadee SaberÎncă nu există evaluări

- The Plan For Every PartDocument7 paginiThe Plan For Every PartThandraelÎncă nu există evaluări

- Homework 1Document5 paginiHomework 1Ian Loke0% (1)

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 paginiProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsÎncă nu există evaluări

- Fluor Upfront BrochureDocument8 paginiFluor Upfront BrochureRiccardo GastaldoÎncă nu există evaluări

- SMED Format-1Document2 paginiSMED Format-1manojbarik1Încă nu există evaluări

- Aggregate Planning OPCDocument20 paginiAggregate Planning OPCMaithili PrabhuÎncă nu există evaluări

- Job ProductionDocument4 paginiJob ProductionTiana 'Chandie' ChandlerÎncă nu există evaluări

- Article On Effective Operational ExcellenceDocument4 paginiArticle On Effective Operational Excellencealaissa cagubcobÎncă nu există evaluări

- Continuous Improvement The BasicsDocument23 paginiContinuous Improvement The BasicsAdonis PajarilloÎncă nu există evaluări

- Reduce inventory A3Document1 paginăReduce inventory A3Krunal PandyaÎncă nu există evaluări

- 12 Success Factors PDF PDFDocument3 pagini12 Success Factors PDF PDFMd. Injamamul HaqueÎncă nu există evaluări

- Process Mapping ChecklistDocument2 paginiProcess Mapping ChecklistCK EspanolÎncă nu există evaluări

- Project Quality Management A Complete Guide - 2019 EditionDe la EverandProject Quality Management A Complete Guide - 2019 EditionÎncă nu există evaluări

- Lean in ServicesDocument1 paginăLean in ServicesSandeep SinghÎncă nu există evaluări

- Process Flowchart - Gadget SamyakDocument9 paginiProcess Flowchart - Gadget SamyakVinay BhandariÎncă nu există evaluări

- Ch-8 (Business Process Reengineering)Document22 paginiCh-8 (Business Process Reengineering)Shrutit21Încă nu există evaluări

- 1 Lean GlossaryDocument7 pagini1 Lean GlossaryHilalAldemirÎncă nu există evaluări

- Productivity Analysis To Increase Overall Equipment Effectiveness (OEE) by Implementing Total Productive MaintenanceDocument7 paginiProductivity Analysis To Increase Overall Equipment Effectiveness (OEE) by Implementing Total Productive MaintenanceInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Short Interval Control Executive SummaryDocument2 paginiShort Interval Control Executive Summaryaminos85Încă nu există evaluări

- A Roadmap To World Class Maintenance in Process IndustryDocument19 paginiA Roadmap To World Class Maintenance in Process IndustryDIPAK VINAYAK SHIRBHATE100% (4)

- 1-800-Flowers Com United StatesDocument435 pagini1-800-Flowers Com United StatesDataGroup Retailer Analysis100% (1)

- System Interfaces A Complete Guide - 2021 EditionDe la EverandSystem Interfaces A Complete Guide - 2021 EditionÎncă nu există evaluări

- Value Analysis and Value Engineering in Material ManagementDocument12 paginiValue Analysis and Value Engineering in Material ManagementKarthik Soundarajan100% (1)

- Sample Project CharterDocument1 paginăSample Project CharterPankajatSIBMÎncă nu există evaluări

- Kaizen CharterDocument3 paginiKaizen CharterDebashishDolonÎncă nu există evaluări

- Lean Operations: MRP vs. JitDocument32 paginiLean Operations: MRP vs. JitSamantha SiauÎncă nu există evaluări

- TPM Literature ReviewDocument49 paginiTPM Literature ReviewJosep PeterÎncă nu există evaluări

- Maintenance Execution & Shutdowns Best PracticeDocument39 paginiMaintenance Execution & Shutdowns Best PracticeSUNIL TVÎncă nu există evaluări

- 1 - Fundamentals of Process Capability - 2017Document15 pagini1 - Fundamentals of Process Capability - 2017Yo GoldÎncă nu există evaluări

- Process Capability Indices Based On Median Absolute Deviation PDFDocument6 paginiProcess Capability Indices Based On Median Absolute Deviation PDFYo GoldÎncă nu există evaluări

- 1 - Process True Capability With Measurement System VariabilityDocument8 pagini1 - Process True Capability With Measurement System VariabilityYo GoldÎncă nu există evaluări

- 2 - A New Measure of Process Capability - CPMDocument14 pagini2 - A New Measure of Process Capability - CPMYo GoldÎncă nu există evaluări

- Process Capability Indices To Measure Performance PDFDocument6 paginiProcess Capability Indices To Measure Performance PDFYo GoldÎncă nu există evaluări

- Process Capability Estimation For Non-Normally DisDocument14 paginiProcess Capability Estimation For Non-Normally DisYo GoldÎncă nu există evaluări

- The Calculation of Process Capability Indices - 1999Document2 paginiThe Calculation of Process Capability Indices - 1999Yo GoldÎncă nu există evaluări

- 1 - Process Capability Indices - 1986Document12 pagini1 - Process Capability Indices - 1986Yo Gold100% (1)

- Reducing Variability - A New Approach To Quality - 1984Document7 paginiReducing Variability - A New Approach To Quality - 1984Yo Gold100% (2)

- Recent Developments in Process Capability AnalysisDocument12 paginiRecent Developments in Process Capability AnalysisYo GoldÎncă nu există evaluări

- Process Capability Indices and Non-Normal DistributionsDocument13 paginiProcess Capability Indices and Non-Normal DistributionsYo GoldÎncă nu există evaluări

- Process Capability Indices - Overview and ExtensionsDocument20 paginiProcess Capability Indices - Overview and ExtensionsYo GoldÎncă nu există evaluări

- 1 - Process Capability Index For Non-Normal ProcessesDocument12 pagini1 - Process Capability Index For Non-Normal ProcessesYo GoldÎncă nu există evaluări

- Process Capability Indices For Skewed PopulationsDocument11 paginiProcess Capability Indices For Skewed PopulationsYo GoldÎncă nu există evaluări

- Weibull and LognormalDocument9 paginiWeibull and LognormalYo GoldÎncă nu există evaluări

- Process Capability Indices For Quality AssuranceDocument22 paginiProcess Capability Indices For Quality AssuranceYo GoldÎncă nu există evaluări

- Process Capability Indices Based On Median Absolute Deviation PDFDocument6 paginiProcess Capability Indices Based On Median Absolute Deviation PDFYo GoldÎncă nu există evaluări

- Distributions of The Estimated Process Capability Indices PDFDocument12 paginiDistributions of The Estimated Process Capability Indices PDFYo GoldÎncă nu există evaluări

- APQP DeliverablesDocument1 paginăAPQP DeliverablesYo GoldÎncă nu există evaluări

- VW 10540 1 enDocument4 paginiVW 10540 1 enYo Gold100% (1)

- Process Capability Ratio Limits For Tolerance AnalysisDocument28 paginiProcess Capability Ratio Limits For Tolerance AnalysisYo GoldÎncă nu există evaluări

- Process Capability Indices-A Review, 1992-2000Document18 paginiProcess Capability Indices-A Review, 1992-2000Yo GoldÎncă nu există evaluări

- Distributions of The Estimated Process Capability Indices PDFDocument12 paginiDistributions of The Estimated Process Capability Indices PDFYo GoldÎncă nu există evaluări

- SDI and DSSA AZ Supplier Quality Assurance ManualDocument14 paginiSDI and DSSA AZ Supplier Quality Assurance ManualJeelanÎncă nu există evaluări

- 01 - Que Es Lean SigmaDocument5 pagini01 - Que Es Lean SigmaYo Gold100% (1)

- New - AIAG - VDA - FMEA - Whitepaper - 1Document14 paginiNew - AIAG - VDA - FMEA - Whitepaper - 1Desmond Mahadeo100% (5)

- Boost Your Career and Bottom Line with CSQP CertificationDocument12 paginiBoost Your Career and Bottom Line with CSQP CertificationYo GoldÎncă nu există evaluări

- Lean Competency and Behavior ModelDocument20 paginiLean Competency and Behavior ModelYo GoldÎncă nu există evaluări

- 1 41577 Cert Factsheet CSQPDocument2 pagini1 41577 Cert Factsheet CSQPYo GoldÎncă nu există evaluări

- Lean Six Sigma Black Belt Outline PDFDocument4 paginiLean Six Sigma Black Belt Outline PDFYo GoldÎncă nu există evaluări

- Ultrasonic Testing Level 2 MCQsDocument8 paginiUltrasonic Testing Level 2 MCQspandab BkÎncă nu există evaluări

- A Report On Workability of Fresh Concrete by Slump TestDocument5 paginiA Report On Workability of Fresh Concrete by Slump TestRishabhJain100% (1)

- Beumer - Pipeconveyor TechnologyDocument51 paginiBeumer - Pipeconveyor TechnologyAli AlatasÎncă nu există evaluări

- 03.job Specification Instrumentaton PDFDocument27 pagini03.job Specification Instrumentaton PDFshareyhouÎncă nu există evaluări

- Filter DesignDocument4 paginiFilter Designhassan11783Încă nu există evaluări

- Application of PLC and SCADA in Auto-Control Systems For Silo Grain HandlingDocument4 paginiApplication of PLC and SCADA in Auto-Control Systems For Silo Grain Handlingshahid_scribdÎncă nu există evaluări

- Supercharging: Superchargers & TurbochargersDocument11 paginiSupercharging: Superchargers & TurbochargersAkhil Here100% (1)

- LMDQDocument601 paginiLMDQMohd Azamuddin Mohd SaifullizanÎncă nu există evaluări

- Saint Gobain - CertainTeed Roofing ShinglesDocument14 paginiSaint Gobain - CertainTeed Roofing ShinglesJagriti KashyapÎncă nu există evaluări

- Deventer04 MACDocument201 paginiDeventer04 MACFrancisco Solano Reyes EspinozaÎncă nu există evaluări

- Unit Conversion Heat TransferDocument5 paginiUnit Conversion Heat TransferFamela GadÎncă nu există evaluări

- Parts List 8198417 RevCDocument12 paginiParts List 8198417 RevCSonaina KhanÎncă nu există evaluări

- Previews AGA XQ9902 PreDocument6 paginiPreviews AGA XQ9902 PreAldrin HernandezÎncă nu există evaluări

- Bottom Ash HopperDocument8 paginiBottom Ash HopperBhargav ChaudhariÎncă nu există evaluări

- TDS2000 Rig Systems DiagramsDocument13 paginiTDS2000 Rig Systems DiagramsBaskar KannaiahÎncă nu există evaluări

- Civil 3 8sem PDFDocument43 paginiCivil 3 8sem PDFG0utham100% (1)

- Reinforced ConcreteDocument13 paginiReinforced ConcreteRenukadevi Rpt17% (18)

- Ceramic Terminal BlocksDocument1 paginăCeramic Terminal BlockselijbbÎncă nu există evaluări

- Dow Corning (R) 200 Fluid, 50 Cst.Document11 paginiDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanÎncă nu există evaluări

- Advantages & Disadvantages CITWDocument5 paginiAdvantages & Disadvantages CITWSreePrakashÎncă nu există evaluări

- Testing Machines For TextilesDocument35 paginiTesting Machines For TextilesAmarech YigezuÎncă nu există evaluări

- SportOptics 2014-2015Document31 paginiSportOptics 2014-2015ivaldeztÎncă nu există evaluări

- Timing Chain Tensioner ResetDocument4 paginiTiming Chain Tensioner ResetHybrid RacingÎncă nu există evaluări

- AP Create Accounting - Options & ExplanationDocument2 paginiAP Create Accounting - Options & ExplanationSaleem JavedÎncă nu există evaluări

- Munsell Color Charts and GaugesDocument2 paginiMunsell Color Charts and GaugesMario DalengkadeÎncă nu există evaluări

- Ps 1 SolDocument3 paginiPs 1 SolPang XsÎncă nu există evaluări

- Hydraulic Mining Shovel 6040AC: 08. Attachment Functions - FSDocument20 paginiHydraulic Mining Shovel 6040AC: 08. Attachment Functions - FShector50% (2)

- Wrangling Logs With Logstash and ElasticSearch PresentationDocument38 paginiWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainÎncă nu există evaluări

- VGS 8.1.2 Rev.20 - UTDocument29 paginiVGS 8.1.2 Rev.20 - UTPaul-Petrus MogosÎncă nu există evaluări

- Linear Slot DiffuserDocument15 paginiLinear Slot DiffuserhyderabadÎncă nu există evaluări