Documente Academic

Documente Profesional

Documente Cultură

ERPModules

Încărcat de

prabhu.gampalaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ERPModules

Încărcat de

prabhu.gampalaDrepturi de autor:

Formate disponibile

Historical development

Initial Computer support to business Early 1970s

Easiest to automate payroll & accounting Precise rules for every case centralized mainframe computer systems MIS systematic reports of financial performance Variance analysis between budget and actual

Material requirements planning Inventory reordering tool Evolved to support planning MRPII extended to shop floor control

SD MM PP QM PM HR FINANCIAL FI CO AM PS R/3 INTERNAL WF

Sales & Distribution Materials Management MRP Production Planning Quality Management Plant Maintenance Human Resources Financial Accounting Controlling Asset Management Project System Workflow: prompt actions MRPII (with others)

SAP SD MM PP QM PM HR FI CO AM PS WF Service

Oracle Marketing, Sales Procurement Manufacturing

PeopleSoft Supply chain Supplier relationship

JDEdwards Order management Inventory, procurement Manufacturing mgmt

Enterprise perform Enterprise service Human capital mgmt Financial mgmt sol.

Technical foundation

Human Resources Financials

Workforce management Financial management Time & Expense mgmt

Asset Management Projects Order Management

Enterprise asset mgmt Project management

Each vendor has turned to customized ERP products to serve industry-specific needs

Examples given from BAAN, PeopleSoft Microsoft also has entered the fray

Discrete Manufacturing Aerospace & Defense Automobile Industrial Machinery Electronics Telecommunications Construction Logistics

Process Manufacturing Chemicals Food & Beverage Pharmaceuticals Cable & Wire Pulp & Paper Metals

Communications Financial Services High Technology

Consumer Products Federal Government Healthcare Industrial Products Higher Education Public Sector

Professional ServicesStaffing Utilities Wholesale Distribution

Accounting & Finance Customer Relationship Management E-Business Human Resources & Payroll Manufacturing Project Accounting Supply Chain Management

Module Financial & Accounting Materials Management Production Planning Order Entry Purchasing Financial Control Distribution/Logistics Asset Management Quality Management Personnel/HR Maintenance R&D Management

Use reported - US 91.5% 89.2% 88.5% 87.7% 86.9% 81.5% 75.4% 57.7% 44.6% 44.6% 40.8% 30.8%

Use reported Sweden 87.3% 91.8% 90.5% 92.4% 93.0% 82.3% 84.8% 63.3% 47.5% 57.6% 44.3% 34.2%

Mabert et al. (2000) surveyed Midwestern US manufacturers

Some modules had low reported use (below 50% in red) Financial & Accounting most popular

Universal need Most structured, thus easiest to implement

Sales & Marketing more problematic

Cost:

Cheaper to implement part of system Conflicts with concept of integration

Best-of-Breed concept:

Mabert et al. found only 40% installed system as vendor designed

50% used single ERP package; 4% used best-of-breed

Different vendors do some things better Conflicts with concept of integration

Third-party software

Integrate software applications from several vendors Could be used for best-of-breed Usually used to implement add-ons (specialty software such as customer relationship management, supply chain integration, etc.)

Davenport (2000) choices:

Rewrite code internally Use existing system with interfaces

Both add time & cost to implementation The more customization, the less ability to seamlessly communication across systems

Davenport (2000)

Roll out different ERP versions by region Each tailored to local needs Used by:

Core modules shared some specialty modules unique Hewlett-Packard Monsanto Nestle

Dell Computers

Chose to not adopt

Siemens Power Corporation

Implementation of selected modules

Evaluation of SAP R/3

Initial project adoption

1994 Dell began implementation of SAP R/3 enterprise software suite Spent over 1 year selecting from 3,000 configuration tables

After 2 year effort ($200 million), revised plan

Dell business model shifted from global focus to segmented, regional focus

In 1996 revised plan Found SAP R/3 too inflexible for Dells new make-to-order operation Dell chose to develop a more flexible system rather than rely on one integrated, centralized system

I2 Technologies software

Manage raw materials flow Order management Manufacturing control

Oracle software Glovia software

Inventory control Warehouse management Materials management

SAP module

Human resources

Glovia system interfaced with

Dells own shop floor system I2 supply chain planning software

This retained a Dell core competency

Would have lost if adopted publicly available system

Demonstrates the need for speed

Prolonged installation projects become outdated Need to continue to evaluate project need after adoption

Tendency to stick with old decision But sunk cost view needed

Demonstrates need to maintain core competitive advantage

Adopting vendor ERP doesnt

Nuclear fuel assembly manufacturer Engineering-oriented

1994 Began major reengineering effort

Reduced employees by 30%

1996 Adopted SAP R/3 system

Replacement of IS budgeted at $4 million

Some legacy systems retained

FI CO AR AP MM PP QC

Finance Controlling Accounts receivable Accounts payable Materials management Production planning Quality control

To be led by users Project manager from User community Consultant hired for IT support

IS group only marginally involved

Oct 1996 Installed FI module Sep 1997 Installed other modules On time, within budget

Made project team a permanent group Project manager had been replaced

2nd PM retained

SAP steering committee SAP project team formed

7 major user stakeholders

Guided operating policy major expenditures major design changes

15 members from key user groups

part-time

Trainer User help Advisors to middle management

End users became more proficient with time

Average of 3 months to learn what needed

Management training took longer

Management didnt understand system well Often made unrealistic requests

During first year

Major errors in ERP configuration Evident that users needed additional training New opportunities to change system scope suggested

Two years after installation

R/3 system upgrade

Core idea of ERP complete integration In practice, modules used

More flexible, less risk Can apply best-of-breed concept

Ideal, but costly

Related concepts

Middleware integrate external software Customization tailor ERP to organization Federalization different versions of ERP in different organizational subelements

S-ar putea să vă placă și

- Steam Its Generation and Use 41st Edition PDFDocument1.106 paginiSteam Its Generation and Use 41st Edition PDFAlberto Valdivia91% (11)

- Enterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectDe la EverandEnterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectEvaluare: 4.5 din 5 stele4.5/5 (5)

- Dr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)Document37 paginiDr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)MohammedSaadaniHassani67% (6)

- Keda's SAP ImplementationDocument7 paginiKeda's SAP ImplementationmathangiÎncă nu există evaluări

- 8187 - BIS Arvind Mills Case StudyDocument8 pagini8187 - BIS Arvind Mills Case StudyCfhunSaat50% (2)

- Leeson Speedmaster ManualDocument80 paginiLeeson Speedmaster ManualOrbán Árpád100% (1)

- FIDIC Red Book Construction Contract 1st Edition 1 9Document9 paginiFIDIC Red Book Construction Contract 1st Edition 1 9raviÎncă nu există evaluări

- Astm A722 PDFDocument5 paginiAstm A722 PDFNguyễn ThạnhÎncă nu există evaluări

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 paginiData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Hour 2: ERP Modules: Historical DevelopmentDocument33 paginiHour 2: ERP Modules: Historical DevelopmentPreeti RanaÎncă nu există evaluări

- ERP Modules: Historical DevelopmentDocument33 paginiERP Modules: Historical DevelopmentSahirÎncă nu există evaluări

- Erp ModulesDocument33 paginiErp Modulesrahul-singh-6592Încă nu există evaluări

- Hour 2: ERP Modules: Historical DevelopmentDocument33 paginiHour 2: ERP Modules: Historical DevelopmentRichard CardenasÎncă nu există evaluări

- Enterprise Resource Planing SystemsDocument70 paginiEnterprise Resource Planing Systemsaagrawal3Încă nu există evaluări

- It and RetailDocument49 paginiIt and RetailchetnachhabraÎncă nu există evaluări

- ERP ModulesDocument24 paginiERP ModulesPradeeps SritharÎncă nu există evaluări

- CH 1 Introduction To Enterprise Resource Planning SystemsDocument20 paginiCH 1 Introduction To Enterprise Resource Planning SystemsPurdianta YoÎncă nu există evaluări

- A Case Study of ERP Implementation IssuesDocument25 paginiA Case Study of ERP Implementation Issuesfero_sher22Încă nu există evaluări

- Enterprise Resource PlanningDocument44 paginiEnterprise Resource PlanningDeepika PatelÎncă nu există evaluări

- ErpmDocument19 paginiErpmakshay kushÎncă nu există evaluări

- ERPDocument33 paginiERPLovepreetSidhuÎncă nu există evaluări

- ERP OverviewDocument33 paginiERP OverviewKhubaibAhmedÎncă nu există evaluări

- ERP AmritaDocument45 paginiERP AmritaUmair KhalidÎncă nu există evaluări

- IIT 13 - Enterprise Apps - ERP (Session 4)Document30 paginiIIT 13 - Enterprise Apps - ERP (Session 4)Sahil WadhwaÎncă nu există evaluări

- Hour 3: Best Practices: Reason For ERP Do Things Better Best PracticesDocument18 paginiHour 3: Best Practices: Reason For ERP Do Things Better Best PracticesmetkoubÎncă nu există evaluări

- Operations StartegyDocument23 paginiOperations Startegyastrobat69Încă nu există evaluări

- Class PresentationDocument142 paginiClass PresentationFaisal RashidÎncă nu există evaluări

- Ilovepdf MergedDocument212 paginiIlovepdf MergedsukeshÎncă nu există evaluări

- Evolution of ERP & Conceptual Model of ERPDocument3 paginiEvolution of ERP & Conceptual Model of ERPneeraj sainiÎncă nu există evaluări

- Nterprise Esource LanningDocument42 paginiNterprise Esource LanningAvay ShresthaÎncă nu există evaluări

- E2E Project CharterDocument27 paginiE2E Project CharterMuhammad JaveedÎncă nu există evaluări

- Johnson IndustriesDocument21 paginiJohnson Industriesaarun01Încă nu există evaluări

- Name: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Document17 paginiName: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Vivek KumarÎncă nu există evaluări

- ERP Intro 2Document52 paginiERP Intro 2Sentthil KumarÎncă nu există evaluări

- ERPDocument60 paginiERPSamÎncă nu există evaluări

- Nterprise Esource Lanning: By: Rahul GuptaDocument20 paginiNterprise Esource Lanning: By: Rahul GuptaRahul GuptaÎncă nu există evaluări

- ERP Implementation4Document43 paginiERP Implementation4Senthil KumarÎncă nu există evaluări

- Enterprise Resource Planning: Presented By:-Gurnoor Kaur (BFT/18/620) Snigdha Das (BFT/18/616)Document34 paginiEnterprise Resource Planning: Presented By:-Gurnoor Kaur (BFT/18/620) Snigdha Das (BFT/18/616)GURNOOR KAURÎncă nu există evaluări

- ERP EvolutionDocument45 paginiERP EvolutionSoumyajyoti Kundu100% (1)

- ERP-04Document21 paginiERP-04Kenneth Wijaya100% (1)

- Vandelay Industries IncDocument22 paginiVandelay Industries Incgaurav swarnkarÎncă nu există evaluări

- mrp2-3 FinalDocument33 paginimrp2-3 FinalMatthew Smith50% (2)

- Enterprise Resource Planning (ERP) : Presented By: Makansingh ChauhanDocument28 paginiEnterprise Resource Planning (ERP) : Presented By: Makansingh ChauhanGuru Darshan0% (1)

- Assignment - 1 On: (Erp Implementation-Case Study)Document39 paginiAssignment - 1 On: (Erp Implementation-Case Study)AlokKumarÎncă nu există evaluări

- Week 2Document5 paginiWeek 2Cipriano Gumafelix100% (1)

- R12 Finance Student GuideDocument479 paginiR12 Finance Student Guidemandeeppathak100% (3)

- Chap 3 Value, Risks and Benefits of ERPDocument28 paginiChap 3 Value, Risks and Benefits of ERPAinul MashieÎncă nu există evaluări

- Erp Session1Document53 paginiErp Session1omid samkanaiÎncă nu există evaluări

- Click To Edit Master Subtitle StyleDocument25 paginiClick To Edit Master Subtitle StyleFikri HilmiÎncă nu există evaluări

- Chapter One Why Study ERP Systems?: "Enterprise Resource Planning Systems", D. E. O'Leary, 2000 ©Document18 paginiChapter One Why Study ERP Systems?: "Enterprise Resource Planning Systems", D. E. O'Leary, 2000 ©chitu1992Încă nu există evaluări

- ERPDocument49 paginiERPDeep MalaniÎncă nu există evaluări

- FI Material 2 PDFDocument568 paginiFI Material 2 PDFVishal YadavÎncă nu există evaluări

- An Overview On ERP - Chapter 1Document26 paginiAn Overview On ERP - Chapter 1Puneet BansalÎncă nu există evaluări

- Enterprise Resource PlanningDocument36 paginiEnterprise Resource PlanningAnwar Bin Saleem MirzaÎncă nu există evaluări

- Introduction To Sap: Overview of The SAP R/3 System & Getting Started With R/3Document23 paginiIntroduction To Sap: Overview of The SAP R/3 System & Getting Started With R/3kshirsagar_amarÎncă nu există evaluări

- Implementation PresentationDocument25 paginiImplementation PresentationSri Kanth100% (2)

- ERP Benefits and RiskDocument13 paginiERP Benefits and Riskchitu1992Încă nu există evaluări

- What Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Document31 paginiWhat Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Faisal AlharbiÎncă nu există evaluări

- Enterprise Resource Planning (Document19 paginiEnterprise Resource Planning (Ninad KhuleyÎncă nu există evaluări

- Function Points?: David LongstreetDocument55 paginiFunction Points?: David LongstreetCibyBaby PunnamparambilÎncă nu există evaluări

- Introduction To ERP - StuDocument56 paginiIntroduction To ERP - Stunydiacassandraa02Încă nu există evaluări

- Business Visibility with Enterprise Resource PlanningDe la EverandBusiness Visibility with Enterprise Resource PlanningÎncă nu există evaluări

- Process Improvement & Performance Management Made Simple: The Fasttrack Approach to Getting Results QuicklyDe la EverandProcess Improvement & Performance Management Made Simple: The Fasttrack Approach to Getting Results QuicklyÎncă nu există evaluări

- Book Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementDe la EverandBook Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementÎncă nu există evaluări

- Cover Block (8383837083)Document7 paginiCover Block (8383837083)BALAJI ENTERPRISESÎncă nu există evaluări

- Project Report On Edible Oil Packaging Machinery: Indian Institute of Packaging, KolkataDocument36 paginiProject Report On Edible Oil Packaging Machinery: Indian Institute of Packaging, KolkataHemlata nagÎncă nu există evaluări

- Technical Summary: Semiconductor MC68HC11A8 MC68HC11A1 MC68HC11A0 8-Bit MicrocontrollersDocument45 paginiTechnical Summary: Semiconductor MC68HC11A8 MC68HC11A1 MC68HC11A0 8-Bit MicrocontrollersElias CoronelÎncă nu există evaluări

- Ascorbic Acid Iodometric TitrationDocument2 paginiAscorbic Acid Iodometric TitrationÂngelo Jesus100% (8)

- Warranty Card PDFDocument1 paginăWarranty Card PDFEy AhÎncă nu există evaluări

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 paginiStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141Încă nu există evaluări

- General Use SOP TemplateDocument2 paginiGeneral Use SOP TemplateBaba HansÎncă nu există evaluări

- TNCS EarthingDocument3 paginiTNCS Earthingjoan benwari100% (1)

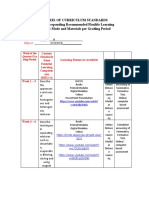

- Matrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodDocument2 paginiMatrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodNora HerreraÎncă nu există evaluări

- Market Consumer Perception Mahindra ThesisDocument95 paginiMarket Consumer Perception Mahindra ThesisHarmeet singh100% (1)

- Security Door InstallationDocument15 paginiSecurity Door InstallationHugo TrindadeÎncă nu există evaluări

- 18CrNiMo7-6 Chromium-Nickel-Molybdenum Case Hardening Steel - Hillfoot Multi MetalsDocument1 pagină18CrNiMo7-6 Chromium-Nickel-Molybdenum Case Hardening Steel - Hillfoot Multi MetalsKunal KoreÎncă nu există evaluări

- JSP BasicsDocument41 paginiJSP BasicsSandeep KavuriÎncă nu există evaluări

- GLR EstimateDocument2 paginiGLR EstimateanbujeÎncă nu există evaluări

- The Wire and Cable Technical Information HandbookDocument313 paginiThe Wire and Cable Technical Information Handbookdannyalarconm64718100% (5)

- Credazone 6 GiudeDocument3 paginiCredazone 6 Giudeguddu84Încă nu există evaluări

- Ptu Datesheet 2013Document4 paginiPtu Datesheet 2013Mugume JosephÎncă nu există evaluări

- FDTP brochure-EC 3354 Signals and Systems 2023Document2 paginiFDTP brochure-EC 3354 Signals and Systems 2023Principal RVSETGI,DindigulÎncă nu există evaluări

- Nokia 5310 Service Manual Level 1 and 2Document16 paginiNokia 5310 Service Manual Level 1 and 2adybosss100% (1)

- Galvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsDocument6 paginiGalvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsMA100% (1)

- Breakwater Vertical BarriersDocument10 paginiBreakwater Vertical BarriersAlbert PranataÎncă nu există evaluări

- Syed Ansar Ahmed: Quantity EngineerDocument7 paginiSyed Ansar Ahmed: Quantity EngineerRavi YadavÎncă nu există evaluări

- SANS Institute: Unix Security ChecklistDocument9 paginiSANS Institute: Unix Security ChecklistRufino UribeÎncă nu există evaluări

- LIFIDocument7 paginiLIFIRajeshÎncă nu există evaluări