Documente Academic

Documente Profesional

Documente Cultură

Prestressing Concrete

Încărcat de

zainab parekh0 evaluări0% au considerat acest document util (0 voturi)

12 vizualizări1 paginăPrestressed concrete is a system where internal stresses are induced in concrete structures through tensioned steel tendons before external loads are applied. This counters the stresses from external loads. There are two methods: pre-tensioning, where steel is tensioned before concrete is cast around it, and post-tensioning, where steel is tensioned after concrete has cured. Prestressing improves efficiency, allows for longer spans, enhances strength and durability. However, it has higher material costs and more complex formwork than reinforced concrete.

Descriere originală:

about prestressed concrete and how its used and where it is used

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPrestressed concrete is a system where internal stresses are induced in concrete structures through tensioned steel tendons before external loads are applied. This counters the stresses from external loads. There are two methods: pre-tensioning, where steel is tensioned before concrete is cast around it, and post-tensioning, where steel is tensioned after concrete has cured. Prestressing improves efficiency, allows for longer spans, enhances strength and durability. However, it has higher material costs and more complex formwork than reinforced concrete.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

12 vizualizări1 paginăPrestressing Concrete

Încărcat de

zainab parekhPrestressed concrete is a system where internal stresses are induced in concrete structures through tensioned steel tendons before external loads are applied. This counters the stresses from external loads. There are two methods: pre-tensioning, where steel is tensioned before concrete is cast around it, and post-tensioning, where steel is tensioned after concrete has cured. Prestressing improves efficiency, allows for longer spans, enhances strength and durability. However, it has higher material costs and more complex formwork than reinforced concrete.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

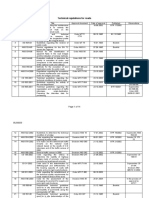

Prestressed concrete is a system into which internal stresses are Concept of Prestressing

P deliberately induced without any form of external loads to improve

The concept can be clearly understood by the example of a

r its performance. The internal stresses induced in the concrete

barrel. A barrel used in olden periods to transports liquids and

structure is used to counteract the stresses coming from the external

e load application.

grains are tightly bound by metal bands. These metal bands

are fitted so tightly that it creates a hoop compression around

s the barrel. When this barrel is filled with liquid, it exerts hoop

Methods of Prestressing tension. The hoop compression that is created by the metal

t The pre stressing can be performed bands helps to counteract the hoop tension created by the

r by two methods: fluid within. This is a Prestressing system.

1. Pre tensioning

e 2. Post-Tensioning

s Pre tensioning:

In the pre tensioning method, the stress is

s induced by initially tensioning the steel

e tendons. These are wires or strands that are

effective internal stresses are induced into

tensioned between the end anchorages. After

d this tensioning process, the concrete casting is the concrete by means of tensioned steel

performed. bars before the concrete structure is

C Once the casted concrete has hardened subjected to any service loads. This stress

o sufficiently, the end anchorages arranged are counteracts with external stresses.

released. This releasing transfers the pre stress

n force to the concrete. The bond between the

Advantages of Prestressed

Concrete

c concrete and the steel tendons facilitates this

stress transfer. the tendons that are protruding

r at the ends are cut and a finished look is • The pre stressing of concrete by using

achieved. In order to induce pre stress force in high tensile steel improve the efficiency

e the pre-tensioning method, a large number of of the materials

Once the pre stressing is complete, • The pre stressing system works for a

t tendons and wires are used. This arrangement

The process of Pre- there is space between the span greater than 35m.

hence demands a large area of surface

e contact to make the bond and stress transfer

tensioning tendons and the duct. This leads • Prestressing enhance shear strength

to: and fatigue resistance of concrete

possible. 1. Bonded Construction the • Dense concrete is provided by pre

space between the duct and stressing systems thus improving the

Post Tensioning the tendon is filled with cement durability

Here, the steel is pre stressed only after the beam grout. The grouting process • Best choice for the construction of sleek

is cast, cured and attain strength to take the pre helps the steel to resist and slender structures

stress. Within the sheathing, the concrete is cast. corrosion to a large extent.

For the passage of steel cables, ducts are 2. Unbonded Construction If no Disadvantages of Prestressed

formed in the concrete. grout is used to fill the space

Once the casted concrete hardens completely, Concrete

between the duct and tendon,

the tendons are tensioned. One end of the it is called as unbonded

tendon is anchored and the other end is • Higher material costs

construction. Here, the steel is

tensioned. In some cases, the tensioning can be • Prestressing is an added cost

galvanized to protect from

performed from either side and anchored • Formwork is more complex than for RC

corrosion. A waterproofing

subsequently. The process of Post- (flanged sections, thin webs) – thus,

material is used for galvanizing.

tensioning precast not as ductile as RC

ADVANCE BUILDING CONSTRUCTION -1 Zainab parekh 91600629026

S-ar putea să vă placă și

- 1748 Nusha Rakhe As 3aDocument4 pagini1748 Nusha Rakhe As 3anusha rakheÎncă nu există evaluări

- Possibilities of Pre-Stressed Concrete in Construction (April 2016)Document3 paginiPossibilities of Pre-Stressed Concrete in Construction (April 2016)JaiÎncă nu există evaluări

- Pre-Stressed Concrete Methods of Producing Pre Stressed ConcreteDocument1 paginăPre-Stressed Concrete Methods of Producing Pre Stressed Concreteapoorva jayaswalÎncă nu există evaluări

- Prestressing of Concrete: Post - TensioningDocument1 paginăPrestressing of Concrete: Post - TensioningPrabhakar SvÎncă nu există evaluări

- Prestress Concrete DPDocument20 paginiPrestress Concrete DPdanielÎncă nu există evaluări

- MMBC Prestressed ConcreteDocument1 paginăMMBC Prestressed ConcreteNiveditha jÎncă nu există evaluări

- Prestressedconstruction 140616163709 Phpapp02Document19 paginiPrestressedconstruction 140616163709 Phpapp02Andy ArenasÎncă nu există evaluări

- Prestressed ConstructionDocument19 paginiPrestressed Constructionindian royalÎncă nu există evaluări

- Pre-Stress Assignment 3 ReportDocument13 paginiPre-Stress Assignment 3 ReportRaunaq ChandaÎncă nu există evaluări

- Pre StressingDocument10 paginiPre Stressingvinita thakurÎncă nu există evaluări

- Prestressed Concrete DesignDocument11 paginiPrestressed Concrete DesignMelchor Jaramilla Oronos100% (1)

- Lecture 1 - Prestressed ConcreteDocument15 paginiLecture 1 - Prestressed ConcreteHasini KadaruÎncă nu există evaluări

- Pre - Stress Concrete: Submitted byDocument16 paginiPre - Stress Concrete: Submitted byTinzar LattÎncă nu există evaluări

- 3-Concept of PrestressingDocument13 pagini3-Concept of PrestressingKavi MaranÎncă nu există evaluări

- Pre-Stressed ConcreteDocument1 paginăPre-Stressed ConcreteAila MaeÎncă nu există evaluări

- Pre Cast and Pre Stressed ConcreteDocument18 paginiPre Cast and Pre Stressed ConcreteJassimar SinghÎncă nu există evaluări

- Pre-Tensioned ConcreteDocument18 paginiPre-Tensioned ConcretePurchia100% (1)

- PCDSDocument3 paginiPCDSaira babehisÎncă nu există evaluări

- Introduction To PrestressedconcreteDocument39 paginiIntroduction To Prestressedconcretelet's talkÎncă nu există evaluări

- Prestressed Concrete: General Method of PrestressingDocument7 paginiPrestressed Concrete: General Method of PrestressingoshileeÎncă nu există evaluări

- Chapter 4 Pre-Stressed ConcreteDocument23 paginiChapter 4 Pre-Stressed ConcreteDdeqz Elina Bueno IÎncă nu există evaluări

- Chapter 10 Design of Prestressed 761661594169023Document15 paginiChapter 10 Design of Prestressed 761661594169023Puzzle ArtsÎncă nu există evaluări

- Prestress 170222194407 PDFDocument20 paginiPrestress 170222194407 PDFprajith mirraÎncă nu există evaluări

- Prestressed ConcreteDocument17 paginiPrestressed ConcreteSoumadip BhuniaÎncă nu există evaluări

- Arch 413 ReviewerDocument22 paginiArch 413 ReviewerErika ParambitaÎncă nu există evaluări

- Irjet V8i5749Document6 paginiIrjet V8i5749Min Khant KyawÎncă nu există evaluări

- Pre Stressed Concrete: Modular Construction Technology: Prepared byDocument28 paginiPre Stressed Concrete: Modular Construction Technology: Prepared byindian royalÎncă nu există evaluări

- BQS502 Lec 5 Pre-Stressed Concrete FramesDocument35 paginiBQS502 Lec 5 Pre-Stressed Concrete FramesUMMI KALTHOM NABILAH ISMAILÎncă nu există evaluări

- Prestressed ConcreteDocument27 paginiPrestressed Concreteyogendra shahÎncă nu există evaluări

- Prestressed Concrete-Basic Concept: Structural EngineeringDocument84 paginiPrestressed Concrete-Basic Concept: Structural EngineeringArhamÎncă nu există evaluări

- 9 Pre - Post Tensioning StructureDocument1 pagină9 Pre - Post Tensioning StructureAr. Osama FirozÎncă nu există evaluări

- Basic Principles of Prestressed-Concrete (Notes)Document17 paginiBasic Principles of Prestressed-Concrete (Notes)sharifah atiqahÎncă nu există evaluări

- Prestressed Concrete, Pre-Tension and Post-TensionDocument6 paginiPrestressed Concrete, Pre-Tension and Post-TensionAjayi PeterÎncă nu există evaluări

- Prestressed Concrete: Theory and Design of Structures Assignment No. 1Document10 paginiPrestressed Concrete: Theory and Design of Structures Assignment No. 1harish guptaÎncă nu există evaluări

- Reinforced and Prestressed ConcreteDocument34 paginiReinforced and Prestressed ConcretecutespyierÎncă nu există evaluări

- Prestressed Concrete 3Document18 paginiPrestressed Concrete 3Samiullah M QaisraniÎncă nu există evaluări

- Prestensioning & Post-TensioningDocument40 paginiPrestensioning & Post-TensioningKURUBA SARAN RAJ SamÎncă nu există evaluări

- Definition of PrestressDocument26 paginiDefinition of Prestressasaad mahmood mezbanÎncă nu există evaluări

- Prestressed ConcreteDocument6 paginiPrestressed Concretepaul machariaÎncă nu există evaluări

- Sanchez, J - Prestressed ConcreteDocument6 paginiSanchez, J - Prestressed ConcreteUniqueQuiverÎncă nu există evaluări

- Pre - Stress ConcreteDocument16 paginiPre - Stress ConcreteKashyap ChintuÎncă nu există evaluări

- Prestressed ConcreteDocument6 paginiPrestressed ConcreteUniqueQuiverÎncă nu există evaluări

- Prestress Concrete ไฟล์รวม PDFDocument430 paginiPrestress Concrete ไฟล์รวม PDFNA Sleeper0% (1)

- Prestressed Concrete Structures: Under The Guidance Of: Prof. & Head Department of Civil EngineeringDocument42 paginiPrestressed Concrete Structures: Under The Guidance Of: Prof. & Head Department of Civil EngineeringPtp AbyÎncă nu există evaluări

- Theory of Structure: Post-Tensioned SlabsDocument18 paginiTheory of Structure: Post-Tensioned SlabsPuru VashisthÎncă nu există evaluări

- Prestress Concrete Gautam 4a 29Document17 paginiPrestress Concrete Gautam 4a 29Soumya SinghÎncă nu există evaluări

- Pre Stressed ConcreteDocument19 paginiPre Stressed ConcretemynameisgunaÎncă nu există evaluări

- Section 1.1Document9 paginiSection 1.1Jayson J. PagalÎncă nu există evaluări

- Report On Post Tensioning & Pre TensioningDocument11 paginiReport On Post Tensioning & Pre TensioningSharandeep Sandhu100% (2)

- Prestressed Concrete - Dis 2020Document48 paginiPrestressed Concrete - Dis 2020Nur Aieshah NasirÎncă nu există evaluări

- 11assignment 3journal On Prestressed Concrete 2Document7 pagini11assignment 3journal On Prestressed Concrete 2ARITRA CHAKRABORTYÎncă nu există evaluări

- 6 0-PrestressedDocument14 pagini6 0-Prestressedmariangeli velez67% (3)

- Pre StressDocument502 paginiPre StressAkshay NaikÎncă nu există evaluări

- Prestressed ConcreteDocument9 paginiPrestressed ConcreteDiploma - CE Dept.Încă nu există evaluări

- Design of Prestressed Concrete ElementsDocument20 paginiDesign of Prestressed Concrete ElementsCivil EngineeringÎncă nu există evaluări

- RC Iii C-4Document45 paginiRC Iii C-4daniel workuÎncă nu există evaluări

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDe la EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionÎncă nu există evaluări

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910De la EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Încă nu există evaluări

- Absorption Chillers PresentationDocument12 paginiAbsorption Chillers Presentationwords4dev0% (1)

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 paginiFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcÎncă nu există evaluări

- Grid MiragridDocument12 paginiGrid MiragridAfidatul AdnÎncă nu există evaluări

- Coal Mill Inspection FormDocument1 paginăCoal Mill Inspection FormErmiyas MistreÎncă nu există evaluări

- 25 1 PDFDocument4 pagini25 1 PDFFrancisco M. RamosÎncă nu există evaluări

- VC 5 VDocument3 paginiVC 5 VLibinÎncă nu există evaluări

- Chap 1 Stress-Life: 1.2 S-N Diagram 1.3 Mean Stress Effects 1.4 Modifying Factors 1.5 Important ConceptsDocument29 paginiChap 1 Stress-Life: 1.2 S-N Diagram 1.3 Mean Stress Effects 1.4 Modifying Factors 1.5 Important Conceptsyucheng122Încă nu există evaluări

- Ripple BookletDocument45 paginiRipple BookletJonasDispersynÎncă nu există evaluări

- ATENA - Theory Nonlinear RCDocument282 paginiATENA - Theory Nonlinear RCPreloxÎncă nu există evaluări

- Designing For Pods: ManualDocument20 paginiDesigning For Pods: ManualPOD ExpertÎncă nu există evaluări

- Air Conditioning DesignDocument17 paginiAir Conditioning DesignEriane GarciaÎncă nu există evaluări

- Phase Diagrams For Metallic SystemsDocument5 paginiPhase Diagrams For Metallic SystemsZesi Villamor Delos SantosÎncă nu există evaluări

- Technical Regulations For RoadsDocument14 paginiTechnical Regulations For RoadsAlexe FloreaÎncă nu există evaluări

- Safety Stations G1950: Guardian EquipmentDocument2 paginiSafety Stations G1950: Guardian Equipmenteisenbarger5607Încă nu există evaluări

- Advanced Design of Steel and Concrete Composite StructuresDocument35 paginiAdvanced Design of Steel and Concrete Composite StructuresCristian BlanaruÎncă nu există evaluări

- TDS - Premcote 101 TropicalDocument1 paginăTDS - Premcote 101 TropicalThomas C. LaneÎncă nu există evaluări

- Tipos de GasketDocument1 paginăTipos de GasketOscar NietoÎncă nu există evaluări

- Law and Code of EthicsDocument53 paginiLaw and Code of EthicsKenn Earl Bringino VillanuevaÎncă nu există evaluări

- Renault Scenic Air ConditioningDocument107 paginiRenault Scenic Air Conditioningwofeba80% (10)

- Fatigue, Creep and Fracture: ME 4031 - Introduction-Lecture# 3Document25 paginiFatigue, Creep and Fracture: ME 4031 - Introduction-Lecture# 3Abdullah Al Bari TusharÎncă nu există evaluări

- Ice-Lined Refrigerator: Refrigeration SystemDocument2 paginiIce-Lined Refrigerator: Refrigeration SystemfranslalaÎncă nu există evaluări

- BAC - VXC-S - Technical Data SheetsDocument12 paginiBAC - VXC-S - Technical Data SheetsMahmoud AliÎncă nu există evaluări

- Electrical Conductivity, Thermal Behavior, and Seebeck Coefficient of Conductive Films For Printed Thermoelectric Energy Harvesting SystemsDocument9 paginiElectrical Conductivity, Thermal Behavior, and Seebeck Coefficient of Conductive Films For Printed Thermoelectric Energy Harvesting SystemsRamakrishna NayakÎncă nu există evaluări

- Dyneema and Spectra Fiber LineDocument3 paginiDyneema and Spectra Fiber Line杨惠玲Încă nu există evaluări

- Code of Practice For Temporary Works Procedures and The Permissible Stress Design of FalseworkDocument10 paginiCode of Practice For Temporary Works Procedures and The Permissible Stress Design of FalseworkHameed AfinnihÎncă nu există evaluări

- BILL No 8 - AtriumDocument86 paginiBILL No 8 - AtriumTigistuÎncă nu există evaluări

- ACI 211.2-98 R04 Standard Practice For Selecting Proportions For Structural Lightweight Concrete - MyCivil - IrDocument20 paginiACI 211.2-98 R04 Standard Practice For Selecting Proportions For Structural Lightweight Concrete - MyCivil - IrEwerton MazoniÎncă nu există evaluări

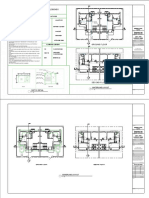

- Plumbing and Electrical LayoutDocument4 paginiPlumbing and Electrical Layoutjohn lawasÎncă nu există evaluări

- ASTM D6049 03 - Standard Test Method For Rubber Property - Measurement of The Viscous and Elastic Behavior of Unvulcanized Raw Rubbers and Rubber Compounds by Compression Between Parallel Plates PDFDocument9 paginiASTM D6049 03 - Standard Test Method For Rubber Property - Measurement of The Viscous and Elastic Behavior of Unvulcanized Raw Rubbers and Rubber Compounds by Compression Between Parallel Plates PDFAndre Rodriguez SpirimÎncă nu există evaluări

- Deformation of The CrustDocument16 paginiDeformation of The CrustLoneSoulÎncă nu există evaluări