Documente Academic

Documente Profesional

Documente Cultură

Design Case Study

Încărcat de

p m yadav0 evaluări0% au considerat acest document util (0 voturi)

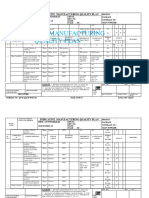

56 vizualizări14 paginiThe document summarizes the 10 step design process for a 10 MVA, 33/11 kV power transformer with the following key details:

- The core diameter is calculated as 40 cm based on the rating of 10 MVA. CRGO steel with a flux density of 1.7 Tesla is selected for the core material.

- Calculations are shown to determine the number of turns in the windings based on the voltages, with 156 turns for the LV winding and 809 turns for the HV winding.

- Core weight is calculated as 6130 kg and no load losses are calculated as 9195 Watts. Copper weights and I2R losses are also calculated for the windings.

Descriere originală:

Design case study

Titlu original

Design case study

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document summarizes the 10 step design process for a 10 MVA, 33/11 kV power transformer with the following key details:

- The core diameter is calculated as 40 cm based on the rating of 10 MVA. CRGO steel with a flux density of 1.7 Tesla is selected for the core material.

- Calculations are shown to determine the number of turns in the windings based on the voltages, with 156 turns for the LV winding and 809 turns for the HV winding.

- Core weight is calculated as 6130 kg and no load losses are calculated as 9195 Watts. Copper weights and I2R losses are also calculated for the windings.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

56 vizualizări14 paginiDesign Case Study

Încărcat de

p m yadavThe document summarizes the 10 step design process for a 10 MVA, 33/11 kV power transformer with the following key details:

- The core diameter is calculated as 40 cm based on the rating of 10 MVA. CRGO steel with a flux density of 1.7 Tesla is selected for the core material.

- Calculations are shown to determine the number of turns in the windings based on the voltages, with 156 turns for the LV winding and 809 turns for the HV winding.

- Core weight is calculated as 6130 kg and no load losses are calculated as 9195 Watts. Copper weights and I2R losses are also calculated for the windings.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

Design of 10 MVA, 33 (D)/11 (Y) kV

Power Transformer

Vector Group: Dyn11

Impedance: 7.0 %

Taps: ± 10% in 1.25% Step

(on HV for HV Variation)

Step – 01: Core Diameter

Core Diameter = 4 KVA Rating x 40

Core Area = 0.86 x (p x D2)/4

• Required Core Diameter,

D = 4 10000 X 40 = 400 mm=40 cm

• Core Area = 0.86 x (p x 4002)/4 = 108071

cm2

Step 2: Core Material & Flux

Density

Core Material: Cold Rolled Grain Oriented (CRGO)

Grade : M4, MOH etc.

Flux Density(Bm):Depends on Saturation Curve of the Core

Material

• Required Core Material Selected as CRGO of M4 Grade.

• Required Flux Density Taken as 1.7 Tesla (17000 Lines/cm2)

Step 3: Calculate (V/T)

V = 4.44 x f x Bm x Ai x T x 10-8

V/T = 4.44 x f x Bm x Ai x 10-8

Where,

V = Voltage Induced (Volts)

V/T = Volts / Turn

f = Operating Frequency (Hz)

Bm = Operating Flux Density (Lines/cm2)

Ai = Core Area (cm2)

T = No. of Turns

• Calculated V/T = 4.44 x 50 x 17000 x 1080.71 x

10-8

= 40.79 Volts/Turn

Step 4: Current Density,

Conductor Insulation &

Clearances

Current Density is taken as 3.5 Amps./mm2

• Paper Covering, Radial & Axial Blocks

taken as per Standards.

• Clearances between Core & Coil, between

Coils, between Phases etc. taken as per

requirement depending upon Basic

Insulation Level (BIL) requirement of the

windings.

Step 5: Calculate Number of

Turns in Windings

* No. of Turns = Phase Voltage/(V/T)

• LV No. of Turns = (11000/)/40.79 = 156

Turns

• HV No. of Turns = 33000/40.79 = 809 Turns

• HV Reg. No. of Turns = 10% of HV Turns

= 81 Turns

* NOTE: Rounded to Nearest Integer

Step 6: Calculate Leg-Length

Adjust Leg Length of the Core so as to

match the required impedance by Trial &

Error Method.

• Calculated Leg Length = 1145 mm

Step 7: Calculate No. of Discs &

Turns/Disc

Adjust No. of Discs according to Leg Length so

as to get desired Conductor

No. of Turns/Discs = Total No. of Turns

No. of Discs

• Required No. of Discs (LV/HV/HVR) =

78/102/48

• Required No. of Turns/Disc (LV/HV/HVR) =

2/8/2

Step 8: Calculate Leg Center

Leg Center of the core depends on the

Radial Depths of the Windings & the

Clearances provided

Leg Center = D+2x(core-coil & Inter Coil Clearances + Radial Depths of

HV, LV & HVR)+Phase to Phase Clearance

• Calculated Leg Center = 785 mm

Step 9: Calculate Core Weight &

No Load Loss

Core Weight = (2.1 x D + 3 x Leg Length + 4 x Leg Center) x 7.65 x Core

Area x 10-6

No Load Loss (NLL) = Core Weight x Watts/Kg x Building Factor

Where,

Watts/Kg = Loss per Kg of core depending upon the Grade of Core

Material & Flux Density (Bm)

• Core Weight = (2.1 x 400 + 3 x 1145 + 4 x 785) x 7.65 x 108071 x 10-6

= 6130 Kg

• NLL = 1.25 x 6130 x 1.2 = 9195 Watts

Step 9: Calculate Copper

2

Weight & I R Losses

Length Mean Turn (LMT) = p x Mean Dia. Of Coil

Total Length of Conductor (L)= LMT x No. of Turns

Weight of Copper = L x Crossectional area of Coil (Ac) x Density of Copper

Resistance (R) = (Resistivity of Copper x L)/Ac

I2R/Coil = 3 x (Phase Current in Coil )2 x R

• Calculated Bare Weighs of Copper:

LV = ((p x 479 x 156 x 154.56 x 8.9)/1000000) x 3 = 970 Kg

HV = ((p x 622 x 809 x 33.44 x 8.9)/1000000) x 3 = 1412 Kg

HVR = ((p x 742 x 81 x 39.60 x 8.9)/1000000) x 3 = 200 Kg

• I2R Losses Of Windings @ Normal Tap:

LV = ((524.86)2 x ((0.021 x p x 479 x 156)/154.56)/1000000) x 3 = 26.35 kW

HV = ((101.01)2 x ((0.021 x p x 622 x 809)/33.34)/1000000) x 3 = 30.47 kW

Step 10: Calculate Total Losses

Total Load Loss (LL) = Total I2R Loss + Eddy Current Loss +

Stray Loss

= I2R Loss x 1.06

• Calculated Load Loss = 56.82 x 1.06

= 60.23 kW

Thank You

S-ar putea să vă placă și

- Indian Standard: Enamel, Synthetic, Exterior: (A) Undercoating (B) Finishing - SpecificationDocument24 paginiIndian Standard: Enamel, Synthetic, Exterior: (A) Undercoating (B) Finishing - SpecificationAnu PrasobhÎncă nu există evaluări

- Simulation Design of Impulse Voltage Generator: Himalayal - Shanghai - ChinaDocument9 paginiSimulation Design of Impulse Voltage Generator: Himalayal - Shanghai - ChinaCRISTIAN ANDRES MAYORGA CASTILLOÎncă nu există evaluări

- EarthingDocument87 paginiEarthingAkhil Gangwar100% (1)

- Calculation of Positive Sequence ImpedanceDocument14 paginiCalculation of Positive Sequence ImpedancesathiyaseelanÎncă nu există evaluări

- Condition Monitoring of Transformers SAILDocument17 paginiCondition Monitoring of Transformers SAILavadiraja100% (1)

- Failure Report October 11 To September 12 PDFDocument34 paginiFailure Report October 11 To September 12 PDFArnav SwarnkarÎncă nu există evaluări

- CRGODocument15 paginiCRGOipraoÎncă nu există evaluări

- IS 2165 Part1-1977 Ins Coord - Phase To Earth PDFDocument28 paginiIS 2165 Part1-1977 Ins Coord - Phase To Earth PDFRohit DeraÎncă nu există evaluări

- Tan Delta Test - Loss Angle Test - Dissipation Factor Test - Electrical4U PDFDocument10 paginiTan Delta Test - Loss Angle Test - Dissipation Factor Test - Electrical4U PDFDan AndreiÎncă nu există evaluări

- Transformer OilDocument1 paginăTransformer Oilswagata12345Încă nu există evaluări

- Section - 1 (Power Transformer) A. Purpose: The Purpose of This Document Is To Design (Sizing Calculation) MainDocument2 paginiSection - 1 (Power Transformer) A. Purpose: The Purpose of This Document Is To Design (Sizing Calculation) Mainsrikanta100% (1)

- Why Transformer Does Not Work On DC Supply Instead of ACDocument4 paginiWhy Transformer Does Not Work On DC Supply Instead of ACAHMED YOUSEFÎncă nu există evaluări

- 00en PDFDocument158 pagini00en PDFmaggam100% (1)

- Calculate IDMT Over Current Relay Setting (50 - 51)Document7 paginiCalculate IDMT Over Current Relay Setting (50 - 51)Woei Song OoiÎncă nu există evaluări

- Capacitance and Dissipation Factor MeasurementsDocument10 paginiCapacitance and Dissipation Factor MeasurementsIrfan AliÎncă nu există evaluări

- Standard For Cables and Cable Installations 12737281Document47 paginiStandard For Cables and Cable Installations 12737281Anupong JIÎncă nu există evaluări

- Summation CTDocument1 paginăSummation CTDHARMENDRAÎncă nu există evaluări

- Deep Bar Vis-À-Vis Double Cage Rotor Design For Large MV MotorsDocument2 paginiDeep Bar Vis-À-Vis Double Cage Rotor Design For Large MV MotorsSUBRATA BISWASÎncă nu există evaluări

- Learning From HMG Training On SwitchgearDocument1 paginăLearning From HMG Training On SwitchgearanjnaÎncă nu există evaluări

- Sizing Stationary Batteries GuideDocument10 paginiSizing Stationary Batteries Guidekritikasharma88Încă nu există evaluări

- Thermal 49 CalculatorDocument2 paginiThermal 49 CalculatorRiansyah Kurnia WibowoÎncă nu există evaluări

- SS-4 HV TestingDocument1 paginăSS-4 HV TestingSoumya BhowmickÎncă nu există evaluări

- BIL Levels For Switchgear - Siemens Tech Topics Rev 0Document2 paginiBIL Levels For Switchgear - Siemens Tech Topics Rev 0Peter DyckÎncă nu există evaluări

- ESS ARR INDUSTRIES TEST CERTIFICATE FOR 315 KVA OUTDOOR TRANSFORMERDocument1 paginăESS ARR INDUSTRIES TEST CERTIFICATE FOR 315 KVA OUTDOOR TRANSFORMERRajeev babbarÎncă nu există evaluări

- BEF Calculation - Part 2 PDFDocument8 paginiBEF Calculation - Part 2 PDFLin HengÎncă nu există evaluări

- 19.auxiliary Trafo GTPDocument11 pagini19.auxiliary Trafo GTPAnkit VishwakarmaÎncă nu există evaluări

- Report Presentation MSETCL KalwaDocument38 paginiReport Presentation MSETCL KalwaManish Kumar Bhardwaj100% (1)

- 22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & CoDocument13 pagini22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & Coshan shanzÎncă nu există evaluări

- A2.24 Thermal PerformancesID55VER20Document15 paginiA2.24 Thermal PerformancesID55VER20Fajar Adi PrabowoÎncă nu există evaluări

- VCB Switching Furnace LoadDocument8 paginiVCB Switching Furnace LoadkrcdewanewÎncă nu există evaluări

- Eeda 512 - Ac/Dc Machinery (Lecture) Lesson 3: Transformers and RegulatorsDocument4 paginiEeda 512 - Ac/Dc Machinery (Lecture) Lesson 3: Transformers and RegulatorsPatrick NavaÎncă nu există evaluări

- Mineral Insulating OilDocument96 paginiMineral Insulating OilnbhawyaÎncă nu există evaluări

- 17-Three Phase Transformers Part2Document7 pagini17-Three Phase Transformers Part2Adithya ChandrasekaranÎncă nu există evaluări

- VR La Batterie Edited 15Document8 paginiVR La Batterie Edited 15SOMU_61Încă nu există evaluări

- Fault Calculation Source Data:: Short Circuit Current (As Per /data)Document7 paginiFault Calculation Source Data:: Short Circuit Current (As Per /data)Mustafa HamidÎncă nu există evaluări

- DGA of CT OilDocument13 paginiDGA of CT Oilraza239Încă nu există evaluări

- IEC VS ANSI CT Burden Comparision PDFDocument3 paginiIEC VS ANSI CT Burden Comparision PDFflyzalÎncă nu există evaluări

- Cable Schedule P 90916 E D2 8532 124 01 PCS PARLI Revision 2Document18 paginiCable Schedule P 90916 E D2 8532 124 01 PCS PARLI Revision 2AnilÎncă nu există evaluări

- Technical Specification of 480V-11KV IDT - CEL Project - R0Document15 paginiTechnical Specification of 480V-11KV IDT - CEL Project - R0Jitendra PathakÎncă nu există evaluări

- 3 66kv630 SQMM 1c Power CableDocument26 pagini3 66kv630 SQMM 1c Power CableKeval VelaniÎncă nu există evaluări

- Basics & Working Principles of BatteriesDocument35 paginiBasics & Working Principles of Batteriespriyanka joshiÎncă nu există evaluări

- Types and Applications of Overcurrent Relay Part 1Document10 paginiTypes and Applications of Overcurrent Relay Part 1carlos vidalÎncă nu există evaluări

- GDocument6 paginiGFooser915Încă nu există evaluări

- Transformer OilDocument1 paginăTransformer OilbinodeÎncă nu există evaluări

- Calculate Numbers of Plate - Pipe - Strip Earthings (Part-3) - Electrical Notes & ArticlesDocument11 paginiCalculate Numbers of Plate - Pipe - Strip Earthings (Part-3) - Electrical Notes & ArticlesMohamad HishamÎncă nu există evaluări

- VSC Course Lecture2Document27 paginiVSC Course Lecture2eng7senÎncă nu există evaluări

- Dry Transformer Training GuideDocument24 paginiDry Transformer Training GuideNguyễn Nhật ÁnhÎncă nu există evaluări

- REF Fuse Application GuideDocument17 paginiREF Fuse Application GuidemuskanumeedÎncă nu există evaluări

- ! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationDocument4 pagini! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationMikeÎncă nu există evaluări

- Design of Single and Three Phase Transformer Using MATLABDocument6 paginiDesign of Single and Three Phase Transformer Using MATLABDevesh JayaswalÎncă nu există evaluări

- Modeling and Testing a Single-Phase TransformerDocument13 paginiModeling and Testing a Single-Phase TransformerMuhammad ImadÎncă nu există evaluări

- Oil Tan Delta and Resistivity Test - OTDDocument5 paginiOil Tan Delta and Resistivity Test - OTDAnand MandalÎncă nu există evaluări

- Product Manual For New Insulating Oils ACCORDING TO IS 335:2018Document8 paginiProduct Manual For New Insulating Oils ACCORDING TO IS 335:2018Ajay KumarÎncă nu există evaluări

- Electrical Resistance Lecture 2Document5 paginiElectrical Resistance Lecture 2bigbang0% (1)

- TransformerDocument9 paginiTransformerSamPolancosÎncă nu există evaluări

- CT Is StandardDocument17 paginiCT Is Standardashutosh2009Încă nu există evaluări

- 24 66 11 KV 5 MVA Transformer With Amendment PDFDocument100 pagini24 66 11 KV 5 MVA Transformer With Amendment PDFNirmal mehtaÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsDe la EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsÎncă nu există evaluări

- Tendernotice 1 37 Compressed 301 377Document77 paginiTendernotice 1 37 Compressed 301 377p m yadavÎncă nu există evaluări

- Highwing Brochure 240106 181011Document16 paginiHighwing Brochure 240106 181011p m yadavÎncă nu există evaluări

- Transformer Fault Record AnalysisDocument4 paginiTransformer Fault Record Analysisp m yadavÎncă nu există evaluări

- 603 Oc PDFDocument4 pagini603 Oc PDFp m yadavÎncă nu există evaluări

- Acknowledgementslip S1315737081000 PDFDocument1 paginăAcknowledgementslip S1315737081000 PDFsdurvasulaÎncă nu există evaluări

- Interview QuestionsDocument6 paginiInterview Questionsp m yadavÎncă nu există evaluări

- Maintaining EHV TransformersDocument3 paginiMaintaining EHV Transformersp m yadavÎncă nu există evaluări

- PTFR Brochure en 2019 02 Grid PTR 0234Document8 paginiPTFR Brochure en 2019 02 Grid PTR 0234p m yadavÎncă nu există evaluări

- TourDocument1 paginăTourp m yadavÎncă nu există evaluări

- SoPs For Domestic FlightDocument3 paginiSoPs For Domestic Flightp m yadavÎncă nu există evaluări

- 610 OcDocument4 pagini610 Ocp m yadavÎncă nu există evaluări

- 604 OcDocument5 pagini604 Ocp m yadavÎncă nu există evaluări

- Statement 1584939644449Document2 paginiStatement 1584939644449p m yadavÎncă nu există evaluări

- 603 OcDocument4 pagini603 Ocp m yadavÎncă nu există evaluări

- ResumeDocument2 paginiResumep m yadavÎncă nu există evaluări

- Commissioning of GT ABBDocument7 paginiCommissioning of GT ABBPandurang YadavÎncă nu există evaluări

- DTL PT-7774 Tan Delta and IR PI PDFDocument4 paginiDTL PT-7774 Tan Delta and IR PI PDFp m yadavÎncă nu există evaluări

- New Doc 2020-02-07 12.22.40 - 1Document1 paginăNew Doc 2020-02-07 12.22.40 - 1p m yadavÎncă nu există evaluări

- BapsDocument1 paginăBapsp m yadavÎncă nu există evaluări

- Mom, Anthiyur pt-7450,7050Document1 paginăMom, Anthiyur pt-7450,7050p m yadavÎncă nu există evaluări

- Laxman Mali Land PDFDocument15 paginiLaxman Mali Land PDFp m yadavÎncă nu există evaluări

- NC PatoleDocument1 paginăNC Patolep m yadavÎncă nu există evaluări

- DTL PT-7774 Tan Delta and IR PIDocument4 paginiDTL PT-7774 Tan Delta and IR PIp m yadavÎncă nu există evaluări

- Vittal Mali LandDocument5 paginiVittal Mali Landp m yadavÎncă nu există evaluări

- Documents Signed by All Brothers PDFDocument6 paginiDocuments Signed by All Brothers PDFp m yadavÎncă nu există evaluări

- Nynas Nytro LibraDocument2 paginiNynas Nytro Librap m yadavÎncă nu există evaluări

- Phephar Uttara ModnimbDocument1 paginăPhephar Uttara Modnimbp m yadavÎncă nu există evaluări

- Trends in Protection & AutomationDocument68 paginiTrends in Protection & Automationp m yadavÎncă nu există evaluări

- Auxiliary Main Transformer 3011Document48 paginiAuxiliary Main Transformer 3011Dileep DudiÎncă nu există evaluări

- SDS for Insulating Oil Nytro LibraDocument15 paginiSDS for Insulating Oil Nytro LibraSaiNaungÎncă nu există evaluări

- CERADocument10 paginiCERAKeren Margarette AlcantaraÎncă nu există evaluări

- Solids Level Measurement Application Guide en 78224 PDFDocument144 paginiSolids Level Measurement Application Guide en 78224 PDFwalcalÎncă nu există evaluări

- Malaysia's Trade Potential in Colourful AfricaDocument18 paginiMalaysia's Trade Potential in Colourful AfricaThe MaverickÎncă nu există evaluări

- The Impact of StressDocument3 paginiThe Impact of StressACabalIronedKryptonÎncă nu există evaluări

- BCM Continuous ImprovementDocument22 paginiBCM Continuous ImprovementnikoÎncă nu există evaluări

- 2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and ChildDocument3 pagini2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and Childclint xavier odangoÎncă nu există evaluări

- wch13 01 Rms 20230817Document24 paginiwch13 01 Rms 20230817halcieeschÎncă nu există evaluări

- 559 Fault CodeDocument4 pagini559 Fault Codeabdelbagi ibrahim100% (1)

- Cfm56-3 Engine Regulation by CFMDocument43 paginiCfm56-3 Engine Regulation by CFMnono92100% (5)

- Spec BoilerDocument9 paginiSpec BoilerAchmad MakmuriÎncă nu există evaluări

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Document3 paginiTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARÎncă nu există evaluări

- Material Handling EquipmentsDocument12 paginiMaterial Handling EquipmentsRahul SheelavantarÎncă nu există evaluări

- Past The Shallows EssayDocument2 paginiPast The Shallows EssaycaitlinÎncă nu există evaluări

- Dimensional Data: For Valves and ActuatorsDocument52 paginiDimensional Data: For Valves and ActuatorsPaulÎncă nu există evaluări

- 8-26-16 Police ReportDocument14 pagini8-26-16 Police ReportNoah StubbsÎncă nu există evaluări

- Base para Detectores de Humo y Temperatura KIDDE KI-SBDocument2 paginiBase para Detectores de Humo y Temperatura KIDDE KI-SBAnderson CastañedaÎncă nu există evaluări

- Q4 Module 8Document14 paginiQ4 Module 8DerickÎncă nu există evaluări

- M-LVDT: Microminiature Displacement SensorDocument2 paginiM-LVDT: Microminiature Displacement Sensormahdi mohammadiÎncă nu există evaluări

- 1 Colmac DX Ammonia Piping Handbook 4th EdDocument64 pagini1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoÎncă nu există evaluări

- Owners Manual Water Mist PDFDocument6 paginiOwners Manual Water Mist PDFZeeÎncă nu există evaluări

- Tumors of The Central Nervous System - VOL 12Document412 paginiTumors of The Central Nervous System - VOL 12vitoÎncă nu există evaluări

- Moral Character ViolationsDocument2 paginiMoral Character ViolationsAnne SchindlerÎncă nu există evaluări

- Family MedicineDocument156 paginiFamily MedicinedtriggÎncă nu există evaluări

- Proper restraint techniques for dogs and catsDocument153 paginiProper restraint techniques for dogs and catsjademattican75% (4)

- Chemical and Physical Properties of Refined Petroleum ProductsDocument36 paginiChemical and Physical Properties of Refined Petroleum Productskanakarao1Încă nu există evaluări

- Disinfecting Water Wells Shock ChlorinationDocument3 paginiDisinfecting Water Wells Shock ChlorinationmayaÎncă nu există evaluări

- Grade 3 science syllabus 1st and 2nd semesterDocument2 paginiGrade 3 science syllabus 1st and 2nd semesterelyzabeth SibaraniÎncă nu există evaluări

- ASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderDocument1 paginăASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderCatalin BailescuÎncă nu există evaluări

- DVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in ElectronicsDocument1 paginăDVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in Electronicsdinple sharmaÎncă nu există evaluări

- Human Capital FormationDocument9 paginiHuman Capital Formationtannu singh67% (6)