Documente Academic

Documente Profesional

Documente Cultură

Operational Checks

Încărcat de

smart_eng2009Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Operational Checks

Încărcat de

smart_eng2009Drepturi de autor:

Formate disponibile

e GE Power Systems

Power Systems University

Operational Checks

Prior to startup or following major maintenance work, it is essential to check all support

systems, power sources and control devices for proper condition. These checks are

dependent on individual station procedures requirements, but may include such areas as

drain valves closed, power breakers in the on position, supply/isolation valves open,

controls in start/operation positions, any tagged out equipment returned to normal state,

all safety equipment in place.

5/12/2019 Operational Checks 1

e GE Power Systems

Power Systems University

Operational Checks (Standby Power Requirements)

Heating and circulating of turbine lube oil at low ambient temperatures to maintain proper

oil viscosity.

Control panel heating.

Generator heating.

Auxiliary lube oil pump should be run at periodic intervals to prevent rust formation in the

lube oil system.

Where fuel heaters are furnished, heat and circulate fuel oil to maintain proper oil

viscosity during periods of low ambient temperature.

Compartment heating.

Operation of control compartment air conditioner during periods of high ambient

temperature to maintain electrical equipment insulation within design temperature limits.

Battery charging.

5/12/2019 Operational Checks 2

e GE Power Systems

Power Systems University

Operational Checks (Checks Prior to Operation)

Check that all piping and turbine connections are securely fastened and that all blinds

have been removed.

Inlet and exhaust plenums and associated ducting are clean and rid of all foreign objects.

All access doors are secure.

Where fuel, air or lube oil filters have been replaced check that all covers are intact and

tight.

Verify that the lube oil tank is at operating level and filled with the recommended quality

and quantity of lube oil. If lube oil flushing has been conducted verify that all filters have

been replaced and any blinds, if used, removed.

Check operation of auxiliary and emergency equipment, such as lube oil pumps, water

pumps, fuel forwarding pumps, etc. Check for obvious leakage, abnormal vibration

(maximum 3 mils), noise or overheating.

Check lube oil piping for obvious leakage. Check sight glasses in bearing drains for oil

flow.

5/12/2019 Operational Checks 3

e GE Power Systems

Power Systems University

Operational Checks (Checks Prior to Operation)

Check all thermocouples and/or resistance temperature detectors (RTDs) on the HMI.

Reading should be approximately ambient temperature.

Check spark plugs for proper arcing.

Devices requiring manual lubrication are to be properly serviced.

Check that the cooling water system has been properly flushed and filled with the

recommended coolant.

At this time, all annunciated faults should be cleared. Immediate action should be taken

to locate and correct the problems.

5/12/2019 Operational Checks 4

e GE Power Systems

Power Systems University

Operational Checks (CHECKS DURING START UP AND INITIAL OPERATION)

The following is a list of important checks to be made on a new or newly overhauled

turbine with the OPERATION SELECTOR in various modes.

CAUTION

Where an electric motor is used as the starting means, refer to the Control Specifications

in regard to maximum operating time.

Crank

Listen for rubbing noises in the turbine compartment and in the reduction gear

compartment especially in the load tunnel area. Shutdown and investigate if unusual

noise occurs.

Check for unusual vibration.

Inspect for water system leakage.

5/12/2019 Operational Checks 5

e GE Power Systems

Power Systems University

Operational Checks (CHECKS DURING START UP AND INITIAL OPERATION)

Fire

Bleed fuel oil filters, if appropriate, then check entire fuel system and the area

immediately around the fuel nozzle for leaks. In particular, check for leaks at the following

points:

Turbine Compartment

Fuel piping/tubing to fuel nozzle

Fuel check valves

Atomizing air manifold and associated piping (when used)

Gas manifold and associated piping (when used)

Accessory Compartment

Flow divider (when used)

Fuel and water pumps

Filter covers and drains

5/12/2019 Operational Checks 6

e GE Power Systems

Power Systems University

Operational Checks (CHECKS DURING START UP AND INITIAL OPERATION)

Use mirrors to view the sight ports in the combustion chambers to visually check that

each chamber is fired, that the flame is steady and that the flame zone is centered within

the liner. In addition, assure that the crossfire tube end is not glowing. Plug and stake

sight ports once satisfactory flame conditions are obtained.

Monitor the turbine control panel readings for unusual exhaust thermocouple

temperature, wheelspace temperature, lube oil drain temperature, highest to lowest

exhaust temperature spreads and “hot spots” i.e. combustion chamber(s) burning hotter

than all the others.

Listen for unusual noises and rubbing.

Monitor for excessive vibration.

5/12/2019 Operational Checks 7

e GE Power Systems

Power Systems University

Operational Checks (CHECKS DURING START UP AND INITIAL OPERATION)

Automatic

Permit the gas turbine to operate for a 30 to 60 minute period in a FSNL condition.

Record all data for future comparison and investigation.

Continue monitoring for unusual rubbing noises and shutdown immediately if noise

persists.

Monitor lube oil tank, header and bearing drain temperatures continually during the

heating period. Adjust VTRs if required.

Perform a thorough vibration check. It is suggested that horizontal, vertical and axial data

be recorded for the:

accessory gear (when used) forward and aft sides

all accessible bearing covers on the turbine

turbine forward compressor casing

turbine support legs

reduction gear (when used) forward and aft sides, gear and pinion

bearing covers on the load equipment

5/12/2019 Operational Checks 8

e GE Power Systems

Power Systems University

Operational Checks (CHECKS DURING START UP AND INITIAL OPERATION)

Check and record wheelspace, exhaust and control thermocouples for proper indication

on the HMI.

Check flame detector operation.

5/12/2019 Operational Checks 9

S-ar putea să vă placă și

- Trip Oil SystemDocument6 paginiTrip Oil Systemsmart_eng2009100% (3)

- 7FA AA SystemDocument50 pagini7FA AA Systemsmart_eng2009100% (2)

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 paginiCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- GT Operation (Nanjin)Document146 paginiGT Operation (Nanjin)Ady FardyÎncă nu există evaluări

- 07 Gas Turbine Valves - 0Document14 pagini07 Gas Turbine Valves - 0VILAS VIJAYANÎncă nu există evaluări

- Detail Writeup of MarkvieDocument128 paginiDetail Writeup of MarkvieramkrishnaÎncă nu există evaluări

- Gas Turbine ControlDocument8 paginiGas Turbine ControlDAHRAOUI Mohamed Riad100% (1)

- GEK103623 DDocument18 paginiGEK103623 DNouman Saeed100% (1)

- GT 9E StartupDocument41 paginiGT 9E StartupNaveed IrshadÎncă nu există evaluări

- Exhaust Temperature Spread 2Document5 paginiExhaust Temperature Spread 2nabil160874Încă nu există evaluări

- Presentation Slides - Mark VIEDocument33 paginiPresentation Slides - Mark VIEolegprikhodko2809Încă nu există evaluări

- Limiting The Gas Turbine Load and Operating at Base LoadDocument6 paginiLimiting The Gas Turbine Load and Operating at Base Loadramkrishna100% (1)

- Sevo CalibrationDocument6 paginiSevo CalibrationlagoskadunaÎncă nu există evaluări

- Mark VIeDocument11 paginiMark VIebobyÎncă nu există evaluări

- GE MS6001B - EmissionDocument33 paginiGE MS6001B - EmissionMohamad AfifÎncă nu există evaluări

- Instrument GEDocument42 paginiInstrument GEnabil160874100% (1)

- GE 9FA Water Wash PROCEDURE FinalDocument43 paginiGE 9FA Water Wash PROCEDURE FinalAbdelaziz EldeebÎncă nu există evaluări

- Learn Gas Turbine by SimulationDocument41 paginiLearn Gas Turbine by SimulationAnonymous 8RRc42G100% (1)

- Med Riad: Sponsored by Control Technology Corp. ..Document8 paginiMed Riad: Sponsored by Control Technology Corp. ..nabil160874Încă nu există evaluări

- DLN Controls Code Development 9fa+ EnhancedDocument28 paginiDLN Controls Code Development 9fa+ Enhancednabil160874Încă nu există evaluări

- Protections MarkVDocument17 paginiProtections MarkVAndri Prodjodiprodjo100% (2)

- Mark V DCCC AlarmsDocument21 paginiMark V DCCC Alarmsnabil160874Încă nu există evaluări

- GT 5-8 Alarm Trip ListDocument3 paginiGT 5-8 Alarm Trip Listmuddasirmasood100% (1)

- Calibration ProcedureDocument2 paginiCalibration ProcedureChidiebere Samuel OkogwuÎncă nu există evaluări

- GT Hot Gas Path Inspection PDFDocument1 paginăGT Hot Gas Path Inspection PDFNagarajakumar DÎncă nu există evaluări

- MKV HMI HardwareDocument20 paginiMKV HMI HardwarehassanaagibÎncă nu există evaluări

- Network Blackout and Mark Vi/Vie Vulnerabilities: Presented by Omran M. Al-Majid Lead Control EngineerDocument21 paginiNetwork Blackout and Mark Vi/Vie Vulnerabilities: Presented by Omran M. Al-Majid Lead Control Engineerkatibra100% (1)

- IGV Operational Principle - 1Document5 paginiIGV Operational Principle - 1ramkrishnaÎncă nu există evaluări

- Combustion EnvelopDocument19 paginiCombustion Envelopferas_elnggar100% (1)

- Gas Turbine Control SystemDocument1 paginăGas Turbine Control SystemSreedev SureshbabuÎncă nu există evaluări

- Fact Sheet: GE Energy EX2100e Excitation Control For Gas Turbine GeneratorsDocument2 paginiFact Sheet: GE Energy EX2100e Excitation Control For Gas Turbine Generatorsvcharles100% (1)

- GE LMS-100 Local and Remote HMI Interconnect Diagram: TCP Unit #1 Customer Control RoomDocument1 paginăGE LMS-100 Local and Remote HMI Interconnect Diagram: TCP Unit #1 Customer Control Roomazizi reÎncă nu există evaluări

- Tab 05 GEK 106899 Startup and Shutdown ControlDocument10 paginiTab 05 GEK 106899 Startup and Shutdown Controlherysyam100% (1)

- Testing Spark Plugs of Mark-V Control SystemDocument21 paginiTesting Spark Plugs of Mark-V Control SystemMuhammad UsmanÎncă nu există evaluări

- Mark-V Ground Fault RectificationDocument5 paginiMark-V Ground Fault Rectificationali_zshan100% (2)

- Basics in Intrumentation in Mark-VDocument11 paginiBasics in Intrumentation in Mark-VGnanaseharan ArunachalamÎncă nu există evaluări

- MARKVE Getting A Better Understanding of Gas Turbine Control 1 2 3Document92 paginiMARKVE Getting A Better Understanding of Gas Turbine Control 1 2 3nabil160874100% (1)

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 paginiVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- MCT Mkvie OmDocument4 paginiMCT Mkvie Omnabil160874Încă nu există evaluări

- DCC I-O Card Obj #4 and Obj#13 Got ResetDocument4 paginiDCC I-O Card Obj #4 and Obj#13 Got ResetHung KettyÎncă nu există evaluări

- Controls - GasDocument35 paginiControls - Gasaustintan100% (1)

- EEI 7FA Supplement r1 2octDocument42 paginiEEI 7FA Supplement r1 2octkshalawi0% (1)

- GFA - GT Exhaust Spread ProblemDocument5 paginiGFA - GT Exhaust Spread Problemأمير معروف100% (1)

- Ms9001E Starting System: GeneralDocument2 paginiMs9001E Starting System: Generalferas_elnggarÎncă nu există evaluări

- 06 UCH GT 9001E - Inlet Filter & Duct SystemsDocument113 pagini06 UCH GT 9001E - Inlet Filter & Duct SystemsHassan Mahmood100% (1)

- Data Historian: GE Industrial SystemsDocument15 paginiData Historian: GE Industrial Systemsman_y2kÎncă nu există evaluări

- GT Control FundamentalsDocument31 paginiGT Control FundamentalsJitu Jena100% (4)

- lIQUID FUEL SYSTEM PDFDocument23 paginilIQUID FUEL SYSTEM PDFJJÎncă nu există evaluări

- GE Ex2100e Generator Controls Ds Gfa2114Document2 paginiGE Ex2100e Generator Controls Ds Gfa2114Iqbal FasyaÎncă nu există evaluări

- 0201 MACH7 Hot Redundant PDFDocument8 pagini0201 MACH7 Hot Redundant PDFSyed Mohammed HussainÎncă nu există evaluări

- Mark-VIe Logic BlockDocument6 paginiMark-VIe Logic BlockMuhammad Usman100% (1)

- From Turbine Manual: Gas Turbine Inlet Bleed HeatingDocument3 paginiFrom Turbine Manual: Gas Turbine Inlet Bleed HeatingSnehal PatelÎncă nu există evaluări

- Control Gas Turbine Power Output in Conjuction With Grid FrequencyDocument32 paginiControl Gas Turbine Power Output in Conjuction With Grid Frequencysmart_eng2009100% (3)

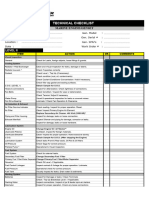

- Technical Report Checklist - MARINE ENGINESDocument2 paginiTechnical Report Checklist - MARINE ENGINESsary qasimÎncă nu există evaluări

- General InformationDocument111 paginiGeneral Informationkhaledserag23Încă nu există evaluări

- Monthly PM - EDGDocument3 paginiMonthly PM - EDGMuhammad RosihanÎncă nu există evaluări

- Mi 1722Document16 paginiMi 1722amir barekati100% (1)

- Induction Motor Testing at FactoryDocument7 paginiInduction Motor Testing at FactorysrinivasgillalaÎncă nu există evaluări

- Amt 643 Lec PrelimsDocument2 paginiAmt 643 Lec PrelimsTyron CastroÎncă nu există evaluări

- Boiler Control Systems Engineering, Second EditionDe la EverandBoiler Control Systems Engineering, Second EditionEvaluare: 4.5 din 5 stele4.5/5 (15)

- Over View of GTG Plant and Control of TurbineDocument27 paginiOver View of GTG Plant and Control of Turbinedimas0% (1)

- 03 ToolboxST BasicsDocument24 pagini03 ToolboxST Basicssmart_eng2009100% (2)

- GE Energy Oil and Gas PDFDocument36 paginiGE Energy Oil and Gas PDFMohammad Shadab AhmadÎncă nu există evaluări

- SPEEDTRONICDocument1 paginăSPEEDTRONICsmart_eng2009100% (1)

- Speedtronic Mark Vie: Maintenance TrainingDocument6 paginiSpeedtronic Mark Vie: Maintenance Trainingsmart_eng2009100% (1)

- GE Mark VDocument3 paginiGE Mark Vsmart_eng2009Încă nu există evaluări

- Cairo North ManualDocument982 paginiCairo North Manualsmart_eng2009100% (2)

- Kurimat SurgeDocument6 paginiKurimat Surgesmart_eng2009100% (1)

- 104E7482G001Document1 pagină104E7482G001smart_eng2009Încă nu există evaluări

- 5 Trenders - 5Document41 pagini5 Trenders - 5smart_eng2009100% (1)

- 5 - LOGIC BANHA G1 p741 PDFDocument1.622 pagini5 - LOGIC BANHA G1 p741 PDFsmart_eng2009100% (2)

- Narratology pdf111Document5 paginiNarratology pdf111smart_eng2009Încă nu există evaluări

- 05 RackConfigrationDocument20 pagini05 RackConfigrationsmart_eng2009100% (1)

- Control Gas Turbine Power Output in Conjuction With Grid FrequencyDocument32 paginiControl Gas Turbine Power Output in Conjuction With Grid Frequencysmart_eng2009100% (3)

- 05 RackConfigrationDocument20 pagini05 RackConfigrationsmart_eng2009100% (1)

- Report GT 298742-28 May 2012Document193 paginiReport GT 298742-28 May 2012smart_eng2009100% (1)

- Gender Stereotyping of Parents RepresntationDocument7 paginiGender Stereotyping of Parents Represntationsmart_eng2009Încă nu există evaluări

- AVK Power GenerationDocument21 paginiAVK Power Generationcuongnv_19Încă nu există evaluări

- Canteen & Garbage Shed - ReportDocument19 paginiCanteen & Garbage Shed - ReportahnafÎncă nu există evaluări

- Material Handling CompleteDocument8 paginiMaterial Handling CompleteAhmad Firdaus Zawawil AnwarÎncă nu există evaluări

- MS-194A Ex View & Parts ListDocument10 paginiMS-194A Ex View & Parts ListChristian GerardoÎncă nu există evaluări

- Weight of Building MaterialsDocument2 paginiWeight of Building MaterialsAswad TonTongÎncă nu există evaluări

- CausewayDocument79 paginiCausewayeddieÎncă nu există evaluări

- Air Cooler 1Document23 paginiAir Cooler 1Vipin SreekumarÎncă nu există evaluări

- In Emi Substrate Flex 0808Document19 paginiIn Emi Substrate Flex 0808satheeshÎncă nu există evaluări

- Resume (AC Technician)Document2 paginiResume (AC Technician)khushwinder86Încă nu există evaluări

- TNC PDFDocument12 paginiTNC PDFketab_doostÎncă nu există evaluări

- Penetron - Ceo - Sonasea - Waterproofing Details and SpecsDocument7 paginiPenetron - Ceo - Sonasea - Waterproofing Details and SpecsNguyễn ThanhÎncă nu există evaluări

- Master Realist Techniques in Colored Pencil PaintingDocument346 paginiMaster Realist Techniques in Colored Pencil PaintingOvidiu Balan100% (4)

- BMI BRG-100RF X-Ray - Circuit Diagrams PDFDocument68 paginiBMI BRG-100RF X-Ray - Circuit Diagrams PDFeduardoÎncă nu există evaluări

- SR352 Perimeter Insulation of Concrete Slab Foundations PDFDocument36 paginiSR352 Perimeter Insulation of Concrete Slab Foundations PDFMichael CollinsÎncă nu există evaluări

- Dredger Pumps For SlurryDocument4 paginiDredger Pumps For SlurryvehptÎncă nu există evaluări

- PPEDocument22 paginiPPEMark Anthony Nieva RafalloÎncă nu există evaluări

- ITOWERS Designer BrochureDocument137 paginiITOWERS Designer BrochureAleksandar ObradovicÎncă nu există evaluări

- STM 800 BuildDocument17 paginiSTM 800 BuildKevin Montañez Huaman0% (1)

- Energy Audit and ManagementDocument5 paginiEnergy Audit and ManagementAnees Hussain100% (1)

- Philips Downlight PDFDocument33 paginiPhilips Downlight PDFEddy Suyono Architects100% (1)

- Block AB Mezzanine FloorDocument5 paginiBlock AB Mezzanine FloorYuvarasuÎncă nu există evaluări

- Advanced Structural DesignDocument2 paginiAdvanced Structural DesignAnonymous zwnFXURJÎncă nu există evaluări

- Alaska Root CellarDocument4 paginiAlaska Root CellarREBogart100% (3)

- Roll Crusher BrochureDocument4 paginiRoll Crusher Brochurelucasmalta0% (1)

- Enerpac Fittings CatalogDocument1 paginăEnerpac Fittings CatalogTitanplyÎncă nu există evaluări

- General Catalogue 2017 18 Armani CasaDocument324 paginiGeneral Catalogue 2017 18 Armani CasaMadaMadutsaÎncă nu există evaluări

- Asi#87296 Sage#50100 DC#100329Document116 paginiAsi#87296 Sage#50100 DC#100329Roberto LeboeufÎncă nu există evaluări

- OcvDocument4 paginiOcvIsmail SetiawanÎncă nu există evaluări

- Butterfly Valves enDocument37 paginiButterfly Valves enMolitorisz AndorÎncă nu există evaluări