Documente Academic

Documente Profesional

Documente Cultură

Calcul Dig de Retinere

Încărcat de

relu59Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calcul Dig de Retinere

Încărcat de

relu59Drepturi de autor:

Formate disponibile

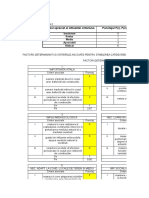

Dimensionarea grosimii digurilor de reinere Pentru calcule, se consider c digul de reinere este o construcie compus, ncastrat jur-mprejur n Exemplu:

Elementele de calcul sunt [24]: pa presiunea maxim orizontal ce va aciona pe suprafaa digului = 310-315 kN/m2.

pa = b= b1 = 31,500.00 daN / mp 0.60 m 3.80 m 31,500.00 x 0.60 = 18,900.00 daN / ml 3.80 ^2 ) / 12 = 22,743.00 daN * ml n calcule se ia valoarea de 31500 daN/m2;

b limea fiei suprafeei digului, aferent unui stlp metalic ce va putea prelua eforturile create de materialul b1 nlimea maxim a fiei, determinat ntre vatra i bolta lucrrii miniere; b1 = 3,8 m; P - sarcina uniform distribuit ce va aciona pe unitatea de lungime a fiei va fi:

P = pa x b =

M - Momentul maxim creat de sarcina uniform distribuit va fi:

M = ( P x b1^2) / 12 = ( 18,900.00 x Aa - aAria armturii unui profil metalic : U 14 Aa = 20.40 cmp ho = 0.73 m 20.40 x 100 ) / ( 0.60 x 0.73 ) = 0.47 %

h0 este grosimea betonului calculat ntre armturile metalice i suprafaa digului ce nu este armat = 73 cm. p% - procentul de armare a digului de reinere va fi :

p% = ( Aa x 100) / ( b x h0 ) = ( = x=( > = 0.11 % 73.00 73.00 8.03 cm 1.75 -( 8.03 /2 )= 67.24 cm

x - axa neutr a zonei de beton ce va fi supus compresiunii va fi :

x h0 ) = 0.11 x

l1 -grosimea peretelui digului de reinere ce va aciona la eforturi de ntindere : (se consider distana ntre fibra

l1 = h0 - exmetalic - x/2 =

N - Verificarea mrimii forei ce poate fi preluat de grosimea digului

N = M / l1 = 22,743.00 / 0.67 = 33,826.13 daN

Verificarea seciunii betonului marca B-200 Anec = N / Ra = 33,826.13 / 2,100.00

16.11 cmp

Cum : aria profilului utilizat : U 14 este : A ef = 20.40 cmp = > Aef = > A nec => Sectiune :

OK!

unde : Ra este rezistena admisibil al ntindere a materialului OL-37 Ra = 2100 daN/cm2

Verificarea seciunii betonului marca B-200

A nec b = (N / Rc ) = 33,826.13 / 95.00 = 356.06 mp

unde :Rc rezistena admisibil la compresiune a betonului;

Rc = 95 daN/cm2

Din calculele de verificare rezult c n digul de reinere, att seciunea armturilor metalice ct i a betonului

Cum : aria ectiva a sectiuni betonului: Ab ef = b * x = => Aef b = > A nec b 60.00 x 8.03 OK! 481.80 cmp

=> Sectiune :

Din calculele de verificare rezult c n digul de reinere, att seciunea armturilor metalice ct i a betonului Detaliul de armare a digului de reinere:

1 U-14, armtur de rezisten pe vertical; 2 5 f 14, armtur de repartiie pe orizontal 3 ancore sudate pe U-14 din OB-37, 3 f 12/ml sudur 1 U-14, armtur de rezisten pe vertical; 2 5 f 14, armtur de repartiie pe orizontal 3 ancore sudate pe U-14 din OB-37, 3 f 12/ml sudur

"BEAMANAL" --- SINGLE-SPAN and CONTINUOUS-SPAN BEAM ANALYSIS

Program Description:

"BEAMANAL" is a spreadsheet program written in MS-Excel for the purpose of analysis of either single-span or continuous-span beams subjected to virtually any type of loading configuration. Four (4) types of single-span beams and two (2) through (5) span, continuous-span beams, considered. Specifically, beam end reactions as well as the maximum moments and deflections are calculated. Plots of both the shear and moment diagrams are produced, as well as a tabulation of the shear, moment, slope, and deflection for the beam or each individual span. Note: this is a metric units version of the original "BEAMANAL.xls" spreadsheet workbook. This program is a workbook consisting of three (3) worksheets, described as follows:

Worksheet Name

Doc Single-Span Beam Continuous-Span Beam

Description

This documentation sheet Single-span beam analysis for simple, propped, fixed, & cantilever beams Continuous-span beam analysis for 2 through 5 span beams

Program Assumptions and Limitations:

1. The following reference was used in the development of this program (see below): "Modern Formulas for Statics and Dynamics, A Stress-and-Strain Approach" by Walter D. Pilkey and Pin Yu Chang, McGraw-Hill Book Company (1978), pages 11 to 21. 2. This program uses the three (3) following assumptions as a basis for analysis: a. Beams must be of constant cross section (E and I are constant for entire span length). b. Deflections must not significantly alter the geometry of the problem. c. Stress must remain within the "elastic" region. 3. On the beam or each individual span, this program will handle a full length uniform load and up to eight (8) partial uniform, triangular, or trapezoidal loads, up to fifteen (15) point loads, and up to four (4) applied moments. 4. For single-span beams, this program always assumes a particular orientation for two (2) of the the four (4) different types. Specifically, the fixed end of either a "propped" or "cantilever" beam is always assumed to be on the right end of the beam. 5. This program will calculate the beam end vertical reactions and moment reactions (if applicable), the maximum positive moment and negative moment (if applicable), and the maximum negative deflection and positive deflection (if applicable). The calculated values for the end reactions and maximum moments and deflections are determined from dividing the beam into fifty (50) equal segments with fifty-one (51) points, and including all of the point load and applied moment locations as well. (Note: the actual point of maximum moment occurs where the shear = 0, or passes through zero, while the actual point of maximum deflection is where the slope = 0.) 6. The user is given the ability to input two (2) specific locations from the left end of the beam to calculate the shear, moment, slope, and deflection. 7. The user is also given the ability to select an AISC W, S, C, MC, or HSS (rectangular tube) shape to aide in obtaining the X-axis moment of inertia for input for the purely analysis worksheets. 8. The plots of the shear and moment diagrams as well as the displayed tabulation of shear, moment, slope, and deflection are based on the beam (or each individual span) being divided up into fifty (50) equal segments with fifty-one (51) points. 9. For continuous-span beam of from two (2) through five (5) spans, this program utilizes the "Three-Moment Equation Theory" and solves a system simultaneous equations to determine the support moments 10. This program contains numerous comment boxes which contain a wide variety of information including explanations of input or output items, equations used, data tables, etc. (Note: presence of a comment box is denoted by a red triangle in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view the contents of that particular "comment box".)

Formulas Used to Determine Shear, Moment, Slope, and Deflection in Single-Span Beams For Uniform or Distributed Loads: Loading functions for each uniform or distributed load evaluated at distance x = L from left end of beam: FvL = -wb*(L-b-(L-e)) + -1/2*(we-wb)/(e-b)*((L-b)^2-(L-e)^2)+(we-wb)*(L-e) FmL = -wb/2*((L-b)^2-(L-e)^2) + -1/6*(we-wb)/(e-b)*((L-b)^3-(L-e)^3)+(we-wb)/2*(L-e)^2 FqL = -wb/(6*E*I)*((L-b)^3-(L-e)^3) + -1/(24*E*I)*(we-wb)/(e-b)*((L-b)^4-(L-e)^4)+(we-wb)/(6*E*I)*(L-e)^3 FDL = -wb/(24*E*I)*((L-b)^4-(L-e)^4) + -1/(120*E*I)*(we-wb)/(e-b)*((L-b)^5-(L-e)^5)+(we-wb)/(24*E*I)*(L-e)^4 Loading functions for each uniform or distributed load evaluated at distance = x from left end of beam: If x >= e: Fvx = -wb*(x-b-(x-e)) + -1/2*(we-wb)/(e-b)*((x-b)^2-(x-e)^2)+(we-wb)*(x-e) Fmx = -wb/2*((x-b)^2-(x-e)^2) + -1/6*(we-wb)/(e-b)*((x-b)^3-(x-e)^3)+(we-wb)/2*(x-e)^2 Fqx = -wb/(6*E*I)*((x-b)^3-(x-e)^3) + -1/(24*E*I)*(we-wb)/(e-b)*((x-b)^4-(x-e)^4)+(we-wb)/(6*E*I)*(x-e)^3 FDx = -wb/(24*E*I)*((x-b)^4-(x-e)^4) + -1/(120*E*I)*(we-wb)/(e-b)*((x-b)^5-(x-e)^5)+(we-wb)/(24*E*I)*(x-e)^4 else if x >= b: Fvx = -wb*(x-b) + -1/2*(we-wb)/(e-b)*(x-b)^2 else: Fvx = 0 Fmx = -wb/2*(x-b)^2 + -1/6*(we-wb)/(e-b)*(x-b)^3-(x-e)^3 else: Fmx = 0 Fqx = -wb/(6*E*I)*(x-b)^3 + -1/(24*E*I)*(we-wb)/(e-b)*(x-b)^4 Fqx = 0 else: FDx = -wb/(24*E*I)*(x-b)^4 + -1/(120*E*I)*(we-wb)/(e-b)*(x-b)^5 F Dx = 0 else: For Point Loads: Loading functions for each point load evaluated at distance x = L from left end of beam: FvL = -P FmL = -P*(L-a) FqL = -P*(L-a)^2/(2*E*I) FDL = P*(L-a)^3/(6*E*I) Loading functions for each point load evaluated at distance = x from left end of beam: If x > a: Fvx = -P else: Fmx = -P*(x-a) else: Fqx = -P*(x-a)^2/(2*E*I) else: FDx = P*(x-a)^3/(6*E*I) else: For Applied Moments: Loading functions for each applied moment evaluated at distance x = L from left end of beam: FvL = 0 FmL = -M FqL = -M*(L-c)/(E*I) FDL = M*(L-c)^2/(2*E*I) Loading functions for each applied moment evaluated at distance = x from left end of beam: If x >= c: Fvx = 0 else: Fmx = -M else: Fqx = -M*(x-c)/(E*I) else: FDx = M*(x-c)^2/(2*E*I) else:

Fvx = Fmx = Fqx = F Dx =

0 0 0 0

Fvx = Fmx = Fqx = F Dx =

0 0 0 0 (continued)

Formulas Used to Determine Shear, Moment, Slope, and Deflection (continued) Initial summation values at left end (x = 0) for shear, moment, slope, and deflection: Simple beam: Vo = Mo = qo = Do = Propped beam: Vo = Mo = qo = Do = Fixed beam: Vo = Mo = qo = Do = Cantilever beam: Vo = Mo = qo = Do =

-1/L*S(FmL) 0 1/L*S(FDL)+L/(6*E*I)*S(FmL) 0

-3*E*I/L^3*S(FDL)-3*E*I/L^2*S(FqL) 0 3/(2*L)*S(FDL)+1/2*S(FqL) 0

-12*E*I/L^3*S(FDL)-6*E*I/L^2*S(FqL) 6*E*I/L^2*S(FDL)+2*E*I/L*S(FqL) 0 0

0 0 -S(FqL) -S(FDL)-L*S(FqL)

Summations of shear, moment, slope, and deflection at distance = x from left end of beam: Shear: Moment: Slope: Deflection: Vx = Mx = qx = Dx = Vo+S(Fvx) Mo+Vo*x+S(Fmx) qo+Mo*x/(E*I)+Vo*x^2/(2*E*I)+S(Fqx) -(Do-qo*x-Mo*x^2/(2*E*I)-Vo*x^3/(6*E*I)+S(FDx)

Reference: "Modern Formulas for Statics and Dynamics, A Stress-and-Strain Approach" by Walter D. Pilkey and Pin Yu Chang, McGraw-Hill Book Company (1978)

"Three-Moment Theory" Used for Continuous-Span Beam Analysis: The "Three-Moment" Equation is valid for any two (2) consecutive spans as follows: Ma*L1/I1+2*(Mb)*(L1/I1+L2/I2)+Mc*L2/I2 = -6*(FEMab*L1/(6*I1)+FEMba*L1/(3*I1))-6*(FEMbc*L2/(3*I2)+FEMcb*L2/(6*I2)) =-(FEMab+2*FEMba)*L1/I1-2*(FEMbc+FEMcb)*L2/I2 where: Ma = internal moment at left support Mb = internal moment at center support Mc = internal moment at right support L1 = length of left span I1 = moment of inertia for left span L2 = length of right span I2 = moment of inertia for right span FEMab = total Fixed-End-Moment for left end of left span FEMba = total Fixed-End-Moment for right end of left span FEMbc = total Fixed-End-Moment for left end of right span FEMcb = total Fixed-End-Moment for right end of right span N = actual number of beam spans "Dummy" spans are used to model the left end and right end support conditions for the beam. A pinned end is modeled as a very flexible span (very long length and very small inertia). A fixed end is modeled as a very stiff span (very short length and very large inertia). Thus, the theoretical number of spans used is = N + 2. By writing an equation for each pair of consecutive spans and introducing the known values (usually zero) of end moments, a system of (N+1) x (N+1) simultaneous equations can be set up to solve for the unknown support moments.

Note:

Reference: AISC Manual of Steel Construction - Allowable Stress Design (ASD) - 9th Edition (1989), page 2-294

"BEAMANAL.xls" Program (metric version) Version 1.0

TEMA DE CASA

Dimensionarea unui dig de retinere

Job Name: Job Number: Introducere date:

Subject: Originator:

c e

Rez & Rez m MPa cm^4 Inc & Inc Rez & Inc

Checker:

Date despre grinda: Tip grinda Inc & Inc Deschidere, L = 3.80 Mod. el, E = 200,000 Inertie, I = 16,500 Incarcari: Permanente: q= Utile Distribuite:

#1: #2: #3: #4: #5: #6: #7: #8:

b a +P +qb

+M

+qe +q

E,I

Liber & Inc

L x RR

RL

Nomenclature 0.0111 b (m) 0.0000

kN/m

Start

Sfirsit

qb (kN/m) -189.0000

e (m) 3.8000

qe (kN/m) -189.0000

REZULTATE: Reactiuni (kN and kN-m): RL = RR = 0.00 -718.16 ML = MR = 1364.50 0.00 Momentul Max. (kN-m) / pozitia (m): +M(max) = 1364.50 @x= 3.800 -M(max) = @x= 0.00 0.000 Max. Deflections (mm) and Locations (m): -D(max) = @x= 0.000 0.000 +D(max) = @x= 49.756 3.800 D(ratio) = L/76

Shear Diagram

Concentrate:

#1: #2: #3: #4: #5: #6: #7: #8: #9: #10: #11: #12: #13: #14:

a (m) 0.0000

P (kN) 0.00

800.0 700.0 600.0

Shear (kN)

500.0 400.0 300.0 200.0 100.0 0.0 0.00 0.23 0.46 0.68 0.91 1.14 1.37 1.60 1.82 2.05 2.28 2.51 2.74 2.96 3.19 3.42 3.42

x (m)

1600.0

Moment Diagram

Moment (kN-m)

#15:

1400.0 1200.0 1000.0 800.0 600.0 400.0 200.0 0.0 0.00 0.23 0.46 0.68 0.91 1.14 1.37 1.60 1.82 2.05 2.28 2.51 2.74 2.96 3.19 3.65

Moments:

#1: #2: #3: #4:

c (m)

M (kN-m)

x (m)

7 of 9

6/28/2013 7:52 AM

3.65

"BEAMANAL.xls" Program (metric version) Version 1.0

For Full Uniform Load, w Loading Functions Evaluated at x = L

kN-m):

pozitia (m):

Locations (m):

3.65

3.65

8 of 9

6/28/2013 7:52 AM

"BEAMANAL.xls" Program (metric version) Version 1.0

CONTINUOUS-SPAN BEAM ANALYSIS

Job Name: Job Number: Input Data:

b

For Two (2) through Five (5) Span Beams (Metric Units Version) Subject: Originator:

Checker:

c e a +P

Beam Data: No. Spans, N = Left End = Right End = Modulus, E =

2 Pinned Pinned 200000

+M +wb

+we +w

Support #1 Support #3 MPa

Span #1

Span #2

Span #3

Span #4

Span #5

E,I VL x

L VR

Span and Support Nomenclature Span Data and Loadings: Span Data: Span, L (m) = Inertia, I (cm^4) = Full Uniform: w (kN/m) =

Start

Load Nomenclature Span #1 6.0000 16274.65 14.6000

End Start

Summary of Results for Entire 2-Span Beam: Support Moments: Support Reactions: M1 = R1 = 0.00 kN-m 32.85 M2 = -65.70 kN-m R2 = 109.50 M3 = R3 = 0.00 kN-m 32.85 M4 = R4 = --kN-m --M5 = R5 = --kN-m --M6 = R6 = --kN-m --Maximum Moments in Beam: +M(max) = @x= 36.96 kN-m 2.250 -M(max) = -65.70 kN-m @x= 6.000 Maximum Deflections in Beam: -D(max) = -3.148 mm @x= 3.480 +D(max) = @x= 0.000 mm 0.000 D(ratio) = L/1906 Span #4 Span #5

kN kN kN kN kN kN m (Span #1) m (Span #1) m (Span #2) m (Span #1)

Span #2 6.0000 16274.65 14.6000

End Start

Span #3

End

Start

End

Start

End

Distributed:

#1: #2: #3: #4: #5: #6: #7: #8:

b (m)

wb (kN/m)

e (m)

we (kN/m)

b (m)

wb (kN/m)

e (m)

we (kN/m)

b (m)

wb (kN/m)

e (ft.)

we (kN/m)

b (m)

wb (kN/m)

e (m)

we (kN/m)

b (m)

wb (kN/m)

e (m)

we (kN/m)

Ta

Point Loads:

#1: #2: #3: #4: #5: #6: #7: #8: #9: #10: #11: #12: #13: #14: #15:

a (m)

P (kN)

a (m)

P (kN)

a (m)

P (kN)

a (m)

P (kN)

a (m)

P (kN)

Moments:

#1: #2: #3: #4:

c (m)

M (kN-m)

c (m)

M (kN-m)

c (m)

M (kN-m)

c (m)

M (kN-m)

c (m)

M (kN-m)

Left End Cantilever Shear = Results: End Shears (kN): 32.85

0.00

kN

Left End Cantilever Moment = -54.75 54.75

0.00 -32.85

kN-m

Right End Cantilever Shear = -----

0.00

kN

Right End Cantilever Moment = -----

0.00

kN-m

---

---

9 of 9

6/28/2013 7:52 AM

S-ar putea să vă placă și

- Curs Plansee Dala Si Plansee Ciuperca M.Gabor PDFDocument23 paginiCurs Plansee Dala Si Plansee Ciuperca M.Gabor PDFAndreea Vaduva100% (1)

- Detalii - Placi Si Grinzi Inclinate - Pormenoresconstrutivos - Cype.ptDocument2 paginiDetalii - Placi Si Grinzi Inclinate - Pormenoresconstrutivos - Cype.ptrelu59Încă nu există evaluări

- Detalii Placi Si Grinzi Inclinate Schite Pormenoresconstrutivos - Cype.ptDocument32 paginiDetalii Placi Si Grinzi Inclinate Schite Pormenoresconstrutivos - Cype.ptrelu59Încă nu există evaluări

- Parametri Geotehnici de Calcul - F1, F2 - DomnestiDocument4 paginiParametri Geotehnici de Calcul - F1, F2 - Domnestirelu59Încă nu există evaluări

- Curs HidrologieDocument21 paginiCurs HidrologieGeambasu Gabriel100% (1)

- P100 2013 PDFDocument925 paginiP100 2013 PDFstonerrrock100% (5)

- Categoria de Importanță Pentru Clădirile de Locuințe Parter Și Un EtajDocument2 paginiCategoria de Importanță Pentru Clădirile de Locuințe Parter Și Un Etajrelu59Încă nu există evaluări

- Clasificarea Constructiilor Dupa Destinatie Si ImportantaDocument11 paginiClasificarea Constructiilor Dupa Destinatie Si Importantarelu59Încă nu există evaluări

- Master Zidarie 2008-2009 Gata Cu CopertaDocument167 paginiMaster Zidarie 2008-2009 Gata Cu CopertaPaul PeterÎncă nu există evaluări

- PD95-2002 - Normativ Privind Proiectarea Hidraulica Poduri Si PodeteDocument37 paginiPD95-2002 - Normativ Privind Proiectarea Hidraulica Poduri Si PodeteRadu-Alex Vornicu100% (4)

- Ingineria Raurilor - MitoiuDocument241 paginiIngineria Raurilor - MitoiuAnca Ecaterina DBÎncă nu există evaluări

- Calcul Hidraulic PodDocument10 paginiCalcul Hidraulic Podrelu59Încă nu există evaluări

- MBD Memoriu Cerere Intrare in LegalitateDocument5 paginiMBD Memoriu Cerere Intrare in Legalitaterelu59Încă nu există evaluări

- Ordinul nr839Document65 paginiOrdinul nr839Melinda SzÎncă nu există evaluări

- C 254-2017 - ÎNDRUMĂTOR Privind Cazuri Particulare de Expertizare TehnicăDocument19 paginiC 254-2017 - ÎNDRUMĂTOR Privind Cazuri Particulare de Expertizare Tehnicărelu59Încă nu există evaluări

- Intrare În Legalitate, Schimbare de Destinaţie Din Spaţii Comerciale - RestaurantDocument5 paginiIntrare În Legalitate, Schimbare de Destinaţie Din Spaţii Comerciale - Restaurantrelu59Încă nu există evaluări

- Categoria de Importanță Pentru Clădirile de Locuințe Parter Și Un EtajDocument2 paginiCategoria de Importanță Pentru Clădirile de Locuințe Parter Și Un Etajrelu59Încă nu există evaluări

- Principii Si Metode de ReabilitareDocument6 paginiPrincipii Si Metode de ReabilitareIlie Nicolae SucalăÎncă nu există evaluări

- Exemplu de Calcul Hala MetalicaDocument52 paginiExemplu de Calcul Hala MetalicaOctavian CicuÎncă nu există evaluări

- C e Normativ VantDocument140 paginiC e Normativ Vantgustic1Încă nu există evaluări

- P118-99 Din 07.04.1999 - Normativul de Siguranta La Foc A Construct Iilor Indicativ PDFDocument150 paginiP118-99 Din 07.04.1999 - Normativul de Siguranta La Foc A Construct Iilor Indicativ PDFrelu59Încă nu există evaluări

- Harta de Zonare Seismică (TC) Din P100-2013 - EncipediaDocument1 paginăHarta de Zonare Seismică (TC) Din P100-2013 - Encipediarelu59Încă nu există evaluări

- Parametri Geotehnici de Calcul - F1, F2 - DomnestiDocument4 paginiParametri Geotehnici de Calcul - F1, F2 - Domnestirelu59Încă nu există evaluări

- Harta de Zonare Seismică (PGA) Din P100!1!2013 - EncipediaDocument1 paginăHarta de Zonare Seismică (PGA) Din P100!1!2013 - Encipediarelu59Încă nu există evaluări

- Clasificarea Constructiilor Dupa Destinatie Si ImportantaDocument11 paginiClasificarea Constructiilor Dupa Destinatie Si Importantarelu59Încă nu există evaluări

- Caracteristici Geotehnice de Calcul-Nota 001Document4 paginiCaracteristici Geotehnice de Calcul-Nota 001relu59Încă nu există evaluări

- Categoria de Importanta 1Document58 paginiCategoria de Importanta 1relu590% (1)

- Note Calcul BazaDocument14 paginiNote Calcul Bazarelu59Încă nu există evaluări

- Note Calcul Cladire BirouriDocument17 paginiNote Calcul Cladire Birourirelu59Încă nu există evaluări