Documente Academic

Documente Profesional

Documente Cultură

Breviar Calcul Acoperis 45 Grade

Încărcat de

Bosincianu Vasile IoanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Breviar Calcul Acoperis 45 Grade

Încărcat de

Bosincianu Vasile IoanDrepturi de autor:

Formate disponibile

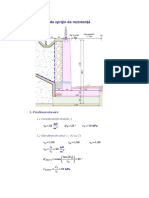

SITUATIE EXISTENTA

CARACTERISTICILE CONSTRUCTIEI

Locatie:

Invelitoare:

Panta:

:

Ionut CARP

Constanta

Tigla ceramica

2 pante

45

I. EVALUAREA INCARCARILOR

1. Incarcarea din zapada

unde:

Sk= 0.64

[kN/m]

i= coeficient de forma pentru incarcarea din zapada pe acoperis

i=

Ce= coeficient de expunere al amplasamentului

Ce= 0.80

(expunere partiala)

0.4

Ct= coeficient termic

Ct=

sok= valoarea caracteristica a incarcarii din zapada pe sol in amplasament

sok= 2.00 [kN/m]

2. Incarcarea din vant

unde:

Sk= iCeCtsok

qref=

W(Z)= qrefce(z)Cp

W(z)= 0.2328 [kPa]

presiunea de referinta a vantului

Ce(z)= factorul de expunere la inaltimea z deasupra terenului

Cp=

1.00

coeficientul aerodinamic de presiune

[kN/m]

qref=

0.5

Ce(z)=

0.665

Cp=

0.7

F

5.625

45

G

G

F

11.25 [m]

15.34 [m]

11.25 [m]

3. Incarcarea utila

qu= 1.00 [kN/m]

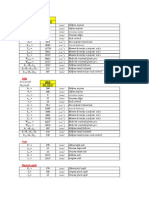

4. Incarcarea permanenta

Material

Tigla

Sipca

Hidroizol.

Incarcare

0.098

0.045

0.001

Coef

Incarc. De calc.

1.35

0.1323

1.35

0.0608

1.35

0.0014

0.1944

SITUATIE EXISTENTA

II. CALCULUL SIPCILOR

1.Evaluarea incarcarilor

a) Incarcarea permanenta aferenta unei sipci

Ip= 0.098+0.045+0.001 Ip= 0.144 [kN/m]

qp= Ip1.35c

qp= 0.068 [kN/m]

c= 0.35 [m]

qpx= qpsin

qpx= 0.0579 [kN/m]

qpy= qpcos

qpy= 0.0357 [kN/m]

b) Incarcarea din vant aferenta unei sipci

qv= w1.05c

qvx=

qv= 0.0855 [kN/m]

[kN/m]

qvy= qv= 0.0855 [kN/m]

c) Incarcarea din zapada aferenta unei sipci

qz= Sk1.5c qz= 0.336 [kN/m]

qzx= qzsin

qzx= 0.2859 [kN/m]

qzcos

qzy=

0.1765 [kN/m]

qzy=

d) Incarcarea utila aferenta unei sipci

Iu=

100

qu= Iu1.5

[daN]

qu=

qux= qusin

qux=

quy= qucos

quy=

1.5

[kN/m]

1.2764 [kN/m]

0.788 [kN/m]

2. Ipoteze de incarcare

a) q1= qp+qz

q1x=

q1y=

0.3438 [kN/m]

0.2123 [kN/m]

b) q2= qp+(1/2)qz+qv

q2x=

q2y=

0.2008 [kN/m]

0.2095 [kN/m]

c') Forta uniform distribuita

q3x= 0.0579 [kN/m]

q3y=

0.0357 [kN/m]

q3= qp

50 x 50 [mm]

SITUATIE EXISTENTA

q3= qu

c'') Forta concentrata

q3x= 1.2764 [kN/m]

0.788 [kN/m]

q3y=

3. Calculul eforturilor in sipci

d= distanta interax intre sipci

d= 0.35 [m]

a) M1= 1 M1x= 1

M1x= 0.015 [kNm]

8

8

M1y= 1

M1y= 0.0093 [kNm]

8

b) M2= 2

M2x= 2

M2x= 0.0088 [kNm]

8

8

M2y= 2

8

M3= 3

8

c)

M3x= 3

8

M3y= 3

8

M2y= 0.0092 [kNm]

M3x= 0.0558 [kNm]

M3y= 0.0345 [kNm]

4. Verificarea rezistentei la capacitate portanta

0.0558

0.2808

0.0345

+ 0.2808 1

a)

Mefx= Mxmax= M3x= 0.0558 [kNm]

Mefy= Mycores= M3y= 0.0345 [kNm]

b)

Mefy= Mymax= M3y= 0.0345 [kNm]

Mefx= Mxcors= M3x= 0.0558 [kNm]

c

Mrx= Rinc WxmTm1

Mrx=

0.3217 < 1

0.2808 [kNm]

0.2808 [kNm]

Mry=

c

Rinc = muimdi

Rinc = 14.975

mui=

1

mdi= 0.55 + 1 mdi= 0.068 0.55 + 1.5 1

+

0.068 + 1.5

c

Ri=

16.8 [N/mm]

i=

1.1

Wx=

Wx= 50 50

6

Wx=

20833 [mm]

mdi=

0.9805

SITUATIE EXISTENTA

6

mT=

0.9

m1=

5. Verificarea de rezistenta la incovoiere statica

fmaxf fadm

fadm=

150

0.0406 < 0.3333 se verifica la incovoiere statica

fadm=

50

150

fadm= 0.3333 [mm]

a) Sageata din incarcarea permanenta aferenta unei sipci

fpx=

fpy=

kdef=

x

fpst (1+kdef)

fpsty(1+kdef)

0.8

fpx= 0.011 [mm]

fpy= 0.0068 [mm]

fpstx=

4

fpsty= 5

384

fpstx=

0.0061 [mm]

fpsty= 0.0038 [mm]

Ix= 520833 [mm]

12

E= 11000

Ix= Iy=

b) Sageata din incarcarea data de vant aferenta unei sipci

kdef=

fvx= 0

fvy= fvsty(1+kdef) fvy= 0.0116 [mm]

fvsty= 5 4

384

fvsty=

0.0116 [mm]

c) Sageata din incarcarea data de zapada aferenta unei sipci

fzx=

fzy=

kdef=

x

fzst (1+kdef)

fzsty(1+kdef)

fzstx=

0.5

fzx= 0.0406 [mm]

fzy= 0.0251 [mm]

5 4

384

4

fzsty= 5

384

fzstx=

0.0271 [mm]

fzsty=

0.0167 [mm]

d) Sageata din incarcarea utila aferenta unei sipci

fux=

fuy=

kdef=

x

fust (1+kdef)

fusty(1+kdef)

0

fux= 0.0004 [mm]

fuy= 0.0002 [mm]

SITUATIE EXISTENTA

1 3

48

1 3

fusty=

48

fustx=

fustx=

0.0004 [mm]

fusty= 0.0002 [mm]

III. CALCULUL CAPRIORILOR

1.Evaluarea incarcarilor

a) Incarcarea permanenta aferenta unui caprior

100 x 150

Ip= 0.324 [kN/m]

G= 0.10.1526

G= 0.18 [kN/m]

Qp= Ip1.35dcos

Qp= 0.1137 [kN/m]

d= 0.4948 [m]

Ip= Ips+Ipc

b) Incarcarea din vant aferenta unui caprior

Qv= w1.05d

Qv= 0.1209 [kN/m]

c) Incarcarea din zapada aferenta unui caprior

Qz= Sk1.5dcos

Qz= 0.2495 [kN/m]

d) Incarcarea utila aferenta unui caprior

Qu= Iu1.5cos Qu= 0.788 [kN/m]

2. Ipoteze de incarcare

a) Q1=Qp+Qz

Q1=

0.3632 [kN/m]

b) Q2= Qp+(1/2)Qz+Qv

Q2= 0.3594 [kN/m]

c') Forta uniform distribuita

Q3= 0.1137 [kN/m]

Q3= Qp

Q3= Qu

c'') Forta concentrata

[kN/m]

Q3= 0.788

3. Calculul eforturilor in capriori

l=

3.97 [m]

a) M1= 1

8

b) M2= 2

8

0.4301 3.5

8

M2= 0.3947 3.5

8

M1=

M1=

0.7156 [kNm]

M2=

0.708 [kNm]

[mm]

SITUATIE EXISTENTA

c)

M3= 3 + 3

4

8

M3= 1.27 3.5

8

+ 0.1149 3.5

4

M3=

2.6274

4. Verificarea rezistentei la capacitate portanta

Mmaxcap Me 2.6274 <

5.0539

se verifica la capacitate portanta

Mmaxcap =max(M1;M2;M3) Mmaxcap=

max(0.6586;0.6044;2.054)

c

Me= Rinc WmTm1 Me= 5.0539 [kNm]

Rincc= muimdi

mui=

1

Rincc= 14.975

mdi= 0.9805

W= W= 375000 [mm]

6

5. Verificarea la moment incovoietor

a) Sageata din incarcarea permanenta aferenta unui caprior

kdef=

0.8

fpc= fpc (1+kdef) fpx= 0.0106 [mm]

4

fpci= 5

fpci= 0.0059 [mm]

384

E= 11000

I= 4.219E+09

b) Sageata din incarcarea data de vant aferenta unui caprior

kdef=

fvc= fvc (1+kdef) fvx= 0.0056 [mm]

4

fvci= 5

fvci= 0.0056 [mm]

384

c) Sageata din incarcarea data de zapada aferenta unui caprior

kdef=

0.45

fzc= fzc (1+kdef) fzx= 0.024 [mm]

4

fzci= 5

fzci= 0.0166 [mm]

384

d) Sageata din incarcarea utila aferenta unui caprior

kdef=

fuc= fuc (1+kdef) fux= 0.0366 [mm]

4

fuci= 5

fuci= 0.0366 [mm]

384

Calculul sagetii pe ipoteze de incarcare

fmaxf fadm

<

19.85 se verifica sageata

Mmaxcap=

2.6274 [kNm]

SITUATIE EXISTENTA

fadm= fadm= 3500

200

200

fmaxf= max(f1;f2;f3)

fadm=

19.85 [mm]

IV. CALCULUL PANEI CENTRALE

1. Evaluarea incarcarilor

a) Incarcarea permanenta aferenta unei pane

qpp= 1.35 +

1.35

qpana= v

qpx=

qpy=

qpp=

qpana=

qpp=

150 x 200

[kN/m]

1.544

0.18 [kN/m]

1.544 [kN/m]

dp= 2.8125 [m]

b) Incarcarea din vant aferenta unei pane

qvp= 1.5

qvpx= qvpsin

qvpy= qvpcos

qvp=

1.8692 [kN/m]

qvpx= 1.5905 [kN/m]

qvpy= 0.9819 [kN/m]

c) Incarcarea din zapada aferenta unei pane

qzp=Sk1.05dp

qzp= 1.89 [kN/m]

qzpx=

qzpy=

qzp= 1.89

[kN/m]

d) Incarcarea utila aferenta unei pane

qup= Iu1.5

qupx=

qupy=

qup=

qup=

1.5

[kN/m]

1.5

[kN/m]

[kN/m]

2. Ipoteze de incarcare

a) q1=qp+qz

[kN/m]

q1x= qpx+qzx

q1x=

q1y= qpy+qzy

q1y=

3.434 [kN/m]

b) q2= qp+(1/2)qz+qv

q2x= qpx+(1/2)qzx+qvx

q2x=

q2y= qpy+(1/2)qzy+qvy

q2y=

q3= qp

c') Forta uniform distribuita

q3x=

qpx=

[kN/m]

1.5905 [kN/m]

3.4709 [kN/m]

[mm]

SITUATIE EXISTENTA

q3y=

qpy=

1.544 [kN/m]

q3= qu

[kN/m]

c'') Forta concentrata

q3x=

qux=

q3y=

quy=

0

1.5

[kN/m]

3. Calculul eforturilor in pana centrala

lp=

a)

2.00 [m]

[kNm]

0

M1x=

b)

M1y= 1

8

M2x= 2

8

M1y=

M2x= 0.7952 [kNm]

M2y= 2

8

M2y= 1.7355 [kNm]

[kNm]

0

3

M3y= 3

+

4

8

c)

1.717 [kNm]

M3x=

M3y=

1.522 [kNm]

4. Verificarea rezistentei la capacitate portanta

a)

Mefx= Mxmax= M2x= 0.7952 [kNm]

Mefy= Mycores= M2y= 1.7355 [kNm]

b)

Mefy= Mymax= M2y= 1.7355 [kNm]

Mefx= Mxcors= M2x= 0.7952 [kNm]

c

Mrx= Rinc WxmTm1

Mrx=

11.55 [kNm]

8.666 [kNm]

Mry=

c

Rinc = muimdi

Rinc = 12.838

mui=

1

mdi= 0.55 + + /2

mdi=

+ + /2

c

Ri=

16.8 [N/mm]

i=

1.1

Wx=

6

Wy=

6

0.8406

Wx= 150 200

6

Wx=

1.00E+06 [mm]

Wy= 200 150

6

Wy=

7.50E+05 [mm]

SITUATIE EXISTENTA

mT=

0.9

m1=

5. Verificarea de rezistenta la incovoiere statica

fmaxf fadm

fadm=

200

0.9358 <

10

fadm= 2000

200

fadm=

se verifica la incovoiere statica

10

[mm]

a) Sageata din incarcarea permanenta aferenta unei pane

fpx=

fpy=

kdef=

x

fpst (1+kdef)

fpsty(1+kdef)

0.8

fpx=

[mm]

fpy= 0.9358 [mm]

5 4 fpstx=

0

[mm]

384

4

fpsty= 5 fpsty= 0.520 [mm]

384

fpstx=

Ix=

Ix=

12

E= 11000

1.00E+08 [mm]

Iy= Iy=

12

b) Sageata din incarcarea data de vant aferenta unei pane

fvx=

fvy=

kdef=

x

fvst (1+kdef)

fvsty(1+kdef)

0

fvx= 0.3012 [mm]

fvy= 0.3306 [mm]

5 4

384

y

fvst = 5 4

fvstx=

fvstx=

0.30

[mm]

fvsty=

0.33

[mm]

384

c) Sageata din incarcarea data de zapada aferenta unei pane

fzx=

fzy=

kdef=

x

fzst (1+kdef)

fzsty(1+kdef)

fzstx=

0.5

fzx=

[mm]

fzy= 0.358 [mm]

5 4

384

4

fzsty= 5

384

fzstx=

fzsty=

[mm]

0.2386 [mm]

d) Sageata din incarcarea utila aferenta unei pane

kdef=

5.63E+07 [mm]

SITUATIE EXISTENTA

fux= fustx(1+kdef) fux=

fuy=

fusty(1+kdef)

[mm]

fuy= 0.0002 [mm]

1 3

48

1 3

fusty=

48

fustx=

fustx=

[mm]

fusty= 0.0002 [mm]

Calculul sagetii pe ipoteze de incarcare

fmaxf fadm

1.4764 <

fadm= fadm= 2000

200

200

fmaxf= max(f1;f2;f3)

10

se verifica

fadm=

2

2

f1= 1.2937 [mm]

(1

+ 1

)

f1x= fpx+fzx f1x= 0

[mm]

1. f1=

f1y= fpy+fzy

f1y= 1.2937 [mm]

2

2

2. f2= (2

f2= 1.4764 [mm]

+ 2

)

f2x= fpx+fvx+fzx/2 f2x= 0.3012 [mm]

f2y= fpy+fvy+fzy/2 f2x= 1.4453 [mm]

2

2

3. f3= (3

f3= 0.9359 [mm]

+ 3

)

f3x= fpx+fux f3x= 0

[mm]

f3y= fpy+fuy f3y= 0.9359 [mm]

10

[mm]

SITUATIE EXISTENTA

V. CALCULUL POPILOR

1. Evaluarea incarcarilor

a) Incarcarea permanenta aferenta unui pop

Npp=

d=

1.35

+ 1.35 + 1.35

qpana= v qpana= 0.18 [kN/m]

Asect= Asect= 0.0201 [m]

4

Acalc=

t= 3.835 [m]

hp= 5.625 [m]

b) Incarcarea din vant aferenta unui pop

Nvp= 1.5

Nvp=

2.6384 [kN/m]

c) Incarcarea din zapada aferenta unui pop

Nzp=

10.231 [kN/m]

Sk1.05dpt Nzp=

d) Incarcarea utila aferenta unui pop

Nu= Iu1.5

Nu=

1.5 [kN/m]

2. Ipoteze de incarcare

a) N1=Np+Nz

b) N2= Np+(1/2)Nz+Nv

N1=

27.94 [kN/m]

N2=

25.463 [kN/m]

3. Verificarea la compresiune cu flambaj

Nmax Cr

Cr= Rc''AcalcmTc

Nmax= max(N1;N2)

Nmax=

27.94 [kN/m]

0.16 [m]

Npp=

0.3*0.3 Acalc=

17.709 [kN/m]

0.09

[m]

SITUATIE EXISTENTA

Rc''= Rc''= 6595.5

0.55 + + /2

mdi=

mdi= 0.687

+ + /2

Acalc= 0.09

= f() =

= =

If =

3 100

125 >

= 0.0192

75

TRUE

5.00 [m]

i= 0.25dpop

i=

0.04

mTc= 0.9

Cr= 102.57

Nmax Cr

27.94 <

102.57 TRUE

VI. CALCULUL TALPII

N < Qr 27.94 < 182.31 TRUE

Verificarea la strivire a talpii se face cu relatia:

unde: N=

incarcarea verticala a popului

N= 27.94 [kN/m]

Qr= capacitatea portanta a elementelor din lemn masiv cu sectiunea simpla, solicitatala compresiune

perpendicular pe directia fibrelor

Qr= AcRc''mTcmr

Qr= 182.31

Ac= aria de contact dintre cele doua elemente, aria popului la rezemarea pe talpa se considera ca popul se

imbina cu talpa cu cep cu dimensiunile 3x3 cm

Ac=

mr=

- 0.030.03

Rc''=

6.5955

mTc=

0.9

coeficient de reazem

mr=

1.6

Ac= 0.0192 [m]

S-ar putea să vă placă și

- LemnDocument7 paginiLemnblack_lady_21Încă nu există evaluări

- Brevier de CalulDocument31 paginiBrevier de CalulVlad AndreiÎncă nu există evaluări

- Calcul La Forta TaietoareDocument5 paginiCalcul La Forta TaietoareRepanovici Alexandru100% (1)

- Armare Grinda StalpDocument5 paginiArmare Grinda StalpDiana BogdanÎncă nu există evaluări

- Calcul Masuri ConsolidareDocument15 paginiCalcul Masuri ConsolidareRîndunica VictorÎncă nu există evaluări

- 1 - PredimensionareDocument4 pagini1 - PredimensionareGabriel_86Încă nu există evaluări

- 03 Plansee-PredimensionareDocument13 pagini03 Plansee-PredimensionareDudila MariusÎncă nu există evaluări

- Mathcad - Explicatii Norm VantDocument4 paginiMathcad - Explicatii Norm VantRomina Ilina-Posea100% (1)

- Breviar de Calcul Zid de Sprijin Gradinita RodnaDocument7 paginiBreviar de Calcul Zid de Sprijin Gradinita RodnaMIHAILA IONUTÎncă nu există evaluări

- Curs 03 04 Structuri de SprijinDocument137 paginiCurs 03 04 Structuri de SprijinVisan AndreeaÎncă nu există evaluări

- Dimensionare Îmbinare Fixă Grindă-StâlpDocument9 paginiDimensionare Îmbinare Fixă Grindă-StâlpFlorin StanescuÎncă nu există evaluări

- Calculul La StrapungereDocument5 paginiCalculul La StrapungereCristian PaladeÎncă nu există evaluări

- Calcul Armatura Stalpi Long +transversalaDocument13 paginiCalcul Armatura Stalpi Long +transversalaAndra GiurgiuÎncă nu există evaluări

- Cadru Transversal GRINZIDocument17 paginiCadru Transversal GRINZIPacepaVasileÎncă nu există evaluări

- Proiectt Fundattii Complet Tooate EtapeleDocument79 paginiProiectt Fundattii Complet Tooate EtapeleRadu AcostoaeiÎncă nu există evaluări

- 6 Fundatii Insurubate 49883 PDFDocument22 pagini6 Fundatii Insurubate 49883 PDFRazvan MarinÎncă nu există evaluări

- Advance Concrete 2012 - Manual de Utilizare PDFDocument110 paginiAdvance Concrete 2012 - Manual de Utilizare PDFradu20122012Încă nu există evaluări

- Dimensionare Fundatie CorectatDocument10 paginiDimensionare Fundatie CorectatSzidonia FejerÎncă nu există evaluări

- Coloane de BalastDocument7 paginiColoane de Balastjohny91mÎncă nu există evaluări

- Amvic - Exemple de Calcul + TeorieDocument33 paginiAmvic - Exemple de Calcul + Teoriebuha_buhaÎncă nu există evaluări

- Incarcari Din Zapada Si VantDocument1 paginăIncarcari Din Zapada Si VantRepanovici AlexandruÎncă nu există evaluări

- Forta Taietoare Ec2Document24 paginiForta Taietoare Ec2Eva GallÎncă nu există evaluări

- Calcul LemnDocument12 paginiCalcul LemnMarcel SteoleaÎncă nu există evaluări

- Calcul SarpantaDocument19 paginiCalcul Sarpantadascaluandreea1997Încă nu există evaluări

- Proiect Memoriu FundatiiDocument45 paginiProiect Memoriu FundatiiviteokmenÎncă nu există evaluări

- Fundatii Izolate ExplicatiiDocument15 paginiFundatii Izolate ExplicatiiAnca Maria MahrusÎncă nu există evaluări

- Moara de FocDocument20 paginiMoara de FocAndreiÎncă nu există evaluări

- Calcul Armatura Placa Peste SDocument21 paginiCalcul Armatura Placa Peste SSebastian StefanescuÎncă nu există evaluări

- Etape SciaDocument4 paginiEtape SciaAfanase ValentinaÎncă nu există evaluări

- Note Calcul (Baza)Document14 paginiNote Calcul (Baza)cmunteanuÎncă nu există evaluări

- Proiect Perete AutoportantDocument20 paginiProiect Perete AutoportantAntoniuDragneaÎncă nu există evaluări

- Tema 1 CM3Document18 paginiTema 1 CM3alexandru_scant915Încă nu există evaluări

- Armare Grinzi Beton Armat CadruDocument3 paginiArmare Grinzi Beton Armat CadruRepanovici Alexandru100% (1)

- CALCUL - Perete Exterior BetonDocument1 paginăCALCUL - Perete Exterior BetonmatrixuulÎncă nu există evaluări

- Calculul Peretilor de SubsolDocument2 paginiCalculul Peretilor de SubsolRaluca MicuÎncă nu există evaluări

- Armare Grinda Cadru. - 29.04.2014Document14 paginiArmare Grinda Cadru. - 29.04.2014Ciprian Alin FarcasÎncă nu există evaluări

- Calcul StrapungereDocument17 paginiCalcul StrapungereMarinoiu MarianÎncă nu există evaluări

- Verificarea Nodurilor de CadruDocument6 paginiVerificarea Nodurilor de CadruAnonymous XTXCntXXHÎncă nu există evaluări

- Lungimi de Ancoraj Pentru Clasa de Ductilitate DCHDocument1 paginăLungimi de Ancoraj Pentru Clasa de Ductilitate DCHmindoiuÎncă nu există evaluări

- CHMDocument5 paginiCHMMihaelaRaduÎncă nu există evaluări

- Tasare CalculDocument3 paginiTasare CalculVadim GrozaÎncă nu există evaluări

- Detalii Fundatii 3Document1 paginăDetalii Fundatii 3Alin TuvicÎncă nu există evaluări

- Calcul Deschidere FisuriDocument1 paginăCalcul Deschidere Fisuriandramgr0% (1)

- Calcul FundatiiDocument22 paginiCalcul FundatiiFlorin Stanescu100% (1)

- Memoriu Tehnic Turn 12m 0.6kpa BR - 0629 - TO Lunca de JosDocument4 paginiMemoriu Tehnic Turn 12m 0.6kpa BR - 0629 - TO Lunca de Jos'Theodora GeorgianaÎncă nu există evaluări

- Linii de Influenţă Ale Reacţiunilor Repartiţiei Transversale Pentru Reţele de 9 GrinziDocument3 paginiLinii de Influenţă Ale Reacţiunilor Repartiţiei Transversale Pentru Reţele de 9 GrinziMircea Remus Andone100% (1)

- Etape EtabsDocument2 paginiEtape EtabsAnonymous QK7Ntv6QÎncă nu există evaluări

- Elasticitate C10 PDFDocument14 paginiElasticitate C10 PDFmajordome71Încă nu există evaluări

- 1-Tema 1 - Evaluarea Fortei SeimiceDocument14 pagini1-Tema 1 - Evaluarea Fortei SeimiceLaurentiu TarbucÎncă nu există evaluări

- Calcul Capacitate Portanta PilotiDocument9 paginiCalcul Capacitate Portanta PilotiJózsef TörökÎncă nu există evaluări

- Calculul SarpanteiDocument29 paginiCalculul SarpanteiCozmin Paloş100% (1)

- Calcul Stalpi Beton ArmatDocument47 paginiCalcul Stalpi Beton ArmatBogdan Botofan100% (1)

- Proiect Constructii Din Beton Armat-MathCadDocument58 paginiProiect Constructii Din Beton Armat-MathCadLechovolea Victor Catalin100% (2)

- Proiectarea Unui Siloz - Pascal IulianDocument8 paginiProiectarea Unui Siloz - Pascal IulianPascal Iulian ClaudiuÎncă nu există evaluări

- SarpantaDocument26 paginiSarpantaAnca CiuchiÎncă nu există evaluări

- Mathcad - Breviar SarpantaDocument16 paginiMathcad - Breviar SarpantastarspleshÎncă nu există evaluări

- Breviar de CalculDocument21 paginiBreviar de CalculIsaincu Claudiu100% (2)

- Cutit de StrungDocument13 paginiCutit de StrungMioara PopescuÎncă nu există evaluări

- Mathcad - Zid de SprijinDocument9 paginiMathcad - Zid de SprijinAndrei KolozsvariÎncă nu există evaluări

- Pana 5 ReazemefffDocument63 paginiPana 5 ReazemefffBosincianu Vasile IoanÎncă nu există evaluări

- F3Document92 paginiF3Bosincianu Vasile IoanÎncă nu există evaluări

- Calcul FundatiiDocument36 paginiCalcul FundatiiBosincianu Vasile Ioan100% (1)

- Planseu Din Beton ArmatDocument75 paginiPlanseu Din Beton ArmatBosincianu Vasile IoanÎncă nu există evaluări

- Norme Deviz - TraDocument44 paginiNorme Deviz - Tracarmen_maria99100% (3)

- Racordari PDFDocument0 paginiRacordari PDFdenisa_tutuÎncă nu există evaluări

- C - Volumul 2Document175 paginiC - Volumul 2Bosincianu Vasile IoanÎncă nu există evaluări

- C - Volumul 4Document131 paginiC - Volumul 4bosi1Încă nu există evaluări

- C - Volumul 3Document161 paginiC - Volumul 3Bosincianu Vasile IoanÎncă nu există evaluări

- C - Volumul 1Document147 paginiC - Volumul 1Bosincianu Vasile IoanÎncă nu există evaluări

- Fundatii IzolateDocument15 paginiFundatii IzolatePolcz Andrea100% (1)