Documente Academic

Documente Profesional

Documente Cultură

Ft. Ft. G3202-1 - 15.05

Încărcat de

Florin ȘandruTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ft. Ft. G3202-1 - 15.05

Încărcat de

Florin ȘandruDrepturi de autor:

Formate disponibile

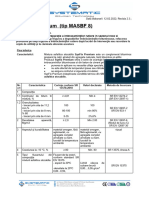

ZINCAMID G 3202-1 S.F.

G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

pag. 1/7

Descriere

Description

Produsul ZINCAMID G 3202-1 este un grund bogat in pulbere de zinc( pulbere ce

respecta cerintele ASTM D 520) pe baza de rasini epoxidice de greutate moleculara mica,

cu intarire amidica. Este un produs pe baza de rasina tip II -organica conform clasificarii

SSPC-20.Asigura o buna protectie catodica, sudabilitate foarte buna, excelenta rezistenta

la intemperii si la coroziune in medii alcaline si slab acide, buna rezistenta la apa si solutie

salina 28%, buna rezistenta la produse petroliere (ulei mineral, motorina, benzina, s.a.),

caracteristici mecanice excelente (duritate, soc mecanic), putere de acoperire buna,

aderenta buna la suport.

ZINCAMID G 3202-1 product is a zinc powder (the powder respect ASTM D 520 request) rich primer

based on epoxy resins with small molecular mass, with amide curing. It is a product based on type II

resin- organic resin according to SSPC-20 classification. Ensures a good cathodic protection, very

good weldability, excellent resistance to weather and corrosion in alkaline and low acid medium,

good resistance to water and salt solution 28%, good resistance to petroleum products (mineral oils,

gas oil, petrol, etc.), excellent mechanical characteristics (hardness, mechanical shock), good

hiding power, good adherence to substrate.

Utilizare

Recommended use

Produsul ZINCAMID G 3202-1 este utilizat pentru:

-protectia reperelor de metal expuse la diverse conditii favorabile coroziunii;

-protectia interioara si exterioara a tancurilor de apa potabila si a rezervoarelor de stocare

a produselor alimentare (aviz sanitar Nr.: 5395/28.06.2001), petroliere, ape reziduale, s.a.;

-protectia utilajelor din industria chimica, alimentara, medicamente, constructii de masini,

vagoane si diverse utilaje;

-ca shopprimer pentru protectia temporara de durata medie (6 luni) a suprafetelor de otel

sablate in perioada dintre curatare si acoperirea finala, protectia navelor, platformelor

marine si a structurilor metalice.

Este recomandat pentru climate:TH,TA, MT, M, F,N.

Este recomandat la grosimi de pelicula mai mari decat 25 m, pentru suprafete din otel

sablate pana la metal alb conform SSPC-SP5, pentru utilizarea conform SSPC-20 in zone

expuse in climate:1A ( interior,uscare normala),1B ( exterior, uscare normala), 2A (stropire

frecventa cu apa ), 2C( imersie in apa ).Poate fi utilizat si in climate 2B ( stropire frecventa

cu apa sarata ), 2D( imersie in apa sarata ) cu un topcoat corespunzator

Conform SR EN ISO 12944-2 produsul poate fi utilizat in sisteme de acoperire exploatate

in spatii interioare si exterioare in medii cu clasa de corozivitate C1-C5 I, M sau exploatate

la imersie Im1, Im2 .

ZINCAMID G 3202-1 product is used for:

-protection of metal parts exposed to corrosion conditions;

-inside and outside protection of tanks of drinking water and of storage tanks for food products

(Sanitary Notification No: 5395/28.06.2001), petroleum products, waste water, etc.;

-protection of equipment from chemical, food, pharmaceutical industry, mechanical engineering,

wagons and different outfits;

-as shopprimer for temporary protection of medium-term (6 months) of blasted steel surfaces

between cleaning and final coating, protection of ships, marine platforms and metallic structures.

It is recommended for TH, TA, MT, M, F, N climates.

It is reccomened for film thickness bigger than 25 m, for sandblast steel surfaces until white metal

according to SSPC-SP5, with utilisation according to SSPC-20 in areas with climatic exposure:

1A (interior, normal drying), 1B (exterior, normal drying), 2A (frequently water spray), 2C (water

sinking). It can also be used in 2B climate (frequently salt water spray), 2D (salt water sinking) with

an appropriate topcoat. According to SR EN ISO 12944-2 the product may be used in covering

system for interior and exterior, in enviroment with C1-C5 I,M aggresion class and in Im1 and Im2

sinking.

Temperatura de lucru

Service temperature

150C max.

ZINCAMID G 3202-1 S.F. G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

Temperatura maxima a

suportului in

momentul aplicarii

Maximum surface

temperature in the

application moment

pag. 2/7

60C max.

Certificate

Certificates

Produsul G 3202-1 este certificat de Germanischer Lloyd (Nr.: 30522- II- 99 En /

19.04.1999) ca shopprimer sudabil.

Produsul G 3202-1 este omologat tehnic de Autoritatea Feroviara Romana cu Certificat de

Omologare Tehnica Feroviara seria OT Nr: 327/2009 si seria OT Nr: 328/2009.

ZINCAMID G 3202-1 are agrement tehnic Nr.: 001- 01 / 1240 -2010 elaborat de INCERC

Bucuresti si emis de Consiliul Tehnic Permanent Pentru Constructii - Bucuresti.

Produsul G 3202-1 este certificat de Germanischer Lloyd (Nr : 47 602-03HH) ca material

de propagare lenta a flacarii.

G 3202-1 product is approved as a welding shopprimer by Germanischer Lloyd (No.: 30522-II - 99

En/ 19.04.1999).

ZINCAMID G 3202 -1 product is technically homologated by ROMANIAN RAILWAY AUTHORITY

with Certificate of Railway Technical Homologation series OT No: 327/2009 and No: 328/2009.

ZINCAMID G 3202-1 product has technical agreement No.: 001- 01/ 1240- 2010, drawn up by

INCERC - Bucharest and issued by Permanent Technical Council - Bucharest.

G 3202-1 product is approved as low flame spread material by Germanischer Lloyd

(No 47 602 -03 HH).

Aspect

Finish

Mat

Flat

vizual

visual

Culoare

Colour

Gri

Light grey

Volum de solide

Volume solids

45% approx. -

Densitate

Specific gravity

1.80 0.5

(at 20 C)

SREN ISO 2811-1:2011

VOC

Volatile organic compound

560 g/l (31,1%) SRENISO 11890-1:2007

Punct de

inflamabilitate

Inflammability point

24C

Timp de curgere

Flow time

20 - 25 s

(at 20 C,cup, 4 mm)

IL-DC-09

Duritate Persoz, min.

Persoz hardness, minimum

140 s SREN SO 1522 : 2007

Elasticitate Erichsen,

min.

Erichsen elasticity, min.

3 mm SRENISO 1520:2007

Aderenta, grila de 1

mm

Adherence to substrate, 1

mm grid

1 SRENISO 2409: 2007

Continut de zinc

raportat la total solide

Zinc content related to total

solid content

min 81% Respecta cerinta SSPC Paint 20

Respects SSPC Paint 20 requirment

ZINCAMID G 3202-1 S.F. G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

Uscare, approx.

Dry -to-touch (Tip B)

Dry -to- handle(Tip D)

Fully cured

(at 20 C, 50 5% rel. hum.)

10 minutes

20 minutes

7 days

pag. 3/7

ASTMD 1640:2003

Valabilitate in ambalaj

Shelf life

6 luni de la data fabricatiei, in conditiile respectarii prevederilor de ambalare si depozitare.

Fiecare din cei doi componenti in ambalajele originale ,sigilate are termen de valabilitate

6 luni in conditiile depozitarii la temperaturi de 10-32 C ( 50-90 F) In functie de conditiile

de depozitare, inaintea utilizarii se recomanda amestecarea produsului

6 months from production date, with the observance of the storage and packing provisions

Depending on storage conditions, it is recommended to stir the product before use.

The both components from the original sealed package, has 6 months valability term with storage

temperature between 10-32 C ( 50-90 F ).

DETALII DE APLICARE

APPLICATION DETAILS

Raport de amestecare

Mixing ratio

Grund G 3202-1 : Intaritor I 324 85p : 15p masic (74p : 26p volumic)

Base G 3202-1 : Curing agent I 324 85p : 15p by weight (74p : 26p by volume)

Timp de prereactie

Pre -reaction time

60 min.

(at 20 C)

-

Interval de utilizare

Pot life

24 hours

(at 20 C)

SRENISO 9514:2005

Metoda de aplicare

Application method

pensulare / roluire

brushing (touch up) / rolling

pulverizare aer

air spraying

pulverizare airless

airless spraying

Diluant utilizat / Dilutie

Thinner / Thinning

D 302 (do not dilute) D 302 (3% max.) D 302 (3% max.)

Presiune

Pressure

- 3 - 4 atm 140 - 160 atm

Diametru duza

Nozzle orifice

- 1.8 - 2.2 mm 0.028 - 0.053

Curatare instrumente

Cleaning of tools

KBER CLEANER DKC 003-02S

Grosime strat umed

Typical wet film thickness

shopprimer: cca. 60m shopprimer: 45m approx.

grund de protectie: cca. 115m protection primer: 115m approx.

SRENISO 2808: 2007

Grosime strat uscat

Typical dry film thickness

shopprimer: cca. 20m shopprimer: 20m approx.

grund de protectie: cca.50m protection primer: 50m aprox.

SRENISO 2808:2007

Interval de reacoperire

Re-coating interval

Vezi mai jos REACOPERIRE

See RE-COATING below

Consum teoretic

Theoretical spreading rate

80 g/m

2

approx. - 20m 200 g/m

2

approx. - 50m

22.5 m

2

/l approx. - 20m 9 m

2

/l approx. - 50m

Observatie

Remark

In cazul aplicarii pe suprafete sablate cu rugozitate 30 - 40 m, consumul practic este de

circa 125g/m

2

- 20 m.

Practical spreading rate is of approx. 125 g/m

2

- 20 m for the application on blasted surfaces with

30 - 40 m roughness.

Consum practic

Practical spreading rate

Consumul practic este functie de conditiile de aplicare (geometria suprafetei, metoda de

aplicare, conditiile de mediu) si poate fi 1.2 1.5 consumul teoretic.

Practical spreading rate depends on the application conditions (surface geometry, application

method, environmental conditions) and can be 1.2 - 1.5 x theoretical spreading rate.

ZINCAMID G 3202-1 S.F. G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

Observatie

Remark

pag. 4/7

Consumul specific practic se calculeaza dupa stabilirea factorului de pierdere LF asociat

aplicarii.

Practical consummation specific to the application is made after LF losser coefficient is

established.

PREGATIREA

SUPRAFETEI

SURFACE

PREPARATION

Gradul de pregatire a suportului este determinant in obtinerea performantelor sistemului

de protectie. Suportul nu trebuie sa aiba defecte de suprafata (suprapuneri de material,

fisuri, stropi de sudura, etc.).

Suprafete metalice noi: curatare generala, degresare, sablare la gradul Sa

2 in

conformitate cu SRENISO 8501-1:2002 sau 2 conform STAS 10166 / 1- 77, pregatirea

suprafetei realizandu-se in conformitate cu SREN ISO 8504-1:2003, SREN ISO 8504-

2:2003, SREISO 8504-3:2003. Se desprafuieste apoi suprafata cu aer comprimat.

Suprafete vechi: indepartare vopsea veche, degresare cu detergent, indepartarea sarii

sau a altor contaminanti prin curatare cu apa (la presiune ridicata), sablare la minim Sa 2

sau curatare mecanica la gradul St 3 (periere energica in directii perpendiculare),

desprafuire. Se evita lustruirea suprafetelor.

The degree of substrate preparation is decisive for the protective system performance. The

substrate should not present surface defects (material overlapping, cracks, welding drops, etc.).

New metallic surfaces: general cleaning, degreasing, abrasive blasting Sa 2 in accordance with

SRENISO 8501-1:2002 or 2 in accordance with STAS 10166 / 1 -77, surface preparation is achieved

in accordance with SREN ISO 8504-1:2003, SREN ISO 8504-2:2003, SREN ISO 8504-3:2003.

Then the surface is dedusted with compressed air.

Old metallic surfaces: removal of the old paint, degreasing with detergent, removal of salt or other

contaminants by high pressure fresh water cleaning, abrasive blasting minimum Sa 2 or mechanical

cleaning at St3 (strong brushing in perpendicular directions), dedusting. The surfaces polishing

should be avoided.

CONDITII DE

APLICARE

APPLICATION

CONDITIONS

Produsul G 3202-1 se va aplica pe suprafete curate si uscate, ce vor avea temperaturi

peste temperatura punctului de roua pentru evitarea condensarii umiditatii pe suport.

Umiditatea relativa va fi de max. 70%. Aplicarea decurge in conditii optime daca se

asigura o temperatura a mediului ambiant si a amestecului de 10-30C.

G3202-1 product should be applied only on dry and clean surfaces with temperatures above the dew

point temperature, in order to avoid condensation. The relative humidity should be of max. 70%.

Application is made under optimal conditions if is ensured a temperature of an medium environment

and mixture of 10-30C.

Observatie

Remark

Produsul G 3202-1 este destinat acoperirilor profesionale.

G 3202-1 product is destined to professional uses.

INSTRUCTIUNI DE

APLICARE

APPLICATION

INSTRUCTIONS

Se conditioneaza componentii la temperatura de 10-30C, se omogenizeaza bine si apoi

se prepara amestecul: 85 parti (masic) grund + 15 parti (masic) intaritor. Pe durata

timpului de prereactie (60 minute) se continua amestecarea prin agitare. Amestecul se

poate aplica la vascozitatea de livrare. Optional, se poate dilua produsul cu maxim 3 %

diluant D 302. Astfel pregatit, produsul G 3202-1 se poate aplica:

-direct pe suprafata metalica pregatita prin sablare la minim 2;

-ca shopprimer utilizat pentru protectia de durata medie a suprafetelor din otel in perioada

de depozitare, transportare si constructie;

-ca strat primar in sistemele de protectie epoxidice, epoxi-gudron, poliuretanice.

ZINCAMID G 3202-1 S.F. G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

pag. 5/7

The components should be conditioned at 10-30C, thoroughly homogenized and then the mixture

should be prepared as follows: 85 parts (by weight) primer + 15 parts (by weight) curing agent.

During pre-reaction time (60 minutes) keep on mixing by stirring. The mixture should be applied on

surface, not thinned at delivery viscosity. Optionally, the product can be thinned with maximum 3%

D 302 thinner. Thus prepared the G 3202-1 product can be applied:

-directly on the metallic surface blasted at minimum Sa 2;

-as shopprimer used for medium -term protection of steel surfaces during storage, transport and

construction;

- as primary coat in protective systems : epoxy, epoxy- tar, polyurethanes.

Observatii

Remarks

Ca shopprimer se recomanda aplicarea produsului intr-un strat uniform si care sa nu

depaseasca grosimea de 25m.Inainte de aplicarea sistemului final de protectie se poate

proceda, dupa situatie la:

a) indepartarea totala a stratului de shopprimer, prin sablare;

b) inspectarea, curatarea si/sau corectarea stratului de shopprimer existent, dupa care

se poate aplica sistemul de protectie recomandat. Pentru indepartarea sarurilor de zinc se

curata suprafata cu jet de apa proaspata sau sablare usoara. Inainte de reacoperire

suprafata trebuie sa fie uscata.

As shopprimer is recommended the application of product in one uniform coat which should not be

thicker than 25 m. Before the application of the final protective system, depending on the situation

you can proceed to:

a) complete removal of the shopprimer coat by blasting;

b) inspection, cleaning and/or correction of the existing shopprimer coat, followed by the

application of the recommended protective system. For removal of zinc salts the surface should be

cleaned with fresh water-jet or easy blasting. Before re-covering the surface must be dry.

REACOPERIRE

RE-COATING

In conditiile unei ventilatii suficiente, intervalele optime de reacoperire pentru produsul

G 3202-1, la temperatura de 20C, sunt urmatoarele (pentru o grosime de strat uscat de

50 micr.):

Under conditions of sufficient ventilation the optimum re-coating intervals for G 3202-1 product

(50 m dry film thickness), at 20C temperature, are as follows :

G 3200S

V 3200S,

V3300HS

E 3200 V 3203-2 E 3900

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

3 h 30 zile 3 h 30 zile 3 h 30 zile 3 h 30 zile 3 h 48 h

3 h 30 days 3 h 30 days 3 h 30 days 3 h 30 days 3 h 48 h

ZINCAMID G 3202-1 S.F. G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

pag. 6/7

Teste de performanta

Performance tests

Sistem1

1 strat de G3202-1 50 m

1 strat de V3300HS 230 m

First system

one layer G3202-1 50 m

one layer V3300HS 230 m

Sistem2

1 strat de G3202-1 50 m

1 strat G3200SFZ -50 m

2-3 straturi de E3200 100 150 m

Second system

one layer G3202-1 50 m

one layer G3200SFZ -50 m

2-3 layers E3200 100 150 m

Ceata salina neutra

Neutral salt fog

( sol. Nacl 50g/l,35 C)

SREN ISO9227:2007

Dupa 720 h de expunere pelicula nu

prezinta deteriorari

After 720 hours exposure, the film has no

degradation.

Dupa 720 h de expunere pelicula nu

prezinta deteriorari

After 720 hours exposure, the film has no

degradation.

Caldura si umiditate

Heat and umidity

(T=38 2C, Ur>90 %)

SREN ISO 6270-1:2002

Dupa 720 h de expunere pelicula nu

prezinta deteriorari

After 720 hours exposure, the film has no

degradation.

Dupa 720 h de expunere pelicula nu

prezinta deteriorari

After 720 hours exposure, the film has no

degradation.

Observatii

Remarks

Inainte de reacoperire, dupa expunerea in medii contaminate, suprafetele vor fi bine

curatate prin spalare cu jet de apa la presiune ridicata, urmata de uscare. In cazul

depasirii intervalului maxim de reacoperire, se va proceda la o asperizare a suprafetei

pentru a se asigura o buna aderenta pentru straturile urmatoare.

Atingerea intervalelor maxime de reacoperire, asigurarea unei bune aderente, precum si

bune proprietati mecanice implica asigurarea urmatoarelor:

-grundul trebuie aplicat intr-o grosime de strat uscat in jurul valorii de 50m, ca

shopprimer in jurul valorii de 20m;

-stratul de grund obtinut trebuie sa fie uniform, de buna calitate si fara urme de pulverizare

uscata;

-conditiile de uscare si intarire vor fi conform celor specificate la punctul CONDITII DE

APLICARE pana la intarirea completa;

-suprafetele TREBUIE sa fie perfect curate inaintea reacoperirii.

Before re-coating, after exposure in contaminated environment, clean the surface thoroughly by

(high pressure) fresh water jetting and let it dry. If the maximum re-coating interval is exceeded,

roughening of the surface is necessary to ensure good intercoat adhesion to following coats.

For reaching the maximum re-coating intervals, ensuring a good adherence as well as good

mechanical properties the following conditions should be ensured:

-the primer has a dry film thickness as near as possible to the 50 m, as shopprimer as near as

possible to the 20 m;

-the film formed is uniform qualitative and "dry spray-free";

-the drying and curing conditions are according to the APPLICATION CONDITIONS until full cure is

obtained;

-the surfaces MUST be completely clean before re-coating.

AMBALARE

PACKING

Grund G 3202-1: bidoane metalice de 22,5kg.

Intaritor I 324: cutii metalice de 4 kg.

G 32002-1 product: metallic buckets of 22,5 kg.

Curing agent I 324: metallic cans of 4 kg.

ZINCAMID G 3202-1 S.F. G 3202-1

KBER Ltd. Turturesti-Girov, NEANT District, RONAN!A, Phone ++0-(02)33-291800, Fax ++0-(02)33-23++50, E-mail vim@kober.ro, Internet http:ffwww.kober.ro

EDITIA 3

REVIZIA 1

DATA 15.05.2012

TECHNICAL DATA SHEET

pag. 7/7

SECURITATEA MUNCII

WORK SAFETY

Toate operatiile de manipulare, transport, depozitare, utilizare se vor realiza respectand cu

strictete normele de prevenire a incendiilor, normele de protectia muncii si igiena sanitara.

Se interzice: prezenta oricaror surse de foc, vopsirea in spatii fara o ventilatie

corespunzatoare, contactul direct al pielii cu produsul respectiv, inhalarea prelungita a

vaporilor, ingerarea produsului.Se vor respecta masurile de precautie indicate in fisele de

securitate ale bazei G 3202-1 si intaritorului I 324 si a diluantului corespunzator D302.

All the operations of handling, transport, storage and use should be accomplished in strict

compliance with the fire prevention, safety and health norms. The presence of any fire source,

painting in areas without adequate ventilation, direct contact of skin with the respective product,

prolonged inhalation of vapors and ingestion of the product, should be forbidden. All the precaution

measures from the G 3202-1 base product, I324 hardner and D 302 solvent technical data sheet will

be respected.

NOTA

NOTE

Toate aceste date au caracter general privind performantele si utilizarea produsului, de

aceea recomandam testarea produsului in conditiile propriei tehnologii de aplicare a

beneficiarului.

Rugam consultati producatorul pentru lamuriri suplimentare.

All these data have a general character regarding the performance and use of the product; therefore

we recommend the testing of the product under conditions specific to the application technology of

the beneficiary.

Please contact the producer for further information.

S-ar putea să vă placă și

- Prezentare - Metrom TradingDocument13 paginiPrezentare - Metrom TradingFlorin ȘandruÎncă nu există evaluări

- Clase Expunere 2Document16 paginiClase Expunere 2ionel_marÎncă nu există evaluări

- Proiect CNC Sandru Dumitru FlorinDocument8 paginiProiect CNC Sandru Dumitru FlorinFlorin ȘandruÎncă nu există evaluări

- Proiect Dinamica Autovehiculelor RutiereDocument82 paginiProiect Dinamica Autovehiculelor Rutierepuybogdan86% (7)

- Ft.e 3900Document6 paginiFt.e 3900tamasraduÎncă nu există evaluări

- Agregate de Cariera - Asfalt Si DrumuriDocument2 paginiAgregate de Cariera - Asfalt Si Drumuricos08Încă nu există evaluări

- Arc ProbDocument6 paginiArc ProbTalmaciu CatalinÎncă nu există evaluări

- Starile de Consistenta Ale Pamanturilor ArgiloaseDocument3 paginiStarile de Consistenta Ale Pamanturilor ArgiloaseRoxana ChiricaÎncă nu există evaluări

- Fisa Tehnica-SysFix Premium 2024Document3 paginiFisa Tehnica-SysFix Premium 2024Doru DoruÎncă nu există evaluări

- Biomateriale Si Biocompatibilitatea Acestora Cu Organismul UmanDocument17 paginiBiomateriale Si Biocompatibilitatea Acestora Cu Organismul UmanMadalina CalcanÎncă nu există evaluări

- Modelarea Curgerii Apei Cu Suprafata Libera Pe Un Rau in Dreptul Unui PodDocument55 paginiModelarea Curgerii Apei Cu Suprafata Libera Pe Un Rau in Dreptul Unui PodSilviu BanutaÎncă nu există evaluări

- Zgurile de OţelarieDocument29 paginiZgurile de OţelariePotrivitu DaniÎncă nu există evaluări

- Catalog Wetterbest 2020 RO TIPAR QQ PreviewDocument56 paginiCatalog Wetterbest 2020 RO TIPAR QQ Previewjustina justinaÎncă nu există evaluări

- PAFSIN CaracteristiciDocument24 paginiPAFSIN CaracteristiciDan PetricÎncă nu există evaluări

- 2 Materii OrganiceDocument3 pagini2 Materii OrganiceTudor BenescuÎncă nu există evaluări

- Protectie CatodicaDocument8 paginiProtectie CatodicaPopa Catalina-ElenaÎncă nu există evaluări

- Raport de Incercare Piloti de Indesare Baia Sprie - BarsanaDocument14 paginiRaport de Incercare Piloti de Indesare Baia Sprie - BarsanaFlorin ManÎncă nu există evaluări

- Manual RAZOR RCS Z-100 Z-200 RO v1.5Document13 paginiManual RAZOR RCS Z-100 Z-200 RO v1.5Cristi Schipor100% (1)

- CUPRINS RD - 001 11 Normativ Reabilitare DR ForestiereDocument4 paginiCUPRINS RD - 001 11 Normativ Reabilitare DR ForestiereSanda-Florentina PopaÎncă nu există evaluări

- Materiale CompoziteDocument18 paginiMateriale CompoziteCornel CostoiuÎncă nu există evaluări

- Coroziunea MaterialelorDocument16 paginiCoroziunea MaterialelorAnonymous aicKhW0lÎncă nu există evaluări

- Declaratie de Performanta Placa Rigola Carosabila PRC1 Dublu ArmataDocument1 paginăDeclaratie de Performanta Placa Rigola Carosabila PRC1 Dublu ArmataBianka DobreÎncă nu există evaluări

- Stabilirea Parametrilor Geomecanici Pentru Rocile Utilizate La Infrastructura Căilor de Comunicații TerestreDocument2 paginiStabilirea Parametrilor Geomecanici Pentru Rocile Utilizate La Infrastructura Căilor de Comunicații Terestrecobraregala21100% (1)

- FT.G 3202-1Document5 paginiFT.G 3202-1tamasraduÎncă nu există evaluări

- ST22 Contoare Electronice PDFDocument64 paginiST22 Contoare Electronice PDFVadimÎncă nu există evaluări

- Superaliaje Pe Baza de CobaltDocument10 paginiSuperaliaje Pe Baza de CobaltAlexandru MihaiÎncă nu există evaluări

- ST22 Contoare ElectroniceDocument64 paginiST22 Contoare ElectroniceZoltan Marosan100% (1)

- VebeDocument72 paginiVebeTibelu'Încă nu există evaluări

- Raport La Studiu de Evaluare A Impactului - Exploatare Si Prelucrare Granit-SC TEHNOLOGICA RADION SRLDocument85 paginiRaport La Studiu de Evaluare A Impactului - Exploatare Si Prelucrare Granit-SC TEHNOLOGICA RADION SRLsovin5100% (1)

- Zguri SiderurgieDocument22 paginiZguri SiderurgieLiviuÎncă nu există evaluări

- Dedurizator Decalux 10 CronoDocument24 paginiDedurizator Decalux 10 CronoTomescu MarianÎncă nu există evaluări

- CAR2013 e ProceedingsDocument1.423 paginiCAR2013 e Proceedingsionescu alexandruÎncă nu există evaluări

- Studiu HidroDocument10 paginiStudiu HidroAnonymous kqcev0Încă nu există evaluări

- Proiect Organe de Masini 1Document83 paginiProiect Organe de Masini 1Bogdan0% (1)

- Catalog Aparate de Reazem Din Neopren Mageba PDFDocument24 paginiCatalog Aparate de Reazem Din Neopren Mageba PDFVasilescu CristianÎncă nu există evaluări

- Raport La Studiul de EIM - Braila PDFDocument428 paginiRaport La Studiul de EIM - Braila PDFHand MadeÎncă nu există evaluări

- AcDocument35 paginiAcbuza29Încă nu există evaluări

- 8 ZincareaDocument10 pagini8 ZincareaAdrienn Csenge Maier100% (1)

- HG 540 - 2000Document112 paginiHG 540 - 2000Florian PasareÎncă nu există evaluări

- Intrebari Examen Tratarea Apei de InjectieDocument12 paginiIntrebari Examen Tratarea Apei de InjectieAnonymous ASmqgNaÎncă nu există evaluări

- Clasificarea Si Simbolizarea Materialelor Metalice Si Nemetalice 2Document21 paginiClasificarea Si Simbolizarea Materialelor Metalice Si Nemetalice 2AnamariaMuscruÎncă nu există evaluări

- 1 Ord 590 1977 SCDocument3 pagini1 Ord 590 1977 SCMihaela ChirvasaÎncă nu există evaluări

- Studiu GEO PDFDocument66 paginiStudiu GEO PDFMadalina NaforeanuÎncă nu există evaluări

- Proiect UpDocument21 paginiProiect UpLarissaÎncă nu există evaluări

- Fereastra nr61 PDFDocument116 paginiFereastra nr61 PDFAndrei OloieriÎncă nu există evaluări

- Coroziunea BiologicaDocument3 paginiCoroziunea BiologicaTanasescu MihailÎncă nu există evaluări

- Retea Hidrologica Jud. Bistrita-NasaudDocument7 paginiRetea Hidrologica Jud. Bistrita-NasaudIulia SingeorzanÎncă nu există evaluări

- BREF Management of Tailings and Waste-Rock in MiningDocument552 paginiBREF Management of Tailings and Waste-Rock in MiningGaby ZgubyutzaÎncă nu există evaluări

- Straturi Stabilizate Cu Lianți Minerali Prin MALDocument29 paginiStraturi Stabilizate Cu Lianți Minerali Prin MALPuiu RoxanaÎncă nu există evaluări

- PUZ SOFIA GeoDocument25 paginiPUZ SOFIA GeoAnca ChiraÎncă nu există evaluări

- Cap 3 AgregateDocument14 paginiCap 3 AgregatedanbelaÎncă nu există evaluări

- Epomid G 3200Hs: Technical Data SheetDocument5 paginiEpomid G 3200Hs: Technical Data SheettamasraduÎncă nu există evaluări

- FT.G 4101Document6 paginiFT.G 4101tamasraduÎncă nu există evaluări

- FT.G 3200S Grund EpomidDocument5 paginiFT.G 3200S Grund Epomidm_a_1993Încă nu există evaluări

- Fisa Tehnica Diluant D302Document2 paginiFisa Tehnica Diluant D302tamasraduÎncă nu există evaluări

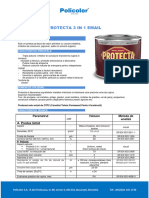

- FT Protecta 3 in 1Document2 paginiFT Protecta 3 in 1RĂZVANÎncă nu există evaluări

- Email 522Document2 paginiEmail 522didapopescuÎncă nu există evaluări

- FT G 3200HS PDFDocument5 paginiFT G 3200HS PDFtamasraduÎncă nu există evaluări

- CS Costinesti2011Document15 paginiCS Costinesti2011Dogarescu RalucaÎncă nu există evaluări

- Proiect AqpsDocument5 paginiProiect AqpsEduard IonutÎncă nu există evaluări

- Grund Pe Baza de Zinc - SikaCor Zinc RDocument3 paginiGrund Pe Baza de Zinc - SikaCor Zinc RMuresan ErnestÎncă nu există evaluări

- Fisa Tehnica Tabla Cutata Grad RF A1Document2 paginiFisa Tehnica Tabla Cutata Grad RF A1nighthawk77Încă nu există evaluări

- Elastocoat C 6335 101 Eng Poliurea Pura Ro 56423Document4 paginiElastocoat C 6335 101 Eng Poliurea Pura Ro 56423benhurrosaÎncă nu există evaluări

- 4.3 Geno Tipul Si Dieta Geno Tipul 3 ÎnvăţătorulDocument46 pagini4.3 Geno Tipul Si Dieta Geno Tipul 3 ÎnvăţătorulFlorin ȘandruÎncă nu există evaluări

- Anunt LuncaDocument1 paginăAnunt LuncaFlorin ȘandruÎncă nu există evaluări

- Proiect Masini UnelteDocument15 paginiProiect Masini UnelteOncioiu CiprianÎncă nu există evaluări

- Proiectarea Unei Freze Cilindro Frontala - Șandru Dumitru FlorinDocument6 paginiProiectarea Unei Freze Cilindro Frontala - Șandru Dumitru FlorinFlorin ȘandruÎncă nu există evaluări