Documente Academic

Documente Profesional

Documente Cultură

DIN 17223-Part PDF

Încărcat de

Beatriz Stockhausenn0 evaluări0% au considerat acest document util (0 voturi)

694 vizualizări12 paginiTitlu original

DIN 17223-Part.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

694 vizualizări12 paginiDIN 17223-Part PDF

Încărcat de

Beatriz StockhausennDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 12

upc 669.14.018.27-426.2: 62.272: 620.1

technische Lieferbedingungen

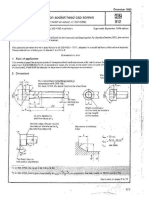

1 Field of application

1.4 This standard applies to patented cold drawn round

con stel wire, normally used for helical springs

(tension, compretion andtosion springs, spring washers

and other wit sprigs

Note Experience suger that afeenceis made to this

‘standard a for ordering patented cold drown

‘wie for springs, of non-ieular cross sction,

‘made of rods staightened and cu to length from

‘ring wite and fr ordering surface treated (for

texample galvanized or tinned) spring wire. In

‘uch one, should be noted thatthe mechanical

proper, the acuracy to sie and surface

Finther specie n shit standard do not apply

‘0 sich products and hence should be separately

asyeed

12. This standard does not apply to:

quenched and tampered spring wire and quanched and

tempered vale spring wire (see DIN 17 223 Part 2);

stainless seo spring wie (see DIN 17 228);

heataseting tel spring wice (ge DIN 17 228),

113. Inaddition to the spacitiatons given inthis

-Aandard, une otherwise stated below, the general

technical delivery conditions for stel and stel products

{pected in DIN 17 O10 shal also apply

2. Concept

‘As described in DIN 17 014 Part 1, patenting is under:

‘food to matn a het aatmant eating of austeniza

tlon and repid cooling to temperature above the

‘martensite poi inorder to achieve astucture

{ovourable for subsequent cold working

‘3. Classification into grades

‘This standerd covers the following grader of ste! spring

ice (referes to below a8 wire grade:

grade Ain nominal size range from 1,00t0 10,00 mm;

‘F240 B in nominal size range fom 030 t0 20,00 mm;

L

DEUTSCHE NORM

Round steel wire for springs

Patented cold drawn, carbon steel wire for springs

‘Technical delivery conditions

Funder Federsahldrant;patetiert.geropener Federdraht aus unleierten Stahlen;

‘In keaping wit curent practic in standards published by the Intemational Organization for Standardization (180),

‘2 comma hasbeen used throughout the decimal marker

‘See Explanetory notes for connection with international documents

‘Sobclaues marked with a dot give specifications which are optional and may be sqreed upon at the time of ordering

December 1984

DIN

17223

Pant

Supersedes

March 1964 edition

‘rade C in nominal size range from 2,0 t0 20,00 mm;

Sade D in nominal sie ange from 0,07 to 20.00 mm.

Wire grades 8,8, C and 0 are distinguished on the bass

ofthe mechanical properties; fr grade D, in adition

Particular requirements eating to the surface condition

Five been speifed Information on tho us of the

‘arious grads is given in clase 7 and table 6.

Note. During the discussion on this standard, the

‘manufactures sated that they were prepared

te continue to supply wie rade spectig in

‘the March 1964 eltion ofthis standard with

{rawnin 1964, for a ransiion period.

4 Designation

4.1. For products canforming to this stander, the

‘standard designation shal give inte following order:

the term (wire):

the number ofthe dimensional standard (DIN 2076);

~ the letter symbol isantifying wie grade A, 8, Cor 0

(soe tables Vand 3) and

= the required nominal diameter, selected from tele 3.

Example

‘Standord designation of a stot spring wire with

‘2 nominal diameter of 25 mm, of wire grade A,

conforming to DIN 17 223 Pat

Wire DIN 2076 ~ A-2,5

4.2 The designation tobe used on ordering sal in

‘eiiton o he standard designation, gve the quantity to

bbe supplied, he surface Finish, if somecother surface finish

‘than bright dy drawn and phosphatized or bright wet

{rau and phosphatized i required (se subelause 5.2),

tnd any partculr agreements that have baen made (see

Subclass marked with).

Example

1000 ka wie DIN 2076—A-2.0 bright dry drawn, reish

1000 kg wire DIN 2076 -A~2,0t bk rt

Contin on pages 2 to 12

DIN 17 22a Par? Eval Price group 8

Page? DIN 17223 Part t

5 Requirements

5.1. Formof supply

“The wire sl be supplied in the form of ells or wound

conto spools in the condition described In subclauses 5.6

tose,

“© Unies otherwise agraed atthe time of ordering, the

Choice between these two forms of supply shall be athe

‘upper's dieretion

5.2. Surface finish

52.1. @ Thewire may be supplied with one of the

folloming surface finishes:

bright dry drawn and phosphatized (tr bk ph 38

specified fn DIN 1653)

bright dry dawn ond grey (tr bk gr 3 specified in

IN 1653);

bright dry drawn and eeddsh (Bk rt as specified in

IN 1653);

bright wet drawn and phosphatized (n bk ph *);

bright wet drawn and gry (n bk or as specified in

IN 1653}

bright wat drawn and redlsh (n bert at spied in

IN 1653).

Uniess otherwise specified inthe order, the material shall

be supplied at the manufacturer’ discretion ether bright

‘ry drawn and phosphatized or bright wot drawn and

phosphatized,

5.22 © Forall surface finishes, the wire may a

tionally be ordered with old surface,

53. Chemical composition

5.31 Table 1 shal apply tothe chemical composition

ofthe varout wire grades as determined inthe cast

nals, Wire rod specified In DIN 17 140 Part 1 shall be

od asthe starting product for wire grades A and B.

15.2.2 The values given in abe 2 shall apply t0 any

subsequent check ofthe chemical composition on the

finished product.

15.4 Mechanical properties

‘SAA The valves given in table 3 shall apply tothe

‘eile strength and reduction in area after fracture of

‘ovis AB, Cand D wire.

{52 The tensile strength voles at any point ina col

Shall not exceed the following:

tor nominal diameter ess than 0,80 mm:

180 Nim?

= for nominal diameters rom 0,80 up to but not

inetuing 1,80 re: 100 N/mm?

= for nominal diameters rom 1,80 mm: 70 Nim?

“Those spectications shall apply to cos with amas, inks,

not exceeding the value 100% d (di the nomial ion

‘ter of wir, nm) or value of 500 Kg, whichever small.

16 Inthe cats of cols of greater mass, eppropriate

‘oreemant hal be made.

5A The modulus of elatcty i taken 25

206 kN/ma, the shear modulus a6 81,5 kN/me®

For the design of sings, the value specified in the

sign standards shall apply

155. Mechanical propertias other than tensile strength

55.1. Behaviour in wrapping test

In order to estes the unitormity ofthe deformability of

the wire and it surface condition, the wrapping test

‘hall be carried out on grades B and D wires with 2

Giameter of less than 0,70 mm. Inthe tact at desided

in subclovse 64.3, the tet pice shall exhibit a perfect

sUrtace and uniform pitch of the turns after plastic

Selormation.

5.5.2 Behaviour in torsion st

For stestng the deformability fracture behaviour nd

surfece condition, th torsion test shal be caried out on

trades A,B, Cand D wires inthe nominal diameter

ange from over 0,70 to 10,00 ram. The minimum

phumbers of ture specified in tale 3 shall be complied

vith up to 7,00 mm nominal diameter, for wires

‘xeteding thie siz, they shall be taken st guidance

values

“The obligatory numberof turn shel be achiaved in the

test dezeribed in subclause 6.44 before the tet place

‘actures. The factore of the torsion test pice in the

Cate of grades A,B, C and D wire shal be perpanicular

{0 the ais of the wire.

Recoil racks of recoil fractures (secondary fractures)

Shall be ignored in the acsersment. Inthe case of grades

‘A.B, Cand D wite, a uniform torsion shall bo present

Jn both af the fractured prs, although the pte ofthe

turns need not be the same inthe two pars. In the ease

‘of grade D wire, no cracks visible tothe naked eye sal

be Besant after the torsion test.

58. Condition of cols and spools

36.1. The wire ofa color spool shall bein one piece,

156.2 In thecsse of coils, the inside diameter shall at

least stain te values specified in table 4,

5.62 In the cre of coils, the wap may extend after the

binding wires hove been removed but shall not become

tral than the diameter of the col

5.64 Thespringwite shall be drawn dad cst. This

‘requirement shall be deemed to have been ret if inthe

case of wires of less than 5 mm nominal ameter, the

tends of the wap tested as deseribed in subclouse 6.4.5

‘hall have an axial daplaernent of not more than

e

i

wee

1s the axial displacement, n am;

D inthe diameter of froe wap, in rm;

4. isthe minal diameter ofthe wir, in mm

565 @ The choice of tha mat of the individual coil

‘or spools i lft to the manufacture’ discretion unless,

‘otherwise apreed at the time of ordering se also

subelause 5.42.

15.7. Surtace condition and skin decarburzaton

571. The trface of the wires shall be smooth

*)Thissurfce finish isnot specified inthe January 1979

‘edition of DIN 1653, but request hat bean made

for it 1 be included in the nex edition of DIN 1653,

6.72 Inthe case of grades A 8 and Cwir, the surface

Shall be fee from scores, pits and other surface defects,

‘hich will have a noticesy adverse eect on the

‘pplication of the wire.

5.7.3 Thedepth of surface defects inthe cae of grade O

‘ite shall be determined 9 specified in subclaue 6.48;

‘the permis values are given in able 3

15.7.4 Inthe cate of grade D wir, no deearburization in

the edge zane shall be present; the decorbutization depth

Getormined at described in subelouse 6.4.7 shall not

‘exceed the permisble values specified in table 3.

58. Dimensions and permissible dimensions! devistons

58.1. DIN2076 shall apply for dimensions and permis-

Sble dimensional deviations subject tothe limitation

‘ven in sbelouse 58.2

Note, The nominal dimensions given in table 3 and the

permissible dimensional devltions ara in apree-

ment with DIN 2076,

15.82 The deviation uf the wire diameter the 2

Gelvered condition, with espectto the nominal diameter

‘ordered, shall be within the imi specified in table 3,

‘the specifications applying to coll with amass, inka.

not exeseding 100% d d's the nominal diameter of

‘wire in ma} oF 500 kg, whichever i smal.

Inthe cae of cols of eeater mass, the permissible

Seviaion shal be agreed,

58.2 Ovalty Le thedltference between the maximum

and minimum diameters ofthe wire a the same cross

‘ection, tall aot be more than BO % ofthe total parmis-

tbl deviation specified in table 3.

6 Testing

6.1 Agreement on tit and documents on

ratorils esting

{61.1 It may be agreed at the time of ordering that one

othe documents specified in DIN 50.089 be furnished

for each supply.

6.1.2 I the issue of atest report i agreed, the results

Of the cat analysis forthe elements sted in able ¥ shall

be given in i

16.1.3 If he itu of an inspection certificate Is agreed,

the specifications in subclaues 6.2065 shal apply with

repsrd to the necessary tests,

The specifications on sampling {se table 5, column 8)

And on the tert procedure [zee subelausa 64) shal epply

tlro to subsequent tests in the case of complaints

62. Scope of tet programme for acceptance

inapecton

“Toe specifications given in table 5, columns 110 7 shall

apply forthe scope of test programme.

63 © Sampling

‘The specifications gven in table, column 8 shall apply

for sampling. Sampling shal always be cried out athe

‘ends of the coils

6A Test procedure

{6.4.1 Thechemical composition shall be determined

sccordng to the methods given in the Handbuch fr das

DIN 17 223 Part Page 3

‘Esenhittentaboratorium) (Handbook for the ferrous

metallurgy laboratory.

{64.2 The tenile test shall be carried out

= on wires of nominal ameter: les than 6 mm, a8

‘Specified in DIN 61 210 Pat,

= on wires of nominal diameters rom 6 mm, 3

specified in DIN 50 145,

on test paces having the full cross section ofthe wire

For ealeuatng the tensile strength, the nominal eros.

‘ction shall ba used in the case of wires of nominal

diameters excoeding 2,00 mm and the acts! eros

Section in the eave of ites of nominal dameters not

‘xeaeding 2,00 mm

6.43 The wrapping tes shal be caried out by analogy

vith DIN 51 21828 follows:

‘A test piece about 600 mm ong shall be closely coiled

‘round amandra of pproximataly 3X (dis the nominal

‘nie diameter), but nt less than 1,0 mm in diameter. The

test piece tall then be extended and released in such

manna ta the legis of th velesse test piece i at

[eat ice the cole length But not moe then four

timer the colle length

“Te surace condition ofthe wire and the equarity of

the pitch of the tune sal be inspected withthe test

piece in this condition

6.4.4 The torsion test shall be corled out by naloay

with OIN'S1 212. The gauge lngth shall however in all

‘ates be 100 X didi he norinl clameterof wire, but

fot more than 300 mm.

GAS. Inthe txt for freedom from corkscrew st, one

free wop shal be taken from wire supplied in cols, after

the binding wire ave been cemoved. The wap shal be

turpended ond the wap ciamater D and the axial

‘placement fof the wire ends measures,

64.6 The check for surface defects shal be carried out

‘on test paces ct from the ends ofthe col either after

deep etching or microscopically on transverse sections

Inthe case of deep etching, the test place to be examined

shall iret be degested tnd stesselieved by tenering

151500". Etching shall be aried out in 1:1 hyo:

‘Horie aid solution at (76°8]°C uni the reduction in

tlameteri about 1%; the eduction shall pot however

‘xceed 0,03 mmm. If surface defoct are detected, their

‘opt canbe meesuad for example by wansvrs sections

‘or by the profile method. Case of dispute shal be

{etad onthe basis of the resul of a measurement

farrad out on a transverse section with 8 magnification

of x 20.

164.7 The depth of decarburization shall be determined

by the microscopic method a specified in DIN 60 192

fon tert aces et from the ands ofthe coil

64.8. "Go" and "Not go” gp gauges or micrometers

‘re suitable for checking the diamater. Ovaity, defined

be the diffrence between the maximum and minum

Aiameters a the came eros setion, shall be checked

1) For supplies, see the "Standards and other documents

refered to cloue

Page 4 DIN 17 223 Part

65 Retests

DIN 17.010 shal apply to retest,

7. Notes on the use of the wires

‘Apart from te tril strength determined by the

‘chemical composition, het trestment and cold working,

‘wie grades A,B, Cand D ifr in their surface quality

nd deformability, The nates on ute in tebe 6 ae based

fon these ciferences,

8 Complaints

8.1. Undercurrent law, a complaint may only be raised

agninet detective product Ifthe defects noticably impale

their processing and ut, This shall apply unless otherwise

agreed at the time of exdering

£82. Its normal ad practical forthe purchaser to give

‘the suppliar the opportunity to judge whether the

‘complains are usd, where possible by submiting

the product objected to or samples ofthe product

supplied.

ee

eco

as

om e |x| * [ol e[S

Fao onion oor] oor [Toman [Eat moans

03010 800 065 toes |o3s| oat 100 | oo | aos | 020

s 6.30 to 1400 o40 woes |035| o30%0100 | 008 | 0040 | 020

18,00 to 20,00 040 10.085 038 | 030 t0 1.50 | 0040 | 0040 0.20

Saleem orang acon om = [es moe

Se eeE easier cee eee tel alles

Seal mom steno go oe oe |p ceo mp fen fom ge

Save tase a cook oor | | cee (toed Geel aoe

1) The ste! sal be ile

2) 1 ye ites use for purposes in which 3

dency tose isnot significant, a lower earbon content may be soreed.

Table 2. Chemieal composition of wire grades at determined in the product analyst

Nominal diameter

{Chemical composition (cat analysis)

]

Wis | ety mas

des |

| c we a mex | mex | mae

- 190 19 1080, a6 wir | 000s | oes | 078

030 «600 age to 14 | pas | oes | ozs

2 830 to 1000 Geto t+ | Oba | dows | O23

1500 to 2900, » 038] S260 185 | does | ooss | 023

© | _ 200%0 2000 098] 0260188 | 00s | oo | oa

» 207 +0 2000 028] axe 18s | ooas | oom | ove

1) Inthe ease of supplies of wire which, according tothe tet report or the inspection certificate (see DIN 60 049),

tha a carbon content of es than 0,55% as determined by the cast analysis, he product analysis may differ from

‘the wale given Inthe document by = 0,03 % C, and atherwise by = 0.08% C.

DIN 17 229 art 1 PogeS

tues mana

‘wnwreui ou “vorED) sa 404 ‘ANUP YM INO PBLIED aq AjuO URD UONJEZLuNGLEDEP 40 WAGED 10 s139}8p 40 widaP au JO wWOUaNSeaLL Pe

Age fe sie Ss eget ope uk eat

come oF oes 0252 0 082 om

| eae 00982 ooge 8 0172 3380

‘ogee 0» 0187 ‘pes 03 Bee 0680 ses

| 0182 oF tt | o95z 8 O1eE 3820 sao

0922 6 0192 0082 oF O6Ez B80

o2ee oF oe 582 610562 1380

Fee 8 099e o58e © O48z 5550) |

0162 8 one eer | oe

eve 0105 0 0222 5869

eee eraiea|| 2 fomcsous 7 _ [seo]

21 08 are

mi oie oF Coae | ro

ee ‘00K © CORE esto

cove 0 coe - vero -

DOLE OF O0Bz | see0

‘DOLE OF 008 ‘100 | voor

018 0 0082 900

wo18 8 e082 [aero]

e918 0 cowe | e600

e018 0 coee zoe |

Fe wl ui oun au ~ | wo | ww | ww

° 2 3 ¥ apie |amey

(om apes 108.05

teunwou) | yonezy 105 wooo | hand

Pawel 020 | sua, ‘sy ozs

ec i euIWON,

Prien

a a é = Zz 2 =

“G pue 9 "Gv epelb aumn so) ewentnboL A

Page DIN 17 223 Part 1

= aise wae Tear oer oo eer |S ee |

1 arse ovoil2 oid Foe | one ot ozai | —a0eh ort

ist 0 oie oeie at cost asst otoret | _2¥00 oe

ace 01 ate vie 016 | one oF oobi | ave wei

oF cove oF ote 912 ot oer | cre ols | ee “ork

‘tbe 03 007 siz © 0961 | Orel rosa | ore | oe

osve & o1zz, ooze OF ‘0861 OF OFLE ore see ees oo

rou yet} eure 4 | SS ouve & OFzz oeez © o@6t | 0161 OF OZLE ne co

_ ‘oer & ose | [lovee 1 o00e es ‘960

‘O1se 1 OLE (oaze 1 O10 co “080

[oesearocce] — _—_[oazz a onae srr sr

ose oF 0182 aver tose see are

‘owse © eee [oeez @ oz0z we 30

oro) c ‘0192 oF OBEZ | osez 0 o80z oro

[os] _ [evar ot vase cue woes) 0

evo. a 892 00882 | COREE 01 tz evox [Cove]

oa ae oust ae cone ore ovoes ow

oro “ [Teoue or ore ere 0s 0uie oF0

0 raat [Deze core 05¥e 01 0012 wo

oo oir ont vere [Cours onze oro

ero oozz 61 dere | ere © ozzz > Lave

sro ez & O1Se 0052 © OveT. an ovo

wn wu) ww % pawn [gui er ~ ww | uw [ww

2 | ‘a laoeviesey) “a "| 7 amo | amev

pen | "08 \ |

ewasoy | on ‘s9peu6 014m 20}

rete) sme | Gowen ree

oo wea | ponitr se

eat | mo ven) om] pmton

ae ming

sing | sung | mane

er

ee mL wor 3 z z mea eam 7 Co

(ponunL08) aL

DIN 17 223 Part 1 Page?

Tesi or br a

o see

| | ae

| zoe] sever | omar

t mac

we]

Ed

| ozrs o ovat | son

se [ozar 1 ora [ ocor ‘oot 01 ores | opri ov ores | sub

vai ci 0661 | ova 1 opor | onoi or ooer | oars or o2es | rab

| 995 00861 | o8B1 ov opps | ovat er oarr | ouri er oazi | est

991 00681 | o9Br oF Gear | ower or cost | oert or osei | s2h _

[Lovet ar ovzr | ooer ot over | oost or ovst | cost ovorst | nr]

‘bet oF orci | oper or orct ofc a opsi | Orsi ov ozei | 95

oa6r or 0820 owe

6 6L

eid

9

a

cor

i

5 ‘gas a carr |S

oeoi a our | 956

[Tose over [orto oer | zie | owas | seovs

aie 00181 | 0912 0 018r oui os. | ee

ooze ot 09st | o0zz oF 09st ‘aut 0 06. | eve

zzz 60002 eit ooo] ez

| [loves ovacoe, [ove ous [ons 0 op8. [oor

[onze ot ovo ‘foe er o1er | ovat a o25i | wus

oszz 01 0902 Gor or coat | o7@t er oesi | es

"auido 10} EPUB TOU ANH BUIRID fe

280d 998 (¢

Deer Ger | GET OF OTT oor

‘oct or cei | 2p on coos | svos [over

‘rot oF 0621 | Oret & oazi ovr

ooet oF ova | o9ei o azz coor | awe [omer

‘Deer oF ove * Le Peo]

_ Forroroer .

‘ovr 04 0821 | ovri © 06z

‘uri 0» o@er | OLvi 2 o2er

‘eri o1 geet | grt or OEE! | eno

00st oF ower | Oost oF Oger |

‘esr 0 ges | Oost o ove

‘5st 0 ogc | ossr oi ose | ect or ceze

oust or o1ni | O18 & ‘ori @ over | ear 8 OoOr

oc [Toast ov oer | oast ov oer | ozrt a oazt | oszr or asor soo: | owes

194 oF spr | 019s © osvs | over ov oxzs | 092s 01 o6oL

a ul usin wun vw Pe Ta

yoaviaoay| “a a v apueg| emery

ope

ene)

z

unioey

‘ exe

reunion

= Z 2 = = l= T

Page 8 DIN 17 223 Part 1

{anu009) aL

‘Table 4, Wire dlameter ranges and associated

‘minimum col inede lametare

Minimum permisile inside

Wire diame diameter of cai

3018 to 5078 100

2028 to <080 180

3050 © <070 10

paraw cio | __280 |

318010 <450 400

>as0 z $00

IN 17223 Pant Page

Page 10 DIN 17 223 Par 1

ope es

(emer es eve

(eyreees. ove oe

eee a)

ji ‘2d 1s naany109 WO

ros sro onsen | a9ev

‘mn |

jpecss ¥99 sanweng) oo8y

v5 ere oa

. . emor ° ooeyv

' . . ene | aoav | ssheuersnpog |

yun spe am

peas. eoundeoe | aun « 40390 Lequiny

oujdiues | sed sounds sd seis at | sourideooy paws | pomawaes [eur

5401

400qu0n |

on a ® : ° 5 ¥ e @ i

“avswieunbos pus sinpesoud yn 6 Bupeps eiep Jo Aiununs pue vopoediu soundense 10) Buydures pue euuseMont een jo e055 9 106]

DIN 17 223 Part 1 Pago 11

Table, Notet on we

Wire

ee Tobe wed for

Tension, compresion, torsion o shaped

18 | springs eubject vo tow stati streses oF

‘oral to eynamie stress

‘eosion, compression torsion or shaped

18 | spring subject to medium state and low

ynamic sess

tension, compression, tosion or shaped

© | spring subject to high static and low

dynamic stresses

‘tension end eompretion spring subject to

1 | high static and a medi dynamic stresses,

nd torsion ond shaped springs subject to

igh static and high dynamic stresses

Other standards and documents referred to

DIN 1653, ‘Surface condition of commercial tel wire; nomenclature and abbreviations

IN 2076 Round spring wie; dimensions, masses, permissible deviations

DIN 17010 General techniea delivery conditions for stel and ste! products

DIN 17014 Part 1 Heat treatment of ferrous materials; technical concepts

DIN 17 140 Part 1 Wire rod for cold drawing; technica delivery conditions fo basic stel and quality carton steels

DIN 17223 Part 2. Round steel wire for eprnge quality specifications: quenched and tempered carbon see spring wire

‘and quenched and tempered carbon steal aie spring wire

DIN 17.224 Stanis stel spring wire and spring sti: technical delivery conditions

DIN 17225 High temperature stoels for springs quality properties

DINOG49 Documents on materia testing

DINSO145 Testing of metalic material; tril test

DINE 192 Determination of cepth of decarouriation

DIN St 210 Port 1 Testing of metalic materials; tril test on wires without wing an extensometer

DIN51 212 Testing of metallic materia; torsion test on wires

OINS1 215 of metalic material; wrapping test on wires: general information

Stah/-Eisen-Prifelet (Irn and ste! test shee) 18052) Probenatme und Probenvorbereitung fir ai Stickanayae bet

Stalen (Samgling end male preparation forthe product analysis of steels)

Handbuch fr dae Eizonhitteniaboratorivm?y;

wolume 2: Die Untersuchung der metlichen Stoffe (investigation of metalic materials);

Diseldort 1988;

solume 5 (supplementary vakumel: 4.4 — Aufsellung onpfohlener Schiecsverfahren

{List of recommended arbitration procedures);

{8 — Probenahmeverfahrn (Sampling procedures);

(C— Anaiveevertanen (Mothods of analysi);

latest ition in ach case

Previous editions

DIN 2076: 02.48; DIN 17 223: 04.55; DIN 17 223 Par 1: 03.64

‘Amendments

“The folowing amendments have been made ia comparison with the March 1964 edition:

8) Wire ade II has boon deleted, wire grade D has been included forthe fis ime

1) For wir grade A, the diameter range from 0,30 t0 0.95 mm hasbeen dropped and for wite grade C, the diameter

‘ang from 0107 to 1,90 mm hos been dropped. For wie grades B and C, che diameter range has been extended Up

10 20,00 mm.

1) Obtainable from: Veriag Stahleizen mbH, Postfach 82 29, D-4000 Disseldorf 1

Page 12. DIN 17 223 Part 1

‘¢)_ The permissible deviations in diamator as given in DIN 2076 have been adopted

1d) For designation of wire grades, only eter symbols are now used and no materi! numbers

ts} The wire may be supplied either in eols or wound onto spools. The posible surface finishes have bown liste

{)_Asregords the chemical composition, limits for the elements C, St and Mn ha

alo been spifod for wire grades A

‘in B the maximum peroentape of Cu has been reduced from 0,26 toa maximum pereantage by mass of 0.20

) A table forthe percentage by mass permissible inthe product analysts forthe elements CS, Mi, Py Sand Cu hat

ben included forthe fst tine.

I The een strength values and minimum value for reduction in area ater fracture and the numberof turns inthe

torsion tet have been specified for the First time (see Explanatory notes

|) For wice grade A, the wrapping test has bean dropped. Apart from thi, the limiting nominal sie forthe wrapping test

{anda «consequence, forthe torsion tert) has been raised from 0,80 to 0,70 mm. The procedure tobe followed in

‘the wrapping test hasbeen modified.

|The data for freadom from corkscrew st have been spaifed for wires of less than mm nominsl diameter by

{opting 2 formula for the maximum axial displacement (sea Explanatory notes)

1) For wire grade D, the maximum permissible depths of surface defects and skin decarburization have been specified

(eee Explanatory rove)

1) definite scope of test programme has been specified for seceptance inspection. Clear specifications have also been

‘ven for sampling

Minimum inside cigmaters of cols have been specified as 2 funetion of the wire diameter.

1 The notes on ute ofthe various grades of wire have been ews.

Explanatory notes

“The tensile stengt values have been specified forthe

First time in comparizon withthe draft for this stander,

taking nto secount agreements reached inthe European

Community. On the basis ofthe state of discussions at

‘the time the present standard was published, on the

‘corresponding EURONORM now being prepared, the

fame tenia strangth values are being specified inthe

EURONOAM ain DIN 17 223 Part 1; DIN 17 223.

Part {however covers a geater range of nomial

diameters for wite grades 8 and D. The tensile strength

‘ales specified in DIN 17 223 Part 1 were proposed for

the 150 Standard on patented cold drawn ste! wire for

‘erie, lea being prepares. The discussions i the

relevant ISO Subcommittee, TC 17/SC 17, on this

‘Proposal had not taken place atthe time the present

Standard was published,

The tenilesrongth values Rg specified in this standard

can be cleulated trom the following equations:

‘rade wire trom 1,00 to 10,00 mm nominal ameter

= lower limit: Ray = 1720 ~ 660 X logd:

over limit: Re, = 1970 — 740 X log d;

rade B wire from 0,30 t0 20,00 mm nominal diameter:

Somer init: Ry = 1980 ~ 740X log

= oper limit: Rig = 2220 ~ 820 X lopd:

grade C wire for 2,00 to 20,00 mm and

{rade D wire from 0,20 020,00 mm nornina diameter:

= lover lit: Ray = 2220 ~ 820 X log:

upper limit: Ry, = 2470 ~ 900 X log

With regard tothe minimum numberof ture in the

torsion test specified in table 3, it should be noted that

the gauge length hat been edced from a maximum of

{500 mm o.9 maxima of 300 rn.

‘The discussions onthe permissible depth of surface

defects and skin decarburiation encountered particular

International Patent Classification

821 F 35-00

lifcuties, because, onthe one hand, users in some

‘ste ecuired value lw that they could rot be

tmessured with normal test fnstruments (xcept meta

Togrephicaly) and because, on the other hand, the steal

wire manufacturer sad that, ons percentage basi, t

‘wat only posible for them to concede defect depths

qual to those permitted fr the wie rod, The wire rod

manufactures rated that even with special reatment of

‘the starting product it was not posible in the present

at of production tnd text tachnology to exclude the

possiblity thet batch of wir suppliad might contain

patil quantities that were defective with regard to the

Fimiting wale forthe crack depth

All participants consiseed the previous specifications

Inadequate ceordig to which the stel spring wit,

after removal the binding wes, should not spring wb

hove the pane of the col. The spring manufacturers

$ated that tha equation adopted in this standard forthe

‘xil deplacarnent had een derived from measurement

Fesults; on the bari of thei experience, it was applicable

for wire up to 5 rm nominal diaater inthe drown

cnton but not inthe tempered contin, but in ny

tae It war not applieableto subsequently svaightoned

wires, Fuad boon found thet wire exhibiting bad aso

‘did nat satity the equation. Since the time had come to

‘eplaca the erm "drawn dead” bya measureablequantity

tie sine freedom from corkscrow at san esental Tector

In procetsng, t wae desirable to adopt the equation in the

standard, Even the wire manufactures conceded that

it would be desirable to have detailed specifications

although they prefered simplified specications,

‘ipeilly a the equation could not be used fr larger

S-ar putea să vă placă și

- Din 934 PDFDocument7 paginiDin 934 PDFtobster9983% (6)

- Din 912 - ParafusoDocument12 paginiDin 912 - ParafusoBeatriz StockhausennÎncă nu există evaluări

- Din 912 - ParafusoDocument12 paginiDin 912 - ParafusoBeatriz StockhausennÎncă nu există evaluări

- DIN 17223-Part PDFDocument12 paginiDIN 17223-Part PDFBeatriz StockhausennÎncă nu există evaluări