Documente Academic

Documente Profesional

Documente Cultură

Steam Turbine

Încărcat de

BlessyJoyPunsalan0 evaluări0% au considerat acest document util (0 voturi)

41 vizualizări31 paginiSteam Turbine

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentSteam Turbine

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

41 vizualizări31 paginiSteam Turbine

Încărcat de

BlessyJoyPunsalanSteam Turbine

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 31

Is rotary heat engine that converts thermal

energy contained in the steam to mechanical

energy and into electrical energy.

One kind of heat engine machine in which

steam's heat energy is converted to

mechanical work.

The first steam turbine was invented by Greek

Mathematician Hero of Alexandria about 120 BC

and it was reciprocating type.

The modern steam Turbine was made by Sir

Charles Parsons in the year 1884.The design has

been changed in many times.

The capacity of the turbine is coming from 0.75

KW to 1000 MW. It is a wide range of uses such

as pumps, compressor etc. Modern steam turbine

is also used as a prime mover in a big thermal

power plant.

Working principle of steam turbine depends

on the dynamic action of steam. A high-

velocity steam is coming from the nozzles

and it strikes the rotating blades which are

fitted on a disc mounted on a shaft. This

high-velocity steam produces dynamic

pressure on the blades in which blades and

shaft both start to rotate in the same

direction.

A. Principle of Operation :

Impulse Turbine

Impulse Reaction Turbine

Impulse Turbine - the total head of

the incoming fluid is converted in

to a large velocity head at the exit

of the supply nozzle. That is the

entire available energy of the water

is converted in to kinetic energy.

The easiest to understand impulse

turbine is the Pelton wheel turbine.

It is most efficient when operated

with a large head and lower flow

rate.

Impulse-Reaction Turbine – :

reaction turbines on the other

hand, are best suited -for

higher flow rate and lower head

situations. In this type of

turbines, the rotation of runner

or rotor (rotating part of the

turbine) is partly due to impulse

action and partly due to change

in pressure over the runner

blades; therefore, it is called as

reaction turbine

B. Direction of Flow :

Axial Flow Turbine

Radial Flow Turbine

Tangential Flow Turbine

Axial Flow Turbine – is a turbine in which the

direction of flow of water jet is axial to the axis of

shaft. It is the most suitable turbine for large

turbo-generators and that is why it is used in all

modem steam power plants.

Kaplan turbine is an axial flow

turbine with movable blades

that's why it can provide constant

efficiency over a wide range of

velocities of jet.

Radial Flow Turbine – Radical flow turbines

are those turbines in which the water flows in

radial direction. The water may flow radically

from outwards to inwards or from inwards to

outwards. The radial is not normally preferred

choice for electricity generation and usually

only employed for small output applications.

Tangential Flow Turbine - the steam flows in

the tangential direction. This turbine is very

robust but not particularly efficient machine,

sometimes used for driving power station

auxiliaries.

C. Means of Heat Supply:

Single pressure turbine

Mixed or dual pressure turbine

Reheated turbine

Single pressure turbine – this type of

turbine, there is single source of steam

supply.

Mixed or dual pressure turbine - This type

of turbines, use two sources of steam, at

different pressures. The dual pressure

turbine is found in nuclear power stations

where it uses both sources continuously.

The mixed pressure turbine is found in

industrial plants. Dual pressure system is

also used in combined cycle.

Reheated turbine - its passage through the

turbine steam may be taken out to be

reheated in a reheater incorporated in the

boiler and returned at higher temperature

to be expanded in. This is done to avoid

erosion and corrosion problems in the

bladings and to improve the power output

and efficiency. The reheating may be single

or double or triple.

D. Means of Heat Rejection

Pass-out or extraction turbine

Regenerative turbine

Condensing turbine

Noncondensing turbine

Back pressure or topping turbine

Pass-out Turbine - a considerable

proportion of the steam is extracted from

some suitable point in the turbine where

the pressure is sufficient for use in process

heating; the remainder continuing through

the turbine. This type of turbine is suitable

where there is dual demand of steam-one

for power and the other for industrial

heating, for example sugar industries.

Double pass-out turbines are sometimes

used.

Regenerative turbine -This turbine

incorporates a number of extraction

branches, through which small proportions

of the steam are continuously extracted for

the purpose of heating the boiler feed water

in a feed heater in order to increase the

thermal efficiency of the plant. Now a days,

all steam power plants are equipped with

reheating and regenerative arrangement.

Condensing turbine - this turbine, the

exhaust steam is condensed in a condenser

and the condensate is used as feed water in

the boiler. By this way the condensing

turbine allows the steam to expand to the

lowest possible pressure before being

condensed. All steam power plants use this

type of turbine.

Noncondensing turbine - the exhaust steam

coming out from the turbine is not

condensed but exhausted in the

atmosphere is called non-condensing

turbine. The exhaust steam is not recovered

for feed water in the boiler.

Back pressure or topping turbine - This

type of turbine rejects the steam after

expansion to the lowest suitable possible

pressure at which it is used for heating

purpose. Thus back pressure turbine

supplies power as well as heat energy. The

back pressure turbine generally used in

sugar industries provides low pressure

steam for heating apparatus, where as a

topping turbine exhausts into a turbine

designed for lower steam conditions.

E. Number of Cylinder

Single Cylinder- When all stages of

turbine are housed in one casing, then it

is called single cylinder. Such a single

cylinder turbine uses one shaft.

Multi-Cylinder- In large output turbine,

the number of the stages needed

becomes so highthat additional bearings

are required to support the shaft. Under

this circumstances, multi-cylinders are

used.

F. Arrangement of Cylinder Based on General

Flow of Steam

Single flow

Double flow

Reversed flow

Single flow -the steam enters at one end,

flows once the bladings in a direction

approximately parallel to this axis, emerges

at the other end. High pressure cylinder uses

single flow. This is also common in small

turbines.

Double Flow -the steam enters at the centre and

divides, the two portions passing axially away from

other through separate sets of blading on the same

rotor. This type of unit is completely balanced

against the end thrust and gives large area of flow

through two sets of bladings. This also helps in

reducing the blade height as mass flow rate

becomes half as compared to single flow for the

same conditions.

Reversed Flow - Reversed flow arrangement

is sometimes used in h.p, cylinder where

higher temperature steam is used on the

larger sets in order to minimise differential

expansion i.e. unequal expansion of rotor

and casing.

G. Number of Shaft

Tandem Compound - most multi-cylinder

turbines drive a single shaft and single

generator. Such turbines are termed as tandem

compound turbines.

Cross Compound - two shafts are used driving

separate generator. The may be one of turbine

house arrangement, limited generator size, or a

desire to run shafting at half speed. The latter

choice is sometimes preferred so that for the

same centrifugal stress, longer blades may be

used, giving a larger leaving area, a smaller

velocity and hence a small leaving loss.

H. Rotational Speed

Constant speed turbines

Variable speed turbines

Constant speed turbine - requirements of

rotational speed are extremely rigid in turbines

which are directly connected to electric generators

as these must be a-c unit except in the smallest

sizes and must therefore run at speeds

corresponding to the standard number of cycles

per second and governed by the following

equation:

N = 120 × Number of cycles per second = 120 f/p

Number of poles

Variable Speed Turbines - these turbines

have geared units and may have practically

any speed ratio between the turbine and the

driven machine so that the turbine may be

designed for its own most efficient speed.

Such turbines are used to drive ships,

compressors, blowers and variable frequency

generators.

S-ar putea să vă placă și

- Chapter 3 Na Di SureDocument4 paginiChapter 3 Na Di SureBlessyJoyPunsalanÎncă nu există evaluări

- Chapter 2Document4 paginiChapter 2BlessyJoyPunsalanÎncă nu există evaluări

- Solar EnergyDocument22 paginiSolar EnergyBlessyJoyPunsalan100% (2)

- Design, Development and Fabrication of Precision Corn Seeder (Title Defense)Document14 paginiDesign, Development and Fabrication of Precision Corn Seeder (Title Defense)BlessyJoyPunsalanÎncă nu există evaluări

- Thesis StatementDocument4 paginiThesis StatementBlessyJoyPunsalanÎncă nu există evaluări

- My Commitment in Teaching EssayDocument1 paginăMy Commitment in Teaching EssayBlessyJoyPunsalan100% (3)

- Daily Lesson Log in Mathematics 5Document2 paginiDaily Lesson Log in Mathematics 5BlessyJoyPunsalanÎncă nu există evaluări

- Academic Achiever Award Certificate TemplateDocument1 paginăAcademic Achiever Award Certificate TemplateBlessyJoyPunsalanÎncă nu există evaluări

- Core Value Certificate TemplateDocument1 paginăCore Value Certificate TemplateBlessyJoyPunsalan0% (1)

- Fourth Quarter Periodical Test Math 5Document6 paginiFourth Quarter Periodical Test Math 5BlessyJoyPunsalan100% (2)

- 3rd Periodical Test 2017-2018 MATHEMATICSDocument5 pagini3rd Periodical Test 2017-2018 MATHEMATICSBlessyJoyPunsalanÎncă nu există evaluări

- Power Plant EngineeringDocument9 paginiPower Plant EngineeringBlessyJoyPunsalanÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Pompa Transfer Mall 1 1000lpm@70m (Evo V 6403-1-18,5kw - 2pole)Document5 paginiPompa Transfer Mall 1 1000lpm@70m (Evo V 6403-1-18,5kw - 2pole)Rinaldy AkbarÎncă nu există evaluări

- Module 4: Hydraulic Turbines: Question No 4.1 (A) : Classify Hydraulic Turbines With ExamplesDocument14 paginiModule 4: Hydraulic Turbines: Question No 4.1 (A) : Classify Hydraulic Turbines With ExamplesSaurav Tiger MÎncă nu există evaluări

- Construction Manual of Solar Operated Pond Sand FilterDocument89 paginiConstruction Manual of Solar Operated Pond Sand FilterMohammad Ali100% (5)

- Kompressor PanasonicDocument6 paginiKompressor PanasonicBudiJuwiÎncă nu există evaluări

- 2012 Bookmatter AirbreathingPropulsionDocument43 pagini2012 Bookmatter AirbreathingPropulsionValBMSÎncă nu există evaluări

- Heat Recovery Steam Generator - HRSG General Usage: Combined-Cycle Gas Turbine CogenerationDocument4 paginiHeat Recovery Steam Generator - HRSG General Usage: Combined-Cycle Gas Turbine CogenerationGustavo FamaÎncă nu există evaluări

- Yearly Schedule Maintenance AcDocument8 paginiYearly Schedule Maintenance AcdimasÎncă nu există evaluări

- Che 416Document42 paginiChe 416Ifiok UsoroÎncă nu există evaluări

- Curva CertificadaDocument1 paginăCurva CertificadaJorge RiveraÎncă nu există evaluări

- API STDS Contents Page HohoDocument2 paginiAPI STDS Contents Page HohoMuhammad HannanÎncă nu există evaluări

- Gas Turbine QuestionsDocument4 paginiGas Turbine Questionspramod saljoshiÎncă nu există evaluări

- Condensate SystemDocument35 paginiCondensate SystemSam100% (6)

- Ansi-Hi Pump StandardsDocument2 paginiAnsi-Hi Pump StandardsAndrés Eduardo100% (1)

- Tapflo Centrifugal PumpsDocument30 paginiTapflo Centrifugal PumpssergiofelipeÎncă nu există evaluări

- T6C T6CM Service HY29 0046Document13 paginiT6C T6CM Service HY29 0046haggÎncă nu există evaluări

- KS-SE3 SEK 50R (1050rpm, 254mm) Data SheetDocument1 paginăKS-SE3 SEK 50R (1050rpm, 254mm) Data SheetRebi OkzamaÎncă nu există evaluări

- RFQ For Pumps-UpdatedDocument3 paginiRFQ For Pumps-UpdatedpragatheeskÎncă nu există evaluări

- Capacity Control of Centrifugal Compressor: By: Raghda AhmedDocument15 paginiCapacity Control of Centrifugal Compressor: By: Raghda AhmedMostafa HosnyÎncă nu există evaluări

- Simulación en Reactor CSTRDocument12 paginiSimulación en Reactor CSTRMaria Fernanda Bermudez ValeroÎncă nu există evaluări

- Factor of EvaporationDocument1 paginăFactor of EvaporationrajakongÎncă nu există evaluări

- Industrial Heat Pumps Industrial Heat PumpsDocument4 paginiIndustrial Heat Pumps Industrial Heat PumpsMaxmore KarumamupiyoÎncă nu există evaluări

- Heat PumpDocument87 paginiHeat PumpAugusto MoisesÎncă nu există evaluări

- GEA UCD 205-DecanterDocument21 paginiGEA UCD 205-DecanterJohn DochertyÎncă nu există evaluări

- Centrifugal Pump MathDocument6 paginiCentrifugal Pump Mathshamiul himelÎncă nu există evaluări

- Tobee THH High Head Slurry PumpDocument1 paginăTobee THH High Head Slurry PumptobeepumpÎncă nu există evaluări

- 442HP Small and Large SizeDocument2 pagini442HP Small and Large SizehufuentsÎncă nu există evaluări

- Centrifugal and Axial Compressor 2Document48 paginiCentrifugal and Axial Compressor 2mbabar81100% (4)

- List of BHEL TOP File Handed Over To DocumentationDocument578 paginiList of BHEL TOP File Handed Over To DocumentationNaresh PattanaikÎncă nu există evaluări

- Condensate Recovery System GestraDocument6 paginiCondensate Recovery System Gestraanita shindeÎncă nu există evaluări

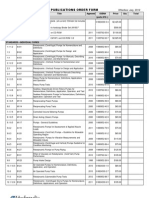

- Whatman Price List Booklet 2018Document96 paginiWhatman Price List Booklet 2018N PhÎncă nu există evaluări