Documente Academic

Documente Profesional

Documente Cultură

Six Sigma

Încărcat de

Sanju DevDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Six Sigma

Încărcat de

Sanju DevDrepturi de autor:

Formate disponibile

The term "Six Sigma" comes from a field of statistics known as process capability studies.

The ability of manufacturing processes to produce a very high proportion of output within specification. To improve the quality of process outputs by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes. A six sigma process is one in which 99.99966% of the products manufactured are, statistically expected to be free of defects (3.4 defects per million).

In Six Sigma, a defect is defined as any process output that does not meet customer specifications. It uses quality management methods, including statistical methods, and a special infrastructure of people within the organization Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified financial targets

The term "six sigma process" comes from the notion that if one has six standard deviations between the process mean and the nearest specification limit, as shown in the graph, practically no items will fail to meet specifications

Six Sigma projects follow two project methodologies inspired by Deming's Plan-Do-Check-Act Cycle. DMAIC DMAIC is used for projects aimed at improving an existing business process D Define M Measure A Analyze I Improve C Control

DMADV or DFSS ("Design For Six Sigma") DMADV is used for projects aimed at creating new product or process designs D Define M Measure A Analyze D Design V Verify

Fish Bone Diagram

Pareto Chart

Histogram

Control Chart

QFD

Six Sigma involves the "professionalizing" of quality management functions. Six Sigma identifies several key roles for its successful implementation. - Executive Leadership includes the CEO and other members of top management. They are responsible for setting up a vision for Six Sigma implementation - Champions take responsibility for Six Sigma implementation across the organization in an integrated manner.

-Black Belts operate under Master Black Belts to specific projects they devote 100% of their time to primarily focus on Six Sigma project execution -Green Belts are the employees who take up Six Sigma implementation along with their other job responsibilities, operating under the guidance of Black Belts.

Focus on customers. Improved customer loyalty. Reduced cycle time. Less waste. Data based decisions. Sustained gains and improvements. Systematic problem solving. Employee motivation. Faster to market. Team building. Reductions of incidents. Knowledge of competition, competitors . Integration of products, services and distribution.

Six Sigma is just for manufacturing Six Sigma is limited to large organizations Six Sigma is always the performance goal Six Sigma is a Tool Six Sigma is just about statistics

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- QUIZ in Marketing Research For PracticeDocument4 paginiQUIZ in Marketing Research For Practicemeenumathur100% (1)

- (On The Letterhead of The Bidder/CONSULTANT) : Format For Advice of Vendor DetailsDocument2 pagini(On The Letterhead of The Bidder/CONSULTANT) : Format For Advice of Vendor DetailsNinad SherawalaÎncă nu există evaluări

- Discounted Cash Flow Analysis Input Parameters and SensitivityDocument13 paginiDiscounted Cash Flow Analysis Input Parameters and Sensitivityfr5649Încă nu există evaluări

- Types of SamplingDocument16 paginiTypes of SamplingNidhin NalinamÎncă nu există evaluări

- Special Consideration For The Sole Practitioner Operating As A Management ConsultantDocument3 paginiSpecial Consideration For The Sole Practitioner Operating As A Management ConsultantJessyÎncă nu există evaluări

- Which Public Goods Should Be Public/privateDocument12 paginiWhich Public Goods Should Be Public/privateRozyÎncă nu există evaluări

- Ezulwini Reinsurance Company ProfileDocument17 paginiEzulwini Reinsurance Company ProfileAnonymous fuLrGAqg100% (2)

- Week 2 Handout 2 - Swakarya Dry and CleanDocument11 paginiWeek 2 Handout 2 - Swakarya Dry and CleantazkiaÎncă nu există evaluări

- B. MG Buys One Month Futures Where It Agrees To Buy, in One Month's Time The SameDocument7 paginiB. MG Buys One Month Futures Where It Agrees To Buy, in One Month's Time The Samemegha sharmaÎncă nu există evaluări

- CS Project Report PDFDocument48 paginiCS Project Report PDFswarajya lakshmi chepuri100% (2)

- Listing Reg. EX-50% NED - 1/3 Ned But Related - 50%Document3 paginiListing Reg. EX-50% NED - 1/3 Ned But Related - 50%Avinash BahadurÎncă nu există evaluări

- Dev EreDocument1 paginăDev Ereumuttk5374Încă nu există evaluări

- Acct 122 Outline (New)Document8 paginiAcct 122 Outline (New)Onika BlandinÎncă nu există evaluări

- 1Document343 pagini1GilÎncă nu există evaluări

- Article 1822, 1823, and 1824Document3 paginiArticle 1822, 1823, and 1824maria cruzÎncă nu există evaluări

- Disadvantages of TriggersDocument1 paginăDisadvantages of Triggerssanand11Încă nu există evaluări

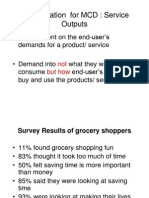

- Segmentation For Marketing Channel Design For Service OutputDocument25 paginiSegmentation For Marketing Channel Design For Service OutputHajiMasthanSabÎncă nu există evaluări

- TOYOTA - Automaker Market LeaderDocument26 paginiTOYOTA - Automaker Market LeaderKhalid100% (3)

- RBL Bank PDFDocument2 paginiRBL Bank PDFALLtyÎncă nu există evaluări

- Glossary: Industry Terms and What They Really MeanDocument4 paginiGlossary: Industry Terms and What They Really MeanJessica MarsÎncă nu există evaluări

- Strama 2015Document72 paginiStrama 2015Millicent Matienzo100% (5)

- Flora and FaunaDocument64 paginiFlora and FaunamerlinlinehanÎncă nu există evaluări

- Check-In Process at Lisbon Airport PDFDocument120 paginiCheck-In Process at Lisbon Airport PDFfreeflyairÎncă nu există evaluări

- Bank Statement Apr2022 Jan2023 - WPW 14 26 - 004Document13 paginiBank Statement Apr2022 Jan2023 - WPW 14 26 - 004Adarsh RavindraÎncă nu există evaluări

- Shriram Transport Finance Company LTD: Customer Details Guarantor DetailsDocument3 paginiShriram Transport Finance Company LTD: Customer Details Guarantor DetailsThirumalasetty SudhakarÎncă nu există evaluări

- Supplier Quality Manual - Edition 3 - April 2010Document14 paginiSupplier Quality Manual - Edition 3 - April 2010sosobigmanÎncă nu există evaluări

- 8963 36Document37 pagini8963 36OSDocs2012Încă nu există evaluări

- ACC501 Solved Current Papers McqsDocument36 paginiACC501 Solved Current Papers Mcqssania.mahar100% (2)

- MEC 1st Year 2018-19 English-Final PDFDocument9 paginiMEC 1st Year 2018-19 English-Final PDFUmesh Kumar MahatoÎncă nu există evaluări

- MCQ in Services MarketingDocument83 paginiMCQ in Services Marketingbatuerem0% (1)