Documente Academic

Documente Profesional

Documente Cultură

Viessmann 6

Încărcat de

Violeta Silaghi0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări8 paginiMontaj Centrală Viessmann 6

Titlu original

VIESSMANN 6

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMontaj Centrală Viessmann 6

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări8 paginiViessmann 6

Încărcat de

Violeta SilaghiMontaj Centrală Viessmann 6

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 8

etn Conan

sone 674 0m. @

Installation / Service Manual

for Side Wall Vent System

Vitola-biferral

Series VBC Hot Water Heating Boiler

VIEZMANN

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

IMPORTANT:

‘The Vitola-biferral installation shall be in accordance with the

regulations of the authorities having jurisdiction or, in the

absence of such requirements, in accordance with National

Codes. In Canada use CSA B-139 for ol boiler installations, or

use CANICGA-B149.1 or 2 for gas boiler installations. In the

USS. use NFPA 31, "Standard for the Installation of Oil Burning

Equipment” for oll boiler installations and the National Fuel

Gas Code ANSI 2223.1 for gas boiler installations, Always use

latest editions of codes.

Selection of sice wall venting system

‘The proper venter and adapter fitings for each Vitole-biferral

boiler model are listed in the table on the following page. The

power venters have been selected to allow for an equivalent

vent pipe length of 100 ft. between the boller vent outlet and

the termina! inlet To calculate equivalent vent pipe length, adel

Up the total length of straight pipe. For each 90° elbow add

10 ft, and for each 45° elbow add 5 ft

Inthe example below (see Fig. 1) the equivalent pipe length is

48

‘This manual covers the selection and installation of side wall Length of straight pipe: 2+4+ 10+2 18 Tt.

venting systems for use with the Violaberral gas boler. 380° elbows ax = an

For cher instalaton information reerto the Viola-bferral” ‘Total equivalent Tg co

Insalaton/Servce Manual.

=

Ezz ZIZZO)

Mount poner verter v20v ]

Minato vere 340 scam

7) SEES, | Sort | fae

, = 4 —t. Oo

Vent {/ }

al 9

| /- Metal vent f we

—t a Pipe power

L\ SRV, SB-VR or womior

sy Tiimaie suppor

See | T Sontal

vt a

Drosera Ste munrbe sasied _VOrter 4

fis tigh temperature secon,

Wssmann Pat No. S502 6 |

ote: Power vane, vent

Food, barca sper

readers ae apps ath

‘Contactor suply vant pip.

r0v

separate

power supply

ferpowor

26.0426 gauge gavarized

Fibers race Gee

FRbatosone my use B vont

Sn nogaiv prescuro eo

owe vente

Kop peste pressure vering

LLL d

Fo.1

[Dpical Vitota-biterral installation with side wall venting

83 Vermont Ave., Bldg. 3,

Tol: (401) 782-0687 Fax:

Warwick, Rhode Isianc) 02888 USA

Barometric

~< I] sane ‘a |

yo _

Qe vem |

aed

sess

fo |_=r Bee.

wo | nti

ae

LLLLELLLELLELL LEELA

Viessmann Manufacturing Company (U.S) Ine. Viessmann Manufacturing Company Inc.

750 McMurray Fioad

Waterloo, Ontario, Canada NoV 265

(401) 782-0590 Tel: (519) 685-6900 Fax: (619) 885-0867

‘Slowed exc treo oxlovn may rot

scene ery aap, prone ot

Do net store of use gasoline or other flammable liquids

In the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliances.

+ Donot touch any electrical switches, do not use any |

phone in your building.

+ Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

+ Ifyou cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

Installer, service agency or the gas suppl

ZS warming

‘The installation, adjustment, service, and maintenance

of this boiler and power vent system must be done by a

professional service technician who is qualified and

experienced in the installation, service, and maintenance

of the gas- or oll-fired hot water boiler used. There are

no user serviceable parts on the boiler, burner, of

Control. Failure to heed this warning can cause property

damage, severe personal injury, of loss of life.

A warning:

Improper installation, adjustment, service, or |

maintenance can cause flue products to flow into living |

‘space. Flue products contain poisonous carbon |

monoxide gas which can cause nausea or asphyxiation |

resulting in severe personal Injury or loss of life. |

AS waring:

Should overheating occur or the gas supply fail to shut

off, do not disconnect the electrical supply to the pump.

Instead, shut off the gas supply at a location external to

the appliance.

Do not use this boller if any part has been under water.

Immediately call a qualified service technician to inspect

the boller and to replace any part of the control system

‘and any gas control which has been under water.

[ Do not store chemicals containing chiorine or other

corrosive materials near the boiler, such as bleach,

cleaning solvents, detergents, acids, hair spray, spray

‘cans, paint thinners, paint, water softener salt,

refrigerants.

[AS wasn:

Before each heating season begins, have the following

service and maintenance done by a professional service

technician:

41) Boller heat exchanger inspected and cleaned.

2) Vent system inspected for deterioration, leaks,

corrosion, proper draft, and proper operation. Check

vent system for compliance with local and national

code requirements. Repair or replace as required.

3) Burner checked and if necessary adjusted for

| proper combustion and operation. Check for

adequate supply of fresh outside combustion and |

ventilation air. |

Neglecting to perform necessary maintenance can cause

unsafe operation.

[AS wig

| Never operate the boiler without an installed venting

system which safely vents all products of combustion to |

the outdoors. The vent system must comply with all

applicable local and/or national codes.

Improper, incomplete, obstructed, or deteriorated vent

ystems can present a serious risk of flue gases leaking

into living space which could cause carbon monoxide

poisoning, Failure to heed this warning can cause

| property damage, severe personal injury, or loss of

[2s win:

Never operate the boiler without an adequate supply of

fresh combustion alr. This boiler needs fresh alr for safe |

‘operation and must be installed so there are provisions |

{for adequate combustion and ventilation air. All

‘combustion and ventilation air must be supplied from

the outside. Failure to heed this warning can cause

‘severe personal injury or loss of I

AS warning:

Shut off all electrical power and tur off gas or oll supply |

| te boiler and power vent before performing any service

| or maintenance on the boiler, burner, or control. Failure

to heed this warning could resutt in electrical shock,

severe personal injury, or loss of life.

Cautior 1

Advise the user/owner that during the winter the exhaust

gases will cause a rising visible mist or fog at the

‘outside vent terminal. Ensure the user/owner does not

consider the fog-like appearance objectionable before

proceeding with installation.

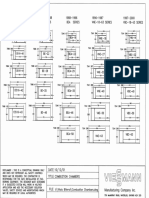

Power venter selection table Vitola-biferral-e (natural gas, LP, or No. 2 heating ol)

Boiler Complete | Boller Vent pipe | Vent | Power | Vent pipe Maximum

‘Model power vent | adaptor to power, pipe | venter ‘eo | equivalent

packs fitting’ | ventadaptor | la. | Modelo. | terminal | Model No. | pipe length

__|_ Grider fo. ‘itting(s) ___|_adaptor_| |

Vaca pvr = std 5 Hers RC Var Toot

~VBC-25 PTE = FoF 5 STAT | RC-4 vee 700%

| vaoss PvTS ~ HSTT AOE Vere | 008

——— 7 7 _|

VBC-40 Burs = FETA RCE VET Toot

VEC-50 Pura Tee e HST ROS Vere | t00%

VBC-6s Pure Fe a eae HST 2 ACS vere ion

Note:

‘The total equivalent length must not exceed 100 ft, The

‘minimum vent pipe equivalent length is 15 ft. from the boler

vent outlet to the power venter inlet. Boller must have

barometric damper installed inthe vent pipe. Failure to install

barometric damper may cause excessive negative pressure in

‘combustion chamber. Ignition may fall to occur because of

high negative pressure.

‘The venting system must be inspected annually for leaks,

blockage, deterioration, or matfunction, Failure to do so can

result in property damage, severe personal injury, or loss of

life. Allinstalation and service work should be done by

experienced, quaitied personnel. Support power ventor with

vibration mounts provided. Venting must be rigidly supported,

Follow all other instructions packaged with power venter.

The barometric damper is Field Type M ~ 6" for VBC-(18, 22,

33, 40, 50, 63) for oll fired boilers and Field Type MGI ~ 6” for

VBO-(18, 22, 33, 40) gas fired bollers and MGI ~ 7° for VBC-

(60, 63) gas fired.

Complete power vent package includes power venter with

factory wired control plug with 20 ft. of wire and vibration

isolation mount, adaptor fitings and vent terminal. Additional

control wire can be added in the field or requested at time of

‘ordering boiler from Viessmann Manufacturing

‘The HST series of power venters includes a time delay to

allow a post purge cycle after burner shutdown. The time delay

is factory set at 60 seconds to 890 seconds.

To set post purge timer (HST models only): Loosen screws on

ppowar venter electrical box and remove cover. Locate timer

relay and adjusting screw. Turn screw in indicated direction,

Fan proving switch pressure setting cannot be adjusted.

The power venter fan proving switch is factory set at 0.40"

0.03°w.c. (vacuum) on all models.

‘Side wall vent installation

In addition to these instructions follow the instructions supplied

by original component manufacturer included withthe power

vent and vent terminal. Note the requirements for vent system

termination on page 5,

‘The area around the side wall vent terminal must be inspected

Weekly to ensure that the vent outlet is not blocked by snow,

ive, or debris.

Horizontal runs of vent pipe must be supported by appropriate

means to avoid sagging, Metal strapping must be used every

81ft o support horizontal runs of vent pipe.

Each VBC boiler in a multiple VBC boiler installation may be

vented with its own side wall vent system. For example, three

VBC-50 boilers for side wall venting raquire three individual

PVT-4 side wall vent systems. Consult Viessmann

representative for further details on mutple side wall venting.

Use approved vent materials only. For venting purposes, B or

C vent may be used between the boiler and power venter for

{gas installations. Vent pipe between the power ventor and vent

terminal (positive pressure side) must be C vent with all joints

‘sealed with high temperature silicone and aluminum vent pipe

tape; C vent is 26 gauge minimum galvanized steel pipe. For

oll fired installations, C vent must be used.

Maintain 6” clearance from combustible material for C vent, for

B vent maintain 1” clearance from combustible material

Clearance for C vent may be reduced to 1” by running inside a

B vent to insulate long runs of C vent, for gas installations,

Wiring

All electrical wiring 's to be done in accordance withthe latest

‘ition ofthe National Electrical Code ANSUNFPA 70. In

Canada use CSA 22.1 Part 1 andlor local codes. The power

venter requires separate 120V supply. Refer to wiring diagram,

‘Support cable from power venter to boiler every 12”. Do not let

cable touch vent pipe. Install disconnect switches for power

venter and boiler incoming power.

AS warning

Never operate the boiler with power vent control cable

unplugged or otherwise disabled. Power venter must be

| operational for boilers installed with sice wall venting.

Operating boiler without burner interlocked with power

vventer control cable can cause flue gases to enter living

‘space which can cause carbon monoxide poisoning

Always check operation of adjustable high limit aquastat by

turning it down to a setting lower than the boller water

temperature and observing the boiler shut down. Hf burner

does not shut down, installer must locate source of problem.

Do not install the vent connector through an unheated space.

Condensation in the vent system may occur if not installed

in a heated space. Do not install boiler or vent system in area

‘where exposure to chlorides or other corrosive chemicals

‘might occur. Corrosive chemicals include refrigerants, bleach,

salt for water softeners, cleaning solvents. Corrosive

chemicals will contaminate the combustion air and cause vent,

system of boiler failure. Ths type of failure Is not covered

under warranty.

pumoers

ns SERIES

Power venter component location

Caution:

This side wall vent system is designed to be used with the 7-

pole plugsin 120V control systems. Earlier Vitola models with

the 6- and 3-pole plug-in 24V control systom cannot use this

side wall vant system.

Power venter mounting

To facilitate installation and reduce vibration we have included

2 mounting brackets, 2 rubber isolators and 2 rubber

{grommets. One of the brackets may be used temporarily as a

“third hand’ while positioning it for permanent installation,

When installing the power venter for horizontal mount, install

‘one of the brackets fo the electrical box using the nut-screw

provided. Install the otner to the damper rad as shown to the

Jeft. When installing the power venter for the vertical mount,

only one bracket is needed. This bracket should be mounted to

the motor as shown to the eft.

Vent pipe must be horizontal, horizontal with an upwards

slope, of vertical with flow upwards. Do not install vent pipe

with flow directed downwards. Do not install vent pipe

underground. The entire vent length must be accessible for

ingpection and service. Do not enclose any part of the vent

system such that it cannot be inspected or serviced. Do not

enclose any part of vent with combustible material

‘Always ensure there Is sufficient supply of combustion and

dilution air. Follow guidelines in current editions of ANSI

2223.1 of CGA B19 instalation codes for combustion and

vonilation air requirements.

® @ @ @ © | o © o |

Boller | Boilerto | Ventpipe | Vent pipe | Power |Powervent) Ventpipe | Vent | Power vent

Model | vent pipe diameter | to power | ventsize | topipe | tovent | terminal | system

‘adaptor vent adaptor | adaptor | terminal |

I adaptor

VBC-18 6 tos” s S04" HSTJ | ~ AC-4 VH1-4" PVT

vac-22 Hst-1_| PvT2

vec-33 = @ | eee | wert | wwe | AGS | VHT | PVTS

vac-40 HST PVES

vacso | Tie |e | Sta [Hera | wwe | AC’) VET | pyre

vec-63 HST-2 | | Pvrs

Noe: Draft gauge

‘must ba used to

festaalsn =,02" wc

Invent Drattmay.

be righer for sho

vent engin

Fig. 2

| ‘VBC boiler

For sizing hole through wall refer to rough-in dimension in chart below.

“lem vert

ogve publ

wows

Fig. 4

Not

Boiler flue gas must be tested by a qualified technician using

proper combustion instruments such as Bacharach Fyrite

‘Combustion Gas Analyzer kit or other suitable and property

‘calibrated instrument. All boiler installations must have carbon

dioxide, carbon monoxide, flue gas temperature measured.

For oil fired installations smoke spot measurements must also

be taken, All measurements should be taken between boiler

‘and barometric damper before dilution air.

Acceptable combustion results must be obtained to ensure

‘safe operation.

Note: C dimension for Vet-4's square ot eeu. |

Baller | — Vent a 8 c] Roughn | |

Model __| Terminal Dimension

VBC-18,22 VH-1-4 ao OK" 6%" 8 square,

Wvac-35.405063 vie | iF | em | ee | oda

Fig.9

Vent terminal location

end ve: toa

masta meuried

Tenens

Temuns ent hood

eS ramam

forgone

Mor doo ana

ae

Tierlund von nova mst.

3 above any outside

-

“ Tremung | seine wha ion bemouniad 48 minum

onto moe

1 Rrabove

200g so Fw

oe

For acceptable values of field measurements refer to those

given in the Burner Installation Instructions of the Vitola-biferral

‘manual packaged with each burner. Bumer may require some

adjustments for acceptable field measurements. Refer to

bumer manual packaged with each burner. All burner

adjustments must be done by @ qualified technician,

POWER VENTER FOR 120V BOILER CONTROLS

Caution: Label all wites prior to

disconnection when servicing controls.

Wiring errors can cause improper and

dangerous operation.

Verity proper operation after servicing,

To counter plug 41 on

Boiler corte SPV, SR-VR,

orteatie Me

20 SRY, SAVE

wv V,

a] | 20

| tay AR

intel | ron o—

Cz

| Bune I

5 |

| | Power venter

e|

due 4

[ee Breet li ee

| pe 2 /eQ |

ae 2 !

f r ale |

i | og} alaigyal &

ia g}

i ! i

t i !

| i i

TSN [Hfetjes pre i. oa!

lar

To counter hg 41 on burner

ver pun ATTENTION:

Do NOT connect #41 plug on boiler control to #41 plug

‘on burner if power vent is installed

[1 Supply: 120v, 60H, 1 PH

Provide disconnect means and overload protection.

Warning! Power venter may have more than one live circuit

Disconnect power supply to boiler and power supply to Tjernlund power

venter before servicing

HST series

HST Motor 950-1020

Whee! 950-1010

Fan prover 950-1030

Timeritelay 950-1060,

HST Motor 950-1020

Whee! 950-1011

Fan prover 90-1030

Timertelay 950-1060

Unit dimensions (in)

HST Motor S50 102 Model | (H)Holght | (W) Wigih | (0) Depih_ | Tevoutet

Whee! 950-1012 Pegs ees ne 32 vee

Fan prover 950-1031 ra +e = =

Timerrolay 950-1060 = = Z

HST We ae é

Electrical

Model Wotor Control He RPM Watts “Amps Thermal

Voltage Circuit Protection

Voltage

HST 120¥ 120v 60 3000 95 1.26 Yes

HST-1 “120¥ 420 60 3000 95. 1.26) Yes

HST-2 120¥ 120 60 3000 224 2.00 Yes

Maintenance - power venter ‘Sequence of operation:

“Tho Tjorniund power venter must be inspected semi-annually

Points of inspection are:

1, Motor ~ Motor must rotate freely. Oil every six months of,

‘operation with 4 drops of SAE 20 ol.

2, Whee! - Wheel must be clean of soot, ash or any other

‘coating which inhibits rotation or air flow. Remove all

foreign material from vent system before operation.

3. Pressure switch — Pressure switch must operate freely,

Verify proper operation by removing pressure sensing

tube. Bummer should not activate with pressure sensing

tube removed

Maintenance - vent system and vent hood.

‘The vent system must be inspected regularly at 3 month:

intervals. Points of inspection are as follows:

1. Screened opening of the vent hood which should be free

from foreign material and cleaned as necessary.

2. Structural integrity of the vent hood should be maintained

'50 as not to reduce vent discharge opening

3. Chock all vent system connections for leakage and re-seal

where needed. If any vent pipe shows signs of

deterioration, replace immadiately and check new

Connections for possible leaks. Re-seal using General

Electric RTV 108 Red HiTemp Silicone Sealer or

equivalent

4, Debris, oe, or snow must not be allowed to block

discharge opening of vent hood. Check vent hood area for

blockage after heavy snowfall

1. Thermostat or other operating contro! cals for heat.

2. Power venter starts, a flow is established.

3, Pressure switch in power venter senses negative

pressure, pressure switch contacis close. Air flow is.

proven.

4, 120V is supplied to bummer through contacts of pressure

‘switch,

5. Bumer tres until operating control is satisfied. Bummer

‘oycles on and off in response to SHL1 (safety high limit 1

= adjustable) during call for heat.

6. Thermostat or other operating control is satisfied. Bumer

shuts down.

7. Power venter will continue to operate for post purge time

of 1 to 10 minutes, Factory setting is 90 seconds.

8 Power venter fan stops after post purge, ready for another

call for heat,

‘This manuals also applicable tothe existing BEA and VNE

boilers with E/KR-120-V or TrimatikeMC control, Use the

following cross reference chart for Btu’h input and power vent

selection.

ll Input Gas (nat. or LP)

(Btuh) Input (Btw)

VBOIVNE-18 equals BEA-18 83,000 90,000

\VBC-22, VNE-27 equals BEA-22 107,000 116,000

VBOIVNE-33 equals BEA-29 135.000 146,000

VBCIVNE-40 equals BEA-35 170,000 185,000

VBCIVNE-50 equals BEA46 219.000 288,000

VBCIVNE-63 equals BEA-S8 300,000 300,000

For example a PVT-6 will work on a BEA-58 and on a VNE-63,

7

Outdoor | sav

aw

eer |

oo ep

‘See Trimatik-MC_ 4 £

feels isl

a

Tose

Soegte,

Law ott

Fs

7-pole #41 plug connections for Vitola leadl/ag arrangement with power vent

boter

wih Say

S-ar putea să vă placă și

- P.I.P MatematicaDocument5 paginiP.I.P MatematicaVioleta SilaghiÎncă nu există evaluări

- 1 DecembrieDocument16 pagini1 DecembrieVioleta Silaghi100% (1)

- Pip Procese PsihiceDocument3 paginiPip Procese PsihiceVioleta SilaghiÎncă nu există evaluări

- Săptămâna Verde Idei de Activități Pentru ProfesoriDocument11 paginiSăptămâna Verde Idei de Activități Pentru ProfesoriVioleta SilaghiÎncă nu există evaluări

- Plan de Interpretare A Naturii Din Rezervație Și Din Imediata Apropiere Băile Felix 1 MaiDocument18 paginiPlan de Interpretare A Naturii Din Rezervație Și Din Imediata Apropiere Băile Felix 1 MaiVioleta SilaghiÎncă nu există evaluări

- SolidaritateDocument15 paginiSolidaritateVioleta SilaghiÎncă nu există evaluări

- Educație Globală - CampanieDocument13 paginiEducație Globală - CampanieVioleta SilaghiÎncă nu există evaluări

- Florance Braunstein - Ghid de Cultura GeneralaDocument369 paginiFlorance Braunstein - Ghid de Cultura GeneralaVioleta Silaghi100% (2)

- Hypogene Speleogenesis in The Cerna River BasinDocument168 paginiHypogene Speleogenesis in The Cerna River BasinVioleta SilaghiÎncă nu există evaluări

- Prezentare Familia - Partener in EducatieDocument7 paginiPrezentare Familia - Partener in EducatieVioleta SilaghiÎncă nu există evaluări

- Viessmann 7Document8 paginiViessmann 7Violeta SilaghiÎncă nu există evaluări

- Talentata ClementinaDocument11 paginiTalentata ClementinaVioleta Silaghi100% (1)

- Viessmann Vitocell BiferalDocument22 paginiViessmann Vitocell BiferalVioleta SilaghiÎncă nu există evaluări

- Viessmann 2Document4 paginiViessmann 2Violeta SilaghiÎncă nu există evaluări

- Viessmann 5Document3 paginiViessmann 5Violeta SilaghiÎncă nu există evaluări

- Viessmann 4Document12 paginiViessmann 4Violeta SilaghiÎncă nu există evaluări

- Viessmann 3Document1 paginăViessmann 3Violeta SilaghiÎncă nu există evaluări

- Viessmann 1Document24 paginiViessmann 1Violeta SilaghiÎncă nu există evaluări

- 100 Proiecte Regio.sDocument126 pagini100 Proiecte Regio.sSeverineanu Victor ConstantinÎncă nu există evaluări