Documente Academic

Documente Profesional

Documente Cultură

Centrifugal Compressors: Fabrizio Tani October 23rd 2001

Încărcat de

Stefano CaidominiciDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Centrifugal Compressors: Fabrizio Tani October 23rd 2001

Încărcat de

Stefano CaidominiciDrepturi de autor:

Formate disponibile

GE-NP Proprietary Information

CENTRIFUGAL

COMPRESSORS

Fabrizio Tani

October 23rd 2001

GE-NP Proprietary Information

GE Overview

g

GEPS Oil & Gas

GE-NP Proprietary Information

Aircraft Engines

Appliances

Capital Services

Industrial Systems

Lighting

Medical Systems

Plastics

Power Systems

Transportation Systems

NBC

Distinct Diverse Global

The GE Portfolio of Businesses

g

GEPS Oil & Gas

GE-NP Proprietary Information

GE Results

Revenues Earnings

($B)

1997 1998 1999 2000

91

100

112

130

1997 1998 1999 2000

8.2

9.3

10.7

12.7

Volume Increase as Result of Customer Satisfaction

g

GEPS Oil & Gas

GE-NP Proprietary Information

Compressors

Gas Turbines

Steam Turbines

Reactors

Air-Coolers

Pumps - Valves

Metering Systems

Fuel Dispensers

High Speed Recips.

TurboExpanders

Low to Medium

Pressure Compressors

Low to Medium Power

Steam Turbines

Multi-Vendor GT Svs

Center of

Excellence for...

Nuovo Pignone

Rotoflow

Thermodyn

Gemini

Odessa

Screw Compressors

A-C Compressor

Multi-Vendor

Compressor Services

CONMEC

Product & Services Leadership

g

GEPS Oil & Gas

GE-NP Proprietary Information

WHAT IS A COMPRESSOR?

COMPRESSOR

PRESSURE RATIO

GAS

Suction Pressure = Ps

Suction Temperature = Ts

Suction Velocity = Us

GAS

Discharge Pressure = Pd

Discharge Temperature = Td

Discharge Velocity = Ud

Compressor = Black Box to increase Gas Pressure

GE-NP Proprietary Information

EFFICIENCY

Ratio advantages / price

OR

Ratio cost in perfect world / cost in real world

GE-NP Proprietary Information

ADIABATIC PROCESS:

No exchange heat with external environment

First law of thermodynamics

H W Q A =

Adiabatic Process :

H W A =

0 = Q

( ) T P f H , =

Enthalpy H

WorkInput W

HeatInput Q

=

=

=

Absorbed Power (P) = Specific Work (W) x Gas Flow (G)

GE-NP Proprietary Information

A further hypothesis:

NO LOSSES

same suction conditions Ps,Ts

same discharge pressure Pd

lower discharge temperature Tis

The isentropic process associated to the real adiabatic process has:

ISENTROPIC PROCESS

Isentropic Process = All Energy to Compress Gas

GE-NP Proprietary Information

ISENTROPIC EFFICIENCY

The ratio of isentropic work to the total adsorbed energy

q

is

is

W

W

=

The ratio between what we would pay to obtain a

needed result in a perfect world and what we pay to

obtain the same result in the real world

Isentropic efficiency is a function of pressure ratio

}

= vdp W

Specific Work:

GE-NP Proprietary Information

TOTAL ADSORBED ENERGY

minus

ISENTROPIC WORK

LOSSES

Losses always associated to the real process

No analytical way to describe the real process point by point

GE-NP Proprietary Information

Solution to control the process

isoentrope from suction conditions to

the final discharge pressure

WORK INPUT ONLY

isobar at constant discharge pressure

to achieve the discharge temperature

HEAT INPUT ONLY

GE-NP Proprietary Information

The equation define the theoretical process called

POLYTROPE

For each step the isentropic work

dw vdp

is

=

dH

vdp

e =

e is the constant for which the path passes

through suction and discharge conditions and

the isentropic efficiency of each step

We define the equation:

POLYTROPIC WORK:

The sum of all the isentropic works step by step

W vdp

p

pol

=

}

.

GE-NP Proprietary Information

POLYTROPIC EFFICIENCY

For a perfect gas

The ratio of polytropic work to the

total adsorbed energy

q

p

p

W

W

=

q

p

n

n

K

K

=

1

1

Polytropic efficiency is not pressure ratio dependant

The ratio between the advantage we

can obtain with the use of a certain

tool and the price we have to pay

GE-NP Proprietary Information

CUSTOMER NEEDS

DIFFERENT POINTS OF VIEW

MANUFACTURER NEEDS

A way to compare compressor of different

manufacturers for the same service

A method to check the performance of the

machine at site

Define a relationship between the

performance and the geometry

Verify the performance

Achieve the performance

GE-NP Proprietary Information

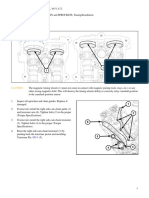

A WORKING IMPELLER

Normally the tangential component of C

1

is negligible

GE-NP Proprietary Information

The radial component of gas

velocity is associated to the flow

Multiply the inlet radial velocity

by the area at inlet to obtain the

volume flow at impeller suction

The tangential component of gas

velocity is associated to the work

made on the fluid

Euler equation

GE-NP Proprietary Information

The energy exchanged, per unit of weight of fluid, between

impeller outlet and inlet by its angular speed

EULER EQUATION

u u

C u C u W

1 1 2 2

=

In the hypothesis that C

1u

is negligible

u

C u W

2 2

=

GE-NP Proprietary Information

EULER EQUATION

u

C u W

2 2

=

Based on mechanical principles

H W A =

FIRST LAW EQUATION

Based on thermal quantities

W is the same!

GE-NP Proprietary Information

To predict performance we need non dimensional coefficients

representing a physical phenomenon that are:

DIMENSIONAL ANALYSIS

Results of experimental works carried out on models of the real stages

independent of the actual size of the machine

independent of the actual impellers speed

independent of gas characteristics

The non dimensional coefficients are:

Inlet Flow Coefficient

Outlet Flow Coefficient

Peripheral Mach Number

Reynolds Number

Head Coefficient

GE-NP Proprietary Information

The ratio between the radial component of the gas

velocity at inlet and impeller speed in the same

point

INLET FLOW COEFFICIENT

1

identifies gas

angles at inlet

1

1

1

u

C

r

=

OUTLET FLOW COEFFICIENT

The ratio between the radial component of the gas

velocity at outlet and impeller peripheral speed

2

2

2

u

C

r

=

A different form

const

v

v

i

o

1 2

=

GE-NP Proprietary Information

The ratio of impeller peripheral speed to the

velocity of sound at impeller inlet:

PERIPHERAL MACH NUMBER

A measure of gas compressibility

in

a

u

Mu

2

=

REYNOLDS NUMBER

ub

= Re

gas suction density

u impeller peripheral speed

b impeller exit width

dynamic viscosity

It can be read as ratio of inertia forces to viscous surface forces

GE-NP Proprietary Information

A measure of the impeller capacity to

energise the gas

HEAD COEFFICIENT

The ratio between the tangential component of the

gas velocity at outlet and impeller peripheral speed

2

2

u

C

u

= t

t

2

2

u W =

u

C u W

2 2

=

Euler equation

GE-NP Proprietary Information

NON DIMENSIONAL

PERFORMANCE CURVES

( )

1

t f =

( )

1

tq g

p

=

( )

1

q h

p

=

GE-NP Proprietary Information

Summary:

Input data:

Suction Pressure

Suction Temperature

Gas Composition

Discharge Pressure

Status Equation (BWRS: Benedict Webb Rubin Starling)

Experimental data:

Flow Coefficient

Head Coefficient

Discharge Pressure

Absorbed Power

Efficiency

GE-NP Proprietary Information

Main Design Criteria of Compressor

- Efficiency:

84 - 87 % for compression ratio up to 2

more than 75 % for compression ratio above 2

- Operating range: from 70 to 140 % of the design point

Design Point

GE-NP Proprietary Information

LNG

Liquefied Natural Gas

NATURAL GAS

Oil Production

Gas Production

Gas Lift

Pipeline

Gas Re-injection

Gas Storage

PETROCHEMICALS

Syngas & Fertilizers:

CO2 compressor for UREA Plants

Ammonia Synthesis

Methanol Synthesis

REFINERY

Fluid catalytic cracking

Reforming

Hydrocracking

Manufacturing Complete Range of Centrifugal Compressors

A comprehensive production for On-Shore and Off-Shore Services since 1960

from the High Volumes - Low Pressure Applications

to the Low Volumes - High Pressure Applications

Over 3500 Units Sold

World Leader in Gas Compression

GE-NP Proprietary Information

Low Pressures - High Volumes

GE-NP Proprietary Information

MCL - 2MCL - 3MCL - DMCL Compressors

High Volume Flows [up to 200,000 m

3

/h for MCL - 300,000 m3/h for DMCL]

Low Discharge Pressures [up to 40 bar]

Casings either cast or fabricated

Cast Iron Diaphragms

Radial and Thrust Bearings Tilting Pad type

Shaft End Seals both Oil film type or dry gas seal type

Low Pressures - High Volumes

GE-NP Proprietary Information

Casings and Diaphragms for High Pressure Compressors

GE-NP Proprietary Information

GE-NP Proprietary Information

BCL (/N-/A-/B-/C-/D) - 2BCL (/N-/A-/B-/C-/D) - 3BCL

Compressors for casing rating ranging up to 15000 Psi (API)

Medium to Low Volume Flows [ranging from 80,000 m

3

/h down to 300 m

3

/h]

Medium to Very High Discharge Pressures [experienced up to 700 bar]

Forged Steel Casings

Forged Steel Inner Casing

Cast Iron Diaphragms (forged steel for high differential Pressures)

Radial and Thrust Bearings Tilting Pad type

Shaft End Seals both Oil film type or dry gas seal type

High/Very High pressures - Low Volumes

GE-NP Proprietary Information

GE-NP Proprietary Information

Overhung Type Beam Type

Axial Inlet

Single Impeller

High Volumes, Low Pressure Ratio

Hydrostatic Lift

Size 800 to 1000

Lateral Flanges

One to Thr ee Impel lers

High Pressure Ratio

Axial Thrust Balance

Sizes 300 to 1000

Gas Pipeline Compressor - PCL

GE-NP Proprietary Information

3D Impeller Technology

Machined by 5-Axis Milling Machines

Barrel Casing With Cartridge Concept Internals

for Easy Maintenance

GE-NP Proprietary Information

Vertically Split Pipeline Compressors

Medium to High Volume Flows [ranging from 80,000 m

3

/h down to 3000 m

3

/h]

Low to Medium Discharge Pressures [experienced up to 110 bar]

Low Compressor Ratio [experienced up to 2]

High Polytropic Efficiency [experienced up to 0.86 with vaned Diffusor]

Axial Gas Inlet Arragement or Traditional Side Inlet Flange Configuration

Forged Steel Casings and inner casing

Radial and Thrust Bearings Tilting Pad type (option for magnetic bearings)

Shaft End Seals with Tandem Dry Gas Seals

Standardized casings for one to three impellers and direct coupling to NP Gas Turbines

Gas Pipeline Compressor - PCL

GE-NP Proprietary Information

Compressor Selection

The compressor is normally driven by Gas Turbine or Electric Motor

Compression selection steps:

Estimated absorbed power with dedicated software

Selection of the suitable GT model

Rotating speed becomes an input, related to the selected GT

Final selection of compressor by specific software

Compressor Configurators are the E-tools to perform a selection

via INTERNET

GE-NP Proprietary Information

GE-NP Proprietary Information

STAGES STANDARDIZATION

Predesigned and tested stages are used to meet

the requested performance and to avoid rotating

stall on statoric and rotating components

Standardization Ensures Reliability of Predicted Performances

GE-NP Proprietary Information

EXPERIENCED UP TO 210 BAR STATIC

TANDEM SEALS

TRIPLE SEALS

EXPERIENCED UP TO 290 BAR DYNAMIC AND 310 BAR STATIC

Shaft end sealing

GE-NP Proprietary Information

Shaft end sealing

Nuovo Pignone

LARGE EXPERIENCE ON DRY GAS SEALS

-Over 200 Compressors with Dry Gas Seals

-Sealing pressures at Settling Out conditions up to 4200 PSIA

-Dry Gas Seals size up to 250MM

Dry Gas Sealing system for 2BCL306C

Statoil Veslefrikk Compressor

GE-NP Proprietary Information

HONEYCOMB labyrinths

on balancing drums and impellers

to increase rotor system damping capabilities

for High Pressure Applications.

Honeycomb for Improved Rotor Stability

GE-NP Proprietary Information

Propane Compressor installed at Bintulu Plant

S-ar putea să vă placă și

- Mazda 32318 I 16 VBPDocument49 paginiMazda 32318 I 16 VBPJon Luc Pulido Julian0% (2)

- AlkylationDocument9 paginiAlkylationabhishek sharma100% (1)

- Layout Plans For Installation of LPG Autogas StationsDocument15 paginiLayout Plans For Installation of LPG Autogas StationsEjaz Ahmed RanaÎncă nu există evaluări

- Centrigual Compressors Course - Very Good PDFDocument91 paginiCentrigual Compressors Course - Very Good PDFVILLANUEVA_DANIEL2064100% (1)

- Presentation Centrifugal 02.ppsxDocument97 paginiPresentation Centrifugal 02.ppsxEslam Elmadboly100% (1)

- Engine System FundamentalsDocument17 paginiEngine System FundamentalsJha PuiÎncă nu există evaluări

- 6 Centrifugal Compressor IDocument40 pagini6 Centrifugal Compressor IBassam AmirÎncă nu există evaluări

- Listing of Installation (Gas Compressor Facilities)Document36 paginiListing of Installation (Gas Compressor Facilities)AyaanÎncă nu există evaluări

- Turboexpanders: CompressorsDocument4 paginiTurboexpanders: Compressorsdhanu_aquaÎncă nu există evaluări

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDocument16 paginiBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengÎncă nu există evaluări

- 02-Gas Compression Fundamentals-1Document47 pagini02-Gas Compression Fundamentals-1Muhammad Asad100% (1)

- S 28AT XP EXP EngDocument6 paginiS 28AT XP EXP EngpramodtryÎncă nu există evaluări

- Dynamic CompressorsDocument48 paginiDynamic Compressorsamrutnerlikar50% (2)

- Standard Operation ProcedureDocument66 paginiStandard Operation Procedureved847100% (2)

- Compressor & TheoryDocument41 paginiCompressor & TheoryJaveed A. KhanÎncă nu există evaluări

- Centrifugal CompressorsDocument106 paginiCentrifugal CompressorsUmair khan100% (1)

- Centrifugal Compressors For CPI Plants PDFDocument4 paginiCentrifugal Compressors For CPI Plants PDFAmanda Aracely Herreria SalazarÎncă nu există evaluări

- Steam Turbine OutageDocument18 paginiSteam Turbine OutageNida AliÎncă nu există evaluări

- MI - 1748 Rev FDocument21 paginiMI - 1748 Rev FSudarshan Dhumal100% (2)

- CENTRIFUGAL COMPRESSOR GUIDEDocument33 paginiCENTRIFUGAL COMPRESSOR GUIDERizwan Bangash50% (2)

- Grayloc Catalog (GLOC-105 - 11-09 - 5M) PDFDocument32 paginiGrayloc Catalog (GLOC-105 - 11-09 - 5M) PDFlsgmz33% (3)

- NewLecture8 Centrifugal CompressorsDocument126 paginiNewLecture8 Centrifugal CompressorsKhalid Mahmood100% (1)

- Turbo ExpanderDocument71 paginiTurbo ExpanderMachineryeng100% (2)

- 6natural Gas CompressionDocument46 pagini6natural Gas CompressionNana Twum100% (3)

- Pyro ProcessingDocument29 paginiPyro ProcessingMKPashaPasha100% (2)

- ACTIVE LEARNING PROCESS ON COMPRESSORSDocument22 paginiACTIVE LEARNING PROCESS ON COMPRESSORSSai Krishna Kiran B VÎncă nu există evaluări

- Timing ChainDocument8 paginiTiming ChainAri Jeep Ppm100% (1)

- BlowersDocument58 paginiBlowersmahmad61100% (1)

- Turbo-Machinery (Meng3201) : Chapter-3Document28 paginiTurbo-Machinery (Meng3201) : Chapter-3Asnake Bahiru100% (1)

- How To Build A Gas Forge BurnerDocument10 paginiHow To Build A Gas Forge BurnerKevin Guy0% (1)

- Turboexpander-Compressor Technology For Ethylene Plants: GE Oil & GasDocument12 paginiTurboexpander-Compressor Technology For Ethylene Plants: GE Oil & Gaspatrickzluo100% (1)

- Gas Compressor GuideDocument6 paginiGas Compressor GuideNicolas LuchmunÎncă nu există evaluări

- 03 FundamentalsDocument32 pagini03 FundamentalsKavi BhandariÎncă nu există evaluări

- Compressors - Written ReportDocument17 paginiCompressors - Written ReportJenina Rosa P. LlanesÎncă nu există evaluări

- CATALYTIC REFORMING: CONVERTING PETROLEUM INTO HIGH-OCTANE GASOLINEDocument15 paginiCATALYTIC REFORMING: CONVERTING PETROLEUM INTO HIGH-OCTANE GASOLINEjohnsonÎncă nu există evaluări

- Compressors IntroductionDocument12 paginiCompressors Introductionhiyeon100% (1)

- Turbomachinery Selection Exploitation and MaintenanceDocument9 paginiTurbomachinery Selection Exploitation and MaintenanceMichael Chikwendu100% (1)

- ELEMENTS OF COMPRESSOR THERMODYNAMICSDocument44 paginiELEMENTS OF COMPRESSOR THERMODYNAMICSSofiane Halimi100% (1)

- Centrifugal Pumps and SealDocument32 paginiCentrifugal Pumps and SealAnatoli KarpobÎncă nu există evaluări

- LAT4Document6 paginiLAT4Said FerdjallahÎncă nu există evaluări

- Introduction to Positive Displacement CompressorsDocument30 paginiIntroduction to Positive Displacement CompressorschaitanyaÎncă nu există evaluări

- 5 Reciprocating Compressor SelectionDocument27 pagini5 Reciprocating Compressor SelectionHazem RamdanÎncă nu există evaluări

- LNG Fuel SystemsDocument33 paginiLNG Fuel Systemssmithwork100% (1)

- CompressorDocument22 paginiCompressorMuhammad Nursalam100% (1)

- Dry Gas Seal1Document8 paginiDry Gas Seal1anshug1016100% (1)

- Reciprocating CompressorDocument7 paginiReciprocating CompressorAlphy Thomas100% (1)

- DCP002FO5 - Strimmer Daily Check SheetDocument1 paginăDCP002FO5 - Strimmer Daily Check SheetSTEVEN DELAHUNTYÎncă nu există evaluări

- Report On Gass CompresorDocument35 paginiReport On Gass CompresorPooyan Hasan Poor100% (1)

- Gas Engine FundamentalsDocument13 paginiGas Engine Fundamentalsherdin56Încă nu există evaluări

- Magnetic BearingsDocument26 paginiMagnetic BearingsakhilthampiÎncă nu există evaluări

- Air and Gas Compressors 14: Rayner Joel, 5 EditionDocument13 paginiAir and Gas Compressors 14: Rayner Joel, 5 EditionJerin Cyriac0% (1)

- Types of CompressorsDocument23 paginiTypes of CompressorsyashÎncă nu există evaluări

- Centrifugal Pumps Bearings - Part 1Document23 paginiCentrifugal Pumps Bearings - Part 1visitabhinav80% (5)

- Thermofluids & Engine: Gas Power CyclesDocument29 paginiThermofluids & Engine: Gas Power CyclesQim SvÎncă nu există evaluări

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDocument38 paginiTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanÎncă nu există evaluări

- Isentropic Efficiencies of Turbines, Compressors and NozzlesDocument24 paginiIsentropic Efficiencies of Turbines, Compressors and NozzlesgrandecaciqueÎncă nu există evaluări

- Centrifugal Compressors: Petroskills CourseDocument23 paginiCentrifugal Compressors: Petroskills CoursedeepikaÎncă nu există evaluări

- Petroleum Gas Compression Centrifugal CompressorsDocument59 paginiPetroleum Gas Compression Centrifugal CompressorsEngr TheyjiÎncă nu există evaluări

- Syn Gas Compressor - Centrifugal Compressors XDocument23 paginiSyn Gas Compressor - Centrifugal Compressors XDavid PierreÎncă nu există evaluări

- Compressors: Presented By: Andrith Fabian Güiza Zambrano 2134124 Presented To: Ing. Nicolas Santos SantosDocument50 paginiCompressors: Presented By: Andrith Fabian Güiza Zambrano 2134124 Presented To: Ing. Nicolas Santos SantosbrandonÎncă nu există evaluări

- Hydrometallurgy Del Cu PDFDocument528 paginiHydrometallurgy Del Cu PDFAnonymous FfIxH2o9100% (1)

- Reciprocating Compressor ValveDocument14 paginiReciprocating Compressor ValvesaikatchoudhuriÎncă nu există evaluări

- Reciprocating Compressor BasicsDocument3 paginiReciprocating Compressor BasicsAsad AshfaqÎncă nu există evaluări

- Gas Compressor AvanceDocument36 paginiGas Compressor AvanceLina VargasÎncă nu există evaluări

- Hoerbiger Rings & Packings Training SeminarDocument20 paginiHoerbiger Rings & Packings Training SeminarinamÎncă nu există evaluări

- Compressor (Disambiguation)Document54 paginiCompressor (Disambiguation)nelsonÎncă nu există evaluări

- An-PP-001 Turboexpander Design FeaturesDocument5 paginiAn-PP-001 Turboexpander Design FeaturesSobhy GendykhelaÎncă nu există evaluări

- Reciprocating Compressor PDFDocument28 paginiReciprocating Compressor PDFmoÎncă nu există evaluări

- Refining Process - Shell Refining CompanyDocument2 paginiRefining Process - Shell Refining Companyce10m034Încă nu există evaluări

- Centrifugal Compressor SystemDocument49 paginiCentrifugal Compressor SystemLuis carlos Ochoa GutierrezÎncă nu există evaluări

- Gas Transportation 2020 PDFDocument93 paginiGas Transportation 2020 PDFNathaliaSihombingÎncă nu există evaluări

- A Balanced View of Reciprocating and Screw Compressor EfficiencieDocument7 paginiA Balanced View of Reciprocating and Screw Compressor EfficiencieGeorge Nobre FilhoÎncă nu există evaluări

- 7 CompressorsDocument49 pagini7 Compressorsparvin.f100% (1)

- Supplemental Manual Bayliner 175Document40 paginiSupplemental Manual Bayliner 175jasonp151515Încă nu există evaluări

- Lubrication Systems QuestionsDocument7 paginiLubrication Systems QuestionsLeo NardoÎncă nu există evaluări

- Renewal and Sustainable Energy ReviewsDocument19 paginiRenewal and Sustainable Energy Reviewsstephenlim7986Încă nu există evaluări

- Cummins QSK23 50Hz 051203-CutDocument2 paginiCummins QSK23 50Hz 051203-CutAnonymous 3RS6JNcÎncă nu există evaluări

- Sotera 825p-850 OriginalDocument64 paginiSotera 825p-850 OriginalPaul Mcallister BelloÎncă nu există evaluări

- Mazda CX 7 p1Document8 paginiMazda CX 7 p1raisviranÎncă nu există evaluări

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 paginiGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraÎncă nu există evaluări

- Fan Coil Units External System Resistance Calculation (Static Pressure)Document4 paginiFan Coil Units External System Resistance Calculation (Static Pressure)Adnan AttishÎncă nu există evaluări

- Bombas de Desagues New OneDocument2 paginiBombas de Desagues New OneJose Alberto Muñoz FloresÎncă nu există evaluări

- New LG 504 - April 2016Document12 paginiNew LG 504 - April 2016Rauf GebreelÎncă nu există evaluări

- R.J. Gayler - BG Tuning ManualDocument68 paginiR.J. Gayler - BG Tuning ManualRajat NanchahalÎncă nu există evaluări

- ReaktorDocument10 paginiReaktoralmiraÎncă nu există evaluări

- LNGDocument11 paginiLNGMuhammad JafarÎncă nu există evaluări

- Cryogenic Insulation - Materials ENDocument6 paginiCryogenic Insulation - Materials ENThamilselvan VengatasalamÎncă nu există evaluări

- g3520c Natural Gas For 1950Document6 paginig3520c Natural Gas For 1950Shahzad AliÎncă nu există evaluări

- Single cylinder engine laboratory exerciseDocument6 paginiSingle cylinder engine laboratory exerciseJojenÎncă nu există evaluări

- AMSOIL Break-In Oil (SAE 30) - BRKDocument2 paginiAMSOIL Break-In Oil (SAE 30) - BRKamsoildealerÎncă nu există evaluări