Documente Academic

Documente Profesional

Documente Cultură

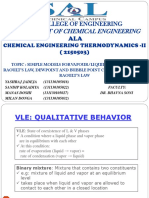

Scet Chemical 1 Year Bee PPT Group-3: Earthing and Its Types

Încărcat de

dhruv0 evaluări0% au considerat acest document util (0 voturi)

74 vizualizări22 paginihhghjg

Titlu original

hjhh

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documenthhghjg

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

74 vizualizări22 paginiScet Chemical 1 Year Bee PPT Group-3: Earthing and Its Types

Încărcat de

dhruvhhghjg

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 22

SCET

CHEMICAL 1ST YEAR

BEE PPT

GROUP-3

EARTHING AND ITS TYPES.

INTRODUCTION TO EARTHING.

DEFINTION:- The process of transferring

the immediate discharge of the electrical

energy directly to the earth by the help of

low resistance wire known as electrical

earthing.

According to Indian electricity rules the

earthing is defined as:-

The earthed or connected with the earth

means connection with the general mass

of the earth in such manner as to ensure

at all times an immediate discharge of

energy without danger.

PURPOSE OF EARTHING

To protect any human from shock by the leakage of current

from the damaged fuse.

To protect all machines and over head lines from lightning.

To protect large buildings from overhead lightning.

To maintain line voltage constant.

To illustrate the purpose of earthing, consider an electric circuit

in the below figure where an electrical appliance of resistance

R is connected to the supply through a fuse and a switch.

When the operator touches the metallic body of the apparatus (a)

having perfect insulation the equivalent circuit (b), where two are

parallel path are formed as shown.

Since the insulation resistance Ri is very high no current flows to the

person and flows through the machine.

When earth fault occurs the live wire directly comes in contact to the

outer body and insulation resistance gets reduced to zero as shown in

figure(c).

Now body resistance is just parallel with the machine resistance. A

heavy current flows through the human body and feels a sever shock.

However if the metallic body or outer frame is properly insulated, under

this condition the circuit will be as shown in figure(d) where earth

resistance Re is just in parallel with the appliance resistance R and

body resistance Rb.

Since earth resistance is very small almost whole current floes through

the earth resistance and no current flows through the body resistance.

So by these steps the person gets saved from shocks

Pipe Earthing

• Pipe Earthing is the most commonly used method

and is the best system of earthing as compared to

other systems.

• In this method of earthing a pipe of sufficient

diameters is selected whose size depend upon: a)

Maximum earth current of that installation. b)

The type of soil.

• As per IS-732-1963 standard, the galvanized pipe

should not have a diameter less than 38 mm and

length should not be less than 2 meter for ordinary

soil.

• If cast iron is used then internal diameter should

be 10 mm.

• The depth at which pipe should be burried,

depends upon condition of soil and moisture.

• The pipes or rods should be as far as possible.

• For pipe earthing a pit of 40 sq. cm is dug in the

soil and the pipe having tapered casting at the

bottom is placed vertical in that pit.

The charcoal and salt are filled

in that pit in the form of alternate

layers about 2 meters from

bottom and for a distance of

about 15 cm around the pipe.

The pipe placed has 12 mm

diameter holes drilled in it so

that water poured from the top

gets easily spread in the media

surrounding the pipe which

helps to keep resistance of earth

low.

At the top a cement concrete

work is done to provide

protection against mechanical

damage.

A water pouring arrangement is

provided by a funnel with wire

mesh at the top.

APPLICATION OF PIPE EARTHING

It is mostly used for:

1. Residential areas

2. Commercial areas

Advantages Of Pipe Earthing

1. Simple design

2. Easy to install in good soils

3. Hardware readily available

Disadvantages Of pipe Earthing

1. High impedance

2. Hard to install in rocky soil

PLATE EARTHING

In case of plate earthing , plate electrodes may

be made of galvanized iron or steel having

thickness of not less than 6.30mm.

If plate electrodes of copper are used these

should have a thickness of not less than

3.15mm.

The size of plate electrode should be 60cm ×

60cm as shown in figure,

Plate electrodes should be buried such that

the top edge is at a depth of not less than

1.5m below the surface of the ground.

For plate earthing a pit of a 4m is during in

to the ground and earth electrodes (plate) is

placed vertical in that pit.

The space around the plate is filled with

layers of charcoal and salt for a minimum

thickness of 15cm.

For connection of earth wire to earth

electrodes, a G.I. pipe of 12.7mm diameter

is connected to electrode (plate).

For connection of earth wire to earth

electrodes, a G.I. pipe of 12.7mm diameter

is connected to electrode (plate).

Earth wire is properly connected to earth

electrode with the help of nut, bolt and

washer.

The pit filled with charcoal and salt also has

a pipe for carrying water from concrete work

to that area.

This will help in increasing the dampness

and moisture surrounding the plate.

APPLICATION OF PLATE EARTHING

It is mostly used for:

1. Industrial areas

2. Generators

3. Transformers

4. UPS

Advantages Of Plate Earthing

1. Can achieve low resistance contact in limited area Easy to

install ingood soils.

2. Higher Efficiency.

Disadvantages Of Plate Earthing

1. Most difficult to install

2. Should be installed Vertically

ROD EARTHING

• Rod Earthing is similar to pipe earthing.

• In this method of earthing a copper rod of diameter 12.5 mm

or 16 mm diameter galvanized steel or a hollow section of

25mm galvanised iron pipe of length not less than 2.5m is

buried vertically underground.

• The pipe can be buried manually or using pneumatic hammer.

•the earth resistance is reduced to a desired value by the

embedded electrode.

LIGHTNING PROTECTION

• When the potential between two

clouds or between earth and cloud

reaches a sufficiently high value,

about 10000V/cm, it results in

ionization of air along a narrow path

and lightning flash.

• The possibility of dischage is very

high on tall tree or buildings rather

than the ground.

• The buildings are protected from

lightning strikes using metallic rod

extending to the ground from a point

above the highest part of the building.

• The conductor has a pointed edge on one side and

the other side is connected to a long thick copper strip

that runs down the building.

• The lower end of the strip is properly earthed. During a

lightning strikes, it hits the metal rod and current flow

don through the copper strip.

• The metal rod provides a low resistance path for the

lightning discharges and prevents its from traveling from

the structure itself.

EARTHING THROUGH TO THE WATER MAIN

• In this type of eathing system, the water main

(galvanized iron) pipe is used for earthing.

• The resistance of the galvanized iron pipes are

checked and earthing clamps are used to

minimise resistance for earthing connection.

• If standard conductors are used as earth wire,

end of the strands are cleaned.

• The earth wire must be straight and paralel to

water main pipe to make firm connection

possible

STRIP OR WIRE EARTHING

In this type of earthing, a strip electrode of cross section

not less than 25mmX1.6mm is buried in a horizontal

trench of depth not less than .5m.

If copper is used then the desired cross section is

25mmX4mm and if galvanized steel/iron is used then

the desired cross section is 3mm2.

When using round conductors made of galvanized steel

or iron, the cross sectional area should not be less than

6mm2.

The length of the conductor buried should not be less

than 15m

EARTHING RULES

According to IEE regulations and IE rules, earth pin in 3

pin plus sockets and 4 pin power sockets must be

efficiently and permanently earthed.

All metal casings and metal coverings containing or

covering electrical supply cable or equipment must be

earthed.

The metallic frames of generators, transformers,

stationary motors etc. must be earth using two separate

earthing or distinct connections with the earth.

In a dc three wire system, the middle wire must be

earthed at the generating station.

Stay wires for the overhead electric lines must be

connected to earth at atleast one strand to the earth

wires

S-ar putea să vă placă și

- CAPACITIVE DISCHARGE IGNITION Vs MAGNETIC DISCHARGE IGNITION PDFDocument73 paginiCAPACITIVE DISCHARGE IGNITION Vs MAGNETIC DISCHARGE IGNITION PDFAmal TharakaÎncă nu există evaluări

- Electromagnetic Waves: By: I Nyoman S. (X-8/09) Raka Pandam G. (X-8/21)Document11 paginiElectromagnetic Waves: By: I Nyoman S. (X-8/09) Raka Pandam G. (X-8/21)Nyoman SuryadinataÎncă nu există evaluări

- Channel v1 n2 Jan-Feb-Mar 1916Document108 paginiChannel v1 n2 Jan-Feb-Mar 1916Joma SipeÎncă nu există evaluări

- Tesla Coils: Unleash The Aether: Hank MillsDocument11 paginiTesla Coils: Unleash The Aether: Hank MillsbubbaclemÎncă nu există evaluări

- Wireless Energy Transfer: Chandana - Ks & Harish E & C Department Govt - SKSJTI, Bangaluru-01Document24 paginiWireless Energy Transfer: Chandana - Ks & Harish E & C Department Govt - SKSJTI, Bangaluru-01Chandana Kumar100% (1)

- Telepathy, Esp: By: Emily BusiDocument15 paginiTelepathy, Esp: By: Emily BusiKarla Calderón CamposÎncă nu există evaluări

- Electric Earthing and ShockDocument17 paginiElectric Earthing and ShockRamakrishna ChaitanyaÎncă nu există evaluări

- Pro-Life Manna Part 2Document24 paginiPro-Life Manna Part 2Timothy50% (2)

- What Is ElectricityDocument7 paginiWhat Is ElectricityArjhay GironellaÎncă nu există evaluări

- Electric Circuits PPT 1-2Document36 paginiElectric Circuits PPT 1-2Fuego McFuegoÎncă nu există evaluări

- Zero News Datapool, TESLA FREE ENERGY PDFDocument2 paginiZero News Datapool, TESLA FREE ENERGY PDFkoconineÎncă nu există evaluări

- Ee 003 Lecture11Document39 paginiEe 003 Lecture11JC LoplopÎncă nu există evaluări

- Module 3: Basic ElectricityDocument18 paginiModule 3: Basic ElectricityApriljoy DannugÎncă nu există evaluări

- Vi 47Document30 paginiVi 47LIto LamonteÎncă nu există evaluări

- What Is Earthing?Document6 paginiWhat Is Earthing?harshalÎncă nu există evaluări

- Student Lab Manual: Fundamentals of ElectricityDocument9 paginiStudent Lab Manual: Fundamentals of ElectricityAbdisalam A. MohamedÎncă nu există evaluări

- Fuels and CombustionDocument26 paginiFuels and CombustionEjaz AhmedÎncă nu există evaluări

- N200 EEG Lab ReportDocument19 paginiN200 EEG Lab ReportMichael SmithÎncă nu există evaluări

- Originile Extraterestre Ale Pamintenilor PDFDocument202 paginiOriginile Extraterestre Ale Pamintenilor PDFMihmikeÎncă nu există evaluări

- Wireless ElectricityDocument25 paginiWireless ElectricityGhanshyam JainÎncă nu există evaluări

- DNA, The Keeper of Life's Secrets, Starts To TalkDocument71 paginiDNA, The Keeper of Life's Secrets, Starts To TalkUSER 15Încă nu există evaluări

- Acoustic Levitation TechnicalDocument20 paginiAcoustic Levitation TechnicalSathish RoyalrajaÎncă nu există evaluări

- Acfrogblykjvqmcdsos8vsw Irtdkrhjhighnykh1ki1ou0mk - 7tizlahxgmmimxff73rht5fddgnoqjkwrkxnuobtjvfgrfnygf83mp14pm-Zioxj0kh32 921goop3iadt9ocbqp9rriruqtDocument74 paginiAcfrogblykjvqmcdsos8vsw Irtdkrhjhighnykh1ki1ou0mk - 7tizlahxgmmimxff73rht5fddgnoqjkwrkxnuobtjvfgrfnygf83mp14pm-Zioxj0kh32 921goop3iadt9ocbqp9rriruqtSaj BhaiÎncă nu există evaluări

- Understanding Time: Time Travel Is PossibleDocument6 paginiUnderstanding Time: Time Travel Is PossibleVeronika BannerjeeÎncă nu există evaluări

- Domestic Electric CircuitsDocument5 paginiDomestic Electric CircuitsGowshikaÎncă nu există evaluări

- Rude Stone Monuments in All Countries - Their Age and Uses by James FergussonDocument389 paginiRude Stone Monuments in All Countries - Their Age and Uses by James FergussonAnonymous R5EiuOYwÎncă nu există evaluări

- Strangled by Roots: The Genealogy Craze in AmericaDocument8 paginiStrangled by Roots: The Genealogy Craze in AmericaAdrian GuzmanÎncă nu există evaluări

- Deck Manual PDFDocument217 paginiDeck Manual PDFBozidar TomasevicÎncă nu există evaluări

- Systemic and Localized Scleroderm11!05!08Document99 paginiSystemic and Localized Scleroderm11!05!08Linux LinuxÎncă nu există evaluări

- Altium Rigid Flex GuidebookDocument40 paginiAltium Rigid Flex GuidebookKiran Jot Singh100% (1)

- Nicola Tesla (US Pat. 685955)Document7 paginiNicola Tesla (US Pat. 685955)GaleriaTechniki.PLÎncă nu există evaluări

- Precognition - A Memory of Things Future?: Approved For Release 2000/08/10 : CIA-RDP96-00787R000100130003-6Document19 paginiPrecognition - A Memory of Things Future?: Approved For Release 2000/08/10 : CIA-RDP96-00787R000100130003-6clekupreÎncă nu există evaluări

- Electrostatics - Direct Current PDFDocument76 paginiElectrostatics - Direct Current PDFRita UmutoniÎncă nu există evaluări

- The History of GFLDocument116 paginiThe History of GFLGobyl AbylÎncă nu există evaluări

- Stan Meyers Secret Preventing Electrolysis (Amended)Document79 paginiStan Meyers Secret Preventing Electrolysis (Amended)Julio MariuzzaÎncă nu există evaluări

- SclerodermaDocument17 paginiSclerodermajobinbionicÎncă nu există evaluări

- Precast Concrete Structures For BuildingsDocument10 paginiPrecast Concrete Structures For BuildingsspqdragadosirelandÎncă nu există evaluări

- DRC MAR - July 7 - GFDocument31 paginiDRC MAR - July 7 - GFInterActionÎncă nu există evaluări

- Circuit Symbols and Circuit Diagrams: Electric Circuits: Lesson 4Document19 paginiCircuit Symbols and Circuit Diagrams: Electric Circuits: Lesson 4Bry RamosÎncă nu există evaluări

- Interferometer: Instruction Manual and Experiment Guide For The PASCO Scientific Model OS-8501Document18 paginiInterferometer: Instruction Manual and Experiment Guide For The PASCO Scientific Model OS-8501Mauricio RaúlÎncă nu există evaluări

- No God No Peace Know God Know Peace FinalDocument81 paginiNo God No Peace Know God Know Peace Finalpremkishor.gkg100% (2)

- Basic Electronics: Subcourse Edition OD1633 8Document117 paginiBasic Electronics: Subcourse Edition OD1633 8yuvionfireÎncă nu există evaluări

- Sharp Lc-60-70le650u 70le657u 70757u C6500u Le755u Le857u C7500uDocument136 paginiSharp Lc-60-70le650u 70le657u 70757u C6500u Le755u Le857u C7500uJuan Carlos Srafan100% (1)

- Nikola Tesla Proposing The Death Ray For DefenseDocument3 paginiNikola Tesla Proposing The Death Ray For DefenseBranko StankovićÎncă nu există evaluări

- Dermatology Scleroderma: Click To Edit Master Subtitle StyleDocument36 paginiDermatology Scleroderma: Click To Edit Master Subtitle StyleAiman Tymer100% (1)

- AetherDocument30 paginiAetherbaldfishÎncă nu există evaluări

- An Introduction To Applied GeostatisticsDocument92 paginiAn Introduction To Applied GeostatisticsAllan ErlikhmanÎncă nu există evaluări

- Chapter 5 Solution of ThermodynamicsDocument30 paginiChapter 5 Solution of Thermodynamicsprakash_krishnan_2100% (1)

- RWB 60-856 Inst - Op. Mantto.Document52 paginiRWB 60-856 Inst - Op. Mantto.Daniel Dennis Escobar Subirana100% (1)

- Chemical Ammonia Report PDFDocument72 paginiChemical Ammonia Report PDFAli J. Hojeij100% (1)

- UreaDocument86 paginiUreaAdi Ahmad100% (1)

- 2013 - To and Fro. Modernism and Vernacular ArchitectureDocument246 pagini2013 - To and Fro. Modernism and Vernacular ArchitecturesusanaÎncă nu există evaluări

- Tor PDFDocument45 paginiTor PDFKartik PatilÎncă nu există evaluări

- Blackbody VITCC PDFDocument21 paginiBlackbody VITCC PDFShreyas SinghÎncă nu există evaluări

- Laser Ignition SystemDocument26 paginiLaser Ignition Systemkrishnasinghrs4546Încă nu există evaluări

- AP Rhetorical Hawken Healing or Stealing-AnnotatedDocument17 paginiAP Rhetorical Hawken Healing or Stealing-AnnotatedLiteracyRm310Încă nu există evaluări

- Lecture-3.3.6-Systemic Autoimmune Diseases With Examples-2Document3 paginiLecture-3.3.6-Systemic Autoimmune Diseases With Examples-2aditya sahuÎncă nu există evaluări

- Report On Systemic Lupus Erythematosus: Mariano Marcos State UniversityDocument16 paginiReport On Systemic Lupus Erythematosus: Mariano Marcos State UniversityKathzkaMaeAgcaoiliÎncă nu există evaluări

- Tesla - US Patent 0685957 - 1901 - Apparatus For The Utilization of Radiant EnergyDocument5 paginiTesla - US Patent 0685957 - 1901 - Apparatus For The Utilization of Radiant EnergyWalid BecharaÎncă nu există evaluări

- PatentyDocument22 paginiPatentyapi-231134847100% (1)

- Sharp Lc-60 Le 630 U-A - lc-60 Le 6300 U-A-b - lc-70 Le 735 U - PWB - Unit - EditionDocument38 paginiSharp Lc-60 Le 630 U-A - lc-60 Le 6300 U-A-b - lc-70 Le 735 U - PWB - Unit - EditionRabshaqa100% (1)

- Ravali PPT 160218122213Document26 paginiRavali PPT 160218122213Amish MehtaÎncă nu există evaluări

- Black BodyDocument23 paginiBlack BodyRoberto BattagliaÎncă nu există evaluări

- Electric CircuitDocument15 paginiElectric CircuittitinadiyantiÎncă nu există evaluări

- Introduction To Combination of Series and Parallel CircuitsDocument16 paginiIntroduction To Combination of Series and Parallel CircuitsXmart UsmanÎncă nu există evaluări

- "Earthing": Eee (2110005) - Active Learning AssignmentDocument16 pagini"Earthing": Eee (2110005) - Active Learning AssignmentDOUGLASÎncă nu există evaluări

- Vidhyadeep Institute of Management and Technology Anita - KimDocument17 paginiVidhyadeep Institute of Management and Technology Anita - KimDhruv KapadiaÎncă nu există evaluări

- Unit 6 - EarthingDocument26 paginiUnit 6 - Earthinggautam100% (1)

- Advances in Earthing System: Presented by Richa Mishra Pranidhi KulshresthaDocument20 paginiAdvances in Earthing System: Presented by Richa Mishra Pranidhi KulshresthaR. K. ViralÎncă nu există evaluări

- Module 3 EarthingDocument9 paginiModule 3 EarthingBUNTI MNÎncă nu există evaluări

- Blank DiagramDocument1 paginăBlank DiagramdhruvÎncă nu există evaluări

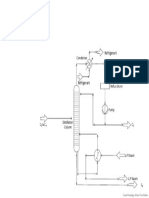

- P&IDDocument1 paginăP&IDdhruvÎncă nu există evaluări

- Study On The Surface Tensions of MDEA-methanol Aqueous SolutionsDocument5 paginiStudy On The Surface Tensions of MDEA-methanol Aqueous SolutionsdhruvÎncă nu există evaluări

- Condenser: RefrigerantDocument1 paginăCondenser: RefrigerantdhruvÎncă nu există evaluări

- Spray TowerDocument6 paginiSpray TowerAndre KusadyÎncă nu există evaluări

- ChernobylDocument12 paginiChernobylCosminaaaaaaaaÎncă nu există evaluări

- Dropwise Condensation Vs Film Condensation With PDFDocument3 paginiDropwise Condensation Vs Film Condensation With PDFdhruv100% (1)

- HENDocument2 paginiHENdhruvÎncă nu există evaluări

- Gas RPDocument46 paginiGas RPdhruvÎncă nu există evaluări

- The Job Profile Is A Mixture of Technical &marketingDocument2 paginiThe Job Profile Is A Mixture of Technical &marketingdhruvÎncă nu există evaluări

- Energy Scenario: Syllabus Energy Scenario: Commercial and Non-Commercial Energy, Primary Energy ResourcesDocument36 paginiEnergy Scenario: Syllabus Energy Scenario: Commercial and Non-Commercial Energy, Primary Energy ResourcesCelestino Montiel MaldonadoÎncă nu există evaluări

- 04 - First Order SystemDocument16 pagini04 - First Order SystemNayyar RazaÎncă nu există evaluări

- Et-Pa - 1 - 19 - 08 - 2020Document1 paginăEt-Pa - 1 - 19 - 08 - 2020dhruvÎncă nu există evaluări

- CPDP PA1 PAPER SOLVEDDocument8 paginiCPDP PA1 PAPER SOLVEDdhruvÎncă nu există evaluări

- Leaching VishadDocument59 paginiLeaching VishaddhruvÎncă nu există evaluări

- Plant LayoutDocument15 paginiPlant LayoutdhruvÎncă nu există evaluări

- 04 - First Order SystemDocument16 pagini04 - First Order SystemNayyar RazaÎncă nu există evaluări

- Mo RPDocument63 paginiMo RPdhruvÎncă nu există evaluări

- 8337632Document31 pagini8337632dhruvÎncă nu există evaluări

- Ipc Notes PDFDocument19 paginiIpc Notes PDFdhruvÎncă nu există evaluări

- 10412176Document33 pagini10412176dhruvÎncă nu există evaluări

- 2150503Document33 pagini2150503Zico VersusÎncă nu există evaluări

- Biodegradability of Biomass Pyrolysis Oi PDFDocument8 paginiBiodegradability of Biomass Pyrolysis Oi PDFdhruvÎncă nu există evaluări

- Lec 09Document11 paginiLec 09rahulÎncă nu există evaluări

- Biology Taxonomy Worksheet ANSWERSDocument3 paginiBiology Taxonomy Worksheet ANSWERSPsudopodÎncă nu există evaluări

- Self-Diagnosis With Advanced Hospital Management-IJRASETDocument5 paginiSelf-Diagnosis With Advanced Hospital Management-IJRASETIJRASETPublicationsÎncă nu există evaluări

- Materi 2 - Obligation, Prohibition, and Suggestion - AdviceDocument12 paginiMateri 2 - Obligation, Prohibition, and Suggestion - AdviceShadrina ChaerunissaÎncă nu există evaluări

- Basic Task 315Document9 paginiBasic Task 315gaikwadamitag1Încă nu există evaluări

- Understanding The Self Lecture Lesson 1 Revised PDFDocument41 paginiUnderstanding The Self Lecture Lesson 1 Revised PDFKylie CuadraÎncă nu există evaluări

- Remembering Thanu Padmanabhan - The HinduDocument3 paginiRemembering Thanu Padmanabhan - The HinduIucaa libraryÎncă nu există evaluări

- Teaching Profession Activities On Modules 1 2Document9 paginiTeaching Profession Activities On Modules 1 2Ana Lea AlmazanÎncă nu există evaluări

- Tutorial Probability and Statistics: SolutionsDocument3 paginiTutorial Probability and Statistics: SolutionsAdnanÎncă nu există evaluări

- 3 Master Star 1 Super Star: Forged Steel Ball ValvesDocument7 pagini3 Master Star 1 Super Star: Forged Steel Ball ValvesAhmed IbrahimÎncă nu există evaluări

- BA427 Chapter 7Document11 paginiBA427 Chapter 7Maloloy-on, JeromeÎncă nu există evaluări

- AI Coming For LawyersDocument4 paginiAI Coming For LawyersbashiÎncă nu există evaluări

- Prompt by NikistDocument4 paginiPrompt by NikistMãnoj MaheshwariÎncă nu există evaluări

- Art & Science: Meeting The Needs of Patients' Families in Intensive Care UnitsDocument8 paginiArt & Science: Meeting The Needs of Patients' Families in Intensive Care UnitsRiaÎncă nu există evaluări

- Excel Tips Tricks e-BookV1.1 PDFDocument20 paginiExcel Tips Tricks e-BookV1.1 PDFSulabhÎncă nu există evaluări

- MLA 7th Edition Formatting and Style GuideDocument14 paginiMLA 7th Edition Formatting and Style Guideapi-301781586Încă nu există evaluări

- Aircraft Tyre Maintenance - SKYbrary Aviation SafetyDocument8 paginiAircraft Tyre Maintenance - SKYbrary Aviation Safetynosh1983Încă nu există evaluări

- Proper Storage of Instruments2Document20 paginiProper Storage of Instruments2Pierre Vincent PorrasÎncă nu există evaluări

- Florian1995, Mental HealthDocument9 paginiFlorian1995, Mental Healthade ubaidahÎncă nu există evaluări

- LED Lighting Applications Design GuideDocument20 paginiLED Lighting Applications Design GuideBank100% (3)

- Real-World Data Is Dirty: Data Cleansing and The Merge/Purge ProblemDocument29 paginiReal-World Data Is Dirty: Data Cleansing and The Merge/Purge Problemapi-19731161Încă nu există evaluări

- Banksy Responses Done With A Partner 655512Document122 paginiBanksy Responses Done With A Partner 655512api-569248887Încă nu există evaluări

- Legend 1028KDocument2 paginiLegend 1028KAndres Fdo Mora DÎncă nu există evaluări

- The Impact of Employees' Commitment Towards Food Safety at Ayana Resort, BaliDocument58 paginiThe Impact of Employees' Commitment Towards Food Safety at Ayana Resort, Balirachelle agathaÎncă nu există evaluări

- FAUDI Aviation Diesel - Company Profile-ENDocument6 paginiFAUDI Aviation Diesel - Company Profile-ENAttila HontváriÎncă nu există evaluări