Documente Academic

Documente Profesional

Documente Cultură

Filler Slab

Încărcat de

Chidambar S DudgikarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Filler Slab

Încărcat de

Chidambar S DudgikarDrepturi de autor:

Formate disponibile

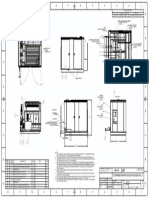

FILLER JOISTS FLOORS

This is a typical type of composite construction in which R.S.J, of small

sections are placed in concrete, as shown in Fig. 12.9. The spacing of the joists

may vary between 40 to 90 cm. The filter joists may either rest on walls (if the

span is less) or on longitudinal steel beams. The joists act as reinforcement, and

no separate reinforcement is provided in the concrete filled in between the joists.

Concrete should completely surround the filler joists and steel beams, with a

minimum cover of 2.5 cm over filler joists.

Filler slab technology is a simple and a very innovative technology for a

slab construction. The reason why, concrete and steel are used together to

construct RCC slab, is in their individual properties as separate building materials

and their individual limitation. Concrete is good in taking compression and steel

is good in tension. Thus RCC slab is a product which resists both compression as

well as tensile.

Knowing this much if we want to move further to understand the “Filler

slab” technology, we will have to further study the cross section of a typical

simply supported RCC Slab. Under its own load and applied load, the slab will

try to bend as shown in the Figure 1.

Fig 2: showing unwanted tension concrete

If we refer Figure 2, which indicates the neutral axis and also tension concrete in

the bottom fibers of the slab which is in tension but the top fibers will be in

compression. Knowing this much is the key to understand the filler slab

technology. Tension in a slab is on the bottom fiber and compression on the top

fiber. That means if we want to optimize the structure we can remove concrete

from the tension zone where it is not much needed. That’s the key behind filler

slab construction.

MATERIALS SELECTION AS PER NEED AND DESIGN

Light weight, inert and inexpensive materials such as low

grade Mangalore tiles, Burnt Clay Bricks, Hollow Concrete blocks, Stabilized

Mud blocks/ Hollow Mud blocks, Clay pots, Coconut shells etc. can be used as

filler materials. These materials are laid in the grids of steel reinforcement rods

and concreting/concrete topping is done over them.

fig : Filler material arrangement

The following points to be kept in mind for filler material selection:

• Filler material should be inert in nature. It should not react with concrete or steel in

RCC slab constructed.

• Filler materials water absorption should be checked for as it will soak the hydration

water from concrete.

• Filler material should be light in weight, so that overall weight of the slab reduces

and also the dead load onto the foundations is reduced.

• Filler material should be low cost so that it cost is much lesser then the cost of the

concrete it replaces. This is very important to achieve economy.

• Filler material should be of a size and cross-section, which can be accommodated

within the

• spacing of the reinforcement and also thickness wise could be accommodated within

the cross

• section of the slab.

• Moreover the Filler slab also provides insulation (compared to a conventional RCC

slab) from the

• hot climate outside the building, providing thermal comfort to the user.

• Filler material texture should match with the desired ceiling finish requirements so

as not to provide an ugly ceiling pattern.

Filler materials like Manglore tiles/Clay tiles can be installed in two layers (2 nos. one over the other)

entrapping an air cavity between the two tiles. A sketch showing cross section of a filler slab with

manglore tile is shown below. This will improve the thermal properties of the slab.

Figure 3: Filler slab section - Manglore tile filler material.

ADVANTAGES OF FILLER SLAB TECHNOLOGY:

• By adopting RCC filler slab construction compared to a RCC solid (conventional) slab in case

where Mangalore tiles are used as a filler material, you can save on approximately 19% of the total

concrete and including the cost of filler material, you can save around 5-10% of your concrete cost.

• Another advantage is, if the filler material is just a waste i.e. for ex temporary Mangalore tiles that

are removed from the roof to construct a pukka roof, you can save upon nearly 15% on your roof

concrete construction cost.

• Building a 25 sq. m slab can save you approx. Rs. 5000 from your concrete cost.

• Filler slab technology can also be applied to mass housing projects and township projects to gain

high cost saving and also saving in high energy consuming materials.

• Another advantage can be of a better thermal comfort if a cavity is kept between the filler material

or the filler material itself has a cavity. For example tow Mangalore tiles/Clay tiles can be kept one

over the other to form an air cavity thus keeping the interiors of your house remain cooler in summer

and warmer in winters.

• Filler slabs can be kept exposed (with proper workmanship) to create aesthetically pleasing ceiling

with a view of filler material from below and thus the cost of plastering and/or painting also can be

avoided.

• RCC being made of cement, steel, sand and aggregates, is a very high energy intensive material.

So reduction in concrete quantity compared to conventional slab construction, adds this technology

to the list of sustainable and environment friendly technologies and corpora ting green building

features.

S-ar putea să vă placă și

- RCC Filler Slab Construction Using Hollow Mud Blocks and Clay PotsDocument20 paginiRCC Filler Slab Construction Using Hollow Mud Blocks and Clay PotsIMRAN KHANÎncă nu există evaluări

- Abstract - Charles Correa MemorialDocument2 paginiAbstract - Charles Correa MemorialHimanshu Kalra100% (3)

- Open Spaces in HousingDocument22 paginiOpen Spaces in Housinglavanya thangavel100% (1)

- The Courtyards of Rajasthan Haveli ArchitectureDocument4 paginiThe Courtyards of Rajasthan Haveli Architectureshantbhardwaj100% (1)

- Bhooshan Architects Mallikarjun Residence BangaloreDocument24 paginiBhooshan Architects Mallikarjun Residence BangaloreLabeeb HRtzÎncă nu există evaluări

- Engineers India HouseDocument6 paginiEngineers India HouseDees_24100% (2)

- Study of With Reference To Priyadarshini Institute of Architecture and Design StudiesDocument22 paginiStudy of With Reference To Priyadarshini Institute of Architecture and Design StudiesPratik Parakh60% (5)

- Hill ArchitectureDocument4 paginiHill ArchitectureShashi Kant SinghÎncă nu există evaluări

- Cheonggyecheon Case Study PDFDocument2 paginiCheonggyecheon Case Study PDFIrene ReyesÎncă nu există evaluări

- Bhonga HouseDocument15 paginiBhonga HousePooja Jabade100% (1)

- Bhuj (Kutch, Gujarat) : Snehal Ramchandra Kamble Roll No-10 AicteDocument16 paginiBhuj (Kutch, Gujarat) : Snehal Ramchandra Kamble Roll No-10 Aictesnehal kambleÎncă nu există evaluări

- Book Review: Architecture as a ResponseDocument4 paginiBook Review: Architecture as a ResponseRishaad AmlaniÎncă nu există evaluări

- Achyut Kanvinde PPT HoaDocument26 paginiAchyut Kanvinde PPT Hoarajesh350Încă nu există evaluări

- HaveliDocument22 paginiHaveliSaeara Saju CÎncă nu există evaluări

- Laurie Baker PresentedDocument33 paginiLaurie Baker PresentedArnav DasaurÎncă nu există evaluări

- Dissertation 2017 PDFDocument44 paginiDissertation 2017 PDFAbdul WajidÎncă nu există evaluări

- Video 3.6: Golconde Dormitory, Pondicherry - A Case Study of Bio-Climatic Architecture in The Warm-Humid TropicsDocument2 paginiVideo 3.6: Golconde Dormitory, Pondicherry - A Case Study of Bio-Climatic Architecture in The Warm-Humid TropicsAissatou Inna YayaÎncă nu există evaluări

- RCC Folded Plates ShortDocument2 paginiRCC Folded Plates ShortdeepshikhaÎncă nu există evaluări

- Charles CorreaDocument20 paginiCharles CorreaAnushree SinghalÎncă nu există evaluări

- Specialized Air Conditioning SystemDocument6 paginiSpecialized Air Conditioning SystemSACHIDANANDA SÎncă nu există evaluări

- Report 6-Folded Plates Case StudyDocument6 paginiReport 6-Folded Plates Case StudySoham SatamÎncă nu există evaluări

- Architectural Considerations for Composite Climate ZonesDocument14 paginiArchitectural Considerations for Composite Climate Zoneseyob0% (1)

- Thesis Final 3Document90 paginiThesis Final 3poonam023580% (5)

- Sangath Architectural Office in AhmedabadDocument9 paginiSangath Architectural Office in AhmedabadShivani SÎncă nu există evaluări

- Charles Correa PDFDocument24 paginiCharles Correa PDFYoonus KÎncă nu există evaluări

- Disaster Resistant ArchitectureDocument287 paginiDisaster Resistant ArchitectureKeerthana ShamÎncă nu există evaluări

- C A PerryDocument17 paginiC A PerryInfanta mary33% (3)

- Architect Balkrishna Vithaldas Doshi: His Philosophy and WorksDocument42 paginiArchitect Balkrishna Vithaldas Doshi: His Philosophy and Workspallavi maheshwariÎncă nu există evaluări

- Tubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsDocument3 paginiTubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsKranthi Kumar Chowdary ManamÎncă nu există evaluări

- Critical Regionalism - 1Document26 paginiCritical Regionalism - 1NikhilÎncă nu există evaluări

- Chawls in MumbaiDocument2 paginiChawls in MumbaiShivangiTanna100% (1)

- 1-4 Building Economics and SociologyDocument37 pagini1-4 Building Economics and SociologySamreen Khan0% (1)

- HASHMUKH CHANDUBHAI PATEL-newFDocument29 paginiHASHMUKH CHANDUBHAI PATEL-newFPankaj DhakedÎncă nu există evaluări

- BHUNGADocument20 paginiBHUNGAVi MiÎncă nu există evaluări

- BV DoshiDocument30 paginiBV DoshiKavya100% (1)

- Vernacular Architecture SHEET X REVISED-ModelDocument1 paginăVernacular Architecture SHEET X REVISED-ModelShalesh YadavÎncă nu există evaluări

- Habib RahmanDocument23 paginiHabib RahmanAkshay KumarÎncă nu există evaluări

- Raj Rewal's masterful design of the Asian Games VillageDocument25 paginiRaj Rewal's masterful design of the Asian Games VillageParvÎncă nu există evaluări

- Charles CorreaDocument71 paginiCharles CorreadhruvÎncă nu există evaluări

- Vernacular ArchitectureDocument25 paginiVernacular ArchitectureRamya Soundarya0% (2)

- Modular Co OrdinationDocument37 paginiModular Co OrdinationShamika AyreÎncă nu există evaluări

- Aurangabadkar Wada PDFDocument35 paginiAurangabadkar Wada PDFkartik chopra100% (1)

- Vernacular Architecture in KashmirDocument6 paginiVernacular Architecture in KashmirGUNJAN33% (3)

- Le - CorbusierDocument34 paginiLe - CorbusierPavani KajaÎncă nu există evaluări

- PneumaticDocument45 paginiPneumaticTanuj BhardwajÎncă nu există evaluări

- Lesson Plan (Climatology s3)Document2 paginiLesson Plan (Climatology s3)Dipu GeorgeÎncă nu există evaluări

- Context and Architecture - A DissertationDocument53 paginiContext and Architecture - A DissertationAbishaTeslinÎncă nu există evaluări

- 2-Laurie Baker PaperDocument28 pagini2-Laurie Baker PaperSudharsana Jeyaraman100% (5)

- ARCHITECT'S ROLE IN PROMOTING SUSTAINABLE DESIGNDocument7 paginiARCHITECT'S ROLE IN PROMOTING SUSTAINABLE DESIGNBibilal VijayadevÎncă nu există evaluări

- Bus Shelter Case StudyDocument24 paginiBus Shelter Case StudyKaran SDÎncă nu există evaluări

- Chitra VishwanathDocument10 paginiChitra Vishwanathpriti kocheta100% (1)

- Design strategies and urban development in Nashik cityDocument22 paginiDesign strategies and urban development in Nashik cityRITIK JAINÎncă nu există evaluări

- The Impact of Climatic and Cultural Factors On Openings in Traditional Houses in MaharashtraDocument14 paginiThe Impact of Climatic and Cultural Factors On Openings in Traditional Houses in Maharashtracoldflame81Încă nu există evaluări

- Torrent Research Centre Ahmedabad Architectural Design For Passive CoolingDocument32 paginiTorrent Research Centre Ahmedabad Architectural Design For Passive CoolingpallaviÎncă nu există evaluări

- Rail Niram Nilayam, HyderabadDocument8 paginiRail Niram Nilayam, HyderabadmanonmaniÎncă nu există evaluări

- Student Housing Complex Inspired by Traditional Indian CitiesDocument16 paginiStudent Housing Complex Inspired by Traditional Indian Citieskhushi chhajedÎncă nu există evaluări

- Tao Zhu Yin YuanDocument14 paginiTao Zhu Yin YuanVedant HingmireÎncă nu există evaluări

- Arch. Anupama Kundoo: Substainable Architecture Design Projects M - Arch: Donata BigazziDocument7 paginiArch. Anupama Kundoo: Substainable Architecture Design Projects M - Arch: Donata BigazziMuhammedd YasirrÎncă nu există evaluări

- Henry Irwin and the Indo Saracenic Movement ReconsideredDe la EverandHenry Irwin and the Indo Saracenic Movement ReconsideredÎncă nu există evaluări

- Human RightsDocument4 paginiHuman RightsChidambar S DudgikarÎncă nu există evaluări

- Floor SlabDocument20 paginiFloor SlabChidambar S DudgikarÎncă nu există evaluări

- Forest Conservation Act 1980Document8 paginiForest Conservation Act 1980Chidambar S DudgikarÎncă nu există evaluări

- Forest Conservation Act 1980Document8 paginiForest Conservation Act 1980Chidambar S DudgikarÎncă nu există evaluări

- Building Services - Drainage Design and Site InspectionDocument31 paginiBuilding Services - Drainage Design and Site InspectionChidambar S Dudgikar100% (1)

- StaircaseDocument16 paginiStaircaseChidambar S DudgikarÎncă nu există evaluări

- FoundationDocument16 paginiFoundationChidambar S DudgikarÎncă nu există evaluări

- StaircaseDocument16 paginiStaircaseChidambar S DudgikarÎncă nu există evaluări

- Electricity 2Document16 paginiElectricity 2Chidambar S DudgikarÎncă nu există evaluări

- ElectricityDocument21 paginiElectricityChidambar S DudgikarÎncă nu există evaluări

- ElectricityDocument21 paginiElectricityChidambar S DudgikarÎncă nu există evaluări

- Seminar IIDocument12 paginiSeminar IIChidambar S DudgikarÎncă nu există evaluări

- BuTech Pipe Valves and FittingsDocument28 paginiBuTech Pipe Valves and FittingsThiago LimaÎncă nu există evaluări

- Specs Alternative Item 2 - Unitile USF-800 Ceramic FinishDocument3 paginiSpecs Alternative Item 2 - Unitile USF-800 Ceramic FinishKanna KumarÎncă nu există evaluări

- The Concepts and Specification of Maintainance Ramp For Military VehicleDocument5 paginiThe Concepts and Specification of Maintainance Ramp For Military VehicleRestu PutraÎncă nu există evaluări

- Register of Significant Twentieth Century ArchitectureDocument8 paginiRegister of Significant Twentieth Century ArchitectureElsa SafriyaniÎncă nu există evaluări

- BS en 15037-5-2013 - (2020-11-09 - 12-17-26 PM) PDFDocument62 paginiBS en 15037-5-2013 - (2020-11-09 - 12-17-26 PM) PDFdenizinakÎncă nu există evaluări

- 00 Incident Investigation Report COMPLETEDocument56 pagini00 Incident Investigation Report COMPLETEShannon MacDonald100% (5)

- CertainTeed Roof Shingles Natural LookDocument2 paginiCertainTeed Roof Shingles Natural LookJuryl ZacariasÎncă nu există evaluări

- Analysis of Project Success Factors in Construction IndustryDocument14 paginiAnalysis of Project Success Factors in Construction IndustryJuan AlayoÎncă nu există evaluări

- What Is Urban DesignDocument18 paginiWhat Is Urban DesignArun RajÎncă nu există evaluări

- Direct Design Method For Prestressed Concrete SlabsDocument11 paginiDirect Design Method For Prestressed Concrete SlabsAhmad HarounÎncă nu există evaluări

- GEZE Installation Instructions en 742566Document120 paginiGEZE Installation Instructions en 742566PiotrÎncă nu există evaluări

- Stack Design CalculationDocument27 paginiStack Design Calculationrupam dey100% (6)

- Chapter 1 - 5 PDFDocument43 paginiChapter 1 - 5 PDFYARLAGADDA_NANIÎncă nu există evaluări

- Pump SCE B 2Document8 paginiPump SCE B 2Zankar R ParikhÎncă nu există evaluări

- Brazing and Braze WeldsDocument13 paginiBrazing and Braze WeldsdocsdownforfreeÎncă nu există evaluări

- Effect of Floating Column On RCC Building With and Without Infill Wall Subjected Seismic ForceDocument7 paginiEffect of Floating Column On RCC Building With and Without Infill Wall Subjected Seismic ForceChime MornÎncă nu există evaluări

- Imw 50 Single Con CabinaDocument1 paginăImw 50 Single Con CabinaIgnacio LopezÎncă nu există evaluări

- Breuer - Sun & Shadow (Inglés) PDFDocument18 paginiBreuer - Sun & Shadow (Inglés) PDFccorrea74100% (1)

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDocument48 paginiSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamÎncă nu există evaluări

- 40N Draft 141205 PDFDocument58 pagini40N Draft 141205 PDFPrabartak DasÎncă nu există evaluări

- Bamboo As A Building MaterialDocument58 paginiBamboo As A Building MaterialAsociación DamaÎncă nu există evaluări

- Timber design guide for columns and beamsDocument10 paginiTimber design guide for columns and beamsKerri-Lyn LordeÎncă nu există evaluări

- Truck Mounted Crane Telescop BrochureDocument9 paginiTruck Mounted Crane Telescop BrochureHino Sales IndonesiaÎncă nu există evaluări

- Postmodern ArchitectureDocument9 paginiPostmodern ArchitectureSandra Samir100% (1)

- Hydraulic Calculation For Fire PumpDocument9 paginiHydraulic Calculation For Fire PumpShaifful NizamÎncă nu există evaluări

- DPP 1 SomDocument2 paginiDPP 1 Somacharjeesneha68Încă nu există evaluări

- Pile Testing - State of The ArtDocument17 paginiPile Testing - State of The ArtNader MehdawiÎncă nu există evaluări

- Steel and Pipes For Africa Price ListDocument1 paginăSteel and Pipes For Africa Price ListG A U G E100% (3)

- EMEA Core Hydraulic Hose Products Brochure - LRDocument16 paginiEMEA Core Hydraulic Hose Products Brochure - LRRomanÎncă nu există evaluări