Documente Academic

Documente Profesional

Documente Cultură

Dinamica Gazelor

Încărcat de

Bardas RaduTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dinamica Gazelor

Încărcat de

Bardas RaduDrepturi de autor:

Formate disponibile

TERMOTEHNICA 1/2011

CONSIDERAII REFERITOARE LA CAPACITATEA

MAXIM DE TRANSPORT A CONDUCTELOR /

REELELOR DE GAZE NATURALE

Mihai ALBULESCU

1

, Sorin NEACU

1

, Cristian EPARU

1

, Sebastian BAMBO

2

, Silvian SUDITU

1

1

Universitatea Petrol-Gaze din Ploieti, Ploieti, Romnia

2

E-on Gaz Romnia, Trgu Mure, , Romnia

Rezumat. Gazele naturale reprezint o important resurs energetic, acestea trebuind transportate prin conducte

de la sursele de gaze ctre consumatori.

n lucrarea de fa sunt prezentate principiile de calcul ale capacitii de transport i factorii care limiteaz aceast

capacitate i care pot conduce la blocarea conductelor.

Sunt prezentate rezultatele obinute cu simulatoarele numerice AFT Arrow i Simone.

Cuvinte cheie: gaz, transport, capacitate, simulare.

Abstract. Natural gas represents a significant energy resource; they must be transported by pipeline from the gas

sources to consumers.

This paper analyzes the principles of calculation of transport capacity and the factors which restrict this ability

and which may therefore lead to blocking pipes.

The results obtained with numerical simulators AFT Arrow and Simone are also presented.

Keywords: gas, transport, capacity, simulation.

1. INTRODUCERE

Conform normativelor europene i a legislaiei

naionale, reprezentat de codul reelei operatorul

reelei naionale de transport gaze trebuie s

permit accesul la reele n mod egal i

nediscriminatoriu tuturor operatorilor din piaa de

gaze.

Accesul la reea se realizeaz prin punctele de

intrare sau de ieire din reea. n aceste puncte OST

(Operatorul Sistemului de Transport) trebuie s

pun la dispoziie capacitatea disponibil n

fiecare punct de intrare sau de ieire din reea.

Aceast capacitate reprezint debitul maxim de

gaze sau energia maxim disponibil ce poate fi

livrat sau primit prin punctul respectiv.

Se definesc conform [4, 5] mai multe tipuri de

capacitate reprezentate grafic funcie de timp n

figura 1 pentru un singur punct de intrare n

sistemul de transport.

n aceast lucrare se vor utiliza definiii din

Directiva Europeana 2003/55/EC(EC 2003) i

Regulamentul privind condiiile de acces la reelele

de transport al gazelor 1775/2005(EC 2005a) [7].

Capacitatea de transport este definit sub form

de debit exprimat n normali metri cubi pe

unitatea de timp. Capacitatea total util este egal

cu capacitatea total teoretic (capacitatea tehnic)

minus capacitatea rezervat pentru operatorii

sistemului de transport, pentru integritatea

sistemului i cerinele operaionale (marja

operaional).

Capacitatea tehnic este capacitatea ferm

maxim pe care o poate oferi operatorul de reele

de transport utilizatorului reelei, lund n

considerare integritatea sistemului i cerinele de

exploatare a reelei de transport.

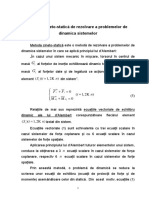

Figura 1 ilustreaz:

variaia n timp a capacitii de la un punct

individual de intrare n reea i defalcarea;

capacitatea tehnic (capacitatea util) care

variaz n timp datorit efectelor de reea;

marja operaional care este considerat a fi

constant n aceast diagram;

modificarea capacitii rezervate n etape

datorit expeditorilor diferii;

modificrile foarte mari a capacitii

nominalizate;

capacitatea disponibil este diferena dintre

capacitatea tehnic minus marja operaional

Mihai ALBULESCU, Sorin NEACU, Cristian EPARU, Sebastian BAMBO, Silvian SUDITU

TERMOTEHNICA 1/2011

i capacitatea rezervat n funcie de debitul

reelei;

capacitatea disponibil operaional este mai

mare dect capacitatea disponibil i

variaz continuu, variaie datorat

modificrii capacitii tehnice i

normalizarea capacitii ntr-un mod

probabilistic. Ideal ar fi ca aceast capacitate

operaional s fie disponibil pe pia, cel

puin parial.

Fig. 1. Reprezentarea grafic a definiiei capacitii

Un alt aspect care trebuie gestionat n timp real

const n determinarea precis a capacitii

disponibile de ctre operatorul sistemului naional

de transport.

2. DEZVOLTAREA METODEI DE CALCUL

A CAPACITII TEHNICE PENTRU

CONDUCTELE DE TRANSPORT GAZE

n conformitate cu poziia GTE capacitatea

tehnic de transport a conductelor, debitul volumic

exprimat la starea normal ce se poate transporta

pe o conduct ntre dou puncte n care la intrare

presiunea p

1

este presiunea maxim de operare, iar

la ieire este definit presiunea minim acceptabil

din motive tehnice sau contractuale.

Capacitatea poate fi calculat cu formula:

( )

5 2

2

2

1

4

d

lZT p

T p p

Q

n n

n

n

= (1)

Avnd n vedere aceste recomandri i faptul c

n general conductele de transport sunt alctuite

din mai multe segmente cu diametre i lungimi

diferite se va dezvolta o formul valabil n aceast

situaie.

Formula (1) se poate obine conform [2]

plecnd de la ecuaia lui Bernoulli scris sub form

diferenial i corectat cu termenul corespunztor

pierderii de energie datorit disipaiei vscoase:

0

d

2

d

d

2

= + +

D

l v p

v v (2)

n formula de mai sus:

v viteza;

p presiunea;

densitatea;

l lungimea conductei;

D diametrul;

coeficientul de pierdere de sarcin

hidraulic.

Ecuaia (2) se poate rescrie n urma unei

operaii simple astfel:

0

d d

2

d

2

2

= + +

D

l

v

v

v

p

(3)

n cazul conductelor de transport gaze naturale

se consider c procesul este izoterm. n aceast

situaie dac notm cu indexul 1 parametrii gazului

la intrarea n conduct, legtura ntre acetia i

parametrii ntr-o seciune oarecare este:

p

p p p 1 1

1

1

1

1

= = (4)

Din ecuaia de continuitate rezult

1 1

1 1

1

v v

v v

= = (5)

CONSIDERAII REFERITOARE LA CAPACITATEA MAXIM DE TRANSPORT A CONDUCTELOR / REELELOR DE GAZE

TERMOTEHNICA 1/2011

nlocuind relaiile (4) i (5) n (3) rezult:

0

d d

2

d

2

2

1 1 1

= + +

D

l

v

v

v p

p p

(6)

Ecuaia (6) este o ecuaie diferenial cu

variabile separate care poate fi integrat termen cu

termen. Integrarea se face de la captul de intrare a

gazului n conduct, notat cu 1, la captul de ieire

a gazului din conduct notat cu 2:

0 ln 2

-

1

2

2

1 1 1

2

1

= + +

D

l

v

v

v p

p p

2

2

(7)

sau

+ =

D

l

v

v

v p p p

2

2

1

2 2

1 1 1

2

1

ln 2 - (8)

Pentru o conduct de gaze variaia vitezei medii

a gazului n lungul conductei este mic astfel nct

se poate neglija termenul 0 ln

1

2

v

v

.

Ecuaia devine

D

l

v p p p

2

2

2

1 1 1

2

1

- = (9)

Din ecuaia de stare a gazelor reale se exprim

densitatea n starea 1

RT Z

p

1

1

1

=

(10)

RT Z

p

1

1

1

= (11)

unde R este constanta gazelor naturale.

nlocuind relaia (11) n ecuaia (9) rezult

expresia vitezei:

l

D

RT Z

p

p p

v

2

1

1 2

1

2

2

1

-

= (12)

Aceasta ne permite exprimarea debitului

volumic

l

D

RT Z

p

p p

v

D

Q

2

1

5

1 2

1

2

2

1

2

-

4 4

= = (13)

Debitul volumic din relaia (13) se poate

exprima n condiii normale de presiune i

temperatur:

Q

T

T

p

p

Z

Z

Q

n

n

n

n

1

1

= (14)

n care:

Z

n

1, Z la starea normal;

Z

n

= Z(p

1

,T) factorul de compresibilitatea

n starea 1;

p

n

= 1,013225 10

5

Pa presiunea strii

normale;

T

n

= 288,15 K temperatura de corecie

reglementat.

n aceste condiii rezult formula pentru

calculul debitului ce poate fi transportat pe

conducta de gaze ntre dou capete care au

presiunea p

1

i p

2

:

l

D

R

T Z

p p

p

T

Q

2

1

n

n

n

5

1

2

2

-

4

= (15)

Formula (15) este identic cu formula propus

de GTE. Utilizarea acesteia ridic cteva probleme.

Coeficientul de pierdere de sarcin hidraulic =

(Re) depinde de viteza de curgerea gazelor care

este funcie de debit. Pentru rezolvarea acestei

nedeterminri trebuie s se fac un calcul iterativ.

Se va prezenta metoda de calcul pentru cazul unei

conducte compus din tronsoane de lungimi

diferite i cu diametre diferite.

Fig. 2. mprirea conductei n tronsoane

Fie conducta AB din figura 2. Pentru tronsonul

i se poate particulariza relaia (15)

i i

i

i

i

2

i

n

n

ni

l

D

T Z

p p

p

T

Q

5 2

1

2

2 2

2

-

16

= (16)

sau

i

i

i i

n

n

ni i

2

i

Z

D

l

R

T

T

p

Q p p

5 2

2

2

2 2

1

16

-

(17)

Dac se scrie relaia (17) pentru toate

tronsoanele conductei i se nsumeaz, rezult:

=

=

n

i

i

i

i i

n

n

n m

2

0

Z

D

l

R

T

T

p

Q p p

1

5 2

2

2

2 2

16

-

(18)

Dac se fac notaiile

R

T

T

p

B

n

n

2

2

2

16

= (19)

=

n

i

i

i

i i

Z

D

l

1

5

(20)

Relaia pentru debit devine:

Mihai ALBULESCU, Sorin NEACU, Cristian EPARU, Sebastian BAMBO, Silvian SUDITU

TERMOTEHNICA 1/2011

SB B

p p

Q

2

m

n

=

2

0

-

(21)

Relaia (21) se poate utiliza ntr-un procedeu

iterativ pentru calculul debitului astfel:

Pasul 0 iniierea calculului. Se folosete

pentru calculul lui o formul care nu depinde de

numrul Re, formula lui Weymouth:

3

009407 , 0

D

= (22)

Se consider toate valorile lui Z

1

egale cu Z

1

(p

1

,

T).

Se determin prima aproximaie pentru valoarea

debitului

) 0 (

n

Q .

Pasul 1. Cu valoarea

) 0 (

n

Q se determin

pentru fiecare tronson coeficienii de pierdere de

sarcin

i

cderile de presiune pe tronsoane i

valorile Z

i

(p

i

, T). Se recalculeaz termenul

i

n

i

i i

Z

D

D l

SB

=

=

1

5

1

cu noile valori apoi se calculez

urmtoarea aproximaie a debitului

) 1 (

n

Q . Cu

valorile

) 1 (

n

Q se repet pasul 1 i se obine

) 2 (

n

Q i

aa mai departe.

Testul de oprire a calculului se poate face fie la

valoarea debitului <

) 1 ( ) ( j

n

j

n

Q Q sau la valoarea

presiunii finale <

) 1 (

2

) (

2

j j

p p .

3. REZULTATELE OBINUTE PRIN

APLICAREA METODOLOGIEI DE MAI SUS

PE CONDUCTA CORUNCA COROI

BUCURETI

Prin aplicarea metodei de calcul descris mai

sus pe conducta Corunca Coroi Bucureti s-au

obinut urmtoarele rezultate care vor fi prezentate

sub forma grafic n continuare. Calculele s-au

realizat pentru mai multe scenarii, n lucrare se vor

prezenta rezultatele numai pentru un scenariu.

Scenariul 1 Determinarea debitului maxim pe

conducta respectiv considernd c nu se livreaz

gaze prin SRM-uri, nu se injecteaz gaze prin

punctele de msur, iar presiunile la capete sunt 25

bar la Corunca i 10 bar la Buciumeni.

n urma calculelor a rezultat un debit de

117169.2 Nmc/h care poate fi considerat

capacitatea tehnic a acestei conducte n condiiile

de presiune date, pentru conducta respectiv.

Analiznd variaia presiunii n lungul conductei

observm c aceasta este influenat n poriunea

final de segmentele de conducte cu diametrul

interior de 492mm fa de segmentele anterioare cu

diametrul interior de 696mm.

Volumul de gaze din conduct s-a calculat pe

fiecare segment de conduct. Se observ c

dimensiunea conductei influeneaz hotrtor

valorile gazelor din conducte.

Fig. 3. Variaia presiunii n lungul conductei

Fig. 4. Variaia vitezei n lungul conductei

Fig. 5. Variaia debitului n lungul conductei

Fig. 6. Volumul de gaze din tronsoanele conductei

Din analiza sumar a rezultatelor se observ

faptul c aceast conduct prezint o limitare a

capacitii de transport, n partea final pe

poriunea cu diametrul redus.

CONSIDERAII REFERITOARE LA CAPACITATEA MAXIM DE TRANSPORT A CONDUCTELOR / REELELOR DE GAZE

TERMOTEHNICA 1/2011

3.1. Simulri cu AFT ARROW 4.0

Pentru aceiai conduct i aceleai scenarii s-au

efectuat calcule cu simulatorul american AFT

ARROW 4.0, soft care folosete metodele

progresive, adic mparte conducta n segmente i

rezolv ecuaiile care guverneaz curgerea pe

fiecare segment de conduct n parte, de la un

capt la cellalt al conductei [8].

n figura 7 este prezentat reeaua construit cu

acest program.

n urma simulrii a rezultat o capacitate de

transport a conductei de 125500 Nm

3

/h (figura 8).

n figurile 9 i 10 sunt prezentate variaia presiunii

respectiv a vitezei n lungul conductei principale

de transport.

Fig. 7. Reeaua construit cu AFT ARROW

Fig. 8. Variaia debitului n lungul conductei

Fig. 9. Variaia presiunii n lungul conductei

Mihai ALBULESCU, Sorin NEACU, Cristian EPARU, Sebastian BAMBO, Silvian SUDITU

TERMOTEHNICA 1/2011

Fig. 10. Variaia debitului n lungul conductei

3.2. Simulri cu SIMONE V5-73

Cel de-al doilea set de simulri a fost fcut cu

programul SIMONE V5-73 [9], lund n

considerare aceleai scenarii. n figura 11 este

prezentat schema conductei pentru care s-a fcut

calculul.

Condiiile la limit au fost puse n punctele de

intrare i ieire din conduct i au constat n

impunerea unor presiuni constante de intrare i

ieire, programul determinnd cderile de presiune

i vitezele de deplasare a gazelor. Se poate astfel

analiza capacitatea de transport a conductei.

Valorile rezultate n urma simulrii sunt prezentate

grafic n figurile 12 i 13.

n urma simulrii a rezultat un debit de 128714

Nm

3

/h (figura 12).

Fig. 11. Modelarea reelei n SIMONE

CONSIDERAII REFERITOARE LA CAPACITATEA MAXIM DE TRANSPORT A CONDUCTELOR / REELELOR DE GAZE

TERMOTEHNICA 1/2011

Fig. 12. Variaia presiunii i debitului

Fig. 13. Variaia vitezei

4. COMPARAIE NTRE REZULTATELE

OBINUTE CU DIVERSE METODE DE

CALCUL

n acest capitol sunt prezentate rezultatele

comparative pentru calculele efectuate pe conducta

Corunca Coroi Bucureti prin trei metode:

folosind formulele recomandate de GTE,

simulatorul AFT Arrow i Simone.

Primul set de date se refer la capacitatea

tehnic maxim de transport a conductei Corunca

Bucureti considerat fr consumatori i fr

punctele de injecie de gaze. Singurul debit de gaze

se introduce pe la captul de la Corunca. S-au

impus presiunile de 25 bar la Corunca i 10 Bar la

Bucureti.

S-au determinat capacitatea tehnic n aceste

condiii (figura 14), variaia presiunilor (figura 15)

i volumul de gaze din conduct (figura 16).

Se consider c toate cele trei metode de calcul

dau rezultate asemntoare. Pentru capacitatea

tehnologic cea mai mare valoare de 129009

Nm

3

/h este dat de Simone, valoare intermediar

125499,99 Nm

3

/h dat de AFT Arrow i 117169,2

Nm

3

/h dat de GTE.

Variaia presiunilor este apropiat. Toate

metodele respect presiunile de la captul

conductei.

Mihai ALBULESCU, Sorin NEACU, Cristian EPARU, Sebastian BAMBO, Silvian SUDITU

TERMOTEHNICA 1/2011

Fig. 14. Capacitatea tehnic a conductei determinat cu diverse metode

Fig. 15. Variaia presiunii n conduct determinat cu diverse metode

Fig. 16. Volumele de gaz din conduct determinate cu diverse metode

CONSIDERAII REFERITOARE LA CAPACITATEA MAXIM DE TRANSPORT A CONDUCTELOR / REELELOR DE GAZE

TERMOTEHNICA 1/2011

Comparaia ntre volumele de gaze din

conduct s-a realizat numai pentru Simone i GTE

deoarece AFT Arrow nu are aceast facilitate.

5. CONCLUZII

Capacitatea de transport este o mrime

important care trebuie determinat conform

reglementrilor europene. Pe baza ei se fac

rezervrile de capacitate pentru toi operatorii care

acceseaz sistemul naional de transport.

Rezultatele comparative ale calculelor efectuate pe

conducta Coroi Bucureti, efectuate n diferite

situaii sunt apropiate ca valori. Avnd n vedere c

s-au utilizat dou simulatoare Simone i AFT

Arrow cu performane recunoscute rezult c

folosirea metodologiei GTE permite obinerea unor

rezultate corecte.

BIBLIOGRAFIE

[1] T. Oroveanu Hidraulica i transportul produselor

petroliere, Editura Didactic i Pedagogic, Bucureti,

1966

[2] C. Trifan, M. Albulescu, S. Neacu Elemente de

mecanica fluidelor i termodinamic tehnic, Editura

Universitii Petrol-Gaze din Ploieti, 2005

[3] *** Calculation of Available Capacities: Understanding

and Issues An ERGEG Public Consultation Paper, 14-

June-2007;

[4] *** GTE comments on - Calculation of Available

Capacities: Understanding and Issues An ERGEG

Public Consultation Paper, 09 August 2007;

[5] *** GTE position Definition of available capacities at

interconnection points in liberalized markets, 22 June

2004;

[6] *** REGULATION (EC) No 715/2009 OF THE

EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 13 July 2009 on conditions for access to the natural

gas transmission networks and repealing Regulation (EC)

No 1775/2005 (Text with EEA relevance);

[7] *** REGULATION (EC) No 1775/2005 OF THE

EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 28 September 2005 on conditions for access to the

natural gas transmission networks (Text with EEA

relevance);

[8] http://www.aft.com/

[9] http://www.simone.eu/simone-company-about.asp

TERMOTEHNICA 1/2011

FREE JETS IN MULTIPHASE ENVIRONMENT

DYNAMIC OF BIBLIOGRAPHY SYNTHESIS

Alexandru CHISACOF, Constantin POPA, Adriana ZAINEA

UNIVERSITY POLITEHNICA OF BUCHAREST, Romania

Rezumat. Lucrarea constituie un mod de abordare modern privind felul n care se realizeaz o sintez

bibliografic bazat pe cuvinte cheie aferente unei anumite teme. Tema la care face referire aceast lucrare este

axat pe jeturi libere n medii polifazice. Autorii au sintetizat elementele caracteristice a peste 250 de lucrri pe

baza cuvintelor cheie, specifice subiectului studiat, mprite n trei mari gupe: aspecte fenomenologice,

standuri experimentale i aparatur de msur, vizualizare i achiziie de date. n lucrare este prezentat un

program dinamic, cu legturi i interconexiuni la referinele bibliografice studiate, care pemite cercettorului un

acces rapid i chiar simultan la acestea. Cercettorul poate astfel face o comparaie rapid a elementelor legate

de un anumit cuvnt cheie al domeniului de cercetare specific, de exemplu sisteme de vizualizare a

fenomenelor. Considerm aceast lucrare util din punct de vedere didactic i metodologic pentru masteranzi,

doctoranzi i cercettori, ceea ce va permite elaborarea unor lucrri de calitate conform exigenelor practicii

internaionale din domeniu.

Cuvinte cheie: sintez bibliografic, jet polifazic, stand experimental, vizualizare fenomene.

Abstract. The present work offers a modern approach concerning the bibliographical synthesis based on a

certain theme with the explicit keywords. The theme developed in this paper is focused on free jets in

multiphase flow and on their implementation in fire extinguish using water mist. The authors made a synthesis

on over 250 works, based on the clear keywords divided in three groups: phenomenological aspects,

experimental stands and adequate measurement equipment, process visualization and data acquisition. The

paper presents a dynamic programme built in Microsoft Excel, with interconnections to the bibliographic

references, which allow a quick and simultaneous access to these. Consequently, the research using a certain

keyword might contain a comparison of the concerned references, e. g. systems of phenomena visualisation.

This paper is useful to master and PhD students, and researchers too, for their highly structured scientific papers

and reports.

Keywords: bibliographic synthesis, multiphase jet, experimental stand, phenomena visualization.

1. INTRODUCTION

The word bibliography derived from the

Greek word bibliographia (2

nd

century AD) which

meant the academic study of books as cultural

objects or even the writing of books [1]. The

meaning of a list of books or source materials used

or consulted in the preparation of a work, arranged

according to some criteria was first used in the 16

th

century. The first bibliographies were lists of

books compiled by writers who guided the readers

to their other books. Later, in the 20

th

century, the

field acquired a special importance because of the

need to access easier all the published works. So,

the function of bibliography is to provide the

needed information to the researchers.

Some states, such as U.S.A. and Netherlands,

have national bibliographies published

commercially, and the U.K. has the British

National Bibliography published by a council,

council which represents the publishers, the

libraries and the booksellers. These bibliographies

are published periodically and they are

alphabetically arranged by authors, titles and

subjects.

Bibliographies differ by size and method,

according to their purpose. The bibliographies of

publications, and not only, on a particular subject

are the most complete and they cover many

derived branches of interest because they also

include the latest articles and actually web-sites.

The objectives of compiling a bibliography, in our

case and according to Britannica 2005, were to

find out books and papers on a certain subject, to

describe those using keywords and to collect the

Alexandru CHISACOF, Constantin POPA, Adriana ZAINEA

TERMOTEHNICA 1/2011

entries into a data-base useful for the focused study.

Depending on the purposes, the author of the

compiled bibliography should arrange the

materials by criteria that make the research easier

and that bring out all the important features he is

looking for. For example, we used a chronological

order. The advent of the computer and the data-

bases we can easily access using it were really

important in this field. In our case, there can be

accessed also sub-lists with the references, using

the keyword feature [2].

2. BIBLIOGRAPHY RESEARCH METHOD

Steps to library research

- the first step and the most important one is to

choose the topic, that subject that you want to

find out more about it. In this case, it is

represented by water mist as a fire fighting

agent. After doing this, keywords identification

is required;

- second step is using the keywords to collect

articles, books, websites, names, dates, people

and other sources associated to the topic;

- the thing that requires a lot of time is evaluating

all the resources, critically analyzing them and

keeping the ones that are truly helpful regarding

the subject.

- after accomplishing the stages above, the paper

will be written. The bibliography is part of it,

its a list of source materials that are used,

consulted or referred to in the work.

The bibliography should highlight the

subjects trace in history if its origins are known. It

also should present a horizontal research. The main

subject should be linked to additional elements

which make it possible. For example, using direct

spray, the mist is created. This is possible when the

water leaves the nozzles. There are different types

of nozzles which have been studied such as simple

nozzles, multi-nozzles, magnetic nozzles, spray

nozzles, shaping nozzles [3-10]. In the last 60

years, there were developed studies and researches

so that the efficiency of using water for fire

suppression could be maximized. In 1955,

Braidech et al. studied and described the

fundamental principles of extinguishment of liquid

and solid fuel fires using finely divided water

sprays [3, 4]. From 1959 to 1961, the relationship

between drop size distribution and spray velocity

for extinguishment of hydrocarbon pool fires was

explored by Rasbash et al. During the 1960's and

1970's, studies occurred in a variety of settings,

from university laboratories to industry and

government research facilities. Work done by the

US Navy in the late 1970's culminated in a

working design for what today would be called a

fixed water mist fire suppression system for

machinery space fires. But this didnt stop with

that, because in 1987, when the Montreal Protocol

was signed, the interest in using fine water sprays

for fixed fire suppression systems was renewed. In

1995, the National Research Council in Canada

(NRCC) used a questionnaire for finding out what

interests in water mist research are [11, 12]. In this

research work were involved a lot of institutes,

universities, departments, colleges and of course, a

lot of people.

Water mist systems have started to be used

instead of traditional sprinklers. Usually, the

primary fire risk in engine rooms and in gas

turbine enclosures consists of leaks of fuel;

lubricating or hydraulic oil coming into contact

with hot surfaces [13]. The investigations came to

the conclusion that this methods performance in

extinguishing fire is really high. But industry isnt

the only environment were water mist systems are

used, so they can be found also in offices, hotels,

passenger ships, computer rooms, etc [11, 12].

Used for fire extinguishments, water is indicated

for many reasons such as: it is non-toxic, it is free

and it is a clean agent for the environment [8, 13-

19].

3. RESEARCH OF THE SPECIFIC

REFERENCES IN WATER MIST USE

The bibliographic research for this topic has

been realized on four connected ways that are:

theoretical aspects, experimental aspects,

phenomena visualization (principles, methods,

systems and equipments), numerical modelling of

coupled transfer processes of a jet. For all of these,

there has been done a bibliographic research based

on international and national magazines from the

Polytechnic University of Bucharests library, on

virtual universitys library, manuals, requested

articles, proceedings of national and international

conferences and also on team members libraries.

There were over 250 bibliographic references.

3.1. Theoretical aspects

These aspects found in a lot of publications are

divided in:

- macroscopic phenomena based on conservation

equations of the entire moving system and

developed using mass and heat transfer. There are

equations for each phase and for each component.

The most studied subjects were the two phase jets

FREE JETS IN MULTIPHASE ENVIRONMENT DYNAMIC OF BIBLIOGRAPHY SYNTHESIS

TERMOTEHNICA 1/2011

and the effects of varying confinement levels on

them. After the water jet leaves the nozzle, the

properties of the environment are different such as

temperature and concentration. There is a mass and

heat transfer during the evaporation process and as

a reaction to this, the evaporation velocity will

decrease and the environment structure change.

These studies were based especially on the models

presented by Mills, Petit, Quintiere et al. [3, 20-

23];

- microscopic phenomena were focused on direct

observation of a droplet in a vapour-liquid system

considering its distribution and velocity. There

were used several theoretical models found in

bibliographical resources, regarding evaporation,

dynamics and thermal behaviour of droplets. An

element which is highlighted in most of the papers

is the behaviour of a duo - droplet-environment

used to find other characteristics of concentration

and not only. There are several works of Anderson,

Myung on these topics [24-27]. Metastable

phenomena, studied by Zheng, Sergeev et al [28-

31], make the vaporisation process slower and also

the changing in phase. The last one is influenced

by droplet composition, by its temperature and by

the environment where all these take place.

Because the evaporation process is slower, the

droplets lifetime increases. About these themes

there are paper of Thompson, Varghese et al and

Adler [32-34].

3.2. Experimental aspects

In the researches developed in this area, there

were designed experimental stands and there were

analyzed the values and observations obtained

during the experiments at real scale. These

experiments could be used not only for studies, but

also in industry, in civil and military domains [7, 8,

15, 34-36].

The experimental stands were made for jets in

open spaces, with exposure to hot and cold

environments. Hot environments are made up of

hot air, gas combustion flames and they can be

vertically or horizontally limited. Experimental

modelling stands are provided with classical

measuring devices for pressure, temperature,

concentration, with data acquisition systems and

also with equipment for process visualization and

which ensure the characteristic properties

measurement.

On the other hand, the stands are fitted with

systems for generating jets, flames and other

components that participate to environmental

changes. There are also used analyzers and as a

well-known technique, there should be mentioned

chromatography. The devices have a raised

sensitivity for obtaining the needed parameters and

for decreasing the errors in measurement. For

example, Thus, K. Varghese [33] and F. Barreras

et al. [36] are analyzing the evolution of pure water

droplets and salt water droplets during a fire

extinguishing. D. Adler, [34] and V. A. Iyer and J.

Abraham [37] refer to the injection of liquid spray

into a hot gas atmosphere with application in diesel

engine technology, gas turbines, air conditioners,

fire fighting etc. Many papers contain the useful

information concerning the test techniques and

measurement equipment [2].

3.3. Phenomena visualization (principles,

methods, systems and equipments)

Flow visualization methods can be classified

in three classes such as:

- flow view by the addition of foreign substances

in the gaseous or liquid flows;

- flow view using optical methods;

- flow view after marking the field with energy and

heat addition.

The first class includes all the techniques by

which a foreign material must be visible. If the

material particles are small enough, it can be

assumed that the movement of these particles is

similar to the fluid in terms of direction and speed.

So it is an indirect method, since it observes the

movement of foreign material and not the

movement of the fluid itself. The difference

between fluid movement and foreign particles can

be minimized but not entirely avoided, by

assuming that the density of foreign particles

almost coincides with the density of the fluid (M.

George et al. and W. Merzkirch [38, 39]). Such

methods give excellent results in the stationary

flows.

Changes in fluid density are the key of the

second class of visualization methods. Since the

fluid density is a function of the refractive index of

medium flow, the compressible flows can be made

visible by optical methods sensitive to changes of

the refractive index in the investigated field.

Variable-density flow field is, in optical terms, a

phase object. A beam of light transmitted through

the object is optically affected, but its intensity

remains the same after it leaves the object. An

optical device located after the object provides a

uniform lighting plan. After analyzing the plan

changes, conclusions were drawn, conclusions

regarding the density variations in the flow field

[35, 36, 40-44].

Alexandru CHISACOF, Constantin POPA, Adriana ZAINEA

TERMOTEHNICA 1/2011

The two methods described above, the

addition of foreign materials and the optical

methods, are recommended for incompressible and

compressible flows. But there is this third class of

flow visualizing techniques which combines the

two first methods. In this case, the added substance

is energy (heat or electricity) 39]). So, the marked

elements sometimes require a viewing optical

method for distinguishing them, but there are cases

when the energy release is so large that the marked

elements can be directly observed. These methods

are often applied for flows with an average density

of low value. [38, 45-47]. Density changes that

occur in this type of flows might be too weak to be

detected by an optical method. For this reason, this

third group of visualization techniques is applied to

a third class of flows - the rarefied one or the ones

with low density gases.

3.4. Numerical modelling of coupled transfer

processes in two-phase jet

Mathematical models used in thermo-fluidic

processes of jets and flames were approached in

two distinct ways: a non-deterministic approach

and a deterministic one. Non-deterministic

approach uses statistics to determine the frequency

of events and their development time. Different

models are embedded in order to make a

connection with the probabilistic described in

literature and with random phenomena [25, 40, 48,

and 49].

The deterministic approach is based on the

chemical and physical relationships of the

combustion phenomenon and it is the most used

method. A specific scenario is considered as a

subject and output data are provided as numerical

values. The mathematical models used today, such

as simple calculation models and calculation based

on computer are based on this method. CFD

(Computational Fluid Dynamics) models can be

divided into two categories based on solving

equations: RANS (Reynolds-averaged Navier-

Stokes) and LES (Large Eddy Simulation). In the

RANS case, the Navier-Stokes equations are

averaged in time before they can be derived to

solve.

In the other case (LES), the time mediation is

not affected and the solution can be considered

accurate reported to time. Hostikka presents the

differences using both approaches. While RANS

approach looks like a laminar flame, LES approach

clearly shows what currents appeared. LES model

is preferred because it can explain better the

buoyancy of hot gases and also the air

incorporation in flame and in smoke pillow.

Examples of CFD models using the RANS

approach: Jasmine, Kameleon, SMARTFIRE,

Sofia and ISIS. Examples of LES models: SDS,

SMAFS [27, 50-52].

For example, in a computer modelling of a fire

in an enclosure could be mentioned two principles:

zone modelling and domain modelling. Zone

modelling describes the influence of fire using a

limited number of zones or of control volumes.

The most common pattern is called "the two zones

model" that divides the space into two distinct

control volumes: one volume under the ceiling

called the "up volume" which is characterized by

hot combustion gases and the other one is the

down volume and it is characterized by fresh air.

Semi-empirical mass equations, momentum and

energy are solved separately for upper and lower

layer. The mass and energy transition between the

areas are treated as a "smoke plume."

Domain modelling assumes from the

beginning defining a space area. It will be the

simulation and its proportions are given by the size

of the object will be the subject of modelling. The

domain is divided into several down volume

controls that will be defined later as walls,

obstacles or simply as a fluid. In this way the

simulation geometry will be built in the previously

defined domain and boundary conditions can be

determined by imposing certain restrictions. CFD

modelling is also used to solve sets of differential

equations derived from natural laws.

Because there are different types of flows, the

modelling should include various models to make

the simulation possible. In order to obtain reliable

results, every model of the three mentioned above

has its own sub-models, for every situation [53-

55].

3.5. Modelling jets

Water jets and barriers are generally used to

extinguish fires, to disperse the dense gas

accumulated in various areas and to control the

spread of smoke. CFD models for fine jets can be

divided into two main categories: the Euler model

and the Lagrange model.

The first model is generally solved faster than

the second one, but it requires starting from the

premise that water droplets act like a continuous

fluid. The Lagrange model is based on the

formation of water droplets phenomenon, it is

more accurate than Euler model, but it requires too

much time. [56-60].

FREE JETS IN MULTIPHASE ENVIRONMENT DYNAMIC OF BIBLIOGRAPHY SYNTHESIS

TERMOTEHNICA 1/2011

4. THE ACCESS TECHNIQUE AND

THE SORTING OF BIBLIOGRAPHIC

ELEMENTS

The bibliographic resources have been

classified in:

- journal papers

- proceedings of conferences

- reports available on-line

- PhD thesis

- reports

- books

- Web-sites.

They have been studied and selected

considering the next 22 keywords:

- water sprays

- water mist

- spray cooling

- drop evaporation

- numerical investigation

- jet free flow

- fire extinguishment by water

- experimental investigations

- fire sprinklers/ nozzles

- temperature measurement

- transfer processes in two phases

- droplet transfer phenomena

- atomization

- turbulence analysis

- industrial applications

- drop size distribution

- non water droplet investigations

- droplet flow measurement

- phase Doppler interferometry/ methods

- radiative field

- scattering calculation

- non isothermal jet.

After that, the bibliographic elements have

been introduced in Microsoft Excel (figure 1) were

they can be sorted depending on:

- type of paper

- year of publication

- number of pages

- title.

Every single bibliographic element is based

on one or more keywords. At the intersection of

these two fields you can find a sign *.

The database can be used as it is or it can be

sorted in sub-lists according to some criteria.

Example: In aim to verify all the references which

contain the keyword Numerical investigation, in

the program, click the arrow from the bottom of

the keyword and mark the *. After doing it, the

database offers all the bibliographic elements

which have this keyword assigned.

Fig.1. The bibliographic database using Microsoft Excel

There are 16 references of which:

- 16 articles

- 1 book

- 4 proceedings of conferences

- 3 reports available on-line

- 4 reports

Alexandru CHISACOF, Constantin POPA, Adriana ZAINEA

TERMOTEHNICA 1/2011

- 2 web-sites

- 1 PhD thesis.

In the next two examples, we searched

references using other keywords such as drop

evaporation, figure 2, and Industrial

application, figure 3. There were found 4

references for drop evaporation, of which 2

proceedings of international conferences and 2

on-line reports, and 9 for industrial

application, of which 7 journal papers and 2

on-line reports.

Fig.2. The bibliographic database for the keyword drop evaporation

Fig.3. The bibliographic database for the keyword industrial application

The references can be sorted using more than

one keyword. Clicking the title of the article will

open its first page, in a pdf file. The articles from

the library were photocopied, scanned and

converted in pdf files.

5. CONCLUSIONS

The above considerations guide us in a full of

meaning understanding of the analysed topic. The

expanded area of research for a certain narrow area

FREE JETS IN MULTIPHASE ENVIRONMENT DYNAMIC OF BIBLIOGRAPHY SYNTHESIS

TERMOTEHNICA 1/2011

will give us the chronological information

concerning the state of knowledge about it. Also,

the interconnections with the other fields linked to

the main topic were displayed.

The analysis of the focussed subject was

developed on the chain containing: the

phenomenology, physical model, numerical model,

experimental investigation and the data exploration.

On this way a complete investigation of the theme

may be apprehended.

The examples regarding the bibliography use

for the proposed approach show us the dynamic

display of the needed details of the specific

elements which enlighten the concerned keyword.

ACKNOWLEDGEMENT

The authors would like to acknowledge the National Council

of University Research from Romania (CNCSIS), Grant

ID_1708, for their support.

REFERENCES

[1]*** Britannica Encyclopaedia, CE-ROM, 2005.

[2] A. Chisacof et al, Fundamental Studies and Researches in

Isothermal and Non-isothermal Two-Phase Jets, CNCSIS

Report ID_1708, September 2009.

[3] V. Novozhilov, Fire suppression studies, Biblid, 2, 161-

180 / 20 pp, 2007.

[4] Z. Liu, A. K. Kim, A Review of Water Mist Fire

Suppression Systems Fundamental Studies, NRC CNRC,

Journal of Fire Protection Engineering, 10, 32-50 / 27 pp,

2000.

[5] *** Fire Detection and Extinguishing Systems, report,

Section 13 - Volume IV: Technical Specification Revision.

http://140.194.76.129/ publications/24 pp, Washington

State Ferries, 2006.

[6]*** High Pressure Water Mist: How the Technology Works

International Fire Protection, http://www.candoifp.com, 3

pp., 2008.

[7] L. W. Owen, Using High Pressure Water Mist Fire

Protection Systems for Offshore Oil Drilling and

Producing Facilities, report, The Oil & Gas Review,

http://www. touchbriefings .com/pdf/951/owen.pdf / 3 pp.,

2004.

[8] J. M. Buchlin, Thermal Shielding by Water Spray Curtains,

report, Von Karman Institute, Applied and Environmental

Fluid Dynamics Department, Belgium, http://www.iitk.ac.

in /che/jpg/papersb/full20paper2071.pdf/ 33 pp, 2004.

[9] J. W. Fleming, A. Awtry, R. S. Sheinson, Fire Suppression

Properties of Very Fine Water Mist, report NRL, Review,

http://www.nrl.navy.mil/content_images/ 05Chemical28

Fleming 29.pdf / 3 pp, 2005.

[10] B. P. Whelan, A. J. Robinson, Nozzle Geometry Effects in

Liquid Jet Array Impingement, Applied Thermal

Engineering, 29, 22112221, 2009.

[11] J. R. Mawhinney, J. K. Richardson, A State of the Art

Review of Water Mist Fire Suppression Research and

Development, industrial report, IRC Canada, 36 pp., 1996.

[12]***Application Guide Water Mist Extinguishing Systems,

report, In Control Systems & Automation, 2009, Canada,

http://www.incontrolsystems.net/downloads/file/in

Control_ Water-Mist-Solutions_Application-Guide_June-

09.pdf/ 6 pp., 2009.

[13] D. Dye, High Pressure Water Mist Fire Extinguishing

Fire Protection for the 21st century, report, Larden

Muniak Consulting Inc. - Canadian Fire Alarm

Association 2004, http://www.cfaa.ca/cfaajournalarticles.

[14] A. Chisacof, D. Pavel, M. Poenaru, Thermogasdynamics

aspects of the droplets use in the cooling of closed and

semiclosed spaces (in Rumanian). 31 National Conference

Caius Iacob of Fluid Mechanics, Mothematical

Modelling, Nonlinear Dynamic Systems and Technical

Applications, Bulletin of the Transylvania University

Braov, Romania, Series B, 13(48), 77-83, 2006.

[15] S. Tsarichenko et al, Fire Extinguishing of Gas Turbo

Compressor Compartment by Water Mist, raport, All-

Russian Fire Protection Science & Research Institute,

http://www.fire. nist.gov/bfrlpubs/ fire04/PDF/f04074.pdf

/ 3 pp, 2003.

[16] J. F. Legrandb, A. Desrumauxa, Analysis of a New Type

of High Pressure Homogeniser, Part B. Study of Droplet

Break-up and Recoalescence Phenomena, Chemical

Engineering Science, 59, 1285 1294, 2004.

[17] F. Barreras et al., Experimental Characterization of

Industrial Twin-Fluid Atomizers, Atomization and Sprays,

16, 127-145, 2006.

[18] B. Hume, M. Eady, The Use of CFD Computer Models

for Fire Safety Design in Buildings: Large Warehouse

Case Study, online, http://www.communities. gov.uk

/documents/fire/pdf/381249.pdf / 41 pp, 2001.

[19] H. P. Jorgensen, Water Mist Improves Safety at Sea,

report, Technology & Services, http://www.touchbriefings.

com /pdf/2590/Jorgensen.pdf / 3 pp., 2007

[20] A. F. Mills, Basic Heat & Mass Transfer, New Jersey,

Prentice Hall, 1999.

[21] J. Taine, J. P. Petit, Transferts thermiques (Thermal

Transfers), in French, Ed. Dunod Univ., Paris, 1989.

[22] B. Abramzon, W. A. Sirignano, Droplet Vaporization

Model for Spray Combustion Calculations, Int. J. Heat and

Mass Transfer, vol. 32, No. 9, pp. 1605-1618, 1989.

[23] J. G. Quintiere, Fundamentals of Fire Phenomena, USA,

John Wiley & Sons, 2006.

[24] P. Andersson, M. Arvidson, G. Holmstedt, Small scale

experiments and theoretical aspects of flame

extinguishment with water mist, Lund Institute of

Technology, Lund University, Report 3080, May 1996.

[25] M. K. Sung, I. Mudawar I, Experimental and Numerical

Investigation of Single-Phase Heat Transfer Using a

Hybrid Jet-Impingement/Micro-Channel Cooling Scheme,

Int. J. Heat and Mass Transfer , 49, 682694, 2006.

[26] G. P. Celata, Single- and Two-Phase Flow Heat Transfer

in Micropipes, 5th European Thermal Sciences

Conference, The Netherlands, 15 pp, 2008,

[27] K. C. Adiga et al, Modeling ultra fine mist transport and

its implications of fire suppression behaviour, report,

Office of Naval Research, http://www.nfpa.org/11 pp.,

2007.

[28] F. Zheng, Q. G. Wang, T. H. Lee, 2005, Adaptive robust

control of uncertain time delay systems, Automatica, 41,

1375 1383, 2005.

[29] Y. A. Sergeev, G. B. Wallis, Concentration/density

shocks in an inertially-coupled two-phase dispersion, Int.

J. Multiphase Flow, 18, 5, 691-704 /1992.

[30] J. C. Kayser, R. L. Shambaugh, 1991, Discharge

coefficients for compressible flow through small-diameter

orifices and convergent nozzles, Chemical Engineering

Science, 46, 7, 1697-1711, 1991.

Alexandru CHISACOF, Constantin POPA, Adriana ZAINEA

TERMOTEHNICA 1/2011

[31] F. Mashayek, F. A. Jaberi, F, R. S. Miller. Dispersion and

Polydispersity of Droplets in Stationary Isotropic

Turbulence, Int. J. Multiphase Flow, 23, 2, 337-355, 1997.

[32] P. A. Thompson, H. Chaves, Wave splitting in a fluid of

large heat capacity, J. Fluid Mech., 185, 385-414, 1987.

[33] K. Varghese Suresh, S. Gangamma, Evaporation of

Water Droplets by Radiation: Effect of Absorbing

Inclusions, Aerosol and Air Quality Research, 7-1, 95-105,

2007.

[34] D. Adler, The Steady Evaporation and Mixing of a Spray

in a Gaseous Swirl, Int. J. Heat Mass Transfer, 14, 793-

812, 1971.

[35] D. Nuyttens, K. Baetens, M. De Schampheleire, B. Sonck,

Effect of nozzle type, size and pressure on spray droplet

characteristics, Biosystem Engineering, 97, 333 345,

2007.

[36] F. Barreras et al., Experimental Characterization of

Industrial Twin-Fluid Atomizers, Atomization and Sprays,

16, 127-145, 2006.

[37] V. A. Iyer, J. Abraham, 2002, Exploring Injected Droplet

Size Effects on Steady Liquid Penetration in a Diesel

Spray With a Two-Fluid Model, Int. Journal of Heat and

Mass transfer, 45, 519-531, 2002.

[38] D. L. George, K. A. Shollenberger, J. R. Torczynski, J.

OHern, S. L. Ceccio, Three-Phase Material Distribution

Measurements in a Vertical Flow Using Gamma-

Densitometry Tomography And Electrical-Impedance

Tomography, Int. J. Multiphase Flow, 27,1903-1930, 2001.

[39] W. Merzkirch, Flow visualization, 2

nd

ed., Orlando

Florida, Academic Press, 1987.

[40] S. V. Apte et al, Stochastic Modeling of Atomizing Spray

in a Complex Swirl Injector Using Large Eddy Simulation,

Proceedings of the Combustion Institute, 32, 22572266,

2009.

[41] G. E. Cossali, M. Marengo, M. Santini, Thermally

Induced Secondary Drop Atomisation by Single Drop

Impact Onto Heated Surfaces, Int. J. Heat and Fluid Flow,

29, 167177, 2008.

[42] P. Nithiarasu P. F. Eng, K. Arnold, Flow And Heat

Transfer In Micro-Channels -Electro-Osmotic Flow (Eof),

5

th

European Thermal-Sciences Conference, The

Netherlands, 14 pp., 2008.

[43] M. S. Balasubramanzam et al, , Numerical Modelling of

Turbulence Effects Within and Evaporating Droplet in

Atomizing Sprays, online report, NASA Marshall Space

Flight Center, http://ntrs.nasa.gov/archive/nasa /casi.ntrs.

nasa. gov/20060047741_20062494, 2005.

[44] B. Batarseh, I. Roisman, C. Tropea, Droplet-Spray/Wall

Interaction and Spray Cooling under High-Pressure

Conditions, Technische Universitt Darmstat, report,

http://www.sla.tu-darmstadt.de/roisman/sprayportal/

Downloads-Dateien/Pressure, 2004.

[45] C. Presser, C. T. Avedisian, Transport of high boiling

point fire suppressants in a droplet laden homogeneous

turbulent flow past a cylinder, Atomization and Sprays

Journal, 16, 627-656, 2006.

[46] Rahman M. A., T. Heidrick, B. A. Fleck, A Critical

Review of Advanced Experimental Techniques to Measure

Two-Phase Gas/Liquid Flow, The Open Fuels & Energy

Science Journal, 2, 54-70, 2009.

[47] R. Hade, B. Lenze, Measurements of Droplets

Characteristics in a Swirl-Stabilized Spray Flame,

Experimental Thermal and Fluid Science, 30, 117130,

2005.

[48] S. Hostikkaa, K. McGrattan, Numerical Modeling of

Radiative Heat Transfer in Water Sprays, Fire Safety

Journal, 41, 1, 7686, 2006.

[49] A. Alexiadis, P. Gardin, J. F. Domgin, Probabilistic

Approach for Break-Up and Coalescence in Bubbly-Flow

and Coupling With CFD Codes, Applied Mathematical

Modelling, 31, 20512061, 2007.

[50] G. H. Heong, K. K. Yuen, Computational Fluid

Dynamics in Fire Engineering , Elsevier Inc., 2009.

[51] Y. Sinai, P. Stopford, M. Edwards, S. Watkins, CFD

Modelling of Fire Suppression by Water Spray: Sensitivity

and Validation for a Pool Fire in a Room, 8

th

Int. IBPSA

Conference, August 11-14, Eindhoven, Netherland, 2008.

[52] K. C. Adiga et al, CFD Modeling Options for Total

Flooding Behavior of Ultra Fine Water Mist, report,

BFRL, http://www.fire.nist.gov/bfrlpubs/fire06/PDF / 13

pp, 2006.

[53] G. Castanet et al, Investigation of Heat and Mass

Transfer Between the two Phases of an Evaporating

Droplet Stream Using Laser-Induced Fluorescence

Techniques: Comparison with Modeling, Int. J. Heat and

Mass Transfer, 50, 36703684, 2007.

[54] J. J. Nijdam, T. A. G., Langrish, D. F. Fletcher,

Assessment of an Eulerian CFD Model for Prediction of

Dilute Droplet Dispersion in a Turbulent Jet, Applied

Mathematical Modelling, 32, 26862705, 2008.

[55] G. G. Chernykh, O. F. Voropayeva, Numerical Modeling

of Momentumless Turbulent Wake Dynamics in a Linearly

Stratified Medium, Computers & Fluids, 28,281-306, 1999.

[56] R. S. Miller, K. Harstad, J. Bellan, Evaluation of

Equilibrium and Non-Equilibrium Evaporation Models for

Many-Droplet Gas-Liquid Flow Simulations, Int. J. of

Multiphase Flow, 24, 1025-1055, 1998.

[57] A. Lipjainen A., Simulation of the fire extinguishment

process by fine water spray, JASS, http://www14.

informatik.tumuenchen.de/konferenzen/Jass08/

courses/5/lipjainen /paper_lipjainen.pdf / 6 pag, 2008.

[58] I. A. Bolotnov, Cascade Modeling of Single and Two-

Phase Turbulence, doctoral thesis, Rensselaer Polytechnic

Institute Troy, New York / 156 pp, 2008.

[59] R. Gomes, Measurement and prediction of droplet size

distribution in sprays, doctoral thesis, Quebec, Canada,

305 pp, 2006.

[60] A. Chisacof, D. Pavel, V. Panaitescu, M. Poenaru, The

Two Phase Jet Use in Semi-open Space, Proceedings of

the ASME 2010, 10th Biennial Conference On

Engineering Systems Design and Analysis 2010, July 12-

14, 2010, Istanbul, Turkey, paper ESDA2010-24961, CD

ROM.

TERMOTEHNICA 1/2011

INFLUENCE OF TRIANGULAR CHEVROANE USED

FOR DOUBLE FLOW TURBOJET ENGINES ON FLUID

FLOW AND ACOUSTIC POWER

Grigore CICAN, Virgil STANCIU, Ion MALAEL

POLITEHNIC UNIVERSITY BUCHAREST, AEROSPACE ENGINEERING, Romania.

Rezumat. Prin initierea unei curgeri vorticulare ajutand la amestecarea a doua fluxuri cu viteze diferite,

chevroanele reduc zgomotul rezultat din interactiunea respectivelor fluxuri. Un studiu detaliat arata influenta

numarului de chevroane si a unghiului de imersie asupra zgomotolui produs de jetul reactiv.

Cuvinte cheie: Chevron , unghi de imersare, poluare fonica ,forta de propulsie.

Abstract. By initiating a vorticulare flow helping to mix two streams with different speeds, chevroanele reduce

the noise resulted from the interaction of those streams. A detailed study shows the influence of the numbers of

chevroane and dip angle of the jet stream noise.

Keywords: Chevron, dip angle, noise pollution, propulsion force.

1. INTRODUCTION

Chevroanele, first introduced by A.Young,

G.M. Lilley (Lilley ecuation author) and

R.Westley in 1953 are gazodynamic devices

which, by initiating a vorticulare flow helps to mix

two streams with different velocities thereby

reducing noise resulting from the interaction of

those streams.[1]

Physical basis of such noise generation type is

the Kelvin-Helmtz turbulence, turbulence that

occurs due to a difference in speed between the

two streams.

Chevroanele works by initiating eddy currents

whose axes are parallel to the axis of the bypass

channel [2].

Fig. 1. Flow around a chevron

This study investigates the possibility of

using triangular chevroane at double flow turbojet

engines to reduce noise pollution. The paper also

includes a case study with an engine equipped with

triangular chevroane highlighting the CFX study

and noise pollution affects on the propulsive force.

2. DESCRIPTION OF GEOMETRY

Nozzle geometry is shown in figure 2. This is a

copy of the reaction nozzle geometry of CFM 56-

3[3] turboreactor whom were added triangular

chevroane.

Fig. 2. Jet nozzle geometry with triangular chevroane

By immersing of certain angles chevroane, as

shown in figure 3, we obtain different results,

preferably at angles of less than 9 degrees because

chevroanele by their nature generate high

frequency noise at levels over 15 degrees of the dip

Grigore CICAN, Virgil STANCIU, Ion MALAEL

TERMOTEHNICA 1/2011

angle, this specific noise of chevroane becomes too

large and cancels the anticipated effect of the

device. [4].

Fig. 3. Viewing angle of dip

Height of a chevron is given by [5]

N

D

h

2

= (1)

Where - D is the diameter of the nozzle exit

- N number of chevroane

Air is considered in this case the working

fluid. Input data are calculated using the computer

program of the engine cycle as input data were

taken turboreactor CFM 56-3.

So for the second output stream after stream

these data were considered:

-speed = 305 m/s

-temperature = 350 K

-turbulence intensity = 5%

-direction of jet exit = perpendicular to inlet

To exit the main stream flow after these data

were considered:

-speed = 465 m/s

-temperature = 721 K

-turbulence intensity = 5%

-direction of jet exit = perpendicular to inlet

To simulate the fact that there are no obstacles

around the aircraft, around the nozzle in our case,

the side walls and top wall outlets are considered

with these characteristics:

-temperature = 288 K

-the considered pressure is the atmospheric one.

Fig. 4. Field work

Disecretize the calculation domain was taken

into account a better resolution around nozzle

reaction using a structured mesh.

Fig. 5. The mesh around the nozzle

3. CALCULATION MODEL

For this calculation was considered a

compressible flow, equations governing this flow

on the Reynolds-Avereged written form aand are

listed below:

1.Continuity equation:

0 =

j

j

x

u

t

(2)

2. Moment equations:

( )

( )

j i ij

j i

j

j i

i

u u

x x

p

x

u u

t

u

=

=

(3)

where

|

|

\

|

=

i

j

j

i

ij

x

u

x

u

represents viscosity tension

3. Energy equations:

( )

( )

ij i ij i

j

j

j j

j

u u

x t

p

x

T

k H u H u

x

H

t

=

=

|

|

\

|

+

+

(4)

Where H is total enthalpy.

4. Equation of state for an ideal gas:

INFLUENCE OF TRIANGULAR CHEVROANE USED FOR DOUBLE FLOW TURBOJET ENGINES ON FLUID FLOW AND ACOUSTIC

TERMOTEHNICA 1/2011

T R

wp

0

= (5)

w Molar mass

5. Lilley equation

( )

5

t

M P

= (6)

a

k

M

t

2

= (7)

where:

a- speed of sound

1 . 0 =

[7] (8)

|

\

|

=

12

10

log 10

p

L

P

(9)

The turbulence models were considered

type k-

k- turbulence model

Values of k and come directly from the

transport equations for the turbulent kinetic energy

and dissipative turbulence presented in the

following:

( )

+

(

|

|

\

|

+ =

= +

k

k

i

P k

Uk

t

k) (

(10)

( )

( )

1 1

) (

C P C P k

U

t

k

i

+

(

(

|

|

\

|

+ =

= +

(11)

where C

S1

, C

S2

,

k

,

are constants.

P

k

is the production of turbulence due to

viscous forces and gravitational

attraction and is calculated as follows:

( )

( )

kb t

T

t k

P k U U

U U U P

+ +

+ =

3

3

2

(12)

Where P

kb

is the term due to the gravitational pull.

The respective equations will be solved with the

comercial code Ansys.[8]

4. CFX STUDY RESULTS

In the following we will present the results

obtained from CFD analysis based on data

obtained with the help of calculating the motor

cycle. Study was done on CFM 56-3 double-flow

turbo nozzle with meant the influence of various

parameters on air flow and the acoustic of that jet.

Study was made on the nozzle with 10

chevroane having a triangular shape and a dip

angle of 0, 6 and 10 degrees.

Fig. 6. Nozzle without chevroane

Fig. 7. Nozzle with 10 chevroane and 0 degrees dip angle

Fig. 8. Nozzle with 10 chevroane and 6 degrees dip angle

Fig. 9. Nozzle with 10 chevroane and 10 6 degrees dip angle

Grigore CICAN, Virgil STANCIU, Ion MALAEL

TERMOTEHNICA 1/2011

Will be presented speed charts and diagrams at the

exit of nozzle being made a comparison between

the nonchevronat nozzle and the chevronat one.

Fig. 10. Highlighting the current line for the nozzle without

chevroane

Fig. 11. Highlighting the current line for the nozzle without

chevroane

By comparing the two diagrams can be seen

how in the case of nozzle without chevroane the

power lines of two streams mingle highlighting the

principles by which these devices operate

Fig. 12. Chart speed along the entire area of the nozzle

without chevroane

Fig. 13. Chart speed along the entire nozzle area for the nozzle

with 10 chevroane and zero degrees angle dip.

Fig. 14. Chart speed along the entire nozzle area for the nozzle

with 10 chevroane and 6 degrees angle dip

Fig. 15. Chart speed along the entire nozzle area for the nozzle

with 10 chevroane and 10 degrees angle dip

Fig. 16. Chart turbulence kinrtiv emergy along the entire area

of the nozzle without chevroane

Fig. 17. Chart turbulence kinrtiv emergy along the entire area

for the nozzle with 10 chevroane and zero degrees angle dip

Fig. 18. Chart turbulence kinrtiv emergy along the entire area

for the nozzle with 10 chevroane and 6 degrees angle dip

Fig. 18. Chart turbulence kinrtiv emergy along the entire area

for the nozzle with 10 chevroane and 10 degrees angle dip.

After conducting measurements at distance of

0,35 meters on the Y axis and one meter interwals

INFLUENCE OF TRIANGULAR CHEVROANE USED FOR DOUBLE FLOW TURBOJET ENGINES ON FLUID FLOW AND ACOUSTIC

TERMOTEHNICA 1/2011

along the X axis was obtained the following flow

diagram of the acoustic power.

Fig. 20. Points in the field

0 1 2 3 4 5 6 7 8 9 10 11 12

50

60

70

80

90

100

110

120

130

140

150

160

170

180

0chevroane

10chevroane 0 dip angle

10chevroane 6 dip angle

10chevroane 10 dip angle

173.826

50

Lp0chev

Lp10chev0

Lp10chev6

Lp10chev10

12 0 m

Fig. 19. Acoustic power in decibels chart depending on the

distance along the flow field

6. CONCLUSIONS

Thee study has revealed the workingfluid flow

along the axis of the engine, observing the mixting

zone between the two streams of fluid. The use of

large dip angles chevroane increase the exhaust

velocity, but also lead to increased turbulence.

Because of too big speeds of the two flows,

mixing layers of fluid that aims to reduce noise

pollution occurs on a too small portion along the

area to have an advantage.

Because the boundary between inner and outer

flow is much smaller than that of the external flow

(secondary) and atmospheric air, and the fact that

differences in speed are comparable, the noise

from the interaction of two air flows is

greater/bigger than the noise resulted from the

interaction of first flow with the second one.

Due to the limited advantage only for a small

area and the disadvantage for the rest of the area

made them not encourage all remaining range use

between primarly and secondary flow which are

suitable for flow 2 with the layers of atmosphere.

REFERENCES

[1] Youn D.. Jet noise suppression means, United State

Patent Office, No. US3153319, oct.20 1964 pp 7

[2] Balzer Segment mixing device having chevrons for

exhaust noise reduction in jet engines, United State

Patent ,No. US6612106, sep.t 2 2003 pp4

[3] ICAO Engine Exhaust Emissions Data Bank,

https://cwcs.cfm56.com/CWCTour/CWC_ONLINE/image/i

mage%20divers/CFM56-7B27-2.pdf

[4] Seiner J. Metod and device for reduction engine noise,

United States Patent Application Publication,No.

US20070246293 oct. 25, 2007 pp 16

[5] Mathews et al. Tabbed nozzle for jet noise

suppression United States Paten, No. US6314721,

nov.13. 2001 pp 8

[6] V. Stanciu Aeroreactors engines Guidelines for pre-

design

[7] S. Sarkar M. Y. Hussaini Computation of the sound

generated by isotropic turbulencenasa Contractor Report

191543-l ICASE Report No. 93-74

[8] Ansys 12 Documentation-Users Guide 2004

TERMOTEHNICA 1/2011

CONSIDERAII PRIVIND SIMULAREA DINAMICII

FLUXURILOR DE GAZE NATURALE N SISTEMELE

DE TRANSPORT

Cristian EPARU, Sorin NEACU, Mihai ALBULESCU, Renata RDULESCU

Universitatea Petrol-Gaze din Ploieti, Romnia

Rezumat. Conform ultimelor normative europene n domeniul transportului gazelor naturale n conductele de

transport trebuie s se injecteze o cantitate de gaze egal cu cea care se livreaz ctre clieni.

Consumurile de gaze ale diverilor clieni sunt variabile funcie de necesitile acestora. n acest caz procesul de

transport gaze naturale este un proces nestaionar.

n lucrarea de fa sunt prezentate cteva exemple de simulare numeric a dinamicii fluxurilor de gaze din

conductele de transport folosind simulatorul SIMONE.

Cuvinte cheie: gaz, transport, flux, simulare.

Abstract. According to the latest European normative framework in the natural gas transport field, a quantity of

gas must be injected in transport pipelines, equal to that which is delivered to customers.

Gas consumption of the various clients is variable according to their needs. In this case the natural gas transport

process is a non stationary process.

This paper presents some examples of numerical simulation of the dynamics of gas flows in pipeline transport

using the SIMONE simulator.

Keywords: gas, transport, flow, simulation.

1. INTRODUCERE

Gazele naturale sunt transportate de la surse

spre utilizatori prin sisteme de conducte.

Capacitatea de transport a sistemelor de conducte

este determinat nc din faza de proiectare

considernd curgerea staionar a gazelor prin

sistemele de conducte, de regul la debitele

maxime de transport.

Noile reglementri europene aprute pentru

sistemele de transport gaze naturale introduc

restricii severe referitoare la cantitile de gaze

care trebuie s existe n conducte pe durata

transportului precum i penalizri chiar i pentru

transportator n momentul cnd nu asigur debitele

de gaze nominalizate i contractate de clieni.

Clieni au consumuri variabile n timp, acest

lucru face ca sistemele de operare pentru

conductele de transport gaze naturale s in seama

de nestaionaritatea fenomenului.

Problema operrii n timp real a sistemelor de

transport gaze naturale este o problem complicat

care se rezolv utiliznd sisteme de tip SCADA

cuplate la simulatoare numerice puternice.

n lucrare de fa este prezentat o analiz a

procesului nestaionar de curgere pentru o conduc

de transport gaze naturale de la o surs de gaze

Bilciureti la un mare utilizator grupul de

cogenerare de 800MW Brazi (Petrom).

Simularea numeric s-a realizat folosind softul

Simone, care reprezint un standard n Europa

pentru simularea numeric a transportului de gaze

naturale. Pentru Simone Catedra de Hidraulic,

termotehnic i inginerie de zcmnt din UPG

Ploieti deine 12 licene.

2. MODELAREA REELEI CU

SIMULATORUL SIMONE

n figura 1 este prezentat schema reelei pe

care s-a fcut experimentul numeric.

Pentru a nu complica schema sunt reprezentate

doar cele dou capete ale conductei, respectiv

captul de intrare i cel de ieire.

Cristian EPARU, Sorin NEACU, Mihai ALBULESCU, Renata RDULESCU

TERMOTEHNICA 1/2011

Fig. 1. Schema conductei

Traseul conductei de gaze Dn 800 x 40 bar x

29,8 km este format din ase tronsoane mari,

fiecare din acestea fiind la rndul su mprit n

buci funcie de grosimea peretelui conductei:

Tronsonul I, L = 5,0 km; format din 4 buci,

Tronsonul II, L = 5,0 km; format din 4 buci,

Tronsonul III, L = 5,46 km; format din 4 buci,

Tronsonul IV, L = 4,54 km; format din 3 buci,

Tronsonul V, L = 5,0 km; format din 3 buci,

Tronsonul VI, L = 4,8 km; format din 3 buci.

n tabelul 1 se pot observa parametrii celor 21

de tronsoane

Tabel 1

Dimensiunile tronsoanelor conductei

Conducta

Lungime

Diametru

interior

Rugozi-

tate

[km] [mm] [mm]

Intrare - S1_017 2.074 801.2 0.012

S1_010 - S1_020 3.214 801.2 0.012

S1_011 - S1_024 4.379 801.2 0.012

S1_012 - S1_027 3.884 801.2 0.012

S1_013 - S1_029 4.502 801.2 0.012

S1_014 - S1_031 3.095 801.2 0.012

S1_017 - S1_018 0.096 798.8 0.012

S1_018 - S1_019 0.39 795.6 0.012

S1_019 - S1_010 2.44 790.8 0.012

S1_020 - S1_021 0.096 798.8 0.012

S1_021 - S1_022 0.47 795.6 0.012

S1_022 - S1_011 0.97 790.8 0.012

S1_024 - S1_025 0.096 798.8 0.012

S1_025 - S1_026 0.07 795.6 0.012

S1_026 - S1_012 0.713 790.8 0.012

S1_027 - S1_028 0.096 798.8 0.012

S1_028 - S1_013 0.56 790.8 0.012

S1_029 - S1_030 0.096 798.8 0.012

S1_030 - S1_014 0.067 795.6 0.012

S1_031 - S1_032 0.065 795.6 0.012

S1_032 - Consum 1.64 790.8 0.012

Calculul conductei s-a fcut cu programul

SIMONE V5-73 i a urmrit, n situaia n care

reeaua nu prezint defecte, determinarea

parametrilor de curgere a gazelor naturale.

Condiiile la limit au fost puse n punctele de

intrare i ieire din conduct i au constat n

impunerea unei presiuni constante de ieire i a

unei presiuni variabile de intrare, programul

determinnd cderile de presiune i vitezele de

deplasare a gazelor. Se poate astfel simula

dinamica fluxurilor de gaze naturale i analiza

capacitatea dinamic de transport a conductei.

Presiunea maxim absolut a gazelor la intrarea

n conduct este de 27 bar. Condiia de proiectare a

conductei este ca presiunea de ieire s nu scad

sub 14 bar.

S-a fcut apoi o simulare a unui scenariu cu

presiune de intrare n conduct variabil pentru a

vedea influena presiunii de intrare asupra

capacitii conductei.

Determinarea parametrilor de curgere a gazelor

naturale pentru toate variantele simulate a fost

fcut pentru o perioad de 24 de ore ncepnd cu

ora 12

00

. Toate simulrile s-au fcut plecnd de la

considerentul c avem o presiune n conduct de

14 bar. Temperatura gazului s-a considerat de 8

o

C

(Figura 2).

Fig. 2. Parametrii iniiali ai gazului din conduct

Scenariul pentru determinarea capacitii

dinamice a conductei

De foarte multe ori parametrii gazului ntr-o

conduct se modific n funcie de condiiile

specifice, de aceea este posibil ca presiunea

gazului la intrare s nu fie constant. Astfel, s-a

realizat un scenariu n care presiunea de intrare n

conduct este variabil, urmrindu-se astfel modul

cum este afectat capacitatea conductei i fluxurile

de gaze. Condiiile puse pentru intrarea i ieirea

gazului din conduct sunt prezentate n figura 3.

CONSIDERAII PRIVIND SIMULAREA DINAMICII FLUXURILOR DE GAZE NATURALE N SISTEMELE DE TRANSPORT

TERMOTEHNICA 1/2011

Fig. 3. Scenariu pentru determinarea capacitii dinamice a conductei

3. PREZENTAREA REZULTATELOR

Aa dup cum s-a artat n descrierea modelului

condiiile la limit sunt adecvate cerinelor de

consum pentru un consumator mare care, n acest

caz trebuie s dispun n permanen de un debit

constant de gaze. Sursa de gaze este plasat lng

Bucureti, un alt mare consumator de gaze.

Datorit condiiilor climatice este posibil ca

debitele i presiunile furnizate de surs s aib

variaii destul de nsemnate.

n figurile 4 i 5 este prezentat situaia la

intrarea n conduct n care s-a simulat o surs

variabil. Variaiile sursei sunt att n presiune ct

i n debit. Aceste variaii se propag prin conduct

iar rezultatul l putem vedea la captul final al

conductei, figurile 6 i 7.

Fig. 4. Variaia presiunii la intrarea n conduct pentru 24 de ore

Fig. 5. Variaia debitului la intrarea n conduct pentru 24 de ore

Cristian EPARU, Sorin NEACU, Mihai ALBULESCU, Renata RDULESCU

TERMOTEHNICA 1/2011

Fig. 6. Variaia presiunii la ieirea n conduct pentru 24 de ore

Fig. 7. Variaia debitului la ieirea n conduct pentru 24 de ore

Din cele dou imagini observm c n urma

simulrii numerice sursa variabil la intrare asigur

totui condiiile minimale cerute de beneficiar.

Semnificaia acestui rezultat este acea c simularea

numeric permite determinarea nivelului de

amplitudine a sursei care s nu afecteze condiiile

minimale ale beneficiarului.

O imagine important este prezentat n figura

8 linepack-ul, cantitatea de gaze prezent n

conduct la diferite momente. Aceast cantitate

trebuie asigurat i gestionat de transportator.

Fig. 8. Variaia pentru 24 de ore a cantitii de gaze din conduct

CONSIDERAII PRIVIND SIMULAREA DINAMICII FLUXURILOR DE GAZE NATURALE N SISTEMELE DE TRANSPORT

TERMOTEHNICA 1/2011

Dinamica fenomenului de propagare a fluxului

de gaze este prezentat n figurile 9 17 la trei

momente de timp diferite, sub forma a trei seturi de

grafice. Simulrile numerice permit determinare

timpului de propagare al fluxului de gaze precum

i dinamica presiunii i a debitului pe durata pe

care s-a realizat simularea. Un aspect remarcabil