Documente Academic

Documente Profesional

Documente Cultură

Viessmann 4

Încărcat de

Violeta Silaghi0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări12 paginiMontaj Centrală Viessmann 5

Titlu original

VIESSMANN 4

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMontaj Centrală Viessmann 5

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări12 paginiViessmann 4

Încărcat de

Violeta SilaghiMontaj Centrală Viessmann 5

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 12

Ploase file in Service Binder

540274 9199

Installation Instructions VIE

ll Chassis Burner-V, VEC Series

{or Vitola-ifertal VBC series hot water heating boiler

input capacities 83 to 219 MBH (24 to 64 KW)

Oil Chassis Burner-V

ee

\\ IMPORTANT

Read and save these instructions

for future reference.

s

Ss

MANN

‘Summary of Important Requirements

Safety Terminology

Safety, Installation and Warranty Requirements,

Please ensure that this manual is read and understood before commencing installation. Failure to comply withthe issues listed

blow and d

Is printed in this manual can cause product/property damage, seve

personal injury, ansior loss of life, Ensure all

requirements below aro understood and filed (including detaled information found in marual subsections)

1 Liconsed professional heating

contractor

The installation, acjustment, service, and

‘maintenance of tis equipment must be

performed by a licensed professional

heating contractor.

> Please see sections

contitled “Safety” and

“important Regulatory and

Instalation Requirements

* Product documentation

ead all applicable documentation before

‘commencing installation. Store

documentation near boler ina readily

accessible location for raference inthe

future by service personnel

> Fora listing of applicable

literature, please see

section entitled “Important

regulatory and Installation

Requirements."

= Advice to owner

(Once work is complet the heating

contractor must familiarize the system

‘perator/utimate owner wth all equipment

as well as safety precautions!

requirements, shutown procedure, and

tno need for professional service atleast

‘once per year.

Safety Terminology

“The following terms are used throughout this manual te bring attention to the presence of potential hazards or Important product information

Please heed the advice given!

= Contaminated ale

Ar contaminated by chemicals can cause

by-produets in the combustion process

‘which are poisonous to inhabitants and

destructive fo Viessmann equipment

> Fora listing of chemicals

which cannot be stored in

or near the mechanical

room, please see section ‘

‘entiied “Combustion Air

Supply.”

Carbon monoxide

Improper installation, adjustment,

andlor maintenance can cause ue

products to flow into living space. Flue

products contain poisonous carbon

monoxide gas. A

> For information

pertaining to the proper

instalation, aoiustment,

service, and maintenance

ofthis equipment to avola

formation of carbon monexide, please s2e

manual enitled “Star-up, Maintanance

and Service instructions.”

ery

ey eo

monoxide detectors. Follow

fete ocr

eres

‘Fresh air

This equipment requires tresh air for safe

operation and must be installed ensuring

provisions for adequate combustion and

ventilation airexit.

> For information

pertaining fo the fresh

‘air requirements of this

product, please see

‘section enttiod

"Combustion Air Supply.”

Equipment venting

Never operate boiler without an installed

venting system. An improper venting

system can cause carbon monoxide

poisoning,

> For information

pertaining to venting and

chimney requirements,

please see Insallation

Instructions ofthe boiler

All products of combustion must be safely

vented tothe outdoors.

= Warranty

Information contained in this and related

product documentation must be read and

followed. Failure to do so renders warranty

pula vo

se

fal

& panceR

Indicates an imminently hazardous

situation which, if not avoided, will

tr is

Seu eee

& warning

ees

A rere)

Pr rd nes

Seta ears

& caution

rer

Ee eng

fe aia

Perec kus

IMPORTANT

Helpful hints for installation, operation

‘or maintenance, which pertain to the

product.

5902 774

590274

1.0 Contents

1 Important Precautions

2 Information

3 Installation Instructions.

4 Operating Instructions

5 Maintonance/Service

11 Safety

1.1 Safety

1.2 Important Regulatory and installation Requirements

Page

1.4 Salety 3

12 Approvals and Standards 3a

2:1 OllChassis Bumer-V 4

2.2 Combustion Air Supply 4

2. Technical Data, 5

3.1 Mounting Bummer on Boiler 5

8.2 Ol Cartridge Assembly 6

3.3 Connections with Two-Pipe Oil Supply i

3.4 Oil Supply with Single-Pipe System °

35 Electrical Connections 10

3.6 Burner Cover installation t

4.1 Operation 12

4.2 Calibration to Ensure Optimal Efciency and Fuel Consumption 2

5 Maintenance/Service 2

‘Take note of all symbols and notations intended to draw attention to potential hazards or important product information.

‘Those include "DANGER", “WARNING”, “CAUTION”, and "IMPORTAN

"Installation

Please carfully read this manual prior to

attempting installation. Any warranty is nll

and void if these instructions are not

followed

‘The bummer installation shall be in

accordance withthe regulations ofthe

‘authorities having jurisiction or, in the

‘absence of such requirements, in

‘aceordance with National Codes. In

Canada use CSA B-199 for oil boiler

Installations Inthe U.S. use NFPA 31,

“Standard forthe Installation of Oil Burning

Equipment” for ol boiler instalation.

‘Always use latest editions of codes.

{All electrical wiring isto be done in

‘accordance with the latest ection ofthe

National Electrical Code ANSIINFPA 70. In

‘Canada use the Canacian Electrical Code

‘CSA 022.1 andlor local codes.

\We olf trequent installation and service

seminars to familiarize our partners with

ur products. Please inquire.

1.2 Important Regulatory and Installation Requirements

' Approvals and Standards

‘Whore requited by the authority having

juriscition, the installation must conform

to the Standard fer Controls and Safety

Devices for Automatically Fired Boilers,

ANSVASME CSD+1

Follow all local codes.

‘The oll urnartboller combinations as

sshown in Section 23 are approvec by CSA

to the latest aitons of the allowing

standards:

~ CANOSA -B140.2.1 - Ol Burners,

‘Atomizing Type

= UL296 - Oi Burners

= CANIGSA - 022.2 No. 0- General

Requirements - Canadian Electrical

ode, Part I

- CSA 022.2 No. 8 - Electrical Features of

Fuel Burning Equipment

‘See page 2 for details,

‘= Working on the equipment

‘The installation, aojustment, service, and

‘maintenance ofthis boiler must be done by

a licensed processional heating

ceontractor wno is qualified and

‘experianced inthe installaton, service,

‘and maintenance of oifired hot water

heating equipment. There are no user

serviceable parts on the boiler, burner, or

conta,

Ensure main power supply o equipment,

the heating system, and all external

‘contro's has been deactivated. Close

main gas supply valve. Take precautions

in both instances to avoid accidental

activation of power during service work.

‘Literature

Literature applicable to installation of the

Oil Chassis Burne:-V:

= Installation Instructions

+ Startup, Maintenance

and Service Instructions

~ Operating Instructions

land User's Information Manual

- Parts List

= Installation codes mentioned inthis

manual

2 Information

2.1 Oil Chassis Burner-V

‘The Viessmann VEC series Ol Chassis

Bumer-V is intended for use with the

Vitola-biterral VNE or VBC sorias hot water

heating boier

‘This burner is factory calibrated for use with

{uel ol #2. No other fuel shall be used.

2.2 Combustion Air Supply

& warninc

eT

Sera i

UCM

et ra tert

“CSA B139 - Installation Code for Oll

Burning Equipment” (Canada) andor

Pree

une eT

sizes outlined in Table 2.3 should be

ren

ate Ears

outside.

Each burner is factory tested on the correct

lr size with the appropriate oll nozzle,

Tho factory test inoludes oil flow rate ana

combustion measurements. Do not over

ith the rating plate input only. A record ot

the flow rate and combustion resuks is being

provided with each bumer

rrr

‘areas or rooms where chemicals

Containing chlorine, bromine, fluorine,

eer oe ee

Pee a tic ces

Ce aetna ans

ea ea ee ees

roe re ramet

Se emis)

above mentioned chemicals.

eee)

ee eR etna

erty

eee or ete

ce ert)

‘components will be null and void.

fire the burner, The burner i fr use

Regional performance mustbe veriied inthe

field and adjusted, necessary, via the air

adjustment on the burner

HW ourner activation occurs prior

‘completion of renovations to the mechanical

room, dit and dust caused by construction

will necesstate a cleaning and recalibration

fof the bumer attr all constuction work is

complete.

During drywall sanding the heating boiler

should be turned off and properly covered

including controls, or the burner must

receive clean combustion sir when operated

during that time - ll controls must be

protected from dust and dit.

902 74

9902 774

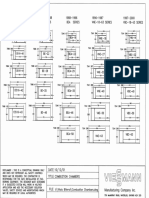

2.3 Technical Data ((o- tue oil #2 only)

2 Information

3 Installation Instructions

Burner Model ModelNo.] vEC-O48] VEC-O22] VEC-033| vEC-O40] VEC-050| VECOeS

Bolter vacis[ vecz| vacss| _vac-4o} __vecso| __vBc-6s,

Input v BH ry 107 135 170 219 na.

kW 28 31 Ee 50 et

Consumption US. gp 059 O76 086 121 758) na.

hth 223 287 363 458 590

Vonage v 120 120 120 120 120 na.

Frequency He 0 60 0 60 0 na.

‘Amperage a 170 170 170 170) 1.70 na

Motor revolutions PM 3,880 3,380 3,380 3,380) 3380 na.

ll pump flow capacity teh 6 5 ® 6 5 na.

Connections (metric fare)

inside threads of supply and

return oll noses Inches | ie a 2 oy na.

Recommended air supply

duct size-round duct 2 inches 3 4 4 5 6 na.

IMPORTANT

Burners are approved for one input

‘each. Do not change input of burner

by oversizing or undersizing of nozzle.

3.1 Mounting Burner on Boiler

(all parts necessary for burner mounting are contained in tne burner packaging)

Fig.

Mounting burner on combustion chamber coor

1. Fasten hood latch () with sheat metal

screws (provided) on boiler tront pane!

2. Mount toe M 8 spacer bots) In threaded

holes of combustion cnamaer doar.

3. Sido burner housing gasker® over spacer

bots

4, Mount burner chassis on spacers with M&

rus and washers.

5. The olfter may be mounted on either boiler

side depending on whether the combustion

‘chamber door Is oviantes for let- ofa right

opening swing

3 Installation Instructions

3.2 Oil Cartridge Assembly

Ht Qele

Gremparatureecteted)

oe ‘

oe Ca

&

Oil cartridge assembly

fee (heaton aptons)

1. Check that al surfaces are clean betore

installing new O-ing supplied with

replacement fiter carvidge.

2, Set O-ring in place and mount new fiter

cartidge.

'3. Attach clear plastic cup and tightan brass

IMPORTANT

Never tighten brass nut with a tool; hand

tighten only. Cap and O-ring might

deform and leak ai.

IMPORTANT

The flare adaptors are tapped 3/8" BSP.

(British straight pipe) at the factory.

Replacement flare adaptors must be

ordered from Viessmann. Do not use

3/8” NPT flare adaptor as roplacement.

& caution

Ceri a

niet ecc Ts

pierre nee ear

Penna)

on

& caution

rm

ese

5202774

3.3 Connections with Two-Pipe Supply

Fig. 3

Oil fiter in two-pioe system

Elevated Tank (two-pipe)

Vessmann strongly recommends two-pipe

oil supply piping wherever possible. For

‘optimum air venting and oll pump

performance use two-pipe oll supply piping,

@ ailine rom tank

@® to ail pump on burner

from oll pump on burner

return to tank

AE

® toot valve

Suction height H Inside diameter of suction ine

ft ™ 3° | 8mm 12" tomm

Maximum supply line length (f/m)

T

13 +0 axa | too m | se | 100 m

Ne 495 32 98 328 100

9% 430 299 ot 328 100

8 425 273 a5 328 100

o% 420 260 73 328 100

5 Hs | 238. rm 328 100

3% 410 216 66 22a 100

1% 405 197 60 328 100

For fuse, 80 GST veeoy Is seu wth ou 80" pp aooms, one sho vale ar ne fot

vale,

Fo. 4

(i supply twepie systom), elevated tank

3 Installation Instructions

AViessmana ai flter assembly and faxble

‘illines must be used inthe ol supply

system. The red flexible oil line connects the

‘ed manual valve side ofthe fer assembly

to the inlet (suction) side ofthe oil pump.

The blue flexible oil ne connects the check

valve side of the oll fiter assembly to the

return side ofthe oll puma,

‘The oil pump is shipped withthe by-pass

plug installed, The two flexible oil ines are to

be used for al installations, The copper tee

is used to convert toa single-pipe supply

from tank to burner, See page 6.

(Observe oil supply dimensions on table below.

‘The oll prassure within the oll supply system

must nat exceed 29 psig /2 bar.

CAUTION

Serre

nie reac

Pe ee er es

eae

atte

Et ete ett]

tetera

not cor

oa

3 Installation Instructions

‘Tank below or at same level as burner (two-}

YA

Nb

Sucton height H

PSSST aed

SS 4

ZMK

/@ |

inside diameter of suction ine

ft m set | 8mm |e 10mm

Maximum supply line length /)

° ° amon | 53 m | ge nt | 100 m

1% 154 a 328 +00

au 135 “ 325 99

5 mm |e 276 84

6% 92 23 233, 68

eK m2 2 75 53

a “9 15 121 a7

At ao | 9 r 2

Fig. 5

it supply (two-pipe system),

tank below or at same level as burner

Observe oll supply dimensions on table below.

‘The height diference (H) between the o

bbumer pump and the tank must not exceed

11.8 ft/ 3.5 m. Greater heights wll cause high

‘vacuum pressures, bumer matiunction and

‘eventually, Burner falure.

CAUTION

eer)

enero

Pe eer err eg

ee eee

Oe tito ty

Rete et]

et eerie r tera

not connected during the pressure

oa

5902 774

5902 74

3 Installation Instructions

3.4 Oil Supply with Single-Pipe System

[A Viessmann ol fier assembly must be

Used inthe ol supply system,

Install tee here

‘A copper tee must be used to connect the

two-pipe filter assembly toa single-pipe olf

supply system,

@® oil line trom tank

© toil pump on bumer

© trom oil pump on burner

ry © return to tank

Fig. 6

(0 iter in single-pioe system

Elevated Tank (single-pipe)

(Observe oil supply dimensions on table below.

I" the oil supply must be converted from a

\worpipe system to a single-pipe system,

please observe supply ine ciameters provided

inFig.7.

CAUTION

errs rr

Pee eer

Pe et eres

cn eure

art tote

® foot vaive ener)

ern aay

Rote Tn cet’

— test!

Suction height [Boller input

8310 107 MBH 13510219 MBH

m “| 6mm «| 8mm

Maximum supply lin length (f/m)

13 +40 ge nt | 100 m | oze ot | 100 m

te 435 928 400 328 100

9% = 430 928 100 318 97

Be 25 28 100 265 8t

6% 320 320 100 213 85

5 8 318 7 160 49

se oe | ta) 6 105 82

te 05 | 108, a 53 16

Sa ol tnas Way asa De eae

Fig. 7

(Ol supply (single-pipe system), elevated tank

3 Installation Instructions

‘Tank at same level as burner (single-pipe)

{A Viessmann oil fiter assembly must be

used inthe ol supply system,

‘A copper tee must be used to connect the

two-pipe titer assembly toa single-pipe oll

supply sysiem

Itis not recommended to use this burner

with asingle-pipe “it” system where the oll

tank is below the level of the burner.

“The maximum oll supply (suction) lin length

{is 328° 100 m of 3/8" ming

3.5 Electrical Connections

4120 V connection to boller control

All power for burner is supplies through

7-pole i plug trom the boiler contro

Connect the 7-pole il] plug of the control

with the 7-p0le plug of the burner. Pugs

‘must snap together with a ‘lick

Electrical configuration

‘See manuel entitled "Start-up, Maintenance

and Service Instructions, Oil Chassis

Bumer-V"

10

590274

3 Installation Instructions

3.6 Burner Cover Installation

1. Mount two locking pins @) on burner cover.

2. Hook burner cover on chassis burner wth

the two claws located atthe bottom ofthe

cover. Insert both locking pins into hood

latches Ci) and turn locking mechanism to

the ght ith the Viessmann Allen key

{prowded) to secure the coverin place

Fig. 8

‘Mount locking pins on burner cover

IMPORTANT

‘Mounting and location of boller control

varies with type of control purchased.

5902 74

Fig. 9

‘Mount burner cover

4 Operating Instructions,

5 Maintenance/Service

4.1 Operation

See manual ented “Start-up, Maintenance,

and Service Instuctions, Oi Chassis

Buren

4.2 Cal

Wo recommend a service inspection ofthe

‘equipment on an annual basis,

Early detection of poor combustion, faulty

components or wear and tear symptoms.

reduces service and maintenance cost,

lensuring peak efficiency and minimum fuel

costs,

5 Maintenance/Service

‘See manual ented “Startup, Maintenance

land Service Instructions, Oil Chassis

BumereV"

IMPORTANT

Regular annual inspection and service by

2 qualified heating contractor is

Tecommended for optimum performance

ff the Viessmann Oil Chassis Burner.

\Viessmann Manufacturing Company (U.S) Ine.

£83 Vermont Avenue, Building 3

Warwick, Rhode Island » 02888 » USA

Tol. (401) 732-0667 » Fax (401) 792-0590

2

‘Neglected maintenance impacts on product

warranty: regular cleaning and maintonance

‘ensures clean, environmentally friendly and

cient operation.

We racommend a maintenance contract with

ration to Ensure Optimal Efficiency and Fuel Consumption

& caution

burner activation occurs prior to

Ce ey

kc

Recurrent

During drywall sanding the heating

boiler should be turned off and

Peper rr

Stony

that time - all controls must be

Peco eee rs

\Viessmann Manufacturing Company Inc.

1750 McMurray Roas

Wiateri00, Ontario + Nz Canada

Tel. (519} 885-6800 « Fax (519) 885-0887

mechanical room, dirt and dust caused

Petar ea rere eters

ae

z

5302 774

S-ar putea să vă placă și

- P.I.P MatematicaDocument5 paginiP.I.P MatematicaVioleta SilaghiÎncă nu există evaluări

- 1 DecembrieDocument16 pagini1 DecembrieVioleta Silaghi100% (1)

- Pip Procese PsihiceDocument3 paginiPip Procese PsihiceVioleta SilaghiÎncă nu există evaluări

- Săptămâna Verde Idei de Activități Pentru ProfesoriDocument11 paginiSăptămâna Verde Idei de Activități Pentru ProfesoriVioleta SilaghiÎncă nu există evaluări

- Plan de Interpretare A Naturii Din Rezervație Și Din Imediata Apropiere Băile Felix 1 MaiDocument18 paginiPlan de Interpretare A Naturii Din Rezervație Și Din Imediata Apropiere Băile Felix 1 MaiVioleta SilaghiÎncă nu există evaluări

- SolidaritateDocument15 paginiSolidaritateVioleta SilaghiÎncă nu există evaluări

- Educație Globală - CampanieDocument13 paginiEducație Globală - CampanieVioleta SilaghiÎncă nu există evaluări

- Florance Braunstein - Ghid de Cultura GeneralaDocument369 paginiFlorance Braunstein - Ghid de Cultura GeneralaVioleta Silaghi100% (2)

- Hypogene Speleogenesis in The Cerna River BasinDocument168 paginiHypogene Speleogenesis in The Cerna River BasinVioleta SilaghiÎncă nu există evaluări

- Prezentare Familia - Partener in EducatieDocument7 paginiPrezentare Familia - Partener in EducatieVioleta SilaghiÎncă nu există evaluări

- Viessmann 7Document8 paginiViessmann 7Violeta SilaghiÎncă nu există evaluări

- Talentata ClementinaDocument11 paginiTalentata ClementinaVioleta Silaghi100% (1)

- Viessmann Vitocell BiferalDocument22 paginiViessmann Vitocell BiferalVioleta SilaghiÎncă nu există evaluări

- Viessmann 2Document4 paginiViessmann 2Violeta SilaghiÎncă nu există evaluări

- Viessmann 6Document8 paginiViessmann 6Violeta SilaghiÎncă nu există evaluări

- Viessmann 5Document3 paginiViessmann 5Violeta SilaghiÎncă nu există evaluări

- Viessmann 3Document1 paginăViessmann 3Violeta SilaghiÎncă nu există evaluări

- Viessmann 1Document24 paginiViessmann 1Violeta SilaghiÎncă nu există evaluări

- 100 Proiecte Regio.sDocument126 pagini100 Proiecte Regio.sSeverineanu Victor ConstantinÎncă nu există evaluări